consolidated pilot operated safety valve brands

The 2900/2900 TM Series Gen II is a full-nozzle pilot-operated safety relief valve (POSRV) matching API 526 direct-spring PRV dimensions. Its patented full-nozzle integral sense design allows for easy maintenance as well as simple spring-loaded to pilot-operated PRV conversions throughout the lifecycle of the valve. The 2900 Triple Media (TM) Series is the first full nozzle POSRV engineered to perform on liquid, air/gas, and steam media and is multi-media certified to meet multiple media capacity stamping per ASME B & PVC Code Case 2787. Both valve series use the same pilot valve technology as the 3900 Series including the ‘True Zero Leakage’ modulating pilot, providing a modernized overpressure protection solution for reducing carbon footprint and emissions.

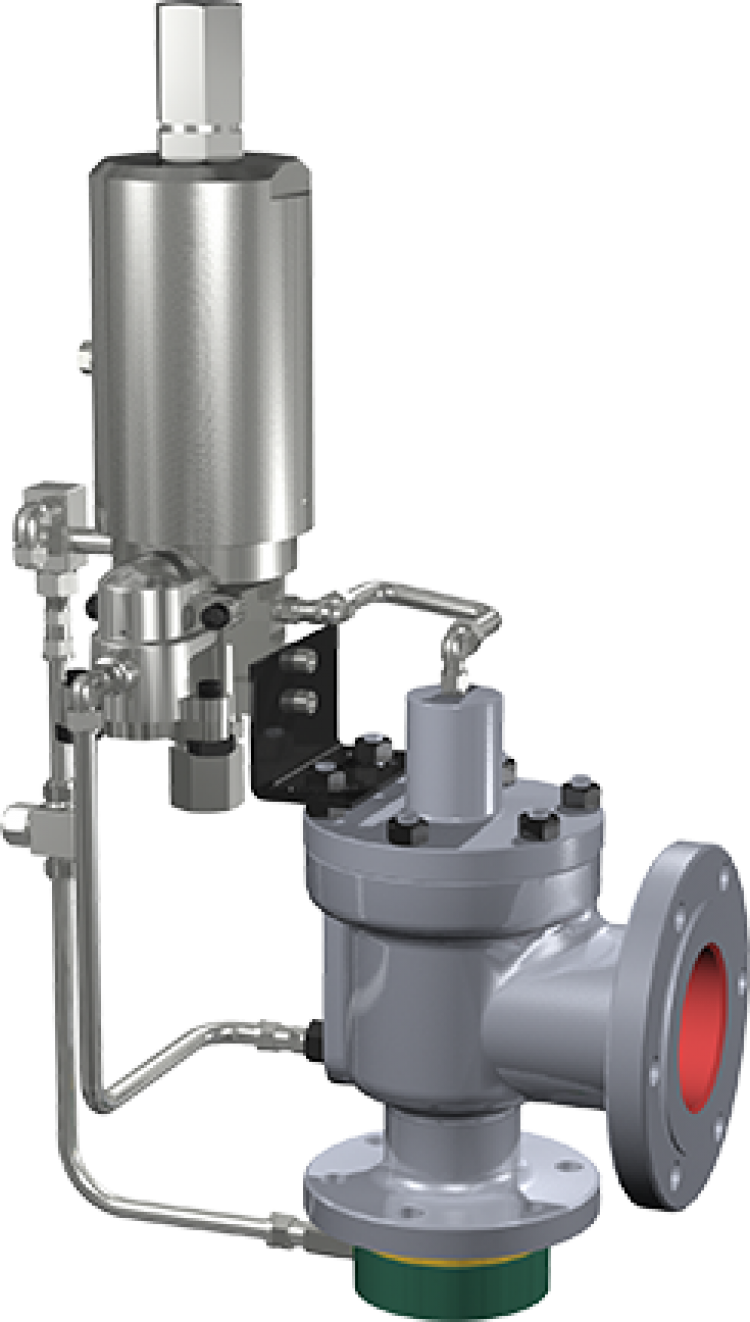

Consolidated 3900/3900 TM Series Pilot-Operated Safety Relief Valves (POSRVs) feature a semi-nozzle main valve design that meets API 526 center-to-face dimensional requirements for POSRVs. The 3900 Triple Media (TM) Series is one of the first POSRVs engineered to perform on liquid, air/gas, and steam media and is multi-media certified to meet multiple media capacity stamping per ASME B & PVC Code Case 2787. Both 3900 series come standard with a non-flowing pilot valve that is suitable for compressible and incompressible fluids. Optional pilot valve constructions are available for either pop or modulating action functionality to meet various pressure range, seat tightness, and blowdown requirements. Highly versatile, these valve technologies offer ease of maintenance, high reliability, flexibility, and efficient operation and performance.

Relief valves are often the last point of protection against dangerous events, so they must be dependable and ready to operate under high pressure situations. With Consolidated’s 140+ years of dedicated Pressure Relief Valve (PRV) engineering and manufacturing expertise under their belt, they know pressure relief valves and offer a wide range of safety relief valve and safety valve styles, sizes, options and configurations for all kinds of applications, environments and media.

Consolidated works closely with customers and regulatory organizations to configure, engineer and manufacture safety valves that can help maintain safer operating conditions in a full range of environments, to name a few:

Over the years we have refined our products so that our customers only have top quality options. Our service offerings are custom-fit to our customer’s individual needs. Our technicians and engineers are some of the most experienced and educated industrial experts available. We never compromise on safety and your satisfaction is our only goal.

Through its improved seat tightness to 98 percent of set pressure, and adjustable blowdown to 2 percent of set pressure, the 2900 series valve allows higher system pressures that can increase the yield of the process

Chalmers & Kubeck –provides prompt delivery from one of the largest pressure relief valve inventories available anywhere. We have in excess of $10 Million in new Baker Hughes Consolidated * pressure and safety relief valves and OEM replacement parts in our C&K family of companies plus an additional $50 Million available from our Green Tag network associates. Strategically located,our knowledgeable, factory trained technicians, are available 24/7 to provide prompt, factory authorized repair service in both our shops or at the customer’s plant site. Territorial restrictions apply.

This unique and patented design offers the ultimate API 526 Direct-Spring to Pilot-Operated PRV upgrade opportunity by allowing the end user to select either Remote Sense or Integral Sense (depending…

The Consolidated Series 3500 Electromatic Ball Valve (EBV) is designed to provide automatic or manual overpressure protection for steam boilers, and can also be used to assist start-up and shut-down…

ASME Section I and VIII approved, the Consolidated Type 2700 steam safety valve is configured to meet the specific requirements of the co-generation and waste-to-energy segments.

The Consolidated Type 1811 is a cost effective, high capacity flanged steel safety valve that offers seat tightness and high performance making it a solution well-suited for steam service applications.

Suitable for steam and other compressible fluid applications, the Consolidated Type 1541 and 1543 safety valves are ASME Section I and VIII approved. They are most commonly used in pharmaceutical,…

The Consolidated Type 1511 safety valves are designed for low pressure steam heating boilers, steam generators and air applications. This valve is ASME Section I and VIII approved.

The Type 3900 modular pilot-operated safety relief valve (MPV) features a separate, non-flowing pilot sub-assembly design making it well-suitable for use with both compressible and incompressible fluids. Optional pilot valve…

The Consolidated Type 1982 conventional process safety relief valve provides seat tightness and blowdown performance for vapor, liquid and steam applications. It is well-suited for applications requiring high relief capacity…

The Consolidated 19000 Series valve provides quality performance in seat tightness, capacity, and blowdown on most media. It surpasses ASME code requirements and is CE compliant to European PED specifications…

The first valve of its size capable of handling liquid and gas interchangeably without adjustments while remaining stable, the Type 1900 safety relief valve offers an innovative solution for multi-phase…

Consolidated Maxiflow high pressure safety valves are premium products that are installed on many power generating stations worldwide to help protect boilers from overpressure conditions. With a proven design, the…

Consolidated Pilot Operated Safety Relief Valves (POSRVs) offer the safety you expect, the dependability you require, and the efficiency you need to keep your operations running smoothly. These valves offer a premium performance and numerous technical benefits and operating advantages over traditional Pressure Relief Devices.

Pilot Operated Safety Relief Valves are designed with several features that differentiate it from traditional spring loaded safety relief valves with superior performance, and with a compact design are lighter weight and easier to install in most applications.

Consolidated Pilot Valves offer industry leading performance with both main valve and pilot seat tightness up to 98% of set pressure. This advanced design ensures zero-leakage during normal operating conditions for even the most demanding high-pressure applications.

Remote sense configuration eliminates rapid cycling valve chatter in applications with >3% inlet line loss, enabling Consolidated POSRVs to open and relieve pressure in a stable and efficient manner. The modulating style opens proportionally to your overpressure pilot, ensuring a smooth opening cycle and relieving only required capacity, keeping your operation safe, efficient and reliable.

Certified on gas, liquid and steam, and configured to suit your application with flexible features including an adjustable blowdown, bolt-on modulator, pilot line pressure surge snubber and dozens of optional accessories, ConsolidatedPOSRVs can be configured for any service.

Pioneer’s cutting-edge Baker Hughes Consolidated relief valves offer Green Tag Center (GTC) support to help your high-pressure safety valve operate efficiently. We offer comprehensive audit programs to validate your product, so the solution we provide for your facility is built to last. Safety relief valves function as the main protection point against dangerous substances; it’s crucial the system you have in place is operating to its optimal potential. Baker Hughes Consolidated safety valves offer styles, sizes, options, and configurations to fit seamlessly into your existing environment for optimal performance.

Consolidated* 3900 MPV Series Pilot-Operated Safety Relief Valve Overview GE’s unique pilot valve design combines enhanced performance, capabilities and features within an economical, modular assembly. The 3900 series valve design provides an optimized safety system that offers application versatility while providing cost-effective standardization. Specifications INLET SIZES OUTLET SIZES INLET RATINGS ASME Class 150 through 2500 OUTLET RATINGS ASME Class 150 through 300 ORIFICE SIZES Eleven inlet sizes: D through T and Full bore options PRESSURE RANGE psig (1.03 barg) to 6250 psig (431 barg) 15 TEMPERATURE RANGE MATERIALS MAIN VALVE (Std.) Carbon steel base and 316 stainless steel internal components 316 stainless steel base and internal components Closed bonnet for spring protection. Pilot gag prevents the pilot-operated relief valve from opening while equipment is undergoing operational hydrostatic testing. Pop action and modulating pilot allows for application versatility. Unique pilot seat design allows for self cleaning operation and is tolerant to icing and dirty conditions. Adjustable blowdown - the first and only non-flowing modulating pilot with main valve blowdown control. Remote actuation and sensing. Operation closer to set point improves process efficiency versus direct spring operated valves. The metal seat option incorporates proven technology from the 1900 series safety relief valve seat design. The addition of the 2900 series POSRV heat exchanger increases the metal seat option temperature range to -320°F (-196°C) to 650°F (343°C). fact sheet

meets numerous application requirements. For example. the type 1900-UM valve is capable of flowing liquid, gas or steam with no adjustment required to switch between different media with the same set pressure.

The ConsolidatedType 19000valve is ASME and PED certified. It meets and exceeds API seat tightness performance. The 19000 offers enhanced capacity and blowdown performance on many media types. In most cases, it does not require parts changes to accommodate different media.

choice for OEM and skid manufacturers requiring high-relief capacity from a small valve. The 1982 offers superior seat tightness and blowdown performance for most media applications.

The ConsolidatedType 11000Series Safety Relief Valve combines performance, quality, reliability and value into a single overpressure device. The 11000 SRV is specifically designed for the most demanding upstream and midstream oil and gas applications where safety is of prime importance.

8613371530291

8613371530291