consolidated pressure safety valve free sample

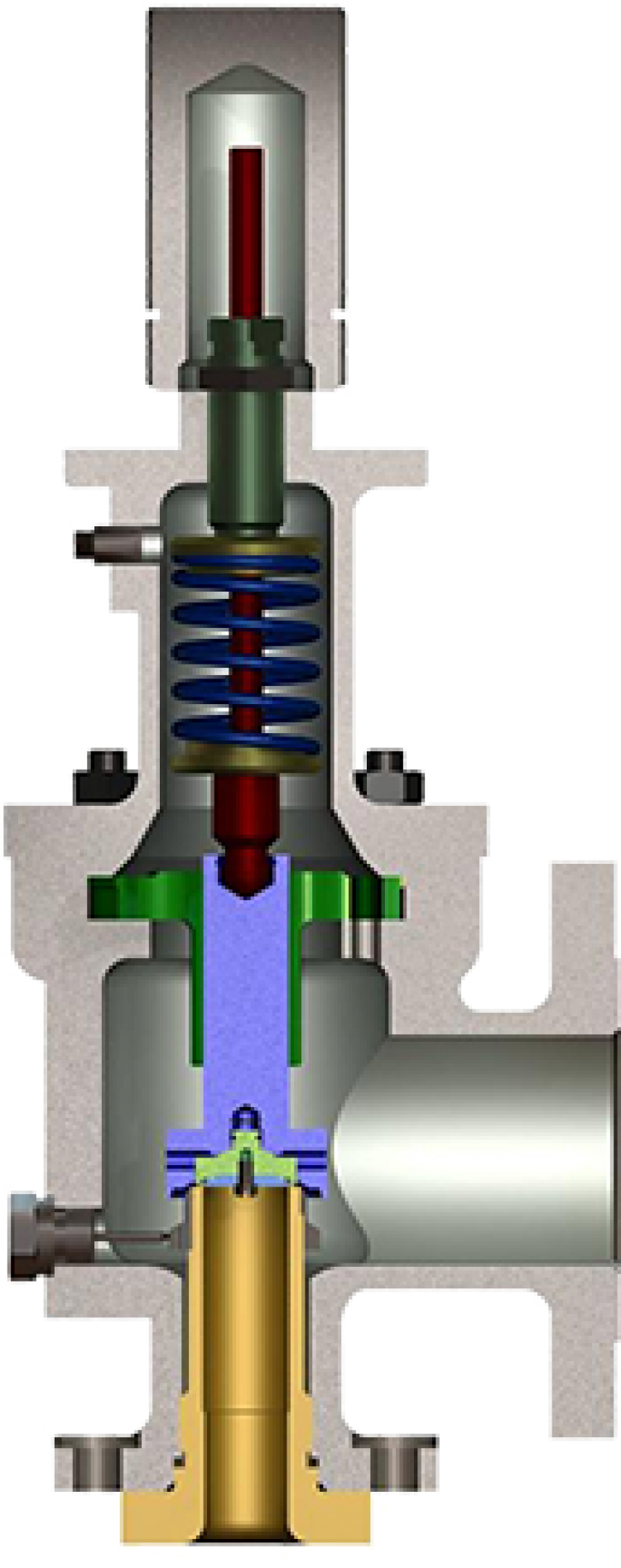

Improved leak protection and safety. A soft seat design feature helps keep the valve leak free at 95 percent of set pressure over 100 psig., while a backup metal seat provides additional safety.

Compliance to API Standard 526-2002. These valves comply with API Standard 526 Fifth edition, 2002. When required for replacement , Consolidated 1900/P series valves are also available with connections and dimensions in accordance with supplanted API Standard Third edition 1984 and prior editions.

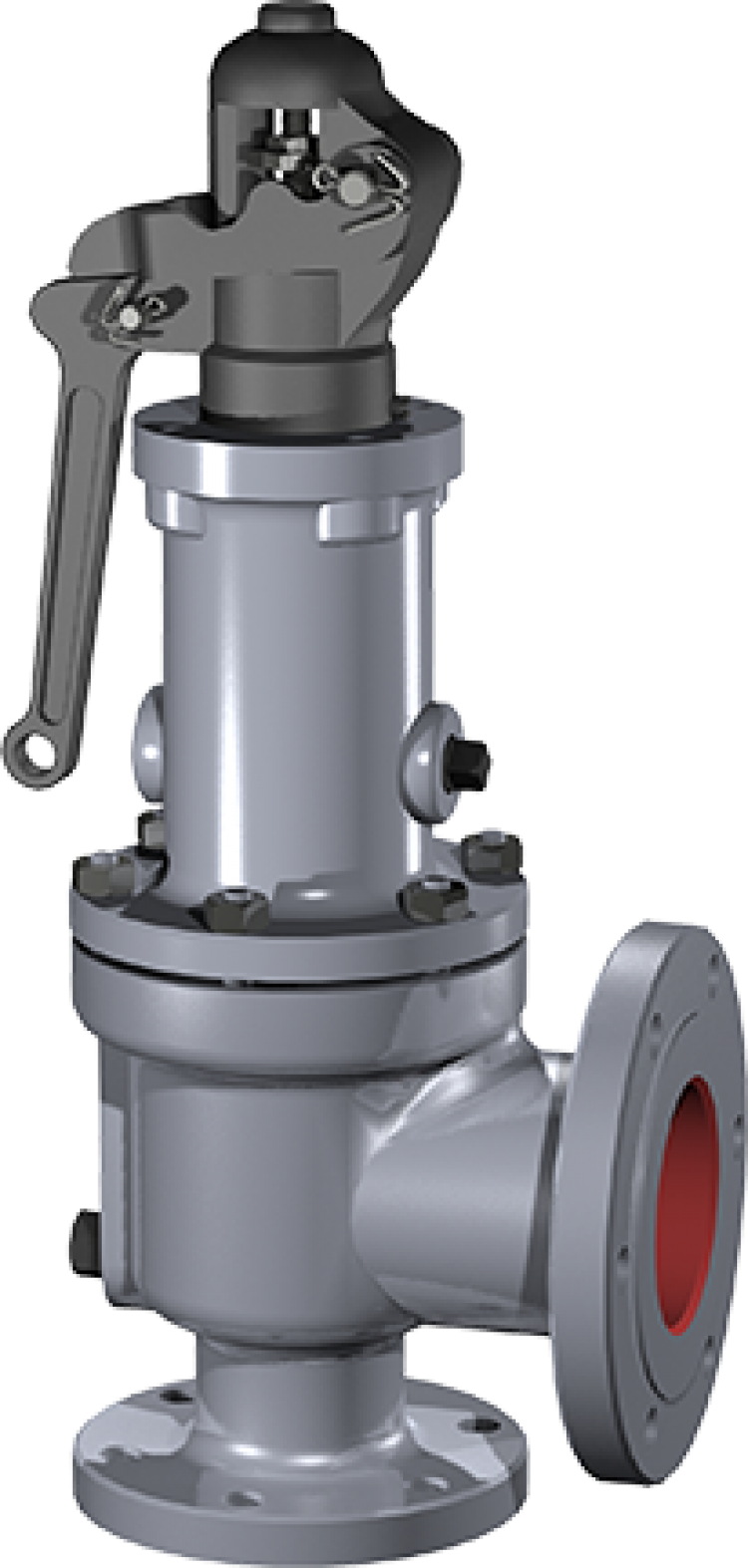

Relief valves are often the last point of protection against dangerous events, so they must be dependable and ready to operate under high pressure situations. With Consolidated’s 140+ years of dedicated Pressure Relief Valve (PRV) engineering and manufacturing expertise under their belt, they know pressure relief valves and offer a wide range of safety relief valve and safety valve styles, sizes, options and configurations for all kinds of applications, environments and media.

Consolidated works closely with customers and regulatory organizations to configure, engineer and manufacture safety valves that can help maintain safer operating conditions in a full range of environments, to name a few:

Safety relief valves often serve as the point-of-protection against potentially dangerous circumstances, so it is important that they be dependable. GE Energy’s Consolidated safety relief valves have maintained a reputation for excellence and reliability for more than a century.

The Consolidated product line has demonstrated a number innovative solutions, too. Safety relief valve innovations from the product line include the Thermodisc® temperature compensating disc and the first modular pilot-operated valve.

GE’s unique pilot valve design combines enhanced performance, capabilities and features within an economical, modular assembly. The 3900 series valve design provides an optimized safety system that offers application versatility while providing cost-effective standardization.

The 2900 series pilot-operated safety relief valve is another innovative Consolidated product line offering from GE, a world leader in pressure relief valve technology. The 2900 series valve is a blend of

GE’s Consolidated pilot valve has a unique design that combines top performance, capabilities and features within an economical, modular assembly. This is based on the successful design of an optimized safety “system” that offers versatility of application, yet provides cost-effective standardization.

GE’s Consolidated* 1982 Series Safety Relief Valves are designed and manufactured in compliance with ASME B & PVC, Section VIII and Section III (Class I, II and III). Mainly used for steam and liquid applications.

Our comprehensive portfolio of safety valves can help to run operations smoothly and cost effectively, particularly in steam service environments. Consolidated safety valves feature a unique pop-action release that can relieve steam over-pressurization if pressures upstream from the valve reach a set point.

What is more, GE’s Consolidated safety valves comply with the ASME Section I code for boiler applications. They are built with many features that meet ASME requirements for steam-compressible fluids. For example, all models feature a lifting lever, required by the code for testing, instead of deadweight or weighted levers. Consolidated safety valves can also withstand set pressures up to 103 percent with a blowdown value of 4 percent, or 96 percent of set pressure drop before the valve re-seats.

The type 1900-30 valve includes the addition of a balanced bellows that is necessary to compensate for the effects of variable back pressure. By isolating the upper structure and allowing the use of less expensive materials, the bellows is also a cost-effective solution in applications where the valve is exposed to highly viscous or corrosive fluids.

The type 1900-DA valve contains an additional O-ring seat seal. This soft seat is the primary seal and it allows the valve to remain leak free at 95 percent of set pressure over 100 psig (6.89 barg). A backup metal seat provides additional safety for fire-relief applications when O-rings can be destroyed by high temperature exposure.

The type 1900-DA O-ring seat is available for set pressures up to 6250 psig (430.92 barg). Some soft seats offered by other manufacturers are limited to 1500 psig.

GE’s Consolidated* 19000 Series valves are designed and manufactured in compliance with ASME B & PVC, Section VIII and Section III (Class I, II and III), and are CE compliant to the European Pressure Equipment Directive 97/23/EC.

Seat tightness, blowdown and capacity on all types of media meet industry needs for overpressure protection in chemical, petrochemical, refinery, power generation (nuclear and conventional) and other commercial applications.

8613371530291

8613371530291