consolidated safety valve distributors price

Relief valves are often the last point of protection against dangerous events, so they must be dependable and ready to operate under high pressure situations. With Consolidated’s 140+ years of dedicated Pressure Relief Valve (PRV) engineering and manufacturing expertise under their belt, they know pressure relief valves and offer a wide range of safety relief valve and safety valve styles, sizes, options and configurations for all kinds of applications, environments and media.

Consolidated works closely with customers and regulatory organizations to configure, engineer and manufacture safety valves that can help maintain safer operating conditions in a full range of environments, to name a few:

Chalmers & Kubeck –provides prompt delivery from one of the largest pressure relief valve inventories available anywhere. We have in excess of $10 Million in new Baker Hughes Consolidated * pressure and safety relief valves and OEM replacement parts in our C&K family of companies plus an additional $50 Million available from our Green Tag network associates. Strategically located,our knowledgeable, factory trained technicians, are available 24/7 to provide prompt, factory authorized repair service in both our shops or at the customer’s plant site. Territorial restrictions apply.

The Consolidated Series 3500 Electromatic Ball Valve (EBV) is designed to provide automatic or manual overpressure protection for steam boilers, and can also be used to assist start-up and shut-down…

ASME Section I and VIII approved, the Consolidated Type 2700 steam safety valve is configured to meet the specific requirements of the co-generation and waste-to-energy segments.

The Consolidated Type 1811 is a cost effective, high capacity flanged steel safety valve that offers seat tightness and high performance making it a solution well-suited for steam service applications.

Suitable for steam and other compressible fluid applications, the Consolidated Type 1541 and 1543 safety valves are ASME Section I and VIII approved. They are most commonly used in pharmaceutical,…

The Consolidated Type 1511 safety valves are designed for low pressure steam heating boilers, steam generators and air applications. This valve is ASME Section I and VIII approved.

The Type 3900 modular pilot-operated safety relief valve (MPV) features a separate, non-flowing pilot sub-assembly design making it well-suitable for use with both compressible and incompressible fluids. Optional pilot valve…

The Consolidated Type 1982 conventional process safety relief valve provides seat tightness and blowdown performance for vapor, liquid and steam applications. It is well-suited for applications requiring high relief capacity…

The Consolidated 19000 Series valve provides quality performance in seat tightness, capacity, and blowdown on most media. It surpasses ASME code requirements and is CE compliant to European PED specifications…

The first valve of its size capable of handling liquid and gas interchangeably without adjustments while remaining stable, the Type 1900 safety relief valve offers an innovative solution for multi-phase…

Consolidated Maxiflow high pressure safety valves are premium products that are installed on many power generating stations worldwide to help protect boilers from overpressure conditions. With a proven design, the…

Improved leak protection and safety. A soft seat design feature helps keep the valve leak free at 95 percent of set pressure over 100 psig., while a backup metal seat provides additional safety.

Compliance to API Standard 526-2002. These valves comply with API Standard 526 Fifth edition, 2002. When required for replacement , Consolidated 1900/P series valves are also available with connections and dimensions in accordance with supplanted API Standard Third edition 1984 and prior editions.

Safety and Safety Relief valves play an important role in keeping people and equipment safe, and Consolidated valves are known for their exceptional quality, performance, and dependability.

With a range of styles, models, options, and configurations, Baker Hughes"s Consolidated safety valves are reliable in even the most demanding applications. They comply with the ASME Section I code for boiler applications and are built with many features that meet ASME requirements for steam-compressible fluids.

Get the support you need, as well, with Contro Valve’s Consolidated Green Tag Centers (GTC) with responsive and effective service through OEM-certified repairs, ValvKeep* valve management and maintenance software, and the EVT* Pro, an electronic valve testing device.

Baker Hughes works closely with customers and regulatory organizations to configure, engineer and manufacture safety valves that can help maintain safer operating conditions in a full range of environments.

Pioneer’s cutting-edge Baker Hughes Consolidated relief valves offer Green Tag Center (GTC) support to help your high-pressure safety valve operate efficiently. We offer comprehensive audit programs to validate your product, so the solution we provide for your facility is built to last. Safety relief valves function as the main protection point against dangerous substances; it’s crucial the system you have in place is operating to its optimal potential. Baker Hughes Consolidated safety valves offer styles, sizes, options, and configurations to fit seamlessly into your existing environment for optimal performance.

Dresser Consolidated is the leader in pressure and safety relief valves with the trusted expertise to provide and service reliable flow safety systems in critical applications around the world.

Dresser Consolidated has built long-term, solid relationships with major oil and gas, power generation and petrochemical companies, and we have consistently helped to advance not only our customers’ operations, but the industry as a whole.

Consolidated is a worldwide leader and full service provider of dependable pressure relief valve solutions. They design, engineer, manufacture, market and service the critical equipment that forms the backbone of pressure relief management throughout industries across the world.

Valves are one of our main specialties, we are able to provide service and sale for all brands ( Emerson, Flowserve, Carraro, Tyco, Tai Milano, Farris…) and also we represent exclusively the brands Masoneilan and Consolidated.

Dresser and Consolidated are brands that are owned and manufactured by General Electric Inc., a worldwide leader in dependable pressure relief valve solutions.

Dresser Valves also delivers reciprocating and rotary valves, field instruments and regulators. The valves of the Dresser Division are reliable, durable and offer high performance at a fair price.

Elettrostar is the exclusive distributor of Baker Hughes Consolidated valves, used around the world to keep power plants, refineries that generate fuel, food and beverage plants that produce essentials for our families, and even pulp and pulp plants running paper.

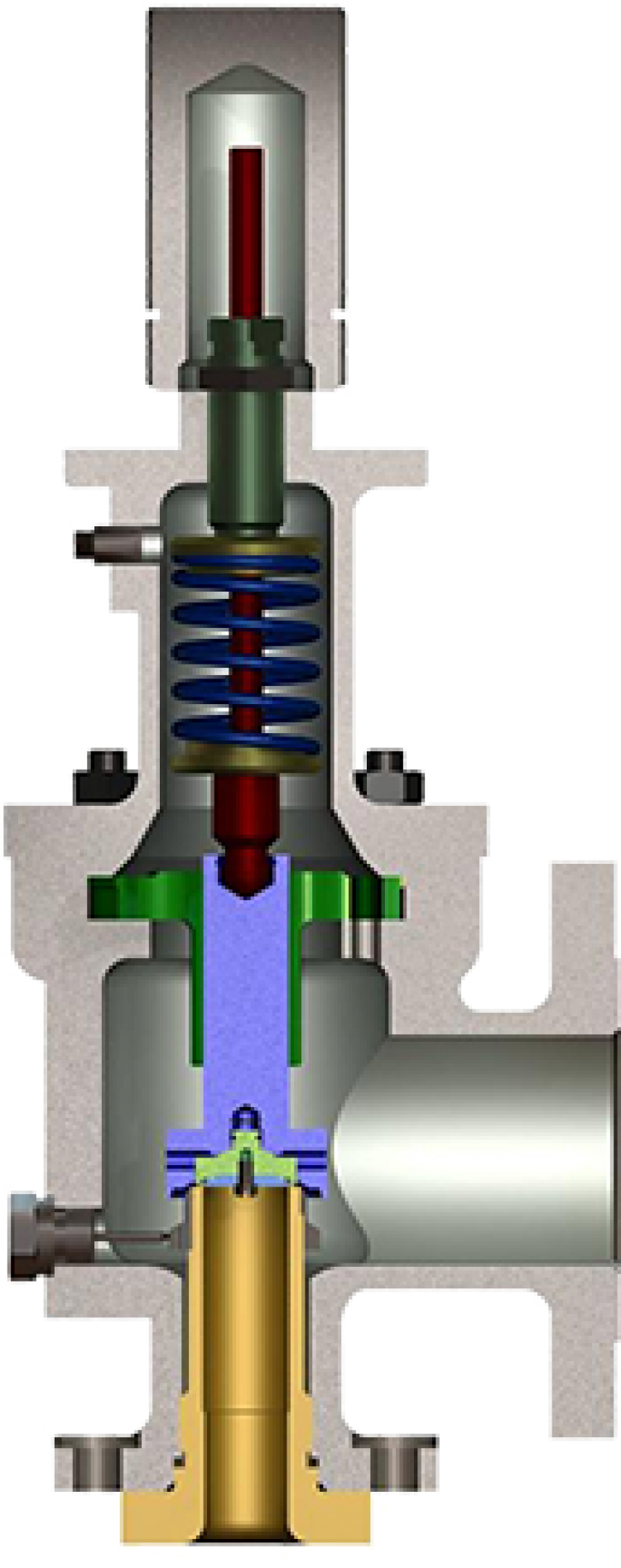

Relief and safety Valves are used in high pressure systems to control the pressure and keep balance of the system. The different between safety valves and relief valves is that the safety valves fully open or close under a certain pressure while the relief valves can open in proportion to the pressure in front of them. The safety and pressure relief valves are used automatically. They both operate under similar conditions. When the pressure builds up in a system, it has to be managed by releasing the material to flow through. These valves have a threshold pressure at which they open. The consolidated safety and safety relief valves comprise of a bonnet vent and bellow with springs.

The springs are set up for the threshold pressure and when the pressure exceeds the threshold, the spring is pushed into the bonnet vent and the bellow opens the valve. The Safety Relief Valves can be open and shut valves. They either open or shut off at any given pressure. This is mostly for the safety of an application not to explode under high pressure. The Pressure Relief Valve on the other hand releases the material after the threshold pressure, but not fully. If the pressure is slightly higher the threshold, then the valve opens slightly. If the pressure is very high above the threshold, it opens wider. It also functions in the same manner when the pressure drops down. The valve closes in proportion to the pressure. The safety valve shuts down at once only when the pressure is below the threshold.

Ready Stock of ASTM A351 CF8M Spring Loaded Safety Valve in wide range of Sizes, Stainless Steel Air Compressor Pressure Relief Valve Manufacturers In India

Relief Valves are designed to control pressure in a system While Safety Valves are used for controlling the pressure in a system they release pressure immediately in the event of an emergency or system failure

The Setpoint of relief valve is usually set at 10 Percent above working pressure limit while safety valve is usually set at 3% above working pressure limit.

If you are operating systems that can only be off for short periods of time, it is sensible to keep a spare valve to swap over and then the removed valve can be inspected and recertified.

8613371530291

8613371530291