cormack propane safety valve brands

Outside the contiguous United States, a 5% discount will be given on orders shipping to Alaska, Hawaii, US Virgin Islands (St. Croix, St. Thomas, St. John, and the Water Island), Puerto Rico, and Guam. All other orders are shipped FOB from a Northern Safety & Industrial warehouse, unless otherwise specified

Forklift Accessories Disclaimer. This device may not comply with your forklift regional/provincial standards. Modifications and additions to the lift truck that affect capacity or safe operation shall not be performed without the written approval of the forklift manufacturer. Where such modifications and additions are performed, capacity, operation and maintenance instruction plates, tags or decals shall be changed accordingly. A pre-use examination shall take place in accordance with CSA safety standard for lift trucks. We will not be held responsible for any loss or damage or misuse that this product has or may have caused.

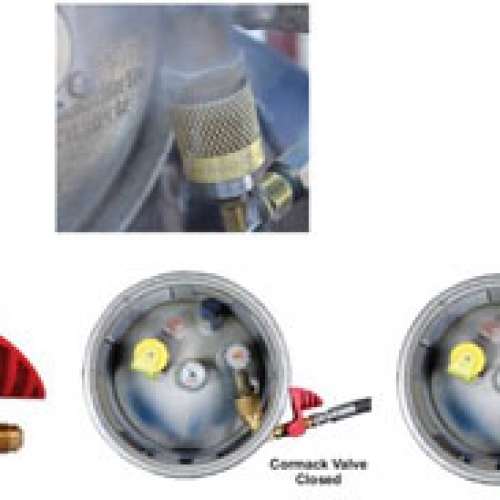

Changing an LPG (Liquid Petroleum Gas, otherwise known as Propane) cylinder can injure a forklift operator if the seal in the cylinder valve has failed, as a defective seal can allow the liquid propane gas to spray over the hand or face of the operator. Since liquid propane vaporizes quickly (-44° F or -42° C), it will cause extreme frostbite when in contact with the skin. The solution is to place this shut-off valve on the hose, preventing the liquid propane from coming back onto the operator. When closed, the valve shuts off LP Gas to the coupler preventing gas from coming back through the hose if the seal fails. This is important, as most LPG forklift cylinders are rented and the operator does not know the condition of the seal or age of the cylinder without rigorous inspection. When the valve is open, the high-visibility shut-off handle covers the coupler so that the valve cannot be disconnected. Quick and easy installation.

Cormack LPG Safety ValveShut-off valve designed for obstructing liquid propane gas (LPG) coming back onto the operatorElbow Angle: 90 DegreeAvoid serious injuries from liquid propane gas hitting operators face or handsFits almost all forkliftsDesigned in case of LPG release, the liquid propane is directed away from the handEasy-Grip ergonomic design allows the operator to hand tighten and loosen the coupler with less effortPlastic nylon material works as an insulator from cold LPG on the brass couplerAll parts are UL rated for forklift LPG applications MOST ORDERS SHIP IN 2-10 BUSINESS DAYS, FREE SHIPPING TO THE 48 STATES Be sure to add me to your favorites list! Check out my other items! Sign up for PayPal; the fast, easy, and secure way to pay online. Feel free to ask us about conversion kits for almost anything including trucks, cars, generators, tractors, boats, motorcycles, RVs etc. We can build a kit to convert almost any engine! WARNING: This product can expose you to chemicals including lead and lead compounds, which are known to the state of California to cause cancer. www.P65Warnings.ca.gov. WARNING: These products contain a chemical known to the state of California to cause cancer and birth defects or reproductive harm. www.P65Warnings.ca.gov.

Of all the challenges you face keeping your customers’ plants operating at full capacity, safety and relief valves shouldn’t be one of them. NASVI’s job is to give you the confidence that your valve supply chain is rock solid regardless the pressure it’s under.

The safety relief valve is one of the most important and vital valves on any LP Gas container. All propane tanks and cylinders are required by law to be fitted with pressure relief devices designed to relieve excess pressure. The function of a safety relief valve is to keep a propane tank from rupturing in the unlikely event of excessive pressure buildup. Propane tank relief valves are also known as pop off valves, pressure venting valves or relief valves.

본 발명의 주요 용도는 자동차, 밴 및 스포츠카와 소형 트럭용 압축 가스 연료 저장 시스템을 위한 가스 분배 매니포울드로서 사용된다. 상기 매니포울드 조립체는 수소, 프로판, 메탄, 천연 가스 또는 자동차 엔진 내부에서 연료원으로서 연소될 수 있는 그 밖의 다른 가스와 같은 압축된 연료 가스와 함께 사용되도록 디자인된다. 이것은 여러 가지 수의 압력 셀과 함께 사용될 수 있지만 본 발명의 가장 선호되는 실시예는 세 개의 압력 셀과 함께 사용되도록 디자인 된다.Its main use is as a gas distribution manifold for compressed gas fuel storage systems for automobiles, vans and sports cars and light trucks. The manifold assembly is designed for use with compressed fuel gas, such as hydrogen, propane, methane, natural gas, or any other gas that can be burned as a fuel source inside an automobile engine. It can be used with a number of pressure cells, but the most preferred embodiment of the present invention is designed for use with three pressure cells.

상기 매니포울드 조립체는 선호되는 실시예에서 세 개의 압력 셀을 상호 연결하는 매니포울드(41)로 구성된다. 이 매니포울드(41)는 차량 전기 시스템에 의해 제어되는, 솔레노이드(51)에 의해 제어되는 밸브(52)(도 4)를 포함한다. 매니포울드(41)와 솔레노이드 제어 밸브의 가스 흐름 제어 특징은 도 2 내지 4를 참고로 잘 이해할 수 있을 것이다.The manifold assembly consists of a manifold 41 interconnecting three pressure cells in a preferred embodiment. This manifold 41 includes a valve 52 (FIG. 4) controlled by a solenoid 51, which is controlled by a vehicle electrical system. Gas flow control features of the manifold 41 and solenoid control valve will be understood with reference to FIGS.

분배 갤러리(45)는 수동 차단 밸브 시트(54)를 통하여 포트(53)에 의해 솔레노이드 밸브 시트(52)에 연결된다. 상기 차단 밸브는 밸브 시트(54)와 관련된 보어 및, 차단 밸브 보어 안으로 관통하는 차단 밸브(55)로 구성된다. 수동 차단 밸 브는 솔레노이드 밸브 시트(52)와 유입/배출 포트(56)를 통하여 압력 셀로부터 차량 연료 시스템 안으로 가스 흐름을 멈추게 하는 장치를 제공한다. 상기 유입/배출 포트(56)는 종래의 고압 피팅 및 스테인레스 강 관 조립체(63)에 의해 차량 가스 흐름 제어 밸브 및 연료 시스템에 결합된다. 상기 차량 가스 흐름 제어부는 보조 시스템을 포함하는데 이것은 매니포울드(41)로부터 차량 엔진까지 또는 연료를 보급할 때 매니포울드(41)를 통하여 압축 가스 공급원으로부터 압력 셀까지 상호 배타적으로 가스의 이동을 허용한다.Dispense gallery 45 is connected to solenoid valve seat 52 by port 53 via manual shut-off valve seat 54. The shutoff valve consists of a bore associated with the valve seat 54 and a shutoff valve 55 penetrating into the shutoff valve bore. The manual shut-off valve provides a device for stopping gas flow from the pressure cell into the vehicle fuel system through solenoid valve seat 52 and inlet / outlet port 56. The inlet / outlet port 56 is coupled to the vehicle gas flow control valve and fuel system by conventional high pressure fittings and stainless steel pipe assemblies 63. The vehicle gas flow control includes an auxiliary system which mutually exclusively moves the gas from the manifold 41 to the vehicle engine or through the manifold 41 from the compressed gas source to the pressure cell when refueling. Allow.

안전 배출 포트(71)는 공압에 의해 분배 갤러리(45)와 결합된다. 상기 안전 배출 포트(71)는 종래의 고압 피팅 및 스테인레스 강 관 조립체(73)에 의해 열 감응 안전 밸브(72)와 공압에 의해 연결된다. 열 감응 안전 밸브(72), 즉 압력 릴리이프 장치는 연료 저장 영역에서 차량에 화재가 발생한 경우에 제어된 속도로 압력 셀에서 공기를 배출하도록 개방된다. 비상 배기 중에, 발화된다면 안전 배기 관 조립체(74)를 통하여 열 감응 안전 밸브(72)로부터 배출되는 연료는 연소되지만 차량으로부터 떨어져 향하고 있는 배기 관 조립체 오우프닝의 위치 때문에 불꽃은 비파괴적이다.The safety discharge port 71 is coupled to the dispensing gallery 45 by pneumatic pressure. The safety discharge port 71 is pneumatically connected to the thermally sensitive safety valve 72 by conventional high pressure fittings and stainless steel pipe assemblies 73. The thermally sensitive safety valve 72, ie the pressure relief device, is opened to vent air from the pressure cell at a controlled rate in the event of a fire in the vehicle in the fuel storage area. During emergency exhaust, the fuel exiting the heat sensitive safety valve 72 through the safety exhaust pipe assembly 74, if ignited, is combusted but the flame is non-destructive due to the location of the exhaust pipe assembly opening facing away from the vehicle.

도 5에 나타낸 것처럼, 가스 제어 매니포울드 조립체(40)의 통합된 실시예는, ISS의 모든 압력 셀을 상호 연결하는 가공되거나 주조되고 선삭된 금속 블록인 가스 분배 매니포울드(41), 압력 셀 공압 연결 라인 조립체(61,62), 안전 배기 관(74) 및 공급 관(63)으로 구성된다. 상기 가스 분배 매니포울드(41)는 압력 셀 공압 연결 라인 조립체(61,62)와 공압 연결 볼트(42)를 통하여 공급 라인과 압력 셀 사이에서 공압 통로를 통제하는 솔레노이드 밸브(51)를 포함한다.As shown in FIG. 5, an integrated embodiment of gas control manifold assembly 40 is a gas distribution manifold 41, pressure, which is a machined or cast and turned metal block that interconnects all pressure cells of the ISS. It consists of a cell pneumatic connection line assembly 61, 62, a safety exhaust pipe 74 and a supply pipe 63. The gas distribution manifold 41 comprises a solenoid valve 51 which controls the pneumatic passage between the supply line and the pressure cell via the pressure cell pneumatic connecting line assemblies 61 and 62 and the pneumatic connecting bolt 42. .

상기 매니포울드 분배 갤러리는 수동 차단 밸브(55) 및 솔레노이드 밸브(51)를 통하여 공급 관(63)에 연결된다. 차단 밸브는 밸브 시트, 결합된 보어 및 차단 밸브 보어 안으로 통과하는 차단 밸브 스템으로 구성된다. 수동 차단 밸브는 솔레노이드 밸브(51) 및 공급 관(63)을 통하여 압력 셀로부터 차량 연료 장치 안으로 가스 흐름을 멈추게 하는 장치를 제공한다. 상기 공급 관(63)은 종래의 고압 피팅 및 스테인레스 강 관에 의해 차량 연료 보급 포트 및 엔진 연료 공급부에 결합된다.The manifold dispensing gallery is connected to the feed tube 63 via a manual shutoff valve 55 and a solenoid valve 51. The shutoff valve consists of a shutoff valve stem passing into the valve seat, the combined bore and the shutoff valve bore. The manual shut-off valve provides a device for stopping gas flow from the pressure cell into the vehicle fuel system through the solenoid valve 51 and the supply pipe 63. The supply pipe 63 is coupled to the vehicle fuel supply port and the engine fuel supply by conventional high pressure fittings and stainless steel pipes.

분배 매니포울드(41)는 열 감응 압력 릴리이프 장치(PRD)를 포함한다. 상기 PRD는 공압에 의해 매니포울드 갤러리에 결합된다. 이 PRD는 연료 저장 영역을 포함해 차량 화재 발생시에, 안전 배기 관(74)을 통하여 제어된 속도로 가스를 배출하도록 열린다. 상기 PRD는, 과잉 트리거(triggers) 내부에서 공융 합금이 불꽃 열로 노출되어 녹을 때 작동된다.The distribution manifold 41 includes a heat sensitive pressure relief device PRD. The PRD is coupled to the manifold gallery by pneumatics. This PRD, including the fuel storage area, is opened to discharge gas at a controlled rate through the safety exhaust pipe 74 in the event of a vehicle fire. The PRD is activated when the eutectic alloy is exposed to flame heat and melts inside excess triggers.

The safety relief valve is one of the most important and vital valves on any LP Gas container. All propane tanks and cylinders are required by law to be fitted with pressure relief devices designed to relieve excess pressure. The function of a safety relief valve is to keep a propane tank from rupturing in the unlikely event of excessive pressure buildup. Propane tank relief valves are also known as pop off valves, pressure venting valves or relief valves.

Relief valves are held in the closed position by the force of a powerful spring. As long as the pressure inside the tank is less than that of the spring, the valve will remain closed. If tank pressure rises to that of the spring, the valve will open resulting in a hissing sound outside the tank. If the pressure in the tank rises significantly higher than that of the spring, the valve will fully open. When the valve fully opens, it initially makes a loud pop followed by a blast of released propane gas. Once the pressure is released and the tank pressure falls below that of the spring, the valve closes.

Most propane tanks in residential and commercial service have internal safety relief valves. The reason for an internal valve as opposed to an external pressure relief valve is it presents less of an obstruction when moving the tank. Internal relief valves are generally placed near the end of the propane tank on above ground containers.

Found primarily on older tanks, external relief valves operate in the same manner as an internal relief valve with the spring mechanism being outside the propane tank itself. Relief valves on multvalves are always fitted with external safety relief valves. Older tanks with an external relief valve installed on the container are generally replaced with internal pressure relief valves, provided they are connected to a dedicated tank opening specifically designed for the placement of the relief valve.

Because the safety relief valve performs such a vital role in the protection of the propane tank, it should be maintained and repaired by licensed propane professionals only. Do not ever look into a relief valve or stand over it.

A protective cover should be placed over the relief valve to ensure proper operation. If the valve has debris in the upper mechanism of the relief valve and it opens, the debris may cause the valve to remain open resulting in a potentially dangerous situation and/or excessive loss of propane. A simple protective relief valve cover can be made from a plastic bag fastened around the external portion of the valve with a rubber band.

If a you encounter a relief valve that seems to be "hissing" (opened to relieve pressure) do not tap it or mess with it. If the tank has been recently filled in hot weather and the face gauge reads over 80 or 85%, spray some water from a hose on the tank. This may cool it down and reduce the expansion of the liquid in the tank. Call your propane company immediately and inform them of the situation.

Pictured here is a relief valve that was apparently leaking. Instead of calling the propane company to replace the valve, the customer decided to fix the problem himself. Using a soldering iron, he soldered the leak until it stopped leaking. In the process of "repairing" the leak, the customer completely sealed the relief valve in a closed position placing himself and his family in a very dangerous situation.

In this type of situation, a relief valve that is sealed shut will not allow the tank to vent excess pressure if it is overfilled or the pressure inside the tank exceeds the working pressure of the container. In a case where the tank is unable to vent to the outside, the tank is subject to rupturing causing more harm and damage than money saved by trying to fix it yourself. Let the propane company or LPG professional handle any problems with thesafety relief valve.

When you choose propane forklifts, you have choices for refueling — both of which your propane supplier can help you navigate safely. You can choose a cylinder exchange program, where your propane supplier refills the cylinders for you. Or you can choose on-site refueling, where trained members of your team refill cylinders themselves.

If you have been searching for a safety release valve that you can use to reduce short-term pressure surges successfully and diminish the effects of gas leaks, this is the product for ...

... regulators have safety valves which will slam shut in the event of emergencies, such as the gas reaching too high a pressure level. The valve works to protect any fittings ...

This product has hydraulically actuated class A gas safety valves to EN 161 used for automatic shut-off. It shuts off when unstimulated for gas and air, ...

The S 104 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

The S50 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

The S100 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

... Pressure Safety Valve + Rupture Disk is protected and may be utilized autonomously as essential security gadgets or in conjunction. There are 3 possible combinations. The first combinations ...

It"s a Safety valve in according with Directives ATEX 20K/34/EU. Technical Norm Fire Prevention 41/256 31/10/2019. d.P.R. 10/520 19/03/1955 and subsequent amendments.

130 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function, ...

V651 Series safety relief valves are produced as safety and relief type. Safety valves are pressure relief elements used to evacuate excessive pressure ...

PVS type slam shut valves are pilot-operated relief valves in which the opening and the closing of the main plug is controlled by a pilot device which is very ...

This range of spring loaded conventional and balanced safety relief valves is specifically designed for overpressure protection of unfired pressure vessel (ASME Section VIII application). ...

The EMERSON BM7 SERIES is a disk slam-shut valve characterized as automatic isolating elements, which are suitable for installation as safety devices in regulating stations. This device has a high operation ...

... control and regulate the gas, air flow to burners and other combustion devices. HMV is a unique safety valve that can be supplied for the requiremen of handling higher ...

Type 50 is a safety valve for universal use. It can be used for nearly any industrial application, e.g. in shipping and pipeline construction, the chemical and petrochemical industries, ...

The RIEGER Safety valve Type SH prevents excessive pressure in steam and gaseous media in plant components and tanks. The set pressure is generally higher than the operating pressure of the system.

... sewage, gas, glycol, diathermic oil, industrial water, steam and other natural and aggressive media, depending on theresistance of materials usedfor the construction ofthe valve.

A certified pressure relief valve testing contractor must perform all inspections. That’s where Foster Fuels comes in. Our inspectors can advise when testing is necessary and when a replacement would be a more cost-effective option. We also offer comprehensive preventative maintenance programs that can extend the life of your pressure relief valves and related safety equipment, saving you money over the long term with services such as:

Reminding you valves over 10 years old must be tested or replaced prior to the following scheduled inspection, which is two years from the current inspection.

Virginia has its own set of requirements for pressure relief valve testing and certification. These are primarily based on NFPA 58 and the Virginia Department of Labor and Industry. State requirements establish a propane pressure relief valve testing frequency of once every 10 years for most equipment. The state code also sets a compliance schedule of two years from the initial inspection date. For more information, contact Foster Fuels directly.

State and NBIC requirements present several challenges for businesses that rely on propane in their facilities. Organizations with multiple tanks may find the time and money required for pressure relief valve testing—including downtime and flaring of vapor, if necessary—to be overly burdensome. The limited time allotted to ensure all tanks are inspected and tested is an additional difficulty.

Houses or buildings utilizing gas energy require a gas piping system to power heaters, ovens, and other heating appliances. One of the most important elements of a gas piping system is the propane service valve, which controls propane gas flow in and out of a building. While there may be many other valves within gas plumbing, this valve functions as an on/off switch and serves as the main point of control for cutting off or allowing for the flow of gas into a piping system.

Propane valves are simply used to turn gas on or off. Similar to that of a water faucet, propane valves consist of a handwheel that controls propane gas flow when turned. When the wheel is turned, a stem and seat mechanism located within the valve opens or closes to prevent or allow gas flow from the tank.

Using propane gas requires an LP gas regulator, which decreases the amount of pressure released into the gas line, keeping it at an acceptable and safe level while still meeting the needs of the application.

There are multiple different valves in any propane system, each of which has a particular job. At IPS Equipment, we provide some of the most common types of valves for propane systems, including:

A pressure or safety relief valve is a safety mechanism that every propane system needs. It allows excess pressure in the tank to be slowly and safely released. Without this valve, pressure can build up and cause the tank to crack or rupture.

The relief valve has a pressurized spring. If the pressure levels within the tank grow too high, the spring forces the valve open just enough to return the pressure levels to acceptable levels. Once the pressure decreases, the spring relaxes, and the valve automatically closes.

This valve is where gas delivery personnel add new gas to a propane tank. Propane delivery trucks have hoses that can be attached to the filler valve so propane can be pumped into the tank. This valve is also pressure-activated, and it opens automatically in response to the pressure in the hose.

Filler valves have gaskets that operators can push the hose end against to avoid propane leaks. They also only allow for unidirectional fluid movement, meaning that once the tank is full, there is no risk of propane escaping when the hose is withdrawn.

This shut-off valve prevents gas from entering the building and any attached appliances. You can use this central point of control like an on/off switch to completely halt the path of gas in the system.

This valve is also called a vapor return valve or vapor eliminator valve. It ensures that propane is delivered at the proper pressure levels from the propane delivery truck to a personal tank and returns any excess propane back to the delivery truck. This is similar to a safety valve, except the vapor equalizing valve ensures the propane is delivered at proper pressures for optimum use, not safety. This is especially crucial during hot weather or in warm environments, as that can increase the pressure.

This specialized valve is meant for use by propane companies only. It allows operators with the proper tools to drain liquid propane from the tank. Propane tanks must be drained to <5% capacity levels before they can legally be moved.

IPS Equipment specializes in supplying propane marketers with reliable valves, fittings, regulators, and more for propane systems. Contact us today to learn more about our comprehensive products or services, or browse through our catalog to start your order.

8613371530291

8613371530291