cormack propane safety valve for sale

Outside the contiguous United States, a 5% discount will be given on orders shipping to Alaska, Hawaii, US Virgin Islands (St. Croix, St. Thomas, St. John, and the Water Island), Puerto Rico, and Guam. All other orders are shipped FOB from a Northern Safety & Industrial warehouse, unless otherwise specified

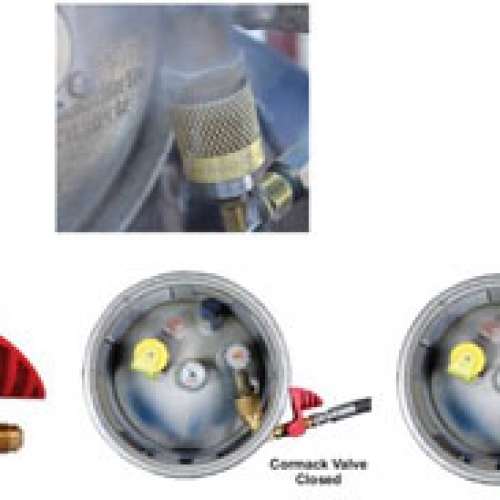

Changing an LPG (Liquid Petroleum Gas, otherwise known as Propane) cylinder can injure a forklift operator if the seal in the cylinder valve has failed, as a defective seal can allow the liquid propane gas to spray over the hand or face of the operator. Since liquid propane vaporizes quickly (-44° F or -42° C), it will cause extreme frostbite when in contact with the skin. The solution is to place this shut-off valve on the hose, preventing the liquid propane from coming back onto the operator. When closed, the valve shuts off LP Gas to the coupler preventing gas from coming back through the hose if the seal fails. This is important, as most LPG forklift cylinders are rented and the operator does not know the condition of the seal or age of the cylinder without rigorous inspection. When the valve is open, the high-visibility shut-off handle covers the coupler so that the valve cannot be disconnected. Quick and easy installation.

Forklift Accessories Disclaimer. This device may not comply with your forklift regional/provincial standards. Modifications and additions to the lift truck that affect capacity or safe operation shall not be performed without the written approval of the forklift manufacturer. Where such modifications and additions are performed, capacity, operation and maintenance instruction plates, tags or decals shall be changed accordingly. A pre-use examination shall take place in accordance with CSA safety standard for lift trucks. We will not be held responsible for any loss or damage or misuse that this product has or may have caused.

Changing a LPG cylinder on a forklift can sometimes give a forklift operator a big surprise! The seal in the cylinder valve can fail causing liquid propane gas to spray over the hand or face faster than they can react. Liquid propane vaporizes quickly (-42 degrees C or -44 degrees F) and will cause extreme frostbite if it contacts the skin.

The Solution: Placing a shut-off valve on the hose with the Propane Coupler to prevent the LPG from escaping back on to the forklift operator and escaping in to the surrounding environment.

Once the propane coupler has been installed and the lever is then opened the lever handle will prevent anyone from removing the Propane coupler. The lever must be closed before the propane coupler can be loosened off.

The safety relief valve is one of the most important and vital valves on any LP Gas container. All propane tanks and cylinders are required by law to be fitted with pressure relief devices designed to relieve excess pressure. The function of a safety relief valve is to keep a propane tank from rupturing in the unlikely event of excessive pressure buildup. Propane tank relief valves are also known as pop off valves, pressure venting valves or relief valves.

Houses or buildings utilizing gas energy require a gas piping system to power heaters, ovens, and other heating appliances. One of the most important elements of a gas piping system is the propane service valve, which controls propane gas flow in and out of a building. While there may be many other valves within gas plumbing, this valve functions as an on/off switch and serves as the main point of control for cutting off or allowing for the flow of gas into a piping system.

Propane valves are simply used to turn gas on or off. Similar to that of a water faucet, propane valves consist of a handwheel that controls propane gas flow when turned. When the wheel is turned, a stem and seat mechanism located within the valve opens or closes to prevent or allow gas flow from the tank.

Using propane gas requires an LP gas regulator, which decreases the amount of pressure released into the gas line, keeping it at an acceptable and safe level while still meeting the needs of the application.

There are multiple different valves in any propane system, each of which has a particular job. At IPS Equipment, we provide some of the most common types of valves for propane systems, including:

A pressure or safety relief valve is a safety mechanism that every propane system needs. It allows excess pressure in the tank to be slowly and safely released. Without this valve, pressure can build up and cause the tank to crack or rupture.

The relief valve has a pressurized spring. If the pressure levels within the tank grow too high, the spring forces the valve open just enough to return the pressure levels to acceptable levels. Once the pressure decreases, the spring relaxes, and the valve automatically closes.

This valve is where gas delivery personnel add new gas to a propane tank. Propane delivery trucks have hoses that can be attached to the filler valve so propane can be pumped into the tank. This valve is also pressure-activated, and it opens automatically in response to the pressure in the hose.

Filler valves have gaskets that operators can push the hose end against to avoid propane leaks. They also only allow for unidirectional fluid movement, meaning that once the tank is full, there is no risk of propane escaping when the hose is withdrawn.

This shut-off valve prevents gas from entering the building and any attached appliances. You can use this central point of control like an on/off switch to completely halt the path of gas in the system.

This valve is also called a vapor return valve or vapor eliminator valve. It ensures that propane is delivered at the proper pressure levels from the propane delivery truck to a personal tank and returns any excess propane back to the delivery truck. This is similar to a safety valve, except the vapor equalizing valve ensures the propane is delivered at proper pressures for optimum use, not safety. This is especially crucial during hot weather or in warm environments, as that can increase the pressure.

This specialized valve is meant for use by propane companies only. It allows operators with the proper tools to drain liquid propane from the tank. Propane tanks must be drained to <5% capacity levels before they can legally be moved.

IPS Equipment specializes in supplying propane marketers with reliable valves, fittings, regulators, and more for propane systems. Contact us today to learn more about our comprehensive products or services, or browse through our catalog to start your order.

The safety relief valve is one of the most important and vital valves on any LP Gas container. All propane tanks and cylinders are required by law to be fitted with pressure relief devices designed to relieve excess pressure. The function of a safety relief valve is to keep a propane tank from rupturing in the unlikely event of excessive pressure buildup. Propane tank relief valves are also known as pop off valves, pressure venting valves or relief valves.

Relief valves are held in the closed position by the force of a powerful spring. As long as the pressure inside the tank is less than that of the spring, the valve will remain closed. If tank pressure rises to that of the spring, the valve will open resulting in a hissing sound outside the tank. If the pressure in the tank rises significantly higher than that of the spring, the valve will fully open. When the valve fully opens, it initially makes a loud pop followed by a blast of released propane gas. Once the pressure is released and the tank pressure falls below that of the spring, the valve closes.

Most propane tanks in residential and commercial service have internal safety relief valves. The reason for an internal valve as opposed to an external pressure relief valve is it presents less of an obstruction when moving the tank. Internal relief valves are generally placed near the end of the propane tank on above ground containers.

Found primarily on older tanks, external relief valves operate in the same manner as an internal relief valve with the spring mechanism being outside the propane tank itself. Relief valves on multvalves are always fitted with external safety relief valves. Older tanks with an external relief valve installed on the container are generally replaced with internal pressure relief valves, provided they are connected to a dedicated tank opening specifically designed for the placement of the relief valve.

Because the safety relief valve performs such a vital role in the protection of the propane tank, it should be maintained and repaired by licensed propane professionals only. Do not ever look into a relief valve or stand over it.

A protective cover should be placed over the relief valve to ensure proper operation. If the valve has debris in the upper mechanism of the relief valve and it opens, the debris may cause the valve to remain open resulting in a potentially dangerous situation and/or excessive loss of propane. A simple protective relief valve cover can be made from a plastic bag fastened around the external portion of the valve with a rubber band.

If a you encounter a relief valve that seems to be "hissing" (opened to relieve pressure) do not tap it or mess with it. If the tank has been recently filled in hot weather and the face gauge reads over 80 or 85%, spray some water from a hose on the tank. This may cool it down and reduce the expansion of the liquid in the tank. Call your propane company immediately and inform them of the situation.

Pictured here is a relief valve that was apparently leaking. Instead of calling the propane company to replace the valve, the customer decided to fix the problem himself. Using a soldering iron, he soldered the leak until it stopped leaking. In the process of "repairing" the leak, the customer completely sealed the relief valve in a closed position placing himself and his family in a very dangerous situation.

In this type of situation, a relief valve that is sealed shut will not allow the tank to vent excess pressure if it is overfilled or the pressure inside the tank exceeds the working pressure of the container. In a case where the tank is unable to vent to the outside, the tank is subject to rupturing causing more harm and damage than money saved by trying to fix it yourself. Let the propane company or LPG professional handle any problems with thesafety relief valve.

JTC Valve Sales is an authorized dealer of industrial grade LPG Valves manufactured by Sherwood Valves, a leading manufacturer of valves. These LPG Cylinder Valves are designed to be used in various LPG applications such as recreational vehicles, engine fuel installations, and fork lift truck. They can also be used with tanks having capacity of 1000 gallons. JTC Valve Sales has been serving the industry with standardized valves since long to meet domestic, agricultural, and commercial applications.

We also have LPG changeover valves that are majorly used in hydrostatic relief devices, liquid withdrawal tubes, liquid level gauges, pressure relief devices and various other outlet connections.

8613371530291

8613371530291