crosby pressure safety valve manufacturer

Crosby pressure relief valves have been on the forefront of overpressure protection for more than 140 years. The direct spring-operated safety and pressure relief valves are among the world’s most widely used in oil and gas production and refining, petrochemical and chemical processing, and conventional and nuclear power industries. Crosby pressure relief valves uphold the industry’s most extensive and capable flow facilities for testing gas, liquid, steam and multi-phase applications.

Crosby is part of Emerson’s pressure relief portfolio, a complete range of standard and customized solutions, whatever need you have for overpressure protection.

Emerson is an industry leader in pressure relief valve technology. A single point provider, they offer an extensive product range for reliable performance with lower valve life-cycle costs and unique solutions. Their unrivaled engineering and technical expertise results in pressure management products, application solutions and services that can positively affect your business, safety, operations and the bottom line. Their engineering teams have designed testing equipment and procedures that assure optimum valve performances under all service conditions.

Facilities have cryogenic flow testing capabilities down to -320°F / -196°C, and flow steam testing, making them amongst the largest in the world that are used for research, experimentation and control of emissions on relief valves, like Crosby’s.

Crosby’s H-Series direct spring-operated safety valves are the trusted and proven solution to thorough overpressure protection for steam safety applications such as economizers, steam drums, superheaters, reheaters and more.

Crosby’s J-Series valves provide high quality and dependable overpressure protection for air, gas, steam, vapor, liquid and two-phase applications in one simple design.

Crosby leads the way in pressure relief valve technology. Explore high quality and dependable overpressure protection and phase applications in their catalog of relief valves.

Crosby pressure relief valves have maintained leadership in overpressure protection for over 140 years. The direct spring-operated safety and pressure relief valves are among the world’s most widely used for oil and gas production and refining, petrochemical and chemical processing, and conventional and nuclear power. Crosby pressure relief valves maintain the industry’s most extensive and capable flow facilities for testing in air, steam, and water.

Through our “VR” certification from the National Board of Boiler and Pressure Vessel Inspectors, Cornerstone provides “24/7” asset management and repair services for all brands of pressure relief products in ASME Section I and VIII applications and is capable of testing on steam, air/gas, and liquid medias.

Crosby™ pressure relief valves have maintained leadership in overpressure protection for over 140 years. The direct spring-operated safety and pressure relief valves are among the world’s most widely used for oil and gas production and refining, petrochemical and chemical processing, and conventional and nuclear power.

WPC provides customers with total pressure relief management solutions that support a facility’s entire lifecycle, transforming the way you ensure plant safety. Using Emerson comprehensive range of Pressure Safety Valves and WPC Engineering Services team ensures that the design of your pressure relief system is done correctly to respond to every overpressure scenario.

Since 1874, Crosby direct spring operated safety and relief valves have been among the world’s most widely used relief valves for gas, liquid, steam and multi-phase applications in Oil & Gas production, refining, petrochemical and chemical processing systems as well as for utility and industrial steam generators & steam systems in power generation facilities.

In the highly specialized field of pressure relief devices, no manufacturer can match the diversified products and experience of Emerson comprehensive range of Pilot operated Pressure Safety Valves with brands like Anderson Greenwood and Birkett.

With more designs than any other worldwide manufacturer, Anderson Greenwood’s and Birkett"s product technology solves applications from the most severe problem to very basic service conditions. These designs include a high temperature metal seated pilot valve, premium performance spring operated valves, API 526 flanged conventional and balanced bellows valves and an extensive iron and bronze product range.

The Crosby OMNI-TRIM pressure relief valve is the proven solution for overpressure protection and/or thermal relief applications on air, gas, vapor, liquid and steam. Its simple design makes it ideal for refineries, chemical and petrochemical plants, power plant auxiliary systems and pulp and paper mills.

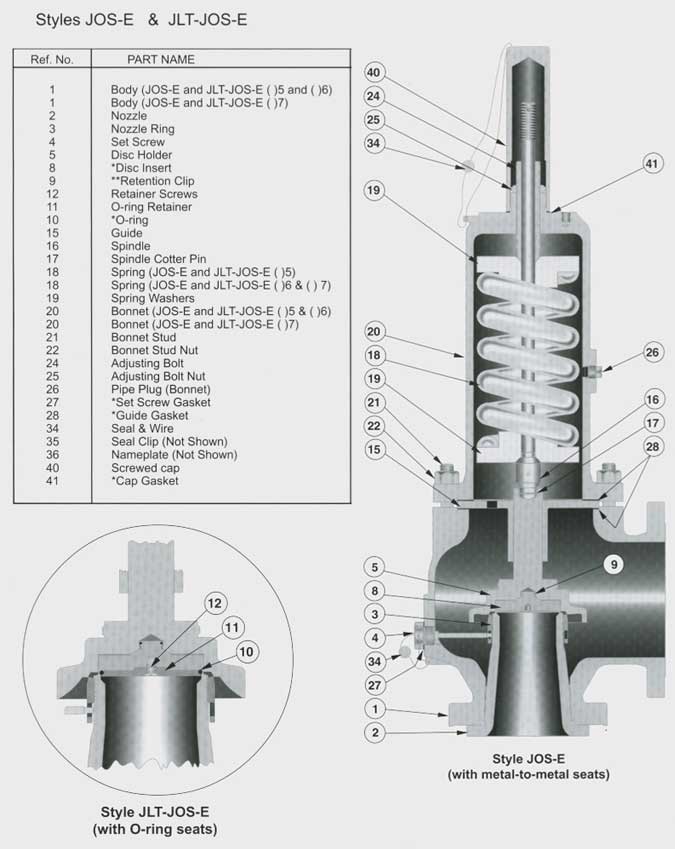

Anderson Greenwood Crosbyr its acquisition of New England-based Crosby Valve Co., Anderson Greenwood has relocated production, and built a modernized plant, in Stafford, TX, its headquarters. The new capacity is dedicated primarily to the Crosby Style JOS pressure-relief valve line (see Fig. 1), said to be the most popular model on the market today.

According to Chris Fadden, a company spokesman, (AGCO) has not only invested in new production, but has also updated the valve design, and is now providing an enhanced customer-service capability. The JOS-E (for "enhanced") valve, in particular, can now handle higher processing severities than preceding models. The production facility has new machining tools (fig. 2), new quality and inventory-control systems, and expedited delivery capability. AGCO had previously unveiled the "Pronto PRV" hot-line service; customers can simply dial 1-877 333 AGCO (2426) to place orders, check order status, and get follow-up service.

The JOS-E (along with other styles, JBS-E and JLT-E) valves provide overpressure protection in air, gas, steam, vapor and liquid service in the process, refining, and power industries. They are available with flat metal-to-metal seats or soft seats for optimum tightness and minimal maintenance.

Together, Anderson Greenwood and Crosby represent 125 years of valve development; Crosby was founded in 1874 to supply the power industry, and Anderson Greenwood in 1947 as an aircraft component supplier. It claims to have the largest range of PRV offerings that meet ASME Section VIII standards. AGCO is a division of Tyco International.

The direct spring-operated safety and pressure relief valves are among the world’s most widely used for oil and gas production and refining, petrochemical and chemical processing, and conventional and nuclear power. Crosby pressure relief valves maintain the industry’s most extensive and capable flow facilities for testing in air, steam, and water.

Crosby supports a wide range of heavy industry applications, and is known for its beyond limits approach to unique customer applications. Crosby also maintain the industry’s most extensive high-flow facilities for valve testing on air, steam and water.HL High Capacity, Flanged Steel Direct Spring Valve

8613371530291

8613371530291