crosby pressure safety valve quotation

Through our “VR” certification from the National Board of Boiler and Pressure Vessel Inspectors, Cornerstone provides “24/7” asset management and repair services for all brands of pressure relief products in ASME Section I and VIII applications and is capable of testing on steam, air/gas, and liquid medias.

Crosby pressure relief valves have been on the forefront of overpressure protection for more than 140 years. The direct spring-operated safety and pressure relief valves are among the world’s most widely used in oil and gas production and refining, petrochemical and chemical processing, and conventional and nuclear power industries. Crosby pressure relief valves uphold the industry’s most extensive and capable flow facilities for testing gas, liquid, steam and multi-phase applications.

Crosby is part of Emerson’s pressure relief portfolio, a complete range of standard and customized solutions, whatever need you have for overpressure protection.

Emerson is an industry leader in pressure relief valve technology. A single point provider, they offer an extensive product range for reliable performance with lower valve life-cycle costs and unique solutions. Their unrivaled engineering and technical expertise results in pressure management products, application solutions and services that can positively affect your business, safety, operations and the bottom line. Their engineering teams have designed testing equipment and procedures that assure optimum valve performances under all service conditions.

Facilities have cryogenic flow testing capabilities down to -320°F / -196°C, and flow steam testing, making them amongst the largest in the world that are used for research, experimentation and control of emissions on relief valves, like Crosby’s.

Crosby’s H-Series direct spring-operated safety valves are the trusted and proven solution to thorough overpressure protection for steam safety applications such as economizers, steam drums, superheaters, reheaters and more.

Crosby’s J-Series valves provide high quality and dependable overpressure protection for air, gas, steam, vapor, liquid and two-phase applications in one simple design.

Crosby leads the way in pressure relief valve technology. Explore high quality and dependable overpressure protection and phase applications in their catalog of relief valves.

Large orifice closed bonnet pressure relief valves. Also available with open bonnet as Styles HS/HSU; and as large orifice pilot operated pressure relief valves. Style JPV-A, for air, gas and steam. Ask for Catalog No. 307. Specifications:

A unique, completely sealed pressure relief valve for transportation and storage of chlorine and other toxic and corrosive fluids. Ask for Catalog No. 306. Specifications:

A sanitary pressure/vacuum pressure relief valve for the beverage, food processing and pharmaceutical industries. This valve provides three modes of self actuated operation:

Non-flowing, snap-acting, pilot operated, pressure relief valves. High performance valves for overpressure protection of pipes and vessels containg gases and vapors. Ask for Catalog No. 318. Specifications:

Non-flowing, modulating, pilot operated, pressure relief valve. Used for overpressure protection of gas, vapor, liquid and steam. Mounted on the same main valve used with Style JPV. Ask for Catalog No. 318. Specifications:

Non-flowing, modulating, pilot operated, pressure relief valve. Used for overpressure protection of high temperature fluids including hydrocarbons, inert gases and steam. Ask for Catalog No. 318. Specifications:

Pressure relief valve with single trim for liquid, gas and steam service. Precision lapped flat metal to metal seats or elastomer and TFE O-ring soft seats provide the ultimate in seat tightness. Blowdown is typically less than 20%. Capacities certified by National Board of Boiler and Pressure Vessel Inspectors. Ask for Catalog No. 902. Specifications:

Series 800 pressure relief valves are designed for use on air, gas, vapor and steam service. External precise blowdown control provides shorter blowdown then the Series 900, typically in the range of 5 to 15 percent. Capacities certified by National Board of Boiler and Pressure Vessel Inspectors. Ask for Catalog No. 902. Specifications:

Nozzle type safety valve for saturated and superheated steam service. Seat tightness up to 95% of valve set pressure. Ask for Catalog No. 408. Specifications:

With eductor-controlled, pressure-assisted blowdown for saturated steam service obiler drums with pressures from 1500-3000 PSIG (103-207 BarG). Ask for Catalog No. 403. Specifications:

Protect superheaters from overheating during startup, prolong the life and reduce maintenace of safety valves. Ask for Catalog No. 403. Specifications:

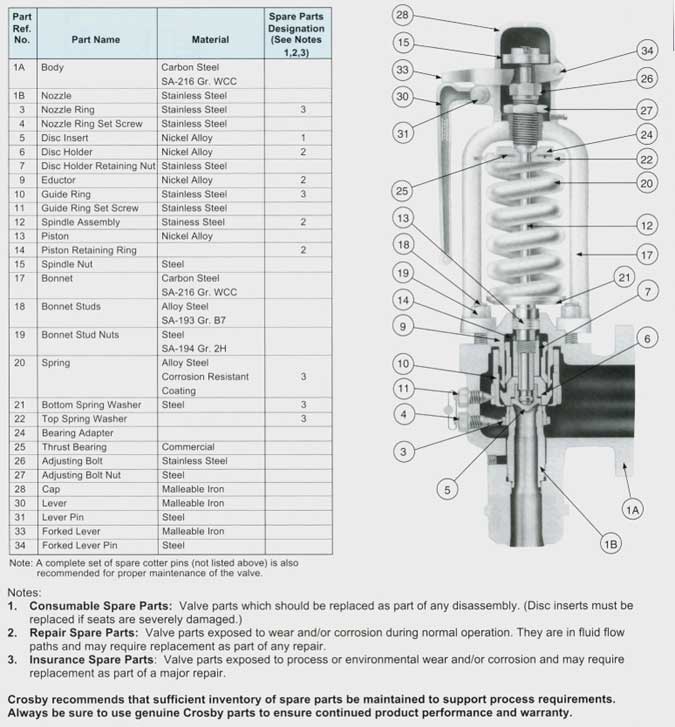

. . . . . Allied Valve Crosby PSV-614506 PSV614506 Pressure Safety Valve, PV/3030-6, VC-CVI-0983, 3/4" x 1" Size, Style 95110MD. Allied Valve. Crosby. PSV-614506.

8613371530291

8613371530291