crosby safety valve manual supplier

Crosby pressure relief valves have maintained leadership in overpressure protection for over 140 years. The direct spring-operated safety and pressure relief valves are among the world’s most widely used for oil and gas production and refining, petrochemical and chemical processing, and conventional and nuclear power. Crosby pressure relief valves maintain the industry’s most extensive and capable flow facilities for testing in air, steam, and water.

Large orifice closed bonnet pressure relief valves. Also available with open bonnet as Styles HS/HSU; and as large orifice pilot operated pressure relief valves. Style JPV-A, for air, gas and steam. Ask for Catalog No. 307. Specifications:

A unique, completely sealed pressure relief valve for transportation and storage of chlorine and other toxic and corrosive fluids. Ask for Catalog No. 306. Specifications:

A sanitary pressure/vacuum pressure relief valve for the beverage, food processing and pharmaceutical industries. This valve provides three modes of self actuated operation:

Non-flowing, snap-acting, pilot operated, pressure relief valves. High performance valves for overpressure protection of pipes and vessels containg gases and vapors. Ask for Catalog No. 318. Specifications:

Non-flowing, modulating, pilot operated, pressure relief valve. Used for overpressure protection of gas, vapor, liquid and steam. Mounted on the same main valve used with Style JPV. Ask for Catalog No. 318. Specifications:

Non-flowing, modulating, pilot operated, pressure relief valve. Used for overpressure protection of high temperature fluids including hydrocarbons, inert gases and steam. Ask for Catalog No. 318. Specifications:

Pressure relief valve with single trim for liquid, gas and steam service. Precision lapped flat metal to metal seats or elastomer and TFE O-ring soft seats provide the ultimate in seat tightness. Blowdown is typically less than 20%. Capacities certified by National Board of Boiler and Pressure Vessel Inspectors. Ask for Catalog No. 902. Specifications:

Series 800 pressure relief valves are designed for use on air, gas, vapor and steam service. External precise blowdown control provides shorter blowdown then the Series 900, typically in the range of 5 to 15 percent. Capacities certified by National Board of Boiler and Pressure Vessel Inspectors. Ask for Catalog No. 902. Specifications:

Nozzle type safety valve for saturated and superheated steam service. Seat tightness up to 95% of valve set pressure. Ask for Catalog No. 408. Specifications:

Protect superheaters from overheating during startup, prolong the life and reduce maintenace of safety valves. Ask for Catalog No. 403. Specifications:

Crosby pressure relief valves have been on the forefront of overpressure protection for more than 140 years. The direct spring-operated safety and pressure relief valves are among the world’s most widely used in oil and gas production and refining, petrochemical and chemical processing, and conventional and nuclear power industries. Crosby pressure relief valves uphold the industry’s most extensive and capable flow facilities for testing gas, liquid, steam and multi-phase applications.

Crosby is part of Emerson’s pressure relief portfolio, a complete range of standard and customized solutions, whatever need you have for overpressure protection.

Emerson is an industry leader in pressure relief valve technology. A single point provider, they offer an extensive product range for reliable performance with lower valve life-cycle costs and unique solutions. Their unrivaled engineering and technical expertise results in pressure management products, application solutions and services that can positively affect your business, safety, operations and the bottom line. Their engineering teams have designed testing equipment and procedures that assure optimum valve performances under all service conditions.

Facilities have cryogenic flow testing capabilities down to -320°F / -196°C, and flow steam testing, making them amongst the largest in the world that are used for research, experimentation and control of emissions on relief valves, like Crosby’s.

Crosby’s H-Series direct spring-operated safety valves are the trusted and proven solution to thorough overpressure protection for steam safety applications such as economizers, steam drums, superheaters, reheaters and more.

Crosby’s J-Series valves provide high quality and dependable overpressure protection for air, gas, steam, vapor, liquid and two-phase applications in one simple design.

Crosby leads the way in pressure relief valve technology. Explore high quality and dependable overpressure protection and phase applications in their catalog of relief valves.

EMERSON. CROSBY H-SERIES DIRECT SPRING SAFETY VALVESDirect spring safety valves that provide comprehensive overpressure protection for ASME Boiler and Pressure Vessel Code Section I, and Section VIII steam safety applicationsFEATURES HCI ISOFLEX" • ASME/NB certified capacities for steam. • Set and tested on steam. • Full nozzle flanged option. • Restricted lift for customized capacity. • Long service life. • Low maintenance. • Two ring set pressure and blowdown control. • ISOFLEX seat tightness up to 93%. For seat tightness greater than 93% consult factory. TECHNICAL DATA GENERAL APPLICATION H-Series direct spring operated safety valves are the proven solution for comprehensive overpressure protection on steam safety applications including economizers, steam drums, superheaters, reheaters and more. Sizes: Orifices: Connections: Temperature range: Set pressures: IVi" F IV2" to 6" RR 10" 0.307 to 19.29 in2 (1.98 to 124.45 cm2) Flanged or welded inlet 1120 °F (604 °C) 15 to 5000 psig (1 to 345 barg) Code: ASME Boiler and Pressure Vessel Code Section I, and Section VIII Emerson.com/FinalControl © 2017 Emerson. All Rights Reserved VCTDS-00595-EN 17/11

Complete overpressure protection for ASME B&PVC Section I A complete safety valve package for utility and industrial steam generators and steam systems. • Boilers with design pressures to 3000 psig (207 barg). • Valves designed to increase plant up-times, extend maintenance intervals and increase total valve life. Steam System Components 7. Boiler feed water pump 8. Cold reheat inlet VALVE SELECTION APPLICATIONS AND RECOMMENDED™ VALVE SELECTION NOTES 1. Selection matrix shows valves in optimum locations - Styles HSJ and HCI may be interchanged to suit a specific application or to obtain a...

STYLE HE ISOFLEX® Style HE ISOFLEX® safety valves are high pressure, high capacity reaction type valves designed specifically for saturated steam service on boiler drums with design pressures above 2000 psig (138 barg) up to critical pressure. FEATURES TECHNICAL DATA • Extends Up-time - ISOFLEX® seat tightness to 93% of set pressure ensures maximum generating times, extending maintenance intervals. For seat tightness greater than 93% consult factory. • Reduces Maintenance Costs - Exceptional seat tightness minimizes maintenance resources and repair times and reduces spare parts purchase and...

PRODUCT OVERVIEW The HE ISOFLEX incorporates our latest field proven seat tightness design which allows boilers to operate close to set pressure without leakage across the valve seat. The HE ISOFLEX also has a unique patented eductor control that permits the valve to attain full capacity lift at a pressure 3% above popping pressure to the requirements of Section I of the ASME Boiler and Pressure Vessel Code. APPLICATION The HE ISOFLEX safety valve is a high pressure, high capacity reaction type valve, designed specifically for saturated steam service on boiler drums having design pressures...

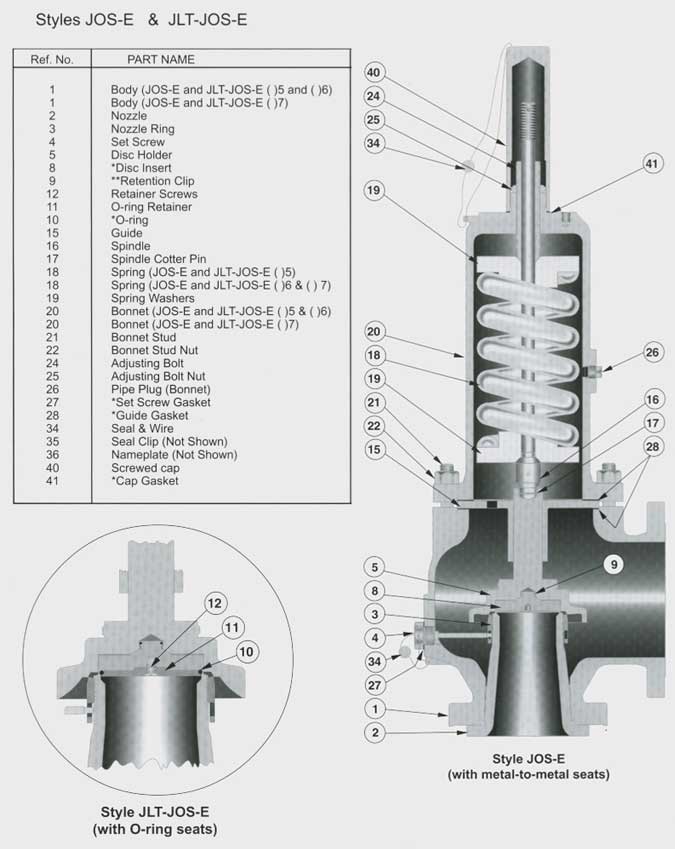

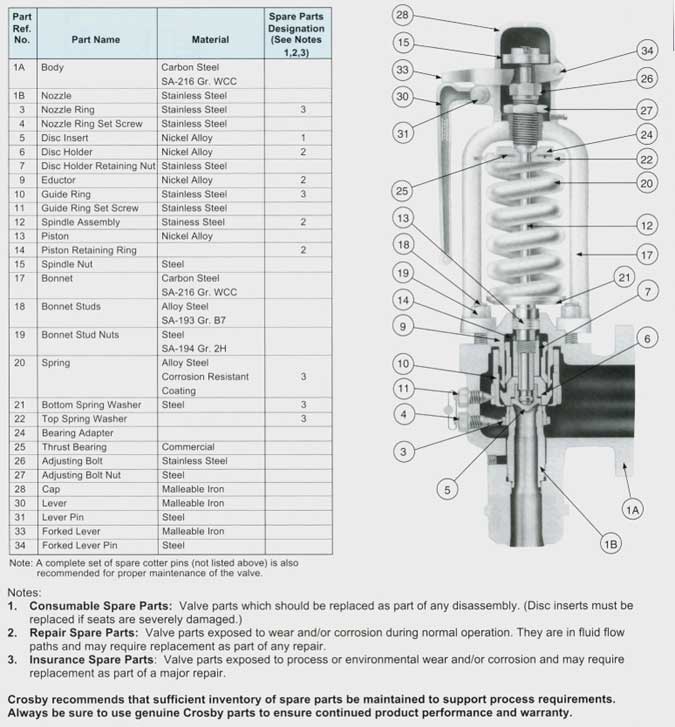

CROSBY H-SERIES STYLE HE ISOFLEX 28 Part name Body Nozzle Nozzle ring Nozzle ring set screw Disc insert Disc holder Disc holder retaining nut Eductor Guide ring Guide ring set screw Spindle assembly Piston Piston retaining ring Spindle nut Bonnet Bonnet studs Bonnet stud nuts Material Carbon steel SA-216 Gr. WCC Stainless steel Stainless steel Stainless steel Inconel® Nickel alloy Stainless steel Nickel alloy Stainless steel Stainless steel Stainless steel Nickel alloy Steel Steel Carbon steel SA-216 Gr. WCC Alloy steel SA-193 Gr. B7 Steel SA-194 Gr. 2H Bottom spring washer Top spring...

2500 psig maximum pressure 1. These style designations are for standard welded inlets. For optional CL 2500 flanged inlet valves, the "W" is dropped from the style designation. 2. Weld prep per customer"s specifications. Safety valves must be mounted on a nozzle with an inlet diameter equal to or greater than the nominal valve inlet size, dimension A. See ASME boiler and pressure vessel code Section I and ANSI/ASME B31.1 for recommended installation. 3. Bolt holes straddle centerline on flanged connections. 4. Dismantling height: an additional 20 inches (508 mm) is required. Drain: main...

1 Increases Operating Efficiency Sizes: - Restricted Lift Option for customized capacity, reduced reaction forces, and boiler design standardization Orifices: - Seat tightness up to 93% of valve set pressure. For seat tightness greater than Connections: 93% consult factory - Two ring control to adjust overpressure and Maximum blowdown independently temperature: - May also be used for ASME Boiler and Maximum Pressure Vessel Code Section VIII off boiler set pressure: steam applications for higher operating Codes: pressures 1 Reduces Maintenance Costs CROSBY H-SERIES STYLE HCI ISOFLEX DIRECT...

CROSBY H-SERIES STYLE HCI ISOFLEX PRODUCT OVERVIEW The HCI ISOFLEX safety valve is a high capacity nozzle type valve suitable for saturated and superheated steam service. The valves are available in inlet sizes of 1½”, 2", 2½”, 3", 4" and 6" and in orifice sizes H2 to RR specifically designed for the power industry. Welded inlets and flanged outlets are standard, with flanged inlets (1) with full (removable) nozzles (2) also available. Blowdown control is precise with two adjustable rings (3 and 12) - one each on the nozzle (1B or 2) and guide (11). Blowdown may be adjusted from 2 to 4%...

EMERSON. CROSBY H-SERIES DIRECT SPRING SAFETY VALVESDirect spring safety valves that provide comprehensive overpressure protection for ASME Boiler and Pressure Vessel Code Section I, and Section VIII steam safety applicationsFEATURES HCI ISOFLEX" • ASME/NB certified capacities for steam. • Set and tested on steam. • Full nozzle flanged option. • Restricted lift for customized capacity. • Long service life. • Low maintenance. • Two ring set pressure and blowdown control. • ISOFLEX seat tightness up to 93%. For seat tightness greater than 93% consult factory. TECHNICAL DATA GENERAL APPLICATION H-Series direct spring operated safety valves are the proven solution for comprehensive overpressure protection on steam safety applications including economizers, steam drums, superheaters, reheaters and more. Sizes: Orifices: Connections: Temperature range: Set pressures: IVi" F IV2" to 6" RR 10" 0.307 to 19.29 in2 (1.98 to 124.45 cm2) Flanged or welded inlet 1120 °F (604 °C) 15 to 5000 psig (1 to 345 barg) Code: ASME Boiler and Pressure Vessel Code Section I, and Section VIII Emerson.com/FinalControl © 2017 Emerson. All Rights Reserved VCTDS-00595-EN 17/11

Complete overpressure protection for ASME B&PVC Section I A complete safety valve package for utility and industrial steam generators and steam systems. • Boilers with design pressures to 3000 psig (207 barg). • Valves designed to increase plant up-times, extend maintenance intervals and increase total valve life. Steam System Components 7. Boiler feed water pump 8. Cold reheat inlet VALVE SELECTION APPLICATIONS AND RECOMMENDED™ VALVE SELECTION NOTES 1. Selection matrix shows valves in optimum locations - Styles HSJ and HCI may be interchanged to suit a specific application or to obtain a...

STYLE HE ISOFLEX® Style HE ISOFLEX® safety valves are high pressure, high capacity reaction type valves designed specifically for saturated steam service on boiler drums with design pressures above 2000 psig (138 barg) up to critical pressure. FEATURES TECHNICAL DATA • Extends Up-time - ISOFLEX® seat tightness to 93% of set pressure ensures maximum generating times, extending maintenance intervals. For seat tightness greater than 93% consult factory. • Reduces Maintenance Costs - Exceptional seat tightness minimizes maintenance resources and repair times and reduces spare parts purchase and...

PRODUCT OVERVIEW The HE ISOFLEX incorporates our latest field proven seat tightness design which allows boilers to operate close to set pressure without leakage across the valve seat. The HE ISOFLEX also has a unique patented eductor control that permits the valve to attain full capacity lift at a pressure 3% above popping pressure to the requirements of Section I of the ASME Boiler and Pressure Vessel Code. APPLICATION The HE ISOFLEX safety valve is a high pressure, high capacity reaction type valve, designed specifically for saturated steam service on boiler drums having design pressures...

CROSBY H-SERIES STYLE HE ISOFLEX 28 Part name Body Nozzle Nozzle ring Nozzle ring set screw Disc insert Disc holder Disc holder retaining nut Eductor Guide ring Guide ring set screw Spindle assembly Piston Piston retaining ring Spindle nut Bonnet Bonnet studs Bonnet stud nuts Material Carbon steel SA-216 Gr. WCC Stainless steel Stainless steel Stainless steel Inconel® Nickel alloy Stainless steel Nickel alloy Stainless steel Stainless steel Stainless steel Nickel alloy Steel Steel Carbon steel SA-216 Gr. WCC Alloy steel SA-193 Gr. B7 Steel SA-194 Gr. 2H Bottom spring washer Top spring...

2500 psig maximum pressure 1. These style designations are for standard welded inlets. For optional CL 2500 flanged inlet valves, the "W" is dropped from the style designation. 2. Weld prep per customer"s specifications. Safety valves must be mounted on a nozzle with an inlet diameter equal to or greater than the nominal valve inlet size, dimension A. See ASME boiler and pressure vessel code Section I and ANSI/ASME B31.1 for recommended installation. 3. Bolt holes straddle centerline on flanged connections. 4. Dismantling height: an additional 20 inches (508 mm) is required. Drain: main...

1 Increases Operating Efficiency Sizes: - Restricted Lift Option for customized capacity, reduced reaction forces, and boiler design standardization Orifices: - Seat tightness up to 93% of valve set pressure. For seat tightness greater than Connections: 93% consult factory - Two ring control to adjust overpressure and Maximum blowdown independently temperature: - May also be used for ASME Boiler and Maximum Pressure Vessel Code Section VIII off boiler set pressure: steam applications for higher operating Codes: pressures 1 Reduces Maintenance Costs CROSBY H-SERIES STYLE HCI ISOFLEX DIRECT...

CROSBY H-SERIES STYLE HCI ISOFLEX PRODUCT OVERVIEW The HCI ISOFLEX safety valve is a high capacity nozzle type valve suitable for saturated and superheated steam service. The valves are available in inlet sizes of 1½”, 2", 2½”, 3", 4" and 6" and in orifice sizes H2 to RR specifically designed for the power industry. Welded inlets and flanged outlets are standard, with flanged inlets (1) with full (removable) nozzles (2) also available. Blowdown control is precise with two adjustable rings (3 and 12) - one each on the nozzle (1B or 2) and guide (11). Blowdown may be adjusted from 2 to 4%...

Crosby Catalog No. 310 310 310 307 902 902

(c) The spring in a safety valve or safety relief valve shall pressure which opens in proportion to the increase in pressure over the opening pressure. A

not be set for any pressure more than 5% above or below safety relief valve is a pressure relief valve characterized by rapid opening or pop action, or by

that for which the valve is marked, unless the setting is application. A pilot operated pressure relief valve is a pressure relief valve in which the major

within the spring design range established by the valve relieving device is combined with and is controlled by a self-actuated auxiliary pressure relief

assembler, and a valve data tag shall be provided that Rupture disks may be designed in several configurations, such as plain flat, prebulged or

identifies the set pressure, capacity and date. The valve reverse buckling, and may be made of either ductile or brittle material; rupture disk material

or safety relief valve and the rupture disk device is ample appropriate allowance for any structual members which may reduce the net flow area through

(2) the stamped capacity of a spring loaded carefully evaluated to ensure that the media being handled and the valve operational

and the vessel shall be multiplied by a factor of 0.90 of the builds up in the space between the disk and the safety or safety relief valve which will occur

the capacity of such a combination shall be established in to minimize the loss by leakage through the valve of valuable or of noxious or otherwise

valve may be established in accordance with the appro- pressure if back pressure builds up in the space between the valve and rupture disk. A

Pentair Valves & Controls’ newly introduced Crosby HCI ISOFLEX is a high-capacity safety valve to help power plant operators reduce lifecycle costs and minimize shutdown periods. The valve ensures cost-effective power plant operation with a unique full-nozzle, flanged design and adjustable lift option that reduces maintenance costs while maximizing plant efficiency. Specifically designed for 300 to 3,000 psig steam generators, the HCI ISOFLEX can withstand temperatures up to 1,100F/593C and is available in various inlet sizes, ranging from 1½ inch (38.1 mm) to 6 inches (15.24 cm). An extensive range of interchangeable spare parts enables operators to repair or exchange components individually, avoiding costly replacements and minimizing shutdown time.

The valve is also available with an optional restricted lift feature to eliminate overcapacity and ensure a more economic distribution of relieving capacity between the drum and superheater safety valves. This design not only reduces reaction forces for a greater lifespan but also allows for the use of smaller superheater safety valves in some operations, reducing overall installation costs. Additional benefits include precise blowdown control due to a two-ring design and exceptional seat tightness up to 95% of valve set pressure. (valves.pentair.com/valves)

Curtiss-Wright"s selection of Pressure Relief Valves comes from its outstanding product brands Farris and Target Rock. We endeavor to support the whole life cycle of a facility and continuously provide custom products and technologies. Boasting a reputation for producing high quality, durable products, our collection of Pressure Relief Valves is guaranteed to provide effective and reliable pressure relief.

While some basic components and activations in relieving pressure may differ between the specific types of relief valves, each aims to be 100% effective in keeping your equipment running safely. Our current range includes numerous valve types, from flanged to spring-loaded, threaded to wireless, pilot operated, and much more.

A pressure relief valve is a type of safety valve designed to control the pressure in a vessel. It protects the system and keeps the people operating the device safely in an overpressure event or equipment failure.

A pressure relief valve is designed to withstand a maximum allowable working pressure (MAWP). Once an overpressure event occurs in the system, the pressure relief valve detects pressure beyond its design"s specified capability. The pressure relief valve would then discharge the pressurized fluid or gas to flow from an auxiliary passage out of the system.

Below is an example of one of our pilot operated pressure relief valves in action; the cutaway demonstrates when high pressure is released from the system.

Air pressure relief valves can be applied to a variety of environments and equipment. Pressure relief valves are a safety valve used to keep equipment and the operators safe too. They"re instrumental in applications where proper pressure levels are vital for correct and safe operation. Such as oil and gas, power generation like central heating systems, and multi-phase applications in refining and chemical processing.

At Curtiss-Wright, we provide a range of different pressure relief valves based on two primary operations – spring-loaded and pilot operated. Spring-loaded valves can either be conventional spring-loaded or balanced spring-loaded.

Spring-loaded valves are programmed to open and close via a spring mechanism. They open when the pressure reaches an unacceptable level to release the material inside the vessel. It closes automatically when the pressure is released, and it returns to an average operating level. Spring-loaded safety valves rely on the closing force applied by a spring onto the main seating area. They can also be controlled in numerous ways, such as a remote, control panel, and computer program.

Pilot-operated relief valves operate by combining the primary relieving device (main valve) with self-actuated auxiliary pressure relief valves, also known as the pilot control. This pilot control dictates the opening and closing of the main valve and responds to system pressure. System pressure is fed from the inlet into and through the pilot control and ultimately into the main valve"s dome. In normal operating conditions, system pressure will prevent the main valve from opening.

The valves allow media to flow from an auxiliary passage and out of the system once absolute pressure is reached, whether it is a maximum or minimum level.

When the pressure is below the maximum amount, the pressure differential is slightly positive on the piston"s dome size, which keeps the main valve in the closed position. When system pressure rises and reaches the set point, the pilot will cut off flow to the dome, causing depressurization in the piston"s dome side. The pressure differential has reversed, and the piston will rise, opening the main valve, relieving pressure.

When the process pressure decreases to a specific pressure, the pilot closes, the dome is repressurized, and the main valve closes. The main difference between spring-loaded PRVs and pilot-operated is that a pilot-operated safety valve uses pressure to keep the valve closed.

Pilot-operated relief valves are controlled by hand and are typically opened often through a wheel or similar component. The user opens the valve when the gauge signifies that the system pressure is at an unsafe level; once the valve has opened and the pressure has been released, the operator can shut it by hand again.

Increasing pressure helps to maintain the pilot"s seal. Once the setpoint has been reached, the valve opens. This reduces leakage and fugitive emissions.

At set pressure the valve snaps to full lift. This can be quite violent on large pipes with significant pressure. The pressure has to drop below the set pressure in order for the piston to reseat.

At Curtiss-Wright we also provide solutions for pressure relief valve monitoring. Historically, pressure relief valves have been difficult or impossible to monitor. Our SmartPRV features a 2600 Series pressure relief valve accessorized with a wireless position monitor that alerts plant operators during an overpressure event, including the time and duration.

There are many causes of overpressure, but the most common ones are typically blocked discharge in the system, gas blowby, and fire. Even proper inspection and maintenance will not eliminate the occurrence of leakages. An air pressure relief valve is the only way to ensure a safe environment for the device, its surroundings, and operators.

A PRV and PSV are interchangeable, but there is a difference between the two valves. A pressure release valve gradually opens when experiencing pressure, whereas a pressure safety valve opens suddenly when the pressure hits a certain level of over pressurization. Safety valves can be used manually and are typically used for a permanent shutdown. Air pressure relief valves are used for operational requirements, and they gently release the pressure before it hits the maximum high-pressure point and circulates it back into the system.

Pressure relief valves should be subject to an annual test, one per year. The operator is responsible for carrying out the test, which should be done using an air compressor. It’s imperative to ensure pressure relief valves maintain their effectiveness over time and are checked for signs of corrosion and loss of functionality. Air pressure relief valves should also be checked before their installation, after each fire event, and regularly as decided by the operators.

Direct-acting solenoid valves have a direct connection with the opening and closing armature, whereas pilot-operated valves use of the process fluid to assist in piloting the operation of the valve.

A control valve works by varying the rate of fluid passing through the valve itself. As the valve stem moves, it alters the size of the passage and increases, decreases or holds steady the flow. The opening and closing of the valve is altered whenever the controlled process parameter does not reach the set point.

Control valves are usually at floor level or easily accessible via platforms. They are also located on the same equipment or pipeline as the measurement and downstream or flow measurements.

An industrial relief valve is designed to control or limit surges of pressure in a system, most often in fluid or compressed air system valves. It does so as a form of protection for the system and defending against instrument or equipment failure. They are usually present in clean water industries.

A PRV is often referred to as a pressure relief valve, which is also known as a PSV or pressure safety valve. They are used interchangeably throughout the industry depending on company standards.

8613371530291

8613371530291