cryogenic safety valve pricelist

Browse our selection of Cryogenic Pressure Relief Valves, designed for use with liquid dewars, oxygen compatible, and rated for different pressure requirements.

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale cryogenic safety valve on Alibaba.com. When you search for cryogenic safety valve and related items, you will be able to find many types of cryogenic safety valve varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of cryogenic safety valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

Cryogenic Safety Valves Type 06011 is made with stainless steel. It is provided as a safety device for protection against thermal expansion in pipework ...

Established as a Sole Proprietor firm in the year 2017, we “Motek Enterprises” are a leading Wholesale Trader of a wide range of Ball Bearing, Brass Pressure Relief Valve, etc.

Cryogenic Valves are valves made for use under very low cryogenic temperatures. The valves have materials that can withstand the low temperatures. There are different types of these valves such as cryogenic gate valves, cryogenic butterfly valves, cryogenic check valves and so on. The Api Cryogenic Valves have dimensions and sizes according to the API standards. The material used in mostly carbon steel, stainless steel and cast steel. The pressure of the valves can range up to PN40 and the temperatures can be well below -150 degrees Celsius. The applications of the valves include liquefied natural gas, ethylene, tank services, gas production plants, compressed natural gas and other low pressure low temperature applications.

The Asme Cryogenic Valves are made under the ASME standards and vary in dimensions from 2 inches to 24 inches. The valve design is made with an extended bonnet. This protects the valve stem from the extreme temperature drop. The elongation thermal expansion and elongation of the material is crucial in making the Cryogenic Control Valves as the can shrink during cold temperatures. The threads, the stem, handle and the bonnet are all designed to handle the low temperature conditions. The valve is mounted on any desired position in the pipeline but the vertical fitting of the valves is common. The Cryogenic Diaphragm Valve uses a diaphragm inside to control the flow of liquids under extreme low temperatures. The diaphragm is made of different materials than the valve body.

ASTM A216 Grade WCB Cryogenic Check/ Relief / Needle Valves in DN6 - DN50 size range, Buy directly from Cryogenic valve manufacturer in India for low cost

The global cryogenic valve market size was valued at USD 3.65 billion in 2021. The market is projected to grow from USD 3.88 billion in 2022 to USD 7.15 billion by 2029, exhibiting a CAGR of 9.1% during the forecast period. The global COVID-19 pandemic has been unprecedented and staggering, with cryogenic valve experiencing lower-than-anticipated demand across all regions compared to pre-pandemic levels. Based on our analysis, the global market exhibited a decline of -4.1% in 2020 as compared to 2019.

Cryogenic valves are used in extreme cold applications. These valves are mostly used by companies that deal in Compressed Natural Gas (CNG) and Liquefied Natural Gas (LNG). Cryogenic valves are used at temperatures of -1500C to -1960C. The major factors driving the market include growing trade for LNG and rising demand for industrial gases.

Furthermore, the development in the exploration and production activities of natural gas has led to the growing demand for liquefied natural gas. Revolution in various fields, such as automobile, pharmaceutical, power generation, and manufacturing, has led to huge industrialization and urbanization, making liquefied natural gas a vital development element. These valves are used to store and transport the cryogenic gases at high pressure such as 750 PSI and a low-temperature range of -1960C.

The emergence of COVID-19 has impeded the demand for cryogenic valves due to the shutdown of manufacturing plants in major industries. Key players operating in the market recorded a significant decline in their revenues due to the COVID-19 pandemic. As the cryogenic valve market is majorly dependent on the natural gas industry, the biggest collapse faced by the oil and gas industry in a long time has also impacted the investment in the product. The excess supply and low demand for natural gas forced leading gas companies to temporarily reduce production activities, which ultimately led to a fluctuation in natural gas prices.

Various countries are readily focused on constructing advanced facilities to fortify the position of their national physics research infrastructure. These valves are widely installed across refrigeration systems and superconducting magnets to maintain extremely low temperatures. The growing need to refurbish the existing substructure for performing high-energy particle collision experiments with multi tera electron volts (TeV) is projected to further complement the industry outlook. These collisions are anticipated to unveil new states of matter and expand the understanding of the basic building blocks of the universe. Furthermore, as the energy for particle and nuclear research analysis increases, the total required cryogenic refrigeration capacity is set to grow significantly. In June 2020, the European Organization for Nuclear Research (CERN) announced an investment of about USD 23 billion to construct a new super-collider facility known as Future Circular Collider (FCC). The new 100-kilometer unit is projected to be completed in two stages, with the initial stage for the collision of positrons and electrons to expand the production of Higgs bosons to gather insights regarding the particles. Additionally, the subsequent stage is set to construct a 100 TeV proton-proton collider for further research and is projected to commence the building of the tunnel by 2038.

The demand for automation is growing as manufacturers are focusing on increasing their operational performance, which is driving the market for automation valves and outperforming traditional valves. Furthermore, the demand for high-tech valves is growing, high-tech valves require specialized casting, and working and finishing techniques will continue to grow. In addition, various countries are focusing on constructing advanced facilities to strengthen the position of their national physics research infrastructure, thereby propelling the global cryogenic valve market growth. These valves are widely installed across refrigeration systems and superconducting magnets to maintain extremely low temperatures.

Rapidly increasing demand for various cryogenic fluids, such as nitrogen, oxygen, hydrogen, argon, helium, and many others for different industrial operations, primarily among the emerging economies, will boost the adoption of cryogenic valves across the globe. Furthermore, a growing focus on expanding the usage of liquefied gases in numerous industry verticals is also likely to encourage industry growth positively. The escalating usage potential is leading to a significant increase in the deployment of customized on-site liquefaction plants to produce, transfer, and store cryogenic effectively. For instance, in March 2020, Japan-based Kawasaki Heavy Industries declared to equip a marine vessel with a liquefied hydrogen storage tank for low emission propulsion. The company further stated to perform other outfitting operations such as piping installations by October 2020. The plan is in line with its hydrogen liquefaction, transfer, storage, and the offloading terminal project called Hydrogen Energy Supply Chain (HESC) project.

Apart from a wide range of beneficial features of these products, susceptibilities toward operational problems, including leakages, replacement, and design of various valve parts may obstruct the market pace. The products are widely accepted in the extended bonnet or extended stem designs, which need significant space for installation leading to the undesirable outlay of time and space. Additionally, the orientations are considerably vulnerable to deformation or bending due to length miscalculations or actuator movements. These valves are designed for handling fluids at extremely low temperatures from about – 50 °C to around absolute zero. The transition of operating fluid temperature may lead to warping bends the sealing surface leading to internal leakages. Furthermore, flanged and gasket connections may also result in external leakages between the valve and pipelines. Thus, it is more feasible to change the flanged type to a welded connection to mitigate leakages at low temperatures.

Based on type, the global market is segmented into gate valve, globe valve, ball valve, butterfly valve, and others. The gate valve segment dominated the global market owing to its preliminary design for starting or stopping the flow; furthermore, it can also be used with slurries or viscous liquids. The ball valves also accounted for a significant share, owing to their high flow rate and easy operations when compared to other valve types.

The global cryogenic valve market is dominated by Asia Pacific. Increasing energy demand from gas-based power plants, owing to depleting energy resources and stringent regulations for emissions fuels the demand for the valves in the region. China has been the undisputed leader in the region in both owing to enormous hydrogen infrastructure development strategies, setup of advanced air separation plants, and continuous construction of new research facilities. For example, in September 2019, the construction of a new support facility called China Spallation Neutron Source (CSNS) to serve the Southern Advanced Photon Source (SAPS) R&D facility in the same year. The nation’s maiden pulsed spallation neutron source to back the high-energy physics research project is set to witness total funding of about USD 83 million with a projected completion date of 2021.

North America also contributes a significant cryogenic valve market share, owing to increasing demand for LNG based power plants. The gas demand is projected to increase due to growth in the industrial and power sectors, as 70 GW of new gas-based power plants were proposed in 2020. Hence, an increase in demand for valves will grow owing to growth in the power industry. Increasing investments in the oil & gas industry, which include gas production & exports are the major revenue-driven sectors propelling the need for cryogenic valves & equipment in the forecast period.

The availability of large spaces to set up large research and observation facilities without harming the ecological balance of nature is projected to complement the Middle East & Africa valve industry. For instance, a collection of eight African nations, including Kenya, Mozambique, Ghana, Mauritius, South Africa, Namibia, Madagascar, Zambia, and Botswana were selected to set up various hosting components of the Square Kilometer Array (SKA) project owing to the desert places with required radio noiseless backdrop. Under the project, South Africa is currently accommodating the MeerKAT telescope array and KAT7 telescope array equipped with 200 dishes and 64 dishes systems, respectively.

Some of the major companies that are present in the market are Baker Hughes, Emerson Electric CO., Flowserve Corp., Neles Corp, KITZ Corporation, Cryostar GmbH, Herose GmbH, Schlumberger, Cryocomp, Bray International, ACME Cryogenics, and Phpk Technologies.

October 2021–Flowserve Corporation, one of the largest suppliers of industrial and environmental machinery, launched the Valtek Multi Z Anti cavitation control valve to eliminate cavitation in high-pressure drop conditions.

March 2020 –Switzerland-based valve manufacturer Weka AG confirmed to ink an agreement with Toshniwal Hyvac Pvt. Ltd. situated in India. The company targets to license its product manufacturing in the country and expand sales & marketing locally in the region. Weka’s sales partnership will include the production and supply of different products, such as special valves, cryo components, and level measurement technology, that were achieved after a two-year search and evaluation phase with the company.

June 2020 –Flowserve Corporation introduced a new range of butterfly control valves called Valtek Valdisk. The advanced product offering is fabricated to deliver low-pressure loss, high capacity, high-performance throttling, and lower maintenance costs. It is designed to operate in a temperature ranging between -268°C to 427°C and can be deployed in various configurations & applications, including air separation, Pressure Swing Adsorption (PSA), oil & gas, chemical refining, and many more.

November 2019 –LESER GmbH announced plans to develop a new facility to enable the company to perform cryogenic testing of safety valves under actual operational conditions. Its new test concept includes a liquid nitrogen-filled 1,000 liters’ cryogenic cylinder with a testing temperature of -196°C. The cryogenic safety valves are examined for three consecutive opening and closing cycles with a test pressure of 16 bar to check the integrity of the products.

April 2019 –RAYS Flow Control, Inc. declared to sign an industry-university-research partnership agreement with the Hefei Institutes of Physical Science under the Chinese Academy of Sciences (CAS). The key focus areas of the collaboration include R&D of new cryogenic valve materials, research on associated science and technology projects, and development & functioning of valve technology.

The global cryogenic valves market research report highlights leading regions worldwide to offer a better understanding of the user. Furthermore, the report provides insights into the latest market trends and analyzes technologies deployed rapidly at a global level. It further highlights some growth-stimulating factors and restraints, helping the reader gain in-depth knowledge about the industry.

Stainless Steel 304 Cryogenic Solenoid Valve is one of the valve types that are used under extreme low temperatures. Suraj Metal Corporationis a leading manufacturer and supplier of the different types such as the Cryogenic Bronze Manual Globe and Butterfly Valveis more corrosive in comparison to the 304 and 316 grade stainless steel grades.

The bronze valves are good for steam operations. The cryogenic ball valves are mostly closed under normal conditions. They have a mechanism to automatically open and close by electric power. The A351 CF8 Stainless Steel 304 Cryogenic Gate Valveis one of the most used for the material’s high strength and corrosion resistance. There are different types such as the zero pressure drop valves and pressure drop assisted valves. The SS 316 Cryo Valvescan require a minimum pressure drop between the inlet and outlet to open which are the pressure drop assisted valves. The ASTM A216 Gr. WCB Cryogenic Relief /Check / Needle Valveand other standards which do not need minimum pressure drop to operate are known as the zero pressure drop valves. Please feel free to contact us for more information and pricing of the different types such as the Alloy Steel ASTM A217 WC1 Cryogenic Shut Off Flow Control Valve.

Extended stem and bonnet to position the stem packing above the cryogenic fluid and providing a column of warmer vapor that insulates the stem seal from the affects of low temperatures

The cryogenic valve is based on the Flow-Tek Triad Series, stainless steel, three piece valve with threaded and socket weld ends and the two-piece F15 flanged end valve designs

Valve is unidirectional with vent holes in both the stem slot and the upstream face of the ball. This prevents the cold liquids from becoming trapped in the valve

"Qigao Valve" expects to continuously improve service quality and strive for excellence. "Sincere service" is the eternal theme of "Qigao". "Qigao" strictly followsIS09001-2000 Quality system certification requirements, strict quality control, responsibility to people, to ensure the healthy operation of production, sales and service. Strengthen communication with users and provide quality products to our customers with perfection and perfect service. Hereby our factory makes the following commitments:

3、If the type and model of the valve are determined by the customer, the customer shall correctly state the meaning and requirements of the model and sign the contract under the condition that the supplier and the buyer understand each other.

4、For futures and order customers, please call us in advance to tell the required valve model, specification, quantity, delivery time and location, and timely transfer to the factory account according to the total 30% deposit or full payment. The rest of the payment is pending. Import before shipment to arrange delivery in time.

Forecasts by Type (Globe Valve, Gate Valve, Ball Valve, Diaphragm Valve, Butterfly Valve, Other), by Application (Tanks & Cold Boxes, Liquefiers. Transfer Lines, Manifolds & Gas Trains, Other), by Media (Air & Gas, Oil, Chemical Products, Water, Fuel, Other), by Operation (Manual, Pneumatic, Electric, Hydraulic, Automatic, Other), by Gas Type (LNG, Oxygen, Hydrogen, Helium, Other) AND Regional and Leading National Market Analysis PLUS Analysis of Leading Cryogenic Valve Companies AND COVID-19 Recovery Scenarios.

New York, July 12, 2021 (GLOBE NEWSWIRE) -- Reportlinker.com announces the release of the report "Cryogenic Valve Market Report 2021-2031" - https://www.reportlinker.com/p06104617/?utm_source=GNW

The Cryogenic Valve Market Report 2021-2031: This report will prove invaluable to leading firms striving for new revenue pockets if they wish to better understand the industry and its underlying dynamics. It will be useful for companies that would like to expand into different industries or to expand their existing operations in a new region.

Because of the coronavirus’s rapid spread, the healthcare and pharmaceutical industries are at the forefront of the battle against COVID-19. The development of all vital medical devices needed to cure COVID patients is increasing. Industrial valves are used in the production of a variety of medical devices, which has enabled many main valve manufacturers to expand their businesses while also fighting the deadly coronavirus. For example, Emerson, a well-known player in the ball valves industry, has benefited from the situation. Emerson valves can handle pressure relief while still keeping steriliser equipment and materials clean.

There are also new designs and metallurgies to properly handle extreme service applications, as well as using the latest electronic technology to include valve diagnostics and wireless communications. Increased development of automated control systems, diagnostics, and tie-ins to digital control systems (DCS) for valves to improve plant operating safety and performance while lowering operating costs are among the product and technology developments

. How will the industry evolve during the period between 2019 and 2031?What are the implication of cryogenic valve projects taking place now and over the next 10 years?

This report tells you TODAY how the cryogenic valve market will develop in the next 10 years, and in-line with the variations in COVID-19 economic recession and bounce. This market is more critical now than at any point over the last 10 years.

. Discover qualitative analyses (including market dynamics, drivers, opportunities, restraints and challenges), cost structure, impact of rising cryogenic valve prices and recent developments.

The report also includes profiles and for some of the leading companies in the Cryogenic Valve Market, 2021 to 2031, with a focus on this segment of these companies’ operations.

Overall world revenue for Cryogenic Valve Market, 2021 to 2031 in terms of value the market will surpass US$xx million in 2021, our work calculates. We predict strong revenue growth through to 2031. Our work identifies which organizations hold the greatest potential. Discover their capabilities, progress, and commercial prospects, helping you stay ahead.

. Revenue forecasts to 2031 for Cryogenic Valve Market, 2021 to 2031 Market, with forecasts for grade, recycle type, product type, end-user each forecasted at a global and regional level- discover the industry’s prospects, finding the most lucrative places for investments and revenues

. Revenue forecasts to 2031 for 4 regional and 20 key national markets - See forecasts for the Cryogenic Valve Market, 2021 to 2031 market in North America, Europe, Asia-Pacific and LAMEA. Also forecasted is the market in the US, Canada, Mexico, Brazil, Germany, France, UK, Italy, China, India, Japan, and Australia among other prominent economies.

. Prospects for established firms and those seeking to enter the market- including company profiles for 20 of the major companies involved in the Cryogenic Valve Market, 2021 to 2031 Market.

We bring to our clients a range of cryogenic valves that are used in various industrial and cryogenic applications. Designed in conformation with international standards, these valves are efficiently be operated in different pressure and temperature conditions. These valves are dimensionally accurate, rust & corrosion resistant and finds usage in power industries, fertilizer industries, refineries and petrochemical & chemical industries.

CRYOGAS offers cryogenic globe valves with fire safety with has stainless steel body and top work. Globe valve apply for air gases, vapours and cryogenic liquefied gases like oxygen, nitrogen, argon, carbon dioxide and LNG processing applications. The working temperature maintain -196°C upto +120°C and available pressure range DN to DN 200.

Pneumatically actuated globe valves are manufactured in stainless steel and bronze, which can be equipped with additional hand wheel, with which the valve can be opened and closed manually in case of temperature pressure loss. In addition, with seawater-resistant materials are available from that type of valves, which are suitable for offshore use.

Pneumatically actuated globe valves with fire safety are manufactured in stainless steel and bronze, which can be equipped with additional hand wheel, with which the valve can be opened and closed manually in case of temperature pressure loss. In addition, with seawater-resistant materials are available from that type of valves, which are suitable for offshore use.

Cryogenic globe valves are available in wide range of material combinations and connections. They are equipped with additional functions like increase tightness requirements during seals or non-return function. Cryogenic globe valves are available in different size and secure pressure up to 50 bar and operating temperatures of -255°C to +120°C.

Cryogenic gate valves, having stainless steel and its flow rate is three to five times higher than with globe valves of comparable size. This speeds up the filling of cryogenic tanks and trailers and saves valuable time for the delivery of cryogenic liquefied gases.

The cryogenic gate valves are available in size from DN25 to DN100 and secure pressures up to 50 bar, at operating temperatures range of 196°C (-321°F) to + 120°C (+248°F).

CRYOGAS cryogenic ball valves have a larger flow diameter than comparable shut-off valves, which provides faster opening and closing times and are suitable for cryogenic and LNG tank applications, as well as for cryogenic pumps, pipelines and pressure regulation trailers.

Cryogenic ball valves are manufactured in stainless steel which are available in sizes from DN8 to DN100 and secure pressure range up to 50 bar, at operating temperatures of - 200°C (-328°F) to + 200°C (+392°F).

A check valve is manufactured in stainless steel and bronze by HEROSE. The check valves are used to secure against undesired return flows in pipelines, as it allows the flow of gases and liquids only in one direction. In the cryogenic area specially designed check valves are required, which are up to the requirements of temperatures well below freezing point.

A combination of individual HEROSE valves with different functions will be pre-assembled at the factory to form a system. This reduces the joining and welding work on site and saves time and costs for installation on vacuum insulated vessels. Cryogenic fill cluster are available in sizes DN25 and DN40 and secure pressures up to 50 bar, at operating temperatures of -196°C to +120°C. The cryogenic fill clusters are manufactured in stainless steel and bronze.

We are affianced in offeringGlobe Valves,control valves, check valves and fills systems for cryogenic services. These products and our service are highly appreciated by our clients due to their reliability, effectiveness and promptness.

Cryogenic Valve is a valve which opens automatically to prevent a predetermined gauge pressure being exceeded and which encloses after a decrease in pressure.

With our expertise in this domain, we are providing an extensive gamut of Gases Safety Valves.These are highly suitable for applications areas where capacity and high pressure is required. Our safety valves are designed by our expert designers to ensure that these meet the needs & demands of the esteemed patrons.

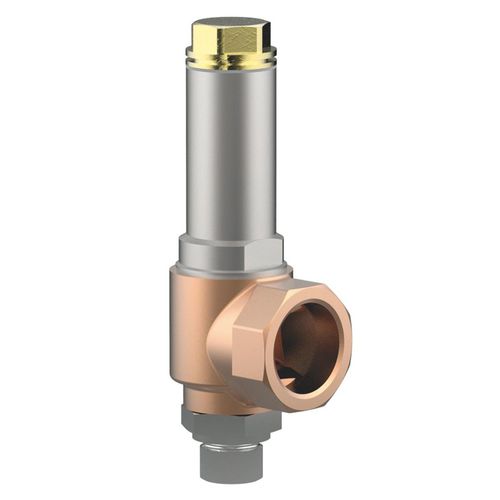

Pressure relief cryogenic valves are technically designed to provide safety from over pressure in vapours, gases, fluids, water, refrigerants, steam and liquid lines. The operating temperature should be -50°C to +225°C in deciding pressure range 0.2 to 30 bar.

We are engaged in renderingCryogenic Safety Valvesto the clients. These services are executed by our professionals who are experts in their field. Our services are rendered in accordance with both the industrial as well as international norms & standards of quality. Further our services are renowned for their reliability, effectiveness and timely execution.

Cryogas manufacture ball valves for lng and cryogenic and industrial gas storage applications, with having fire safety and stainless steel lockable handle in body and topwork, with pneumatic actuator, clean and degreased for Oxygen Service. Fire safe ball valves are available in sizes from DN8 to DN100 and secure pressure range up to 50 bar, at operating temperatures of - 200°C (-328°F) to + 200°C (+392°F).

Our organisation is engaged in providingDrain Valves,Three-Way Valves & Gate Valves For Oil-Cooled Transformers. These are manufactured using the premium quality material, which is sourced from the most trusted vendors of the market. Our products are tested by the quality controllers to ensure their flawlessness and compliance with the international standards of quality.

Leveraging on the proficiency of our professionals, we are engaged in manufacturing a wide array of Transformers Valves. These are manufactured using the superior quality material, owing to which are highly effective and highly demanded among our clients. Our products are available at market leading prices along with customization options as per the demands of our patrons.

Filtration of the medium ensures compliance with the specified level of purity for downstream processes. For this various screens and filters with different mesh sizes are available. Cryogenic strainers are available in sizes from DN10 to DN200 and secure pressures up to 50 bar, at operating temperatures of -196°C to +120°C. The strainers are manufactured in stainless steel and bronze.

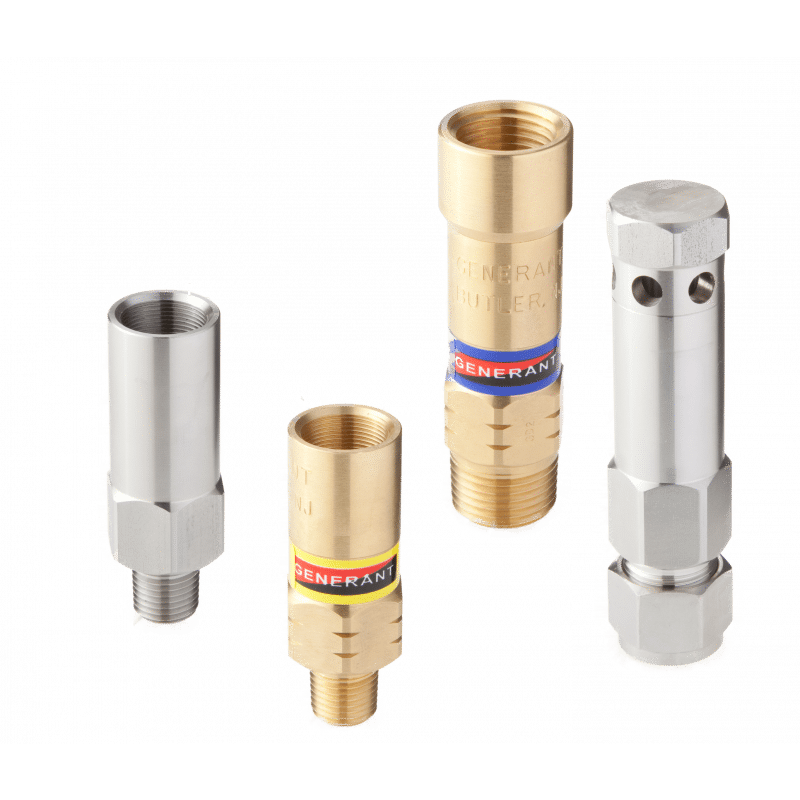

Cryogenic safety valves are manufactured primarily not only from stainless steel but also in brass and bronze. Safety valves are available in sizes from DN6 to DN50 and secure pressures up to 0.2 to 50 bar, at operating temperatures of -270°C to +225°C.

We offer a wide range ofCryogenic Regulator.Cryogenic Regulator provides high flow during Cryogenic Vessel Pressure Build function and increased sensitivity to downstream

8613371530291

8613371530291