dead weight safety valve pricelist

Level and Flow Control Engineers manufacturing and exporting Dead Weight Safety Valves which is mainly used in the Power Plants, CPP, Sugar Plants for Low Pressure applications. Brand Name : Beekay-Made in INDIa

If you rate our Dead Weight Safety Valve on attributes such as ergonomics and operational efficiency, you will find it right there at the top of the class. We have used only the highest quality materials and components in manufacturing our Valve assembly, which exhibits in the performance. No denying, we are among the leading manufacturers, exporters and suppliers from Chennai, Tamil Nadu.

With the strong assistance of our professionals, we are able to manufacture and supply an extensive array of Pressure Safety Valve. This is efficiently manufactured with the help of progressive methodology using the high quality material. This is commonly used terms to identify pressure relief devices on a vessel. It has applications in boiler, pressure vessel, or other system. It is widely demanded in distinct industries such as food, pharmaceuticals, cosmetics and chemicals. Moreover, our valuable clients can avail this product from us in varied specifications at highly reasonable prices.

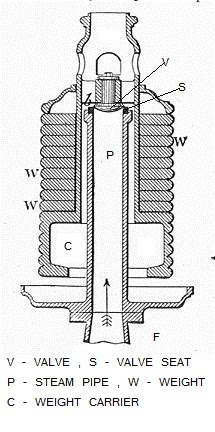

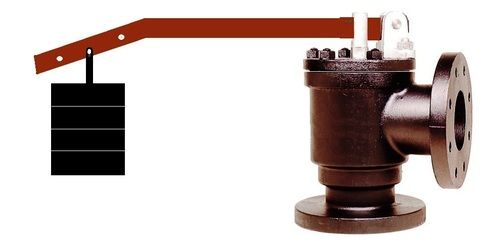

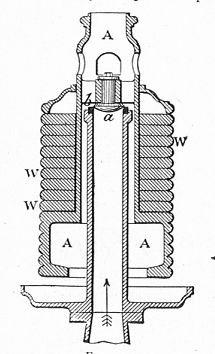

afety valve consists of a valve seat where the pressure in the boiler or pressure vessel when it exceeds the normal working pressure lifts the valve seat with its weight. The excess pressure fluid therefore escapes through the pipe to the atmosphere, until the pressure reaches its normal value. It is the simplest type of safety valve; it is suitable for stationary boilers and pressure vessels only, because it cannot withstand the jerks and vibration of mobile boilers or pressure vessels. Another disadvantage of this valve is the heavy weight required to balance the pressure. Hence, it is not suitable for high pressure boilers.

safety valves, Safety Relief Valve, Industrial Safety Relief Valve, Safety Relief Valve Dealers, Safety Relief Valve Distributors, Safety Relief Valve Exporters, Safety Relief Valve Suppliers, Safety Relief Valve Manufacturers in india, Safety Relief Valve Price in India

safety valve, safety relief valve, pressure relief valves, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve

safety valve, safety relief valve, pressure relief valve, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions

We provide superior quality valves, industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves that are specially designed to offer high durability and optimum performance. Using materials like pure aluminum, cast iron and stainless steel trim these valves are made to high resistance to temperature and corrosion. Functionally different valves like Safety Valve, Safety Relief Valve, Pressure Reducing Valves, Breather Valves, Globe & Ball Valves, Pipeline Specialty Valves, Flush Bottom Valves and Float Valves are available with us.

Fluidyne carried out an extensive market research to manufature durable and effective safety relief valves, industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves that are highly suitable for most chemical, petrochemical, oil, pharmaceutical, phartilizer, power industries and more. These industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves have high reliability and are approved by factory inspectors, inspectors under Indian Boiler Regulation (IBR), B.V., Lloyds and Chief Controller of Explosives. Citizen Metal safety and relief valves are in used in above industries for over 50 years.Flanged Safety Relief Valves

Our range of small bore safety valves, industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves offer superior performance and maximum functionality. They are available in Screwed, Socket weld, Flanged Construction type or flanged-inlet, Screwed-outlet connection type. Their simplicity in construction makes them pretty cost effective and easy to use.

For Storage Tank, complete range of sizes :- 15 NB to 600 NB Flame and Detonation Arresters, Spark Arresters Free-Emergency-Conservation Vents Dip Gauges and Gauge HatchsVent nuts/Caps, Syphon bush, Fill caps, Lightning Arresters etc. Tyrus Valve, Vacuum Relief, Pressure Relief Valves. Available in : CS, CI, SS304, 316, AI etc. For more details on Tank Fittings, Flame / Spark Aresstors plz refer our section on "Safety Fittings"

Model PV - 1230 is one of our specially designed range of relief valves that has got connection flanged pallets of Al or Stainless Steel. This model comes with a tank accessory that is suitable for storage of chemicals and hydrocarbons. Model Pv 1230 is most suitable for low pressure and low vacuum operations.

Designed mostly like model PV 1220 our PV - 1240 range of vauts also offer high performance & durability. These efficient valves are commonly suitable for vacuum service. The disc available with these vaults is either weight loaded or spring loaded.

Safety Valves are designed and manufactured to meet the requirement of all a variety of applications as per API 526 and API 520. They also conforms to Standard VIII and the design requirement of Indian Boiler Regulations, they are of Full Lift type direct spring loaded, with a top guide, The full nozzle has the eliminating distortion of the seating surface, as body strain is not transmitted The Nozzle is made from a corrosion resistance stainless Steel material, When closed position, the fluid does not come in contact with the valve Body an therefore only subject to the outlet pressure which is very much lower pressure.

Similar to FTVC-520, but with closed bonnet & closed cap. Also available with same sizes and rating as FTVC - 520.Close Bonnet Safety Valve For Steam Application

Full lift safety relief valve, offers the combination of top guiding and unobstructed seat bore, producing a valve with maximum discharge capacity. Supplied with certificate confirming set lift pressure.

Tag : safety valves, Safety Relief Valve, Industrial Safety Relief Valve, Safety Relief Valve Dealers, Safety Relief Valve Distributors, Safety Relief Valve Exporters, Safety Relief Valve Suppliers, Safety Relief Valve Manufacturers in india, Safety Relief Valve Price in India, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions

Safety Relief Valves, Stainless Steel Forged Steel 304 Valve, Stainless Steel F321 Safety Relief Valves, F347 Safety Relief Valves, SS High Pressure Safety Relief Valves, Class 150, 300, 600, 900, 1/2 inch stainless steel Safety Relief Valves, 1/2" stainless steel Safety Relief Valves, 3/4 Size Safety Relief Valves, 4 inch stainless steel Safety Relief Valves, Industrial Safety Relief Valves, Stainless Steel 316 Safety Relief Valves Suppliers in India...Read more

Alloy Steel Safety Relief Valves, Chrome Moly Alloy A217 / SA217 Cast Valves, WC9 Alloy Steel Globe Valve, 4 Inch, 2500#, A350 LF3, A352 LC3, A182 F5A/F5, A217 C5, A182 F9, A217 C12, A182 F11, A217 WC6, A182 F22, A217 WC9, A182 F91, A217 C12A, 10 Inch, RF, WC9 Gate Valve, PSB, 12 Inch, 2500 LB, Alloy Steel Valves Dealers & Distributors in India.. Read more

Safety Relief Valves, Carbon Steel Safety Relief Valves, Carbon Steel Valve Material, ASTM A350 LF2 Safety Relief Valves, Carbon Steel ASTM A106 Safety Relief Valves, ASME B 16.10, ASME B 16.5, ASME B 16.25, ASME B 16.34 ASTM A105N Safety Relief Valves, Cast Carbon Steel Safety Relief Valves, API 600 Cast Steel Safety Relief Valves, Forged Carbon Steel Safety Relief Valves Exporters & Suppliers In India.. Read more

Hastelloy Safety Relief Valves, Hastelloy C276 Safety Relief Valves, Hastelloy C22 Safety Relief Valves, Hastelloy B2 Safety Relief Valves, Hastelloy C276/C22 Valves, ASTM B 435 Hastelloy X Safety Relief Valves, Hastelloy B2 Safety Relief Valves, ASME B16.34 Safety Relief Valves, UNS N10665 Hastelloy B2 Safety Relief Valves, UNS N10276 Hastelloy C276/C22 Manufacturer / Suppliers in Mumbai India. Read more

Wholesale Various High Quality Industrial Safety Relief Valves Products from Citizen Metals, Largest Suppliers of Alloy 20 Safety Relief Valves, Alloy 20 Safety Relief Valves Dealers, Alloy 20 Check Valve, UNS N08020 Alloy 20 Safety Relief Valves, Alloy 20 Safety Relief Valves Suppliers, Alloy 20 Safety Relief Valves Manufacturer, Alloy 20 Safety Relief Valves Manufacturers in India. Read more

We supply broad range of Nickel 200/201 Safety Relief Valves, Leading Suppliers of Nickel 200/201 Valves, Ni-200 Safety Relief Valves, Ni-201 Safety Relief Valves, Uns N02200 Safety Relief Valves, Uns N02201 Safety Relief Valves, Nickel 200/201 Safety Relief Valves Dealers, Safety Relief Valves Suppliers, Nickel 200/201 Safety Relief Valves Manufacturer, Nickel 200/201 Safety Relief Valves Manufacturers in India. Read more

we supply Monel 400 Valves with high quality and best affordable rate., Monel 400 Safety Relief Valves, Monel DIN 2.4360, 2.4375 Safety Relief Valves, Monel UNS N04400 Safety Relief Valves, Monel UNS N05500 Safety Relief Valves, Monel Safety Relief Valves, Monel K500 Safety Relief Valves, Monel 400 Safety Relief Valves Distributors in India... Read more

We specialize in the oil & gas industries and offer specialty Duplex Steel Safety Relief Valves, UNS S31803 Safety Relief Valves Suppliers in India, DIN 1.4410 Super Duplex Steel Safety Relief Valves, ASME B 16.10 UNS S32760 Safety Relief Valves, ASTM A351 Duplex Steel UNS S31803, ASME SA494 Duplex Steel UNS S31803, Duplex Steel UNS S31803 Class 900 Safety Relief Valves Exporters in India. Read more

Safety Relief Valves, 254 Smo Safety Relief Valves, Cryogenic 254 SMO gate valve, ASME B16.34 SS 254 SMO Safety Relief Valves, Stainless Steel 254 SMO Safety Relief Valves, ASTM A351 SS SMO 254 Safety Relief Valves, ASME B 16.10, ASME B 16.5, ASME B 16.25, ASME B 16.34, 254 SMO Industrial Valves, Stainless Steel 254SMO Safety Relief Valves Suppliers in India.. Read more

Safety Relief Valves, 904l Stainless Steel Safety Relief Valves, 904l Stainless Steel Industrial Safety Relief Valves, SS 904L ASTM A351 Safety Relief Valves, ASME B 16.10 Safety Relief Valves, ASME B 16.5, ASME B 16.25, ASME B 16.34, UNS N08904, 1.4539, BS 904S13, JIS SUS 890L Safety Relief Valves

Safety Relief Valves, Inconel Safety Relief Valves, Inconel 600 Safety Relief Valves, INCONEL WERKSTOFF NR. 2.4816 Safety Relief Valves, Inconel 600N06600 Safety Relief Valves, Inconel 2.4816 Safety Relief Valves, UNS N06600 Safety Relief Valves, Inconel 600 Safety Relief Valves, API 600/ BS1414, ALLOY 600 Safety Relief Valves, ASME B 16.5 Safety Relief Valves Dealers in India.. Read more

We are the one of the top most manufacturers of different types of Industrial Safety Relief Valves, We have a large inventory of Safety Relief Valves in a variety of options., Largest Suppliers of Titanium Gr2(B367 Gr C2) Safety Relief Valves, Titanium Gr3(B367 Gr C3) Safety Relief Valves, Titanium TA1, TA2, Titanium Gr.5, Gr6 Safety Relief Valves,Gr7 ,Gr12, Titanium TC4,TA9,TA10 Dealers in India.. Read more

Brass Safety Relief Valves, brass Safety Relief Valves price list in India, brass Safety Relief Valves 1/2, 1 inch brass Safety Relief Valves, brass Safety Relief Valves 3/4, brass Safety Relief Valves price list india, 3 inch brass check valve, brass Safety Relief Valves price list, 1/2 inch Safety Relief Valves, 4 brass Safety Relief Valves, 3/4 brass Safety Relief Valves, 4 inch brass Safety Relief Valves, 2 inch brass Safety Relief Valves Read more

Experience Of 50 Years In Copper Knife Gate Valve, We have a large inventory of Copper Safety Relief Valves, Copper 90/10 Safety Relief Valves, Copper 70/30 Safety Relief Valves, Copper Cu-Ni 70/30 Safety Relief Valves, Copper 90/10 Safety Relief Valves Dealers, Copper 70/30 Safety Relief Valves Suppliers, Copper Cu-Ni 70/30 Safety Relief Valves Manufacturer, Copper Cu-Ni 90/10 Safety Relief Valves Manufacturers in India. Read more

Tags : safety valve, safety relief valve, pressure relief valve, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch Dealers, Distributors, Exporters, Suppliers india, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions,

Tags : safety valve, safety relief valve, pressure relief valve, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions

In 2023, the sales of Pressure Relief Valve in Global Market is expected to reach US$ 4,509.8 Mn. and is projected to expand steadily at a CAGR of 4.6% to reach a market valuation of close to US$ 7,070.9 Mn by 2033.

In recent past valve costs have increased globally, which can be attributed to growing tariffs from the North American region, particularly the US. Leading players from the European and American regions have facilities in both high- and low-income nations. In contrast, labor-intensive production processes like the creation of rough castings for valves and valve components take occur in low-cost manufacturing nations like China. These processes include design, research and development, and testing. Due to low prices and quality maintenance, OEMs are able to do so. However, growing US government tariffs on steel and aluminum imports from China have had a substantial negative influence on pressure relief valve profit margins and costs.

However, the rapid growing industrialization and increasing safety precaution are the factors that are expected to fuel the market growth of Pressure relief valves across the globe during the assessment period, the Pressure relief valve market is expected to experience demand growth with CAGR of 4.6% during the forecasted period.

From 2017 to 2022, the Global Pressure Relief Valve Market expanded at a CAGR of around 2.4%. The advancement in product technology to connect the valves digitally enables end users to monitor pressure in various applications digitally which has generated significant demand from the various industry sector during the forecasted period.

Numerous applications where pressure levels are crucial for continuous and efficient machinery performance demand for the utilization of pressure relief valves. These include the various sectors operating with steam, air, gas, or liquid such as oil and gas, power generation and the petrochemicals industry. Multiphase applications and chemical processing systems both have high installation rate of pressure relief valves. With rapid development industrial sector & expansion of oil & Gas pipelines across the developing as well as developed economies the demand for PRV is also expected to expand, Persistence Market Research expects the market to expand at a 4.6% CAGR through 2033.

Both emerging and advanced regions have seen a surge in oil and gas consumption. In order to meet the rising demand and supply for oil and gas, industries are concentrating on expanding their production facilities through onshore and offshore exploration. Since the oil and gas sector is one of the key end uses for the global pressure relief valves market thus expanding oil & gas Sector is generating lucrative opportunity for the demand growth of PRVs in upcoming period.

Furthermore, growing regulation for use of pressure relief valves in power generation sector is further set to create opportunities for the market. For instance, there are currently about 50 nuclear reactors under development. By safeguarding turbines, super heaters, and boilers to enable the stations to operate at prescribed pressures, pressure relief valves play a crucial part in the successful and safe operations of nuclear facilities.

Manufacturing businesses will be significantly and directly impacted by the Asia Pacific region"s volatile and uncertain markets. The operational costs of the manufacturing processes, which are the main concern of manufacturers, will be directly impacted by rising tariffs and raw material costs used to manufacture valves. Rising raw material costs immediately impact the integrity of the supply chain and the selling price of a product. Manufacturers in the Asia Pacific region are becoming increasingly concerned about the steady growth in cost of the raw materials used to make pressure relief valves. This is expected to, restrain the market"s expansion for pressure relief valves.

With an absolute dollar opportunity of around US$ 600.0 Mn, North America is expected to be the most lucrative market for pressure relief valves suppliers. U.S is leading the North American market, and is expected to witness a 1.5X growth during 2023-2033. The market for pressure relief valves has recently experienced considerable growth in sales as a result of growing industrialisation and advancements in urban waste water management systems. Apart from that U.S. is also second largest importer & Exporter of Pressure relief valves, which makes it a targeting region for the manufacturers & Suppliers.

In 2023, the German Pressure Relief Valve market is likely to hold around 25% of the market by value share in Europe. Germany"s extensive remanufacturing capabilities are likely to play a crucial part in development of industrial growth. Sales growth for pressure relief valves is anticipated to be boosted in the upcoming years as manufacturers are planning to invest more in safety & developments of industrial Sites.

With a CAGR of 5.9%, India is expected to lead the South Asian market throughout the assessment period and experience significant expansion. Pressure relief valve demand is anticipated to increase as a result of India"s low production and labour costs, as well as less regulations & certifications required for PRVs, which are encouraging various industry players, including oil & gas, pharmaceutical, chemical, and textile manufacturers, to expand their manufacturing facilities in India.

By the end of the assessment period, spring-loaded pressure relief valves will hold a value share of over 40% of the market for pressure relief valves worldwide. Due to its broad range of applications and other technological advantages over other valves, this valve is widely utilized. The design and use of pressure relief valves is covered by a number of international codes and standards, the most popular of which being the ASME (American organization for mechanical engineers) Boiler and Pressure Vessel Code, also known as ASME code. Despite the fact that this code varies by region.

In 2023, the demand for pressure relief valves is primarily driven by the Medium Pressure segment in Set Pressure segment of the market. By the end of the forecast period, it is projected that pressure relief valves with a medium pressure range will still be widely utilized in a variety of end use sectors. The market for medium pressure relief valves is expected to continue expanding due to rising end-use sectors including oil and gas, chemical, and others.

C) Manual override handles available to open the valve without changing the set pressure Hikelok provided 316,304,316L and 304L/A182 body materials RV4 series Low pressure relief valve. Manual override handles available to open the valve without changing the set pressure. Hikelok is designed and precisely manufactured to intermix and interchange major global brands .

Providing you the best range of screwed safety valve, air compressor safety valve, spring loaded valves, safety relief valve, air release valves and dead weight safety valves with effective & timely delivery.

UsageIndustrialWe are a leading manufacturer of high quality valves serving the compressed air pressure washer automotive fluid power fire protection specialty gas and pneumatic industries

Country of OriginMade in IndiaIn a direct spring loaded safety valve the closing force or spring force is applied by a helical spring which is compressed by an adjusting screw The spring force is transferred via the spindle onto the disc The disc seals against the nozzle as long as the spring force is larger than the force created by the pressure at the inlet of the valve The figure shows the enlarged nozzle and disc area of a safety valve with the forces acting on the disc

UsageIndustrialWe are a market-leading firm engaged in Manufacturing, Supplying and Exporting premium quality Safety Relief Valve. We manufacture these valves using excellent quality raw material procured from certified and authentic vendor-base. Our vast infrastructure and professional experts enabled us to produce these qualitative valves on a very large scale to meet the high demands country-wide. We also provide customization facilities to our customers as per their requirements and demands

UsageIndustrialWe are the leading manufacturers and suppliers of Air Release Valves,which are produced from a very high quality raw materials sourced from the most renowned vendors of the industry. The product is available to the clients at reasonable prices. It is composed of cast iron and cast steel. They can automatically release accumulated air and gases from the fluid system while the system is working.

UsageIndustrialWe are the manufacturer, and exporter of Dead Weight Safety Valves from Chennai-India to Globally are spring loaded right angled which are used in the pressure vessels, pipelines and reactors to control the excess pressures

UsageIndustrialWe have carved a niche as one of the majorSafety Valve Manufacturer in India. Our Boiler Safety Valves are precisely designed to control excess pressure in various equipments like pipelines, pressure vessels and reactors. Automatic opening as well as closing of our safety valves assures complete protection of the equipments. Today, our company is well reckoned as one of the leading Safety Valves Exporters.

InternalsSS-410 / SS-304 /SS-316 / BrassOur company is engaged in the manufacturing of Safety Valves, which guarantee to reduce the over pressure in steam,gas or liquid. Available in different sizes, these products can be availed from us at a very reasonable price. We also have a expert team, which deals with the customization of products according to the needs of our clients.

TheAustralia Pressure Safety Valve Marketsize was valued at $52.12 million in 2017 and is expected to reach $65.38 million by 2025, registering a CAGR of 2.88% from 2018 to 2025. Pressure safety valves, also known as pressure relief valves or simply relief valves, ensure safety of pressure-based systems.

Industrial valves comprise many products that manage the flow of gases and fluids in industrial applications. Among these, pressure safety valves are designed for process control, process safety, original equipment manufacturer (OEM) applications, and others across several end-user industries. These valves prevent the over-pressurization of pressure-based equipment and machineries by sensing and subsequently guiding the additional surge in pressure towards alternate passages or into atmosphere. As a result, they are used in steam boilers, heating boilers, pressure-based vessels and systems, OEM applications, industrial machineries, and other applications. The valve design and construction are varied to have a manual or automatically-operated opening and closing of valves at working settings during the system operation.

Industrial spending towards increasing the manufacturing and production capabilities of Australian end-user industries has a profound influence over the growth of pressure safety valve market over the forecast period. To cater to the increase in demand to improve plant efficiency, equipment and machinery are constantly operated around maximum capabilities. As a result, to ensure the workplace safety and prevent over-pressurization of pressure systems, constant observation and supervision of pressure safety valves are mandatory to reduce the additional pressure developed during operation. This drives the demand for safety valves and their components across many end-user industries. Moreover, the Australian governments initiatives towards extensive offshore exploration of Australian waters to determine the potential availability of natural gas and petroleum reserves are also anticipated to boost the demand for safety valves in the oil & gas sector. However, the increasing technical and manufacturing capabilities of emerging economies in the Asian region are expected to hinder the growth of certain end-user industries, such as chemicals, textile, paper & pulp, commercial construction, and others. Whereas, achieving competitive prices in niche segments, such as OEMs and industry sectors, is anticipated to provide profitable opportunities for the Australian pressure safety valve market players.

The safety valve market provides safety valves and their components for subsequent maintenance, services, and repairs. As a result, on the basis of offering, the market is bifurcated into safety valve and safety valve component. Further, the safety valve types are spring loaded valves, pilot operated valves, and dead weight valves. Safety valves have numerous applications across different industry verticals. For instance, safety valves find significant application in chemicals dosing, water treatment, mid-stream, up-stream, down-stream, chemicals processing, construction, food processing, industrial waste treatment, and others. Safety valves are used in various end-user industries, such as oil & gas, power & energy, healthcare & pharmaceutical, water supply system, and others.

As depicted in the figure above, the safety valve market constitutes a significant market share among the offerings. However, the safety valve component market is expected to witness attractive growth rates in the forecast period. Factors, such as new plant installations, sophisticated machinery, and expansion of production capacity, are major driving factors for the safety valve segment. In addition, the continuous maintenance, services, and repairs-related activities continue to provide a steady stream of revenue for safety valve manufacturers. Thus, the Australian pressure safety valve market is anticipated to witness a moderate growth rate in the coming years.

The application of safety valves in mid-stream, up-stream, and down-stream applications in the oil & gas industry has resulted in significant installation of safety valves. Further, the wide distribution network of the oil & gas industry requires constant maintenance and services of its safety valves. As a result, the oil & gas industry accounted for a significant market share in the safety valve market shown below. Further, the increasing demand for water supply systems for non-residential and residential applications is anticipated to provide lucrative business opportunities for the market players resulting in a high growth rate during the forecast period.

The report details a competitive analysis and profiles of the major players, such as Emerson Electric Co., Spirax Sarco Pty. Limited., Cebeco, Score Pacific PLC, Callidus Group, LESER, Powerflo Solutions, Mercer Valve Co., Inc., Western Process Controls, and Bourke Valves, in the Australian pressure safety valve market. Acquisition and partnerships are the key strategies adopted by the major players to retain their standing in the market.

Key BenefitsThe report provides an extensive analysis of the current and emerging trends and dynamics in the global Australian pressure safety valve market.

The key market players are profiled, and their strategies are analyzed thoroughly to understand the competitive outlook of the Australia pressure safety valve market.

With wide and rich industrial experience, we are able to offer the best in class Dead Weight Safety Valves. These valves are used in industrial boilers for safety purpose and ensure safety by releasing excess pressure. Provided valve is highly recognized for high performance, requires less maintenance and smooth operations. Our offered safety valve is made available in number of specifications for our clients to choose from. Our valued clients can avail these Dead Weight Safety Valves from us at market leading price.

At almost every show I attend, I ask a few engine owners and operators if they are satisfied with their new-style safety valves. It would be only a small exaggeration to say that I get just two responses. “I have been using a new-style valve for 15 years and I haven’t had any trouble with it” or “They are junk!” I have cleaned up the second response to spare the reader the unpleasant expletives.

As the result of these conversations, I have attempted to understand why there is such a discrepancy between the reactions to modern safety valves. It now appears that there are a few simple steps we can take when purchasing and installing these valves that might improve our satisfaction with the new-style valves, which are the only ones currently available.

To understand the issues involved in the selection of a safety valve, it is necessary to review the history of safety valves used on hand-fired boilers. I am referring to hand-fired boilers rather than historical boilers because the issues are determined by how the boilers are fired, not how they are constructed or how old they are. The requirements for a modern welded boiler made to the American Society of Mechanical Engineers (ASME) code are the same as for a 100-year-old riveted boiler, if both boilers are hand-fired. The requirements for a safety valve for a boiler that is automatically fired are dramatically different.

With automatic firing, the safety valve’s function as defined by Anderson Greenwood Crosby, a manufacturer of modern safety valves, is to protect life and property if all other safety measures fail. A safety valve on a hand-fired boiler, as defined by ASME almost a hundred years ago, is to give notice of the highest pressure permissible and to give alarm that more water or less fuel is needed. (The evolution of the purpose of the safety valve is summarized in “The Purpose of a Safety Valve,” at the end of this article.)

When hand-fired boilers, such as found on traction engines, steam cranes and locomotives disappeared, most of the boilers that remained were automatically fired. The safety valve manufacturers adapted their designs accordingly. The old-style valves with bottom guided, beveled seats were capable of withstanding vibration and operating near their setpoint, and were replaced by smaller top-guided valves with flat seats.

At the same time, steam system designs were adapted so there was no need to operate within 10 percent of the setpoint of the safety valve. Not all old-style valves had beveled seats, but the ones that didn’t were designed much differently from the modern flat-seated valves.

When I speak of a modern-style safety valve, I am referring to a valve shown in the second diagram of this article’s image gallery. An example of an old-style safety valve can also be seen in the image gallery. Changes in the design of safety valves had a dramatic effect on their capacity in pounds of steam per hour. If a boiler built in 1920 required a valve capable of releasing 1,000 pounds of steam per hour at a pressure of 100 pounds per square inch, it would have been equipped with a 2-inch safety valve. Today, 3/4-inch valves are available to release that much steam at that pressure.

The evolution of the safety valve did not end with the development of the modern, flat-seated valve. In the last 20 years, the design of safety valves has continued to evolve.

In 1985, a new-style 3/4-inch valve set at 150 pounds per square inch could have a capacity of 1,497 pounds of steam per hour. In 2002 this same valve could have a capacity of 1,651 pounds of steam per hour.

From 1914 until 1998, the blowdown allowed by the ASME boiler code was 2 to 4 percent of the setpoint. In 1998, this was changed to allow the blowdown to be as high as 6 percent. Beginning with the 2004 ASME code, there is no limit on blowdown. The code has not required that the amount of blowdown be stamped on a safety valve since 1986.

When I asked owners and operators how well they liked their new-style safety valves, I was not aware of the need to ask about the age of the valve. Instead, I would ask about the amount of blowdown. In almost every case, the people who were satisfied had valves that would blowdown 4 percent or less. It appears that this is almost the same as if I had asked the age of the valve. If the valve were purchased prior to 1998, it would have been set for 4 percent blowdown. If purchased after that date, unless specified otherwise, it would have been set for 6 percent. The change from 4 to 6 percent causes a 50 percent increase in the amount the pressure changes in a boiler each time the valve pops. The resulting increase in the flexing of the components of the boiler may be associated with a corresponding increase in seepage at stay bolts and tubes.

When you order a new safety valve, you will need to provide four pieces of information: the setpoint, the capacity in pounds of steam per hour, the blowdown and the requirement that the valve be stamped with the ASME “V” stamp. If you specify the pipe size, you may get a valve with far too much capacity, as I have already explained. To determine the capacity you need, do not use the capacity stamped on the old valve. First, if the valve has been replaced, it might not be the right capacity. Secondly, the capacity stamped on the valve is probably the capacity of the smallest valve available and might be significantly larger than the required capacity.

As I talked to many owners, they would offer other comments regarding their valves. One comment I heard from several owners who were satisfied with the new-style valves was that their valves were larger in pounds per hour than the minimum required by the ASME code. I am not certain as to exactly how the capacity affects the operation of the valve. What I do know is the larger the valve, the more force it takes to raise it off its seat. The force of the steam on the boiler-side of the valve cannot overcome the force of the spring in the safety valve until the pressure in the boiler rises to the setpoint of the valve.

When this happens, the valve pops open. It seems the larger diameter, and thus the greater forces, may result in more stable operation of the valve near its setpoint. There is a concern in the boiler code that safety valves should not be so large that water is drawn out of the boiler. It would seem, because of the relatively small size of portable and traction boilers, the pressure would drop so quickly that little water, if any, would be lost. I have seen boilers where the owners have installed modern safety valves of the same pipe size as the old style valves installed by the factory. The capacity of these valves was far greater than I believe anyone would recommend, but I am not aware that they caused water to be discharged from the boiler. It is important to be careful when sizing a safety valve. I suggest owners talk to each other and share their experiences before making such a decision.

If you would prefer to have a top-discharge safety valve, which looks more authentic, shop around. They are available in a few sizes. You might also want to consider specifying that the valve have a non-metallic seat.

When installing a safety valve, do not install any fitting smaller than the inlet to the valve and do not install any kind of valve between the safety valve and the boiler. Examples of what not to do can be seen in the image gallery. Do not use a pipe wrench on a safety valve, it can damage or destroy the valve.

Once you have carefully selected your safety valve and have installed it on your boiler, it is important to verify the setpoint and the blowdown have been set according to your specifications. The first step in this process is to have the accuracy of your steam gauge checked with a dead-weight gauge tester. If your gauge does not agree with the setpoint of your new safety valve do not assume that the gauge is wrong.

Do not use the lifting lever to lift the valve from its seat until the boiler pressure is up to 75 percent of the setpoint of the valve. If the valve is lifted from its seat at a lower pressure, any dirt or foreign material in the valve might not be blown clear of the seat and could damage the seats when the valve closes.

Because new-style safety valves are not designed to be operated within 10 percent of their setpoint, many owners have elected to install the new valve along with an old-style valve. In doing so, the old style valve operates in the range of 5 to 10 percent below the setpoint of the new valve. With this arrangement, the new valve satisfies the code requirements while the old-style valve performs the function for which it was designed. Two possible arrangements can be seen in the image gallery.

In response to complaints from owners of historical boilers who had recently purchased new safety valves, Dean Jagger, Ohio’s chief boiler inspector, requested that the National Board test valves from the manufacturer to determine if the valves complied with the requirements of the ASME boiler code. As a result of these tests the Ohio Department of Commerce issued a safety notice:

“The State of Ohio Boiler Division has been made aware of the fact that some recently purchased Kunkle safety valves, which were assembled by Allied Industries, have been tested by the National Board Testing Laboratory and found not to be in compliance. The tests indicated that the valves blowdown and setpoint pressure settings were out of tolerance as established by Section I of the ASME Boiler Code.”

This may be an indication that all of the problems with modern safety valves are not entirely the result of design issues, but insufficient oversight of manufacturing and quality control processes may also be a factor. A new valve may be “junk” as has been so often alleged.

The errors found by the National Board Laboratories were significant. One of the valves was stamped 165 psi but popped low at 148.8 psi. Another was stamped 150 psi and popped high at 164.5 psi. On the other three valves the pop was consistent with the setting stamped on the valve. The 2001 edition of the ASME Boiler Code specifies that for pressures from 70 to 300 psi the tolerance, plus or minus from the set pressure, shall not exceed 3 percent of the set pressure. The 165 psi valve popped 9.6 percent below the set pressure stamped on the valve, and the 150 psi valve popped 9.7 percent above the set pressure stamped on the valve.

The blowdowns on all of the valves that were tested were out of tolerance. The 2001 edition of the ASME Boiler Code specifies that for pressures from 67 to 250 psi the blowdown shall not be greater than 6 percent of the set pressure. With such a wide range of variations in both setpoint and blowdown, in a sample of just five valves, it seems reasonable to suspect that even greater variations may exist. The results of the tests are shown in the image gallery.

Complaints about quality problems are not limited to the five valves recently tested by the National Board; for example, an engine owner told me of purchasing a new 1-1/4-inch valve stamped 175 psi. When installed on a traction engine, the valve consistently popped at 185 psi and blew down 15 psi. (A pressure of 11.1 psi equals the allowed 6 percent.) The manufacturer told the owner that the valve had been tested properly prior to shipment but accepted it back. The owner had verified the accuracy of the pressure gauge prior to contacting the manufacturer.

The ASME and National Board procedures for safety valves merely confirm the adequacy of the design of the valve and do not assure the adequacy of production and quality control practices. Each boiler owner and operator must carefully confirm the accuracy of the setpoint and blowdown on every safety valve and not rely on the ASME and National Board stamps as assurances of quality. At this time, I have no reason to believe the monitoring of the ASME and National Board requirements at other valve manufacturers and assemblers is any different than what existed at Kunkle and Allied.

One scenario that concerns me is the owner who installs a new safety valve on his boiler and, seeing that the pop does not coincide with the reading on his 80- or 100-year-old gauge, decides that obviously his gauge must be wrong. This is a conclusion I am sure I would have considered when I first began my study of safety valves.

Incorrect settings of safety valves are more likely to be detected when the valves are used on hand-fired boilers than when used on modern boilers. If the controls on a modern boiler are to limit the pressure to 10 percent or more below the setpoint of the safety valve, the valve can be set as much as 10 percent below its rating and the error might not be apparent. Errors above the setpoint also wouldn’t be obvious even if the boiler were operated up to the setpoint stamped on the valve. Also, incorrect setting of the blowdown would not be apparent until the valve had operated.

1909: “The function of the safety valve is two fold: (A) it gives notice of the highest pressure permissible; (B) it gives alarm that more water or less fuel is needed.”

Today: “A PRV (pressure relief valve) is a safety device intended to protect life and property if all other safety measures fail.” – Anderson Greenwood Crosby, 2001 (safety valve manufactuer)

Global Cast Iron Safety Valve Market, By Product Type (Spring-Loaded Pressure-Relief Valves, Dead-Weight Pressure Relief-valves, Pilot-Operated Pressure-Relief Valves), Size (Less Than 6 Inch, 7-25 Inch, 26-50 Inch, Above 50 Inch), End User (Oil and Gas, Energy and Power, Chemicals, Metals, Food and Beverage, Waste and Wastewater Treatment, Agriculture, Pharmaceuticals, Mining, Others) – Industry Trends and Forecast to 2029.

The cast iron safety valves have widely been used in oil and gas sectors due to rise in the demands for the safety framework and safety regulations across the industrial sectors. They have been in high demands due to enhanced efficiency and increased outcomes of production.

Global cast iron safety valve market was valued at USD 3,189.20 million in 2021 and is expected to reach USD 4747.92 million by 2029, registering a CAGR of 5.10% during the forecast period of 2022-2029. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

Product Type (Spring-Loaded Pressure-Relief Valves, Dead-Weight Pressure Relief-valves, Pilot-Operated Pressure-Relief Valves), Size (Less Than 6 Inch, 7-25 Inch, 26-50 Inch, Above 50 Inch), End User (Oil and Gas, Energy and Power, Chemicals, Metals, Food and Beverage, Waste and Wastewater Treatment, Agriculture, Pharmaceuticals, Mining, Others)

Emerson Electric Co. (U.S.), Schlumberger Limited. (U.S.), Bosch Rexroth AG (Germany), General Electric (U.S.), Curtiss-Wright Corporation (U.S.), The Weir Group PLC (U.K.), Forbes Marshall. (India), ALFA LAVAL (Sweden), IMI (Philippines), Spirax Sarco Limited. (U.K.), Baker Hughes Company (U.S.), Danfoss (Denmark), GEA Group Aktiengesellschaft (Germany), VYC Industrial (Spain), SMC Corporation (Japan), Taylor Valve Technology, Inc.(U.S.), LESER GmbH & Co. KG (Germany)

The cast iron safety valves are used for safer transmission of gases in oil and gas industries. They have wide range of applications such as printing, protection and others in the industrial and oil and gas sectors.

Increasing applications of cast iron safety valves across various sectors such as oil and gas, construction and others is the primary factor driving the growth of the market over the forecasted period. The safety valves are used for boiler overpressure protection and also for the applications such as downstream of pressure reducing controls. This factor is driving the growth of the market over the forecasted period.

The rising awareness regarding the safety guidelines in the industrial sector fuels the market growth. The rising number of accidental incidences, the safety frameworks across oil and gas sectors and the high demands for highly-efficient and safer valves are also the major factors driving the growth of the market over the forecasted period. The critical process in the manufacturing lines has also driven the market’s growth.

The growing penetration of 3-D printing in manufacturing lines is estimated to generate lucrative opportunities for the market, further expanding the future cast iron safety valve market"s growth rate. The 3-D printing technologies can actively address the problems related to the product handling such as enhancing component consistency through re-designing abilities. Additionally, it can minimize the manufacturing time periods, reduce production costs and increase the outcomes" efficiency. All these factors are creating lucrative growth opportunities for the cast iron safety valve market over the forecasted period.

The volatile prices of production sectors is the major factor creating hindrance for the market. Additionally, high fabrication costs and operational safety are projected to be challenging for the cast iron safety valve market over the forecast period.

This cast iron safety valve market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the cast iron safety valve market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

The cast iron safety valve market is segmented on the basis of product type, size and end user. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

The cast iron safety valve market is analyzed and market size insights and trends are provided by product type, size and end user as referenced above.

The countries covered in the cast iron safety valve market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

North America dominates the cryogenic safety valve market because of the rising prevalence of manufacturing units and rising investments in various industries such as construction and oil and gas industries within the region.

Asia-Pacific is expected to witness significant growth during the forecast period of 2022 to 2029 due to the rising demands of the safety valves across various emerging economies and rapid urbanization within the region.

The cast iron safety valve market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies" focus related to cast iron safety valve market.

8613371530291

8613371530291