difference between safety valve and relief valve marine insight brands

As you already know, there are a multitude of pressure relief valves out there. In the industry, we tend to use terms like safety valve and relief valve interchangeably. And for the most part, this makes sense. Most pressure relief valves are designed to do the same thing — release pressure in a system.

But is there a difference between some of these commonly used terms, and if so, what does it mean for you? Here’s a quick breakdown of two popular terms: safety valve vs. relief valve.

While both terms refer to valves used to release pressure from a pressurized system, their technical definitions are a bit different. In general, the term relief valve refers to a valve within a pressurized system that is used to control pressure for the optimal functionality of the system. Relief valves are designed to help your facility avoid system failures, and protect equipment from overpressurized conditions.

The term safety valve, on the other hand, refers to pressure valves that are designed to protect people, property, and processes. In other words, the term safety valve refers to a failsafe, last resort valve that will release pressure to prevent a catastrophe, usually in the event that all other relief valves have failed to adequately control pressure within a system.

The general purpose of both safety valves and relief valves are the same. Both are pressure relief valves, and they are designed to let off pressure in any situation where a system becomes overpressurized. That said, relief valves and safety valves do function slightly differently:

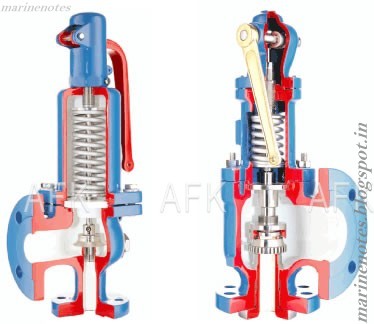

Relief Valves are designed to control pressure in a system, most often in fluid or compressed air systems. These valves open in proportion to the increase in system pressure. This means they don’t fly all the way open when the system is slightly overpressure. Instead, they open gradually, allowing the system to return to the preset pressure level. When that level is reached, the valve shuts again.

Safety Valves are used for one reason — safety. Instead of controlling the pressure in a system, they’re designed to immediately release pressure in the event of an emergency or system failure. Unlike relief valves, safety valves open immediately and completely to avoid a disaster, rather than to control the pressure of a system.

While both safety valves and relief valves work to release excess pressure, the way they go about it is a little different. Check out this table, courtesy of Difference Between, for a little more information about the differences between the two valves:

Whenever we talk about the pressure in the process industries we come across two types of safety equipments and that is the safety v/v and the relief v/v.

Most of us think that both are same thing but that’s not the case. Though their functions are same yet there are certain differences among them. Both of them are used in the industry to prevent the accumulation of excess pressure, but there are operational differences between them.

Relief valves which are also known as Pressure relief valves are one of the protective devices which are used to protect a pressurize working system and equipments from getting damaged due to an over-pressure or excessive pressure conditions.

In every pressurized working system there is a set pressure under which the system works properly and efficiently, this set pressure is known as set point and when the pressure is above set point the relief valve opens and the excess pressure is released.

It is made very sensitive such that even for a slight increment in the pressure lifts the safety valve and gets closed quickly as soon as the pressure is released to maintain the desired pressure in the vessel.

1. A relief valve is a device used to limit the pressure in the system within certain specified limit or a set level.A safety valve is a device designed to actuate automatically when the pressure becomes excess.

2. The opening of a relief Valve is directly proportional to the increase in the vessel pressure.2. A safety valve opens almost immediately and fully in order to prevent over pressure condition.

3. A relief valve opens when the pressure reached the specific limit and it is usually operated by an operator.3. The purpose of the safety valve is mainly to safeguard people, property and the environment. It operates without any human intervention.

4. The set point of a relief valve is usually set at 10% above working pressure.4. The set point of safety valve is usually set at 3 % above working pressure.

5. Relief valves are categorized into pop-type, direct-operated, pilot-operated, and internal relief valves.5. Safety valves are divided into wide variety of types based on their applications and performance in different areas of use.

From the definition of both the valves we can conclude that the relief v/v which is also known as the pressure relief v/v is a safety device which is used to maintain a proper preset pressure in the vessel or the system within a prescribed limit condition to prevent a situation of over pressure.

On the other hand, the safety valve is a protective device which is used in a system to control the pressure inside the system under a predetermined limit.

The pressure relief valves are generally used in the hydraulic systems to control the pressure within specified limit and when the pressure increases than the preset value.

It lifts up and provide an escape of the excess pressure through an alternate channel or bypass provided in the system back to the source from where the input is coming or may be a different chamber provided to accept the excess of the liquid.

On contrary in case of safety valve, the main function of the safety valve is to provide safety to the property, life, and the environment which can get damaged due to failure of the system because of the excess pressure.

The pressure relief valves are generally used in the hydraulic systems to control the pressure within specified limit and when the pressure increases than the preset value, it lifts up and provide an escape of the excess pressure through an alternate channel or bypass provided in the system back to the source from where the input is coming or may be a different chamber provided to accept the excess of the liquid.

On contrary in case of safety valve, the main function of the safety valve is to provide safety to the property, life, and the environment which can get damaged due to failure of the system because of the excess pressure.

We used the set point in case of the relief valve, the “Set Point” basically refers to a point set to the lowest maximum pressure rating which means that the pressure is set below the maximum operative pressure which is allowed for a system to operate without being get into the state of overpressure.

In Simple words we can say that the relief valve pressure is set to maintain and control the pressure inside the system, the set pressure is dependent on the working pressure of the system.

On the other hand , the pressure of safety valve is set on the basis of various factors of consideration like the material used, the environment in which it has to be used, the type of work it has to perform.

The boilers material used for 6 Bar will have the materials which can withstand upto 12 Bar (it depends on the manufacturer) So the Safety valve will be set to 7-8 bar so as to prevent the boiler failure.

Oils containing water can only be de-watered in a perfect manner if the bowl is accurately adjusted to the difference in densities of oil and water. The gravity disc with proper inner diameter i.e. with the diameter that corresponds to the difference in densities of the oil-water mixture to be treated should, therefore, be inserted in the bowl, This disc can be chosen from the set of disc provided with the separator. The inner diameter of the disc to be chosen can be determined by: Calculation Experiment The general rule is : Small diameter gravity disc when treating heavy oil Large diameter regulating ring when treating light oil Determining the size of gravity disc by calculation: For a given separating temperature, the inner diameter of the gravity disc and if the desired density of the oil can be determined from the diagram, provided that the density of the oil at a temperature ranging 15℃ and 90℃ is known. For example; Given: Density of oil at 20℃ ρ oil

Both the terms are used interchangeably in the process industry as every pressurized system requires safety devices to protect life, property, and environment. Relief valves and safety valves are the two principle safety devices designed to prevent overpressure conditions in process industries. Although, both the devices are used almost for the same purpose, the difference lies mainly in how they operate.

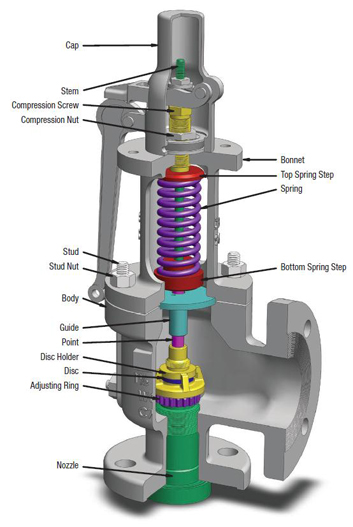

Relief valves, or commonly known as pressure relief valves (PRVs), belong to the family of protective devices specifically designed to protect pressure-sensitive systems and equipment from the damaging effects of overpressure conditions. A relief valve device is basically immune to the back pressure effects of a system and is subject to periodic stripdown. Pressure relief valves are one of the most critical parts of a pressure system that are set to open at a preset pressure level in order to avoid system failures. Every pressure system is set with a predetermined design limit called a setpoint, above which the valve begins to open to prevent overpressure conditions.

A safety valve is the last resort of people, property, and processes in the process industry comprising of power plants, petrochemicals, boilers, oil and gas, pharmaceuticals, and many more. It’s kind of a fail-safe device that actuates automatically in order to prevent the accumulation of pressure in a vessel or system beyond a preset limit. The device is so designed so that the safety valve trips automatically when the given pressure is attained. It simply allows the excess pressure to escape in order to prevent any damage to the vessel. Additionally, it also makes sure the pressure remains within the limits in the future. Even a slight increment in pressure lifts the safety valve and it closes as soon as the pressure is reduced to the prescribed limit.

A relief valve, also known as pressure relief valve (PRV) or safety relief valve, is type of a safety valve device used to limit or control the pressure level in a system within a safe threshold limit to avoid an overpressure condition. In simple terms, a relief valve is a device designed to control the pressure in a vessel or system to a specific set level. A safety valve, on the other hand, is a device used to let go excess pressure from a vessel or equipment when the pressure crosses a certain predetermined limit. It simply allows liquids or gases to escape if the pressure gets too high to prevent any damage.

Pressure relief valves are mainly used in hydraulic systems to limit the pressure in the system to a specific preset level and when the pressure reaches the safety design limit, the relief valve responds by releasing the excess flow from an auxiliary passage from the system back to the tank in order to prevent equipment failure. The main purpose of a safety valve is to protect life, property, and environment against failure in the control system pressure. Simply put, a safety valve opens when the pressure exceeds the designed set pressure limit.

For a safety relief valve, the opening is directly proportional to the increase in the vessel pressure. This means the opening of the valve is rather gradual than sudden, allowing it to open only at a preset pressure level and release fluids until the pressure drops to the desired set pressure. A safety valve, on the other hand, will open immediately when the system pressure reaches the set pressure level in order to system failure. It is safety device capable of operating at all times and is the last resort to prevent catastrophic failure in systems under overpressure conditions.

A pressure relief valve is designed to open at a certain pressure level which is generally called as a “setpoint”. A setpoint should not be confused with the set pressure. In fact, a setpoint of a relief valves is adjusted to the lowest maximum pressure rating meaning it is set below the maximum system pressure allowed before the overpressure condition occurs. The valve begins to open when the pressure reaches up to some level above the setpoint. The setpoint is measured in pounds per square inch (PSIG) and must not exceed the maximum allowable working pressure (MAWP). In safety valves, the setpoint is usually set at 3 percent above the working pressure level whereas in relief valves, it is set at 10 percent.

Both relief valves and safety valves are high-performance pressure-sensitive safety devices so designed to control or limit the pressure inside the system or vessel by releasing the excessive pressure from the auxiliary passage out of the system. Although both are common terms used for safety valves, the difference lies mainly in the capacity and setpoint. While the former is operator-assisted and is designed to relieve pressure in order to avoid overpressure condition, the latter is a self-operated device which opens automatically when the maximum allowable pressure is reached. Relief valves are mostly used in fluid or compressed air systems, whereas safety valves are mainly used to release vapor or steam into the atmosphere.

Sagar Khillar is a prolific content/article/blog writer working as a Senior Content Developer/Writer in a reputed client services firm based in India. He has that urge to research on versatile topics and develop high-quality content to make it the best read. Thanks to his passion for writing, he has over 7 years of professional experience in writing and editing services across a wide variety of print and electronic platforms.

Outside his professional life, Sagar loves to connect with people from different cultures and origin. You can say he is curious by nature. He believes everyone is a learning experience and it brings a certain excitement, kind of a curiosity to keep going. It may feel silly at first, but it loosens you up after a while and makes it easier for you to start conversations with total strangers – that’s what he said."

Industrial equipment often uses either safety or relief valves to prevent damaging pressure levels from building up. Though they perform similar functions, there are some critical differences between safety and relief valves. Understanding these two valves’ differences is essential for proper pressure system operation. So here we discuss the pressure safety valve vs pressure relief valve.

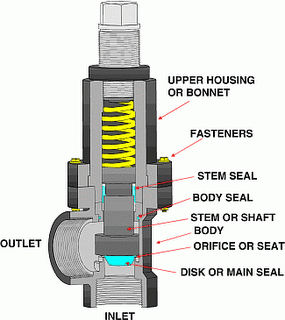

A pressure relief valve is a device that releases pressure from a system. The relief valve is generally immune to the effects of back pressure and must be periodically stripped down. Pressure relief valves are one the essential parts of a pressure system to prevent system failures. They are set to open at a predetermined pressure level. Each pressure system has a setpoint that is a predetermined limit. The setpoint determines when the valve will open and prevents overpressure.

Pressure relief valves are typically used in gas or liquid systems where there is a need to prevent excessive pressure from building up. When the pressure in the system reaches a certain level, the valve will open and release the pressure. Pressure relief valves are an essential safety feature in many designs and can help to prevent damage to the system or components.

PRVs are generally considered to be safe and reliable devices. However, before installing a PRV in a system, some potential disadvantages should be considered. Here are five pros and cons of pressure relief valves:

Pros: Pressure relief valves are anessential safety feature in many systems. They protect against over-pressurization by relieving excess pressure from the system. This can help to prevent severe damage or even explosions.

Pressure relief valves can help to improve the efficiency of a system. The system can operate at lower overall pressure by relieving excess pressure and saving energy.

Pressure relief valves can be used as a safety device in systems that are susceptible to overpressurization. By relieving pressure before it builds up to a dangerous level, they can help to prevent accidents and injuries.

Cons: Pressure relief valves can be a potential source of leaks. If not properly maintained, the valve may not seat properly and can allow fluids or gasses to escape.

Pressure relief valves can sometimes cause problems if they do not open or close properly. This can lead to process disruptions and may cause safety issues.

A pressure safety valve is a device used to release pressure from a system that has exceeded its design limit. This safety valve is a fail-safe device. This type of valve is typically used in systems that contain fluids or gasses under high pressure. Pressure safety valves are designed to open and release pressure when the system has exceeded its maximum pressure limit. This helps to prevent the system from rupturing or exploding.

Pressure safety valves are an essential part of many different types of systems and can help keep both people and property safe. If anyone is ever in a situation where they need to release pressure from a system, it is essential to know how to use a pressure safety valve correctly.

A pressure safety valve (PSV) is a type used to relieve a system’s pressure. PSVs are commonly used in chemical and process industries, as well as in some kinds of pressure vessels. There are both advantages and disadvantages to using a PSV. Some of the pros of using a PSV include: PSVs can help to prevent overpressurization, which can be dangerous.

A safety valve is a pressure relief device used to prevent the over-pressurization of a system. On the other hand, a relief valve is a device used to relieve pressure from a system that is already overpressurized. Function Of Pressure Relief Valve Vs Safety Valve

The function of a pressure relief valve is to protect a system or component from excess pressure. A safety valve, on the other hand, is designed to protect from overpressurization. Both types of valves are used in various industries, but each has unique benefits and drawbacks.

Pressure relief valves are typically used in systems where a small amount of overpressure can cause damage. On the other hand, safety valves are designed for systems where overpressurization could be catastrophic. Both valves have advantages and disadvantages, so choosing the right type of valve for the specific application is essential.

Relief valves are usually set to open at a specific pressure and will close once the pressure has been relieved. Safety valves are similar in that they are also used to protect equipment from excessive pressure. However, safety valves are designed to stay open until they are manually closed. This is because safety valves are typically used in applications where it is not safe to have a closed valve, such as in a gas line. Operation Of Safety Relief Valve Vs Pressure Relief Valve

Two types of valves are commonly used in industrial settings: relief valves and safety valves. Both of these valves serve essential functions, but they operate in different ways.

Relief valves are designed to relieve pressure build-up in a system. They open when the system pressure reaches a certain point, which allows excess pressure to be released. On the other hand, safety valves are designed to prevent accidents by preventing system pressure from getting too high. They open when the system pressure reaches a certain point, which allows excess pressure to be released before an accident can occur.

So, which valve is better? That depends on the situation. A relief valve is the better option to protect the system from pressure build-up. If anyone need to protect the system from accidents, then a safety valve is the better option Setpoint Of Pressure Relief Valve Vs Safety Relief Valve

The relief valve is made to open when it reaches a specific pressure, commonly described as a “setpoint”. Setpoints shouldn’t be misinterpreted as the pressure set. A setpoint on a relief valve is set to the lowest possible pressure rating, which means it is set to the lowest system pressure before an overpressure situation is observed. The valve will open as the pressure increases to a point higher than the setpoint. The setting point is determined as pounds per square inch (PSIG) and should be within the maximum allowed operating pressure (MAWP) limits. In safety valves, the setpoint is typically placed at about 3 percent over the working pressure level, whereas relief valves are determined at 10 percent.

No, the safety valve and relief valve can not be used interchangeably. Though both valves are seal butterfly valve and used for safety purposes, they serve different functions. A safety valve relieves excess pressure that builds up in a system, while a relief valve regulates the pressure in a system.

Knowing the difference between these two types of valves is essential, as using the wrong valve for the intended purpose can potentially be dangerous. If unsure which type of valve to use, it is always best to consult with a professional.

A few key points help us understand the safety valve vs pressure relief valve. Safety valves are designed to relieve pressure in a system when it gets too high, while relief valves are designed to relieve pressure when it gets too low. Safety valves are usually set to open at a specific pressure, while relief valves are generally open at a particular vacuum. Safety valves are typically intended for one-time use, while relief valves can be used multiple times. Choose the trusted valve manufactureraccording to the specific business needs.

opening the valve in response to a control signal. A safety valve ismeantto relieve pressure without operator assistance and a safety valve, or combination of safety valves, must be have a capacity to relieve more than the

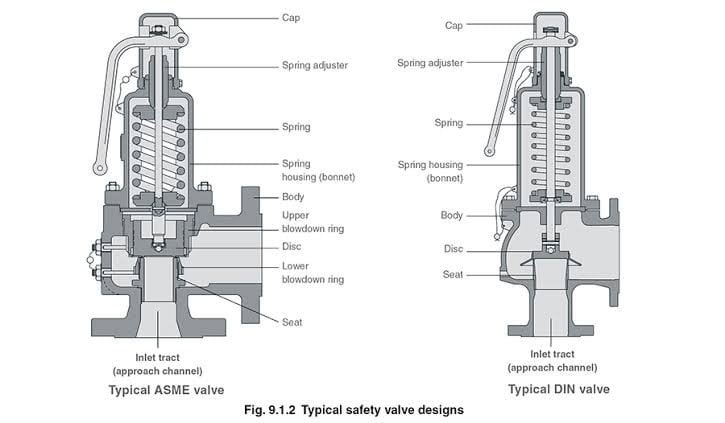

Relief Valve–is the term used to describe relief device on a filled vessel. For such a valve the opening is proportional to increase in the vessel pressure. Hence the opening of valve is not sudden, but gradual if the pressure is increased gradually.

Safety Valve–is the term used to describe relief device on a compressible filled vessel. For such a valve the opening is sudden. When the set pressure of the valve is reached, the valve opens almost fully.

The difference is generally in capacity and setpoint. A relief valve is ment to relieve pressure to prevent an over pressure condition. A relief valve may have an operator on it to assist in opening the valve in response to a control signal. A safety valve is ment to relieve pressure without operator assistance and a safety valve, or combination of safety valves, must be have a capacity to relieve more than the energy input to the volume being protected.

For example, a thermal relief valveis used to bleed off pressure in a heat exchanger if the heat exchanger is isolated but the possibility of thermal expansion of the fluid could cause over pressure conditions. The capacity of thermal reliefs are generally small.

A safey valve on a boiler or other types of fired pressure vessels must be capable of removing more energy that is possible to be put into the vessel. 110 percent of boiler rated capacity may be acceptable. The ASME Boiler & Pressure Vessel Code would be the source to check for adaquatley sizing safety valves.

Pressure and safety relief valves are one of the most critical valves in your plant since they are responsible for protecting life, property, and the environment.

Contact the Collins Companies" engineering team if you have questions on what pressure and safety relief valve is right for your application. Collins carries relief valves from reliable manufacturers such as Farris and Kunkle valves.

The National Board of Boiler & Pressure Vessel Inspectors is an organization comprised of chief inspectors from various states and territories of the US and Province and territories of Canada. The primary mission is to promote public safety.

The NBIC provides rules, information, and guidance to manufacturers, Jurisdictions, Inspectors, owner-users, installers, contractors, and other individuals and organizations performing or involved in post-construction activities, thereby encouraging the uniform administration of rules pertaining to pressure retaining items.

We sat down to ask a few clarifying questions with our very own Marianne Brodeur, who was the owner of International Valve and Instrument (IVI), before its purchase by Collins in October of 2019. She also sits on the National Board as Chairperson of the subcommittee on Pressure Relief Devices. IVI has held a VR stamp for the last 34 years.

Wärtsilä is a global leader in innovative technologies and lifecycle solutions for the marine and energy markets. We emphasise innovation in sustainable technology and services to help our customers continuously improve their environmental and

We"re dedicated to improving people"s lives and the environment with power management technologies that are more reliable, efficient, safe and sustainable.

Every day, all around the world, people depend on technology, transportation, energy and infrastructure to live and work. With rapid growth in electrification, an energy transition driven by climate change and explosive growth in connectivity, we’re well positioned to solve the world’s toughest electrical and mechanical power management challenges. Because that’s what really matters. And we’re here to make sure it works.

From our beginning more than 100 years ago, our products and services have helped people work more safely, be more energy efficient and reduce emissions.

Eaton announced third quarter 2022 earnings on Tuesday, November 1, 2022 before the opening of the New York Stock Exchange. The company hosted a conference call that day to discuss earnings results with securities analysts and institutional investors. The webcast replay and corresponding presentation materials will be available on the financial presentations and webcasts page.

The world of power management is ever-changing. Stay informed with news and insights that matter to you and get quarterly updates sent direct to your inbox.

The water-filtering abilities of farmed kelp could help reduce marine pollution in coastal areas, according to a new University of Alaska Fairbanks-led (UAF) study.

The paper, published in the January issue ofAquaculture Journal, analyzed carbon and nitrogen levels at two mixed-species kelp farms in southcentral and southeast Alaska during the 2020-21 growing season. Tissue and seawater samples showed that seaweed species may have different capabilities to remove nutrients from their surroundings.

“Some seaweeds are literally like sponges—they suck and suck and never saturate,” said Schery Umanzor, an assistant professor at UAF’s College of Fisheries and Ocean Sciences and the lead author of the study.

“Although carbon and carbon sequestration by kelp received most of the attention, kelp is actually much better at mitigating excessive amounts of nitrogen than carbon,” Umanzor said. “I think that’s a story that’s really underlooked.”

Nitrogen pollution is caused in coastal areas by factors such as urban sewage, domestic water runoff, or fisheries waste disposal. It can lead to a variety of potential threats in marine environments, including toxic algae blooms, higher bacterial activity, and depleted oxygen levels. Kelp grown in polluted waters shouldn’t be used for food but could still be a promising tool for cleaning such areas.

Kelp farming is an emerging industry in Alaska, touted to improve food security and create new job opportunities. It’s also been considered as a global-scale method for storing carbon, which could be a way to reduce levels of atmospheric carbon that contribute to climate change.

Analysis of kelp tissue samples from the farms determined that ribbon kelp was more effective than sugar kelp at absorbing both nitrogen and carbon, although that difference was somewhat offset by the higher density of farmed sugar kelp forests.

“Maybe it’s a function of species, maybe it’s the site, maybe it’s the type of carbon and nitrogen out there,” Umanzor said. “There’s a lot to know in a follow-up study.”

SafeSTSis a UK based ship-to-ship service provider. The company is ranked in the Business Expansion, Innovation, Product Launches and Safetycategories in the 2022 Ship Technology Excellence Rankings.

One of the company’s biggest innovations recently has been the introduction of a new cargo transfer system for oil tankers. The system known as Transhipment via Buoy (TVB) involves using a single point mooring buoy as a transfer point between two tankers, with oil transferred via hoses and the buoy keeping the tankers apart with the dynamically positioned (DP) tanker moving around the buoy and maintaining distance from the export tanker. This allows the system to be used in more extreme and uneven seas without the fear of collision that would arise through traditional hull to hull methods.

The system’s other benefits are that, as it is a buoy-based system, it can be located closer to operating fields, reducing the distance tankers need to travel. There are also further safety methods built in through a ‘green line’ system, which stops the operation if any issue is found in any part of the system.

At SafeSTS we are committed to the highest standards of safety. Established by a team with over 30 years’ expertise and experience, we are employed by some of the world’s foremost charterers to conduct STS transfers. We commit to doing the job to the very highest standard, every single time. Successfully audited by leading oil majors and pioneering new STS business to facilitate economic development and growth from East Africa to Japan and trusted globally by charterers and IMO member’s state to protect their interest.

Operating in a global network of numerous lightering locations, we carry out the ship-to-ship transfer of oil and gas. We use only the highest quality equipment and a global pool of highly experienced Marpol compliant Mooring Masters. All operations are carried out in strict accordance with OCIMF/ICS and SIGTTO guidelines and comply fully with Marpol Chapter 8 requirements.

One of our core strengths is understanding vessel dynamics, operability, and logistics underpinned by a respect for the country and culture in which we work, taking the interest of all stakeholders into consideration. Our job is to manage and minimise the clients’ risk, every step of the way.

Safety is our mantra and what we have been proud to deliver from day one. When offering our services, we always make sure we do it in the best and safest possible way. From ship-to-ship (STS) transfers, through to marine consultation, STS equipment sale and rental, vessel charter, expert witness or when training, we fully commit ourselves to ensure what we do is what meets the market requirements and expectations at the highest level.

We conduct STS transfers of oil, gas and in some cases dry cargo around the globe 24 hours a day 365 days a year. We are fully Marpol compliant and ensure that operations happen safely and efficiently. STS services allow draft restricted or developing countries to import and export oil and gas supplies, helping them to develop and providing essential resources. We have considerable experience and expertise in emergency contingency STS and have been instrumental in the mitigation and prevention of oil spills globally.

Our in-house marine experts have a wide-ranging skills base, so whether your project is an FPSO, (side by side or tandem moor), an FSU or the mooring systems design for an FLNG, we have people who can support you with years of real, practical experience and a full understanding of your needs from project feasibility to operability.

We develop, implement and manage QHSE systems for third parties, using our in-house expertise and bespoke system SafeOps to encourage consistent standards within the industry. Working in accordance with IMO, OCIMF/ICS, ISGOT, ISO, ISM & OHSAS standards we are proud to have developed an industry leading system.

With extensive global experience of operations both underway and at anchor we are well placed to deliver training in the classroom and in the field. We are developing a bespoke competence programme for Mooring Masters, covering oil, gas and dry cargo STS.

Our highly experienced Mooring Masters and marine consultants are qualified to offer expert witness testimony and advice in various maritime disciplines such as LNG transfers, salvage and emergency operations and offshore projects.

With over 30 years’ experience in the selection, certification and sourcing of STS transfer equipment we are well placed to manage your procurement requirements. Working with world renowned manufacturers and a full understanding of your equipment needs you can be sure that what we provide will always be fit for purpose and cost effective.

With the rapidly increasing size of the world LNG fleet, comes the inevitable increasing demand for ship-to-ship (STS) transfers together with the probability of emergency lightering.

LNG side-by-side is not the same as oil STS although some of the skills required translate directly. The operation, equipment required, transfer method, cargo properties and even the culture of safety is different.

Our team is here to assist your need for LNG transfers including emergency situations. We are very happy to share our knowledge and extensive experience to make your transfer as smooth as possible, even in challenging environments.

8613371530291

8613371530291