double safety valve free sample

Besides the P/T value of the sleeve the limitations of the valve bodies also have to be considered. Please refer to the EN 12516-1 resp. ASME B16.34 in order to choose a proper pressure rating (PN/class). The shown values refer to austenitic stainless steel 1.4408 (A351 Gr. CF8M).

Besides the P/T value of the sleeve the limitations of the valve bodies also have to be considered. Please refer to the EN 12516-1 resp. ASME B16.34 in order to choose a proper pressure rating (PN/class). The shown values refer to austenitic stainless steel 1.4408 (A351 Gr. CF8M).

Find check safety valve on Microchek.com. The system is available in a variety of polymers and elastomers to ensure compatibility with most liquids and gases. We can select valves that fall into a specific cracking pressure range if needed. We want the opportunity to help you solve your flow control applications and we can build special configurations. Relief valves are used to hold a fluid circuit or reservoir at a positive or negative pressure. Our staff is available to advise you on your applications. Please ask for a FREE sample that meets your needs. If your design requires a unique configuration, we will be pleased to quote your needs. Related terms include idle control valve location, 2-phase steam relief valve, closet flange check valve, double a relief valve qbj, and consolidated relief valve 1905jc-31-gs. Call us for a FREE check valve sample. 1-800-780-0008 Or fax us at 1-800-622-0002. The Microchek system incorporates this cartridge and a wide selection of end pieces to accommodate most connection requirements. This valve is the heart of our system and has a great design.

Microchek is a company with an expertise in cartridge check valves. Check safety valve related phrases are on Microchek.com. The Microchek valve is a cartridge check valve incorporating an innovative guided poppet design. The Microchek valve has a low pressure drop and can be specified with a wide variety of cracking pressures. Other phrases include closet flange check valve, double a relief valve qbj, idle control valve location, consolidated relief valve 1905jc-31-gs, 2-phase steam relief valve. This vaulve may be used alone or as the central component of the system. We offer competitive pricing and reliability because we are the manufacture. Parts are molded and assembled in the U.S. Look for check safety valve on Microchek.com. The Microchek valve incorporates our innovative check valve module with ultrasonically welded end pieces. Microcheks innovative designs use a minimum number of parts to assure reliability through simplicity. Related phrases are 2-phase steam relief valve, consolidated relief valve 1905jc-31-gs, idle control valve location, closet flange check valve, and double a relief valve qbj. The Microchek valve has a low pressure drop and can be specified with a wide variety of cracking pressures.

Check safety valve is related to Microchek.com. We offer competitive pricing and reliability because we are the manufacture. Parts are molded and assembled in the U.S. Call us for a FREE check valve sample. 1-800-780-0008 Or fax us at 1-800-622-0002. This valve is the heart of our system and has a great design. The Microchek valve is a cartridge check valve incorporating an innovative guided poppet design. Other phrases are closet flange check valve, consolidated relief valve 1905jc-31-gs, double a relief valve qbj, 2-phase steam relief valve, and idle control valve location. We want the opportunity to help you solve your flow control applications and we can build special configurations. We can select valves that fall into a specific cracking pressure range if needed. This vaulve may be used alone or as the central component of the system. Our staff is available to advise you on your applications. Please ask for a FREE sample that meets your needs. Microcheks innovative designs use a minimum number of parts to assure reliability through simplicity. The Microchek valve incorporates our innovative check valve module with ultrasonically welded end pieces.

The primary purpose of a safety valve is to protect life, property and the environment. Safety valves are designed to open and release excess pressure from vessels or equipment and then close again.

The function of safety valves differs depending on the load or main type of the valve. The main types of safety valves are spring-loaded, weight-loaded and controlled safety valves.

Regardless of the type or load, safety valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

Type 125A is the standard DN50 sampling valve by FAMAT. Used for sampling applications of powders, granules, pastes and liquids under process conditions in the pharmaceutical, chemical and food industries.

This sampling valve has one Tri-Clamp (TC) 1.5" near the handwheel called " EasyClean ", the piston can be removed from the valve housing with a minimum of effort allowing full cleaning as shown on the picture. This permits a complete cleaning of internals between batches.

This valve is used for products which could clog inside the dryer or vessel and block the piston. To eliminate the risk of this impeding product flow in to the sampling valve, FAMAT has developed the 125CC. With this kind of valve type, the crust will be broken by the piston before the sample is taken.

The 135A sampling valve is equipped with a metallic piston (Stainless Steel, Hastelloy) for sampling process up to 300ºC (572ºF). Unlike the PTFE or PEEK piston, the metal piston has a high temperature gasket around it. To avoid any damage when closing the piston, the gasket is receding into the piston and seals against the valve cylinder wall making contact only after the final sealing turn of the handwheel. Tightness from vacuum up to 10 bar (145 psi).

The sample is taken in the same way as the standard Famat sample valve. The indicator (A) shows the position of the piston. This indicator has to show " closed " to allow the security lock (B) to be moved to the open position. Only Then, the sampling bottle can be removed from its bayonet coupling. The piston is locked inside the valve until the sample bottle is refitted and the security lock (B) is moved to "closed"

Type 130C is the standard DN25 sampling valve by Famat. The same concept of the 125A valve has been applied in a smaller version, to best suit smaller reactors, and machines

For cleaning internals between batches The same Easyclean technology present in 125TC is adapted to our DN25 valve. The easy disassembly of the piston is a great advantage in rapid batch exchanges, typical and small size production plant.

For all the situation in which the product is not easily flowing and could clog the sampling valve bore, 130CC has been developed by FAMAT. By moving the bigger handwheel, the piston is entering inside the vessel breaking eventual material deposit and allowing the product flow.

In certain situation, the installation of FAMAT Sampling valve in horizontal position, is not enough to permit the sampling of the product. The new 45º version of the 130TC valve, permit a better flow of product, with improved angle for optimal product flowing

The versatility of the valve, combined with the proven reliability, will make this valve the perfect solution for many application in pharmaceutical business.

The new design has been created and successfully tested for a service up to 50 bar (Class #300). The Product is in compliance with PED requirement (Cat. II Equipment) The valve can be modified as per customer requirements.

On top of the advantage of expanding piston, when used as a charging valves, the piston has the advantage of pushing all the load inside the vessel, without any loss of product.

The best basis for efficient and safe production processes due to the wide variety of options provided by our modular system, ease of maintenance, cleanability, and the options for the valves to meet the latest hygiene and aseptic requirements.

Südmo offers a comprehensive, refined double seat valve for implementation and automation of widely varying production processes in the food and beverage industry.

Südmo Comprehensive hygienic butterfly valve line features both manual and pneumatic drive options, including lockable handles and vertical actuators.

Pentair Südmo Valve Manifolds offer professional design, combined with the highest processing quality and permit optimum cleaning for perfect product quality.

As a design engineer responsible for developing and specifying boilers, dryers, furnaces, heaters, ovens and other industrial heating equipment, you face a daunting labyrinth of standards and industry regulations. Regulatory bodies sound a bit like alphabet soup, with acronyms like UL, FM, CSA, UR, AGA, ASME, ANSI, IRI, CE and NFPA tossed about. This article will help explain a common task for many thermal processing equipment specifiers: meeting the requirements of key codes — including Underwriters Laboratories (UL), Factory Mutual Insurers (FM) and the National Fire Protection Association (NFPA) — for safety valve equipment used in process heating applications.

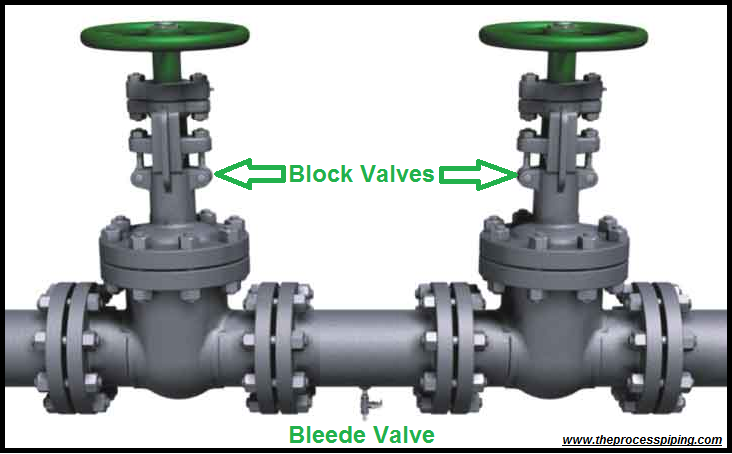

Key to designing safety into your fuel train configurations are familiar technologies such as safety shutoff valves and vent valves as well as visual-indication mechanisms and proof-of-closure switches.

Your design skills come into play with how you take advantage of the wide range of products available. You can mix and match solenoid and safety shutoff valves — within designs from catalytic reactors to multi-zone furnaces — to create easily installed, cost-effective solutions that comply with all necessary standards. (See table.)

Make sure, however, that you start with a good grasp of valve element fundamentals. For example, examining a proof-of-closure (POC) switch underlines how reliably modern valves can ensure combustion safety. The POC unit provides an electrical contact interlocked with the controller safety circuit. In a typical design, the switch is located at the bottom of the valve, positioned to trace the stroke of the valve disc. When the disc seal reaches the fully closed position, it triggers the mechanism to push down on the contact, closing it and triggering the unit’s visual indicator to show open or closed status. As a result, the operator can act with full confidence in situations where it is critical that a safety valve be safely closed.

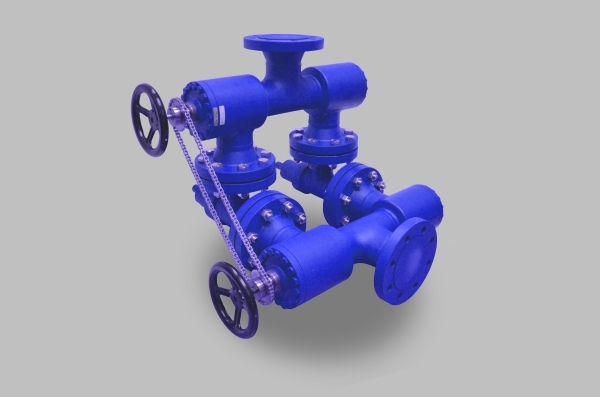

To provide ease of installation, many users prefer valves with modular capabilities. For example, to reduce mounting complexity, you can choose modular gas safety shut-off valves — combining a solenoid valve with an electrohydraulic motorized valve for a compact double-valve footprint, a slow-open feature and high flow rates. An accompanying actuator can provide on/off or high/low/off firing rates as well as visual indication and proof of closure for compliance with most industry standards.

Also, you may want to look for valves that include useful features such as pipe taps, which can facilitate accurate pressure readings and leakage testing.

Knowing your valve choices — and how they meet given codes and standards — can reduce the time required for design and production while facilitating compliance. This results in safer, more efficient and cost-effective heating process installations.

Besides the P/T value of the sleeve the limitations of the valve bodies also have to be considered. Please refer to the EN 12516-1 resp. ASME B16.34 in order to choose a proper pressure rating (PN/class). The shown values refer to austenitic stainless steel 1.4408 (A351 Gr. CF8M).

Qosina offers the largest in-stock inventory of medical valves that are ready to ship. With low minimum orders and just-in-time delivery, we’ll help you keep your project on track.

Qosina offers an extensive line of valves including check valves, relief valves, hemostasis valves, luer-activated valves, tuohy borst adapters and drain valves. In a variety of sizes and material options, Qosina can provide the right valve for any application. Hemostasis valves and tuohy borst adapters prevent leakage and backflow. Injection and pressure monitoring can be performed through the sidearm of a hemostasis valve Y connector. One-handed hemostasis valves feature an easy push/pull apparatus that allows for a single-handed process when opening and closing the valve.

Qosina also offers a double hemostasis valve that allows for easier manipulation and control of interventional devices. Our relief valves are used to control or limit the pressure in a system. The relief valve is designed or set to open at a predetermined set pressure. When the set pressure is exceeded, the valve is forced open and a portion of the fluid or gas is diverted through an auxiliary route.

Find assembly cuffs for medical valves in a variety of colors in our inventory. These high-quality assembly cuffs are made of BPE-free polypropylene. Contact us for custom sourcing of the size or color that completes your project. Free samples are available so you can try our plastic medical check valves, assembly cuffs and other products in your project before committing to a purchase.

Qosina is a worldwide supplier of thousands of stock OEM disposable components to the medical and pharmaceutical industries. We offer single-use connectors, luers, clamps, adapters, clips, valves, needle hubs, stopcocks, hemostasis valves, tuohy borst adapters, surgical swabs and spikes. We operate in a 95,000-square-foot climate-controlled ISO 13485, ISO 22301, ISO 9001 and ISO 14001 registered facility with an ISO Class 8 Clean Room. Our mission is to help you get your innovations to market quickly. 3D CAD models of all our Quick Disconnect Couplings and many of our other components are available to download in a variety of formats. Engineers can use them to adapt virtual drawings and share visuals with nontechnical team members to make sure the components will work before you purchase.

Other downloadable resources available on our website include comprehensive technical specifications, such as material safety and data sheets, technical data sheets, material certification, and compatibility information on all products. If you can’t find the specific item your team needs in our extensive catalog, contact us about custom sourcing. Altering an existing mold for color or size can be a cost-effective way to keep your project within budget and on deadline.

Reliably safe processes - this is what our KIESELMANN safety valves with EAC certification and CE type approval for gases stand for. They protect automatically, without additional auxiliary power, as soon as the system pressure has exceeded the adjusted system pressure and close reliably and quickly when the safe operating pressure is reached again.

With safety valves from our company you ensure trouble-free operation and avoid damage due to overpressure. The ideal protection for all connected system parts, containers, pipelines and your employees.

KIESELMANN safety valves open automatically as soon as the pressure has exceeded a previously defined value. The closing is then effected by the force of a spring or weight. They are used in systems where liquids and gases are present. The response pressure is set at the factory precisely according to your requirements and is sealed to protect against unwanted changes. We will be happy to help you with the design of the appropriate safety valve.

Against overpressure, for the highest hygiene requirements. KIESELMANN safety valves feature a compact and closed housing construction. All moving parts are inside the housing, so no functional parts can be blocked from the outside. This also allows adequate cleaning of the exterior surfaces. The spherical inner contour with the hygienically designed clamping connections provides excellent CIP (cleaning-in-place) and SIP (sterilisation-in-place) properties. And we also thought: the valve insert can be removed from the housing for maintenance purposes without changing the pressure setting.

We like to be measured by our success: Our safety valves have been used successfully for many years in numerous processes in the food and pharmaceutical industries.

8613371530291

8613371530291