downhole safety valve price

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale subsurface safety valve on Alibaba.com. When you search for subsurface safety valve and related items, you will be able to find many types of subsurface safety valve varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of subsurface safety valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

Surface-controlled subsurface safety valves (SCSSVs) are critical components of well completions, preventing uncontrolled flow in the case of catastrophic damage to wellhead equipment. Fail-safe closure must be certain to ensure proper security of the well. However, this is not the only function in which it must be reliable—the valve must remain open to produce the well. Schlumberger surface controlled subsurface safety valves exceed all ISO 10432 and API Spec 14A requirements for pressure integrity, leakage acceptance criteria, and slam closure.

Through decades of innovation and experience, Schlumberger safety valve flapper systems are proven robust and reliable. The multizone dynamic seal technology for hydraulic actuation of subsurface safety valves is a further improvement in reliability performance when compared with traditional seal systems in the industry.

The multizone seal technology is currently available in the GeoGuard high-performance deepwater safety valves, which is validated to API Spec 14A V1 and V1-H.

At the Well Services Department of Pemex, Seal-Tite® cured a simulated severe leak in a subsurface safety valve. After curing the leak, Pemex was able to cycle the test valve repeatedly to verify that the valve was fully functional.

After the successful shop test, a leaking installed SCSSV was selected to verify the shop results in the field. The selected SCSSV was of a different manufacturer and type. The high viscosity oil used to maintain the valve open was displaced and sealant injected into the control line. Over a brief period of time, the leak was cured to a pressure of 5000 psi. After verifying the functionality of the valve, the pressure was reduced to the operating pressure of 3200 psi and the valve tied back into the main hydraulic control panel.

The Super Safety Valve is a sort of Fail Safe Safety Valve for well testing from a land or jack-up rig. The SSV is normally run inside or below the Blow Out Preventer (BOP) and is used to control well flow. The ID is 3.0 in., OD is 8.0 in., and the working pressure of Super safety valve is 15,000 psi. This safety valve has a port for chemical injection downhole or to control a subsurface safety valve. It is capable of cutting wireline and coiled tubing using the nitrogen charge or by application of balance line pressure.

* With two hydraulic lines and a chemical injection port, the super safety valve is designed to close by spring force but has a nitrogen charge chamber to quicken the closing time.

Typically, the nitrogen charge chamber of the valve is charged with nitrogen to 1000 to 1500 psi. This charge is sufficient to cut 7/32 inch mono-conductor cable, but it is not adequate to cut coiled tubing. The valve can be charged with nitrogen sufficient to cut coiled tubing, but this raises the required hold open pressure. The tool is capable of cutting 1.50 inch OD x 0.125 inch wall thickness coiled tubing by application of balance line pressure. Halliburton T&T Engineering should be consulted whenever coiled tubing cutting is anticipated.

*Drill stem testing tools: RTTS packer, circulating valve, safety joint, select tester valve, omni valve, hydraulic jar, shock absorber, RD safety circulating valve, high pressure retrievable packer with bypass, IPO valve, tubing string test valve, and so on.

*Coiled Tubing Tools: Double slip connector, roll on connector, roll on x thread connector, double flapper check valve, motor head, dual function circulating valve, hydraulic jar, fishing tools etc.

Halliburton provides proven, high-performance tubing-retrievable and wireline-retrievable subsurface safety valves (SSSV) designed to reliably shut-in (fail safe) if a catastrophic event occurs, allowing operators to maintain safe operations.

Maintaining fluid control and well protection is critical in your shallow depth well operations. The SelecT™ subsurface safety valve from Baker Hughes addresses the unique challenges that shallow set safety valves (typically <1,000 ft) endure.

The tubing-retrievable SelecT valve includes an ultra-strong power spring that delivers the high closing forces needed to reliably and consistently close the valve in the presence of paraffin and other produced solids.

The SelecT is engineered to avoid failures due to wireline damage during downhole interventions. The valve’s advanced flapper design prevents damage and ensures that all seal surfaces are protected from wireline contact—even during accidental closure of the valve during wireline operations.

Ensure greater seal integrity with the SelecT valve’s patented advances that include thru-the-flapper self-equalizing system. And the radial punch control fluid communication system eliminates accidental communication associated with linear shifting sleeves.

PLUSCO 621-622 Safety Valve Sealant will improve the overall performance of the safety valve by insuring a continuous seal for extended operation. It eliminates line leaks, improves the hydraulic pump performance, maintains tighter seals and valve seating and reduces fluid friction in the system. The benefits of sealing, lubricity and operations efficiency are provided by PLUSCO 621-622 Safety Valve Sealant. Safety Valve Sealant will insure a continuous flow of the gas well without interruption or unnecessary shutdown.PLUSCO 621-622 Safety Valve Sealant is available in two grades depending on the severity of the leak in the system.

PLUSCO 621-622 Safety Valve Sealant is a high tech safety valve additive specifically designed for sealing hydraulic controlled surface or subsurface safety valves.PLUSCO 621 is designed for slow weeping leaks while PLUSCO 622 is for heavy pinhole type leaks.

Designed to provide protection from well-control events, Superior surface-controlled subsurface safety valves are built and tested to the highest API standards. Our field-proven line will allow you to quickly close a well when needed, protecting assets and people. Available in sizes from 2-3/8” to 7”, our retrievable safety valves are designed for setting depths of up to 3,000 feet and pressures of up to 10,000 psi.

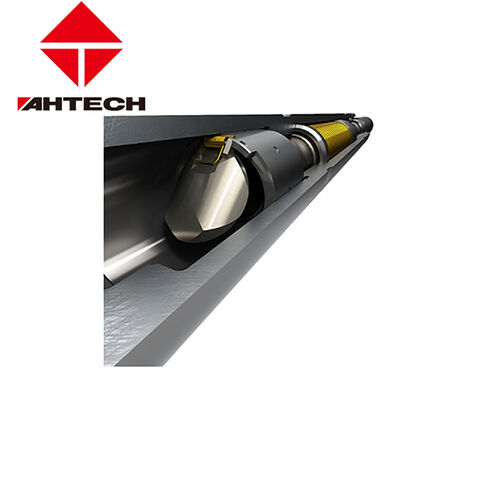

Subsurface Safety Valve TRSSSV is a kind of tubing retrievable safety valve which is controlled at the surface. It directly connects to the tubing string. There is a hydraulic control line connecting to the safety valve from the ground. While a certain amount of pressure is supplied through this control line to the safety valve, the valve remains open; while the pressure is released, the safety valve will close and the tubing pass is closed at the same time.

Global Downhole Safety Valve Market Report (90 Pages) provides exclusive vital statistics, data, information, trends and competitive landscape details in this niche sector.

The global Downhole Safety Valve market is projected to reach USD million by 2028 from an estimated USD million in 2022, at a CAGR of % during 2023 and 2028.

North American market for Downhole Safety Valve is estimated to increase from USD million in 2022 to reach USD million by 2028, at a CAGR of % during the forecast period of 2023 through 2028.

Asia-Pacific market for Downhole Safety Valve is estimated to increase from USD million in 2022 to reach USD million by 2028, at a CAGR of % during the forecast period of 2022 through 2028.

The major global companies of Downhole Safety Valve include Schlumberger, NOV, Weatherford, Scale Protection, Baker Hughes, Novomet, WEB Nordeste, Baohao Petroleum Machinery and ZZ Top Oil Tools, etc. In 2021, the world"s top three vendors accounted for approximately % of the revenue.

The global market for Downhole Safety Valve in Onshore is estimated to increase from USD million in 2022 to USD million by 2028, at a CAGR of % during the forecast period of 2022 through 2028.

Considering the economic change due to COVID-19 and Russia-Ukraine War Influence, Temporary, which accounted for % of the global market of Downhole Safety Valve in 2021, is expected to reach million USD by 2028, growing at a revised CAGR of % from 2022 to 2028.

This report aims to provide a comprehensive presentation of the global market for Downhole Safety Valve, with both quantitative and qualitative analysis, to help readers develop business/growth strategies, assess the market competitive situation, analyze their position in the current marketplace, and make informed business decisions regarding Downhole Safety Valve.

The Downhole Safety Valve market size, estimations, and forecasts are provided in terms of output/shipments (K Units) and revenue (USD millions), considering 2021 as the base year, with history and forecast data for the period from 2017 to 2028. This report segments the global Downhole Safety Valve market comprehensively. Regional market sizes, concerning products by types, by application, and by players, are also provided. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes.

Chapter 2:Detailed analysis of Downhole Safety Valve manufacturers competitive landscape, price, output and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 3:Production/output, value of Downhole Safety Valve by region/country. It provides a quantitative analysis of the market size and development potential of each region in the next six years.

Chapter 4:Consumption of Downhole Safety Valve in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and capacity of each country in the world.

The readers in the section will understand how the Downhole Safety Valve market scenario changed across the globe during the pandemic, post-pandemic and Russia-Ukraine War. The study is done keeping in view the changes in aspects such as demand, consumption, transportation, consumer behavior, supply chain management, export and import, and production. The industry experts have also highlighted the key factors that will help create opportunities for players and stabilize the overall industry in the years to come.

Reasons to Buy This Report: ● This report will help the readers to understand the competition within the industries and strategies for the competitive environment to enhance the potential profit. The report also focuses on the competitive landscape of the global Downhole Safety Valve market, and introduces in detail the market share, industry ranking, competitor ecosystem, market performance, new product development, operation situation, expansion, and acquisition. etc. of the main players, which helps the readers to identify the main competitors and deeply understand the competition pattern of the market.

● This report will help stakeholders to understand the global industry status and trends of Downhole Safety Valve and provides them with information on key market drivers, restraints, challenges, and opportunities.

Surface Controlled Subsurface Safety Valve failure data from 14 North Sea fields have been collected and failure rates for the various valve types and makes calculated. Failure rates have been compared to well data in order to identify critical well parameters and give guidance to operators when selecting valves for new fields.

Finally, models are developed for calculating well safety and production availabilities. Input to these models is failure rates, testing and maintenance routines, frequency of other well service operations etc.

Most people involved in production of oil and gas from high pressure reservoirs will probably agree that the Down Hole Safety Valve is one of the most important components for controlling blowout risk. In particular this is the case offshore where one platform may be producing from more than 30 wells. In such situations it is very important to be able to shut off the wells with a down hole device if a hazardous situation should arise on the platform.

In spite of this importance, there are still endless arguments regarding what kind of safety valve to use, e.g. from which manufacturer, flapper or ball valve, or maybe to install two valves in series. No clear cut criteria for selecting valves for various types of fields and uses exists. The study documented this paper was aiming at recommending such criteria, based on an investigation of past safety valve performance in North Sea fields. In this area only surface Controlled Subsurface-Safety Valves (SCSSV) are used, and the study is therefore restricted to this type of valves.

The selection criteria that were sought, should reflect both well safety and production availability. Disregarding one of these factors will inevitably result in suboptimal solutions.DATA COLLECTION

To obtain a reasonably correct picture of past SCSSV performance, all major operators in the North Sea area were contacted, and asked to participate in the study by releasing their data regarding valve failure statistics and field parameters. Fortunately, most operators were willing to release their data, provided the information was published in a pooled manner. The information necessary wasValve type, make and dimensions

Field data (e.g. reservoir type, pressure, temp., H2S and CO2 content, GOR, oil gravity) From the 10 operators supplying data from a total of 14 fields, it was possible to obtain a sufficient amount of data for the following valvesWire line Retrievable (WR) valves:–

Aberdeen-based oil and gas production technology business Pragma said it has developed an advanced downhole safety valve to create an improved well control solution for cable deployed Electric Submersible Pumps (ESPs) retrofitted to production wells.

The new valve will enable on and offshore installations to meet all safety regulations while improving the operational footprint at the wellsite during installation and retrieval by reducing time, cost, personnel and risk.

An API 14A qualified subsurface safety valve (SSSV) is a legal requirement for producing wells in many regions. These devices generally use a flapper style mechanism and are incorporated in the production tubing during completion. However, when an ESP is retrofitted to a well, its surface control lines run through the inside of the production tubing, obstructing the SSSVs and creating the requirement for an additional safety valve. A rig would usually be mobilized to deploy the valve and then the ESP in separate runs, however cable deployment now provides significant cost and efficiency savings.

Pragma said its ESP safety valve has been designed to complement this type of deployment. It is a compact device, integrated within the lower portion of the ESP assembly and is deployed and retrieved through the production tubing in the same run as the ESP. It is the only device on the market which offers wellbore closure below the ESP control lines, the developer said. By installing the valve between the ESP and ESP packer, the valve does not rely on the integrity of aged well completion components unlike alternative systems.

The valve’s functionality is based on a novel pressure differential, or lift actuated design, requiring no pressurized chambers, hydraulic control lines or electrical power, which safeguards reliability. The valve will fail-safe close when the ESP is switched off and can be opened and closed as many times as required. The technology can also be applied to alternative artificial lift systems including capillary strings, gas lift velocity strings, progressive cavity pump and jet pump systems. A high temperature version is also available.

Pragma Technology Manager, Matt Manning, said, “Like a demand valve, or pressure regulator between the tank and mouthpiece of deep-sea diving equipment, our valve uses the ESP’s lifting capability to open or close it in line with production. The unique design advantages of this technology, combined with its compact nature, not only provide greater safety and reliability assurances to the operator, but also lower installation, operation and retrieval costs. The technology has been developed in-house and we are conducting prototype testing, with field trials and API 14A certification planned later this year.

“As the oil and gas industry continues to evolve, it’s important the supply chain also adapts to deliver quality solutions to support cost reduction and production optimization. The ESP safety valve is just one example of how Pragma continues to pioneer advanced technologies to deliver safety and efficiency gains.”

Starpetrotech Type Tubing Retrievable Safety Valves are self-equalizing, flapper type safety valves designed to shut in a well at a point below the surface. The safety valve is a surface controlled subsurface safety valve and is normally closed. The valve is held open by hydraulic control pressure and remains open until the control-line pressure is exhausted. The hydraulic control pressure is transmitted from a remote location through a control line to operate the valve. The valves are value engineered to provide long-lasting, safe, and reliable operation.

Rod Piston Safety Valves are designed and built for performance and reliability. The rugged hydraulic actuator of the safety valve provides durability and isolates the internal workings from well fluids through its unique construction. The metal-to-metal sealing integrity in the body joints and closure mechanism places it in a premium valve category while featuring an economical price. The simple, compact design enhances the valve’s overall reliability and provides for trouble-free operation. Rod piston safety valves are available with working pressure rating to 10,000psi.

Single Rod Piston Safety Valves are used a single rod piston with reliable spring-energized, no-elastomer dynamic seals; a static, full-closed, metal to metal seal. The valves are designed for general production with enhanced reliability and long life. The valves provide reduced OD, premium piston system, deep set design and many other optional features. Single Rod piston safety valves are available with working pressure rating to 10000psi and always be used in the wells with extreme downhole conditions.

8613371530291

8613371530291