downhole safety valve animation manufacturer

Our downhole safety valves provide your testing operations with fail-safe sustained control downhole in the event of an emergency or to facilitate test procedures.

Baker Hughes’s portfolio of subsurface safety valves deliver reliable performance when it matters the most, providing emergency closure in the event that well control is lost. We offer a full range of valves to suit applications ranging from shallow- to deep-set, and the valves are available in surface- and subsurface-controlled, tubing-retrievable, and wireline-retrievable options. All Baker Hughes valves undergo stringent prototype testing and conform to standards and specifications such as API and ISO, as well as requirements requested for your unique situation.

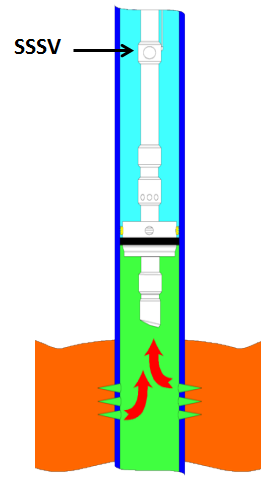

A downhole safety valve refers to a component on an oil and gas well, which acts as a failsafe to prevent the uncontrolled release of reservoir fluids in the event of a worst-case-scenario surface disaster. It is almost always installed as a vital component on the completion.

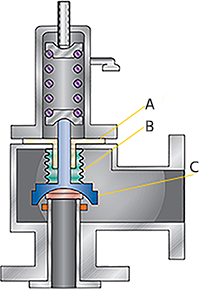

These valves are commonly uni-directional flapper valves which open downwards such that the flow of wellbore fluids tries to push it shut, while pressure from the surface pushes it open. This means that when closed, it will isolate the reservoir fluids from the surface.

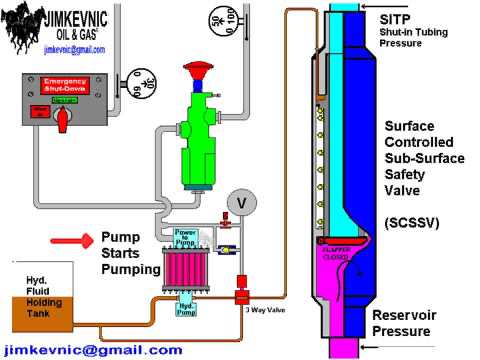

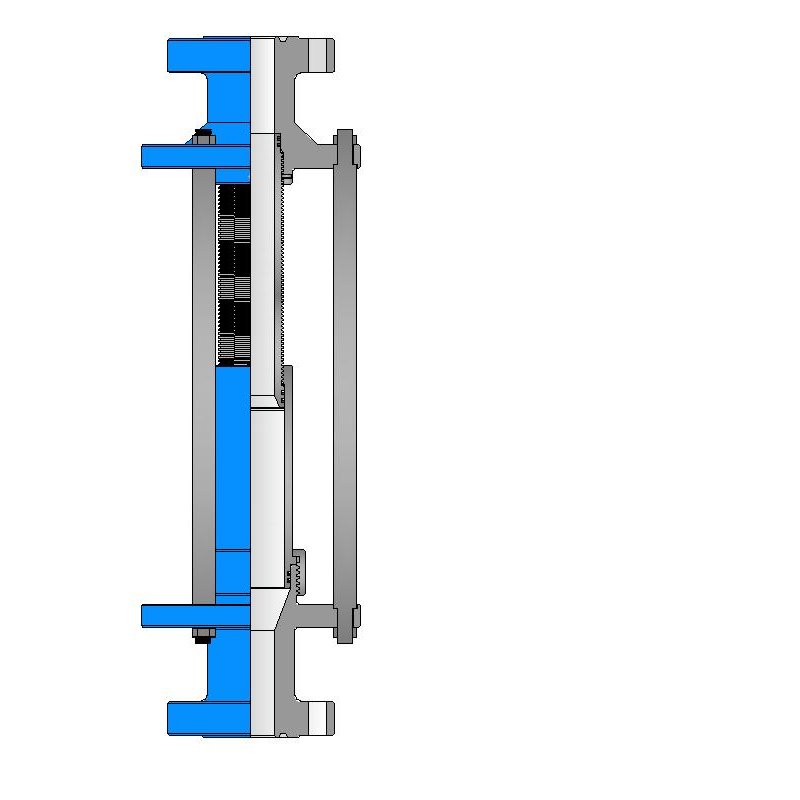

Most downhole safety valves are controlled hydraulically from the surface, meaning they are opened using a hydraulic connection linked directly to a well control panel. When hydraulic pressure is applied down a control line, the hydraulic pressure forces a sleeve within the valve to slide downwards. This movement compresses a large spring and pushes the flapper downwards to open the valve. When hydraulic pressure is removed, the spring pushes the sleeve back up and causes the flapper to shut. In this way, it is failsafe and will isolate the wellbore in the event of a loss of the wellhead. The full designation for a typical valve is "tubing retrievable, surface controlled, subsurface safety valve", abbreviated to TR-SCSSV.

The location of the downhole safety valve within the completion is a precisely determined parameter intended to optimise safety. There are arguments against it either being too high or too low in the well and so the final depth is a compromise of all factors. MMS regulations state that the valve must be placed no less than 30 m (100 ft) below the mudline.

The further down the well the DHSV is located, the greater the potential inventory of hydrocarbons above it when closed. This means that in the event of loss of containment at surface, there is more fluid to be spilled causing environmental damage, or in the worst case, more fuel for a fire. Therefore, placing the valve higher limits this hazard.

Another reason relates to the hydraulic control line. Hydraulic pressure is required to keep the valve open as part of the failsafe design. However, if the valve is too far down the well, then the weight of the hydraulic fluid alone may apply sufficient pressure to keep the valve open, even with the loss of surface pressurisation.

As part of the role of the DHSV to isolate the surface from wellbore fluids, it is necessary for the valve to be positioned away from the well where it could potentially come to harm. This implies that it must be placed subsurface in all circumstances, i.e. in offshore wells, not above the seabed. There is also the risk of cratering in the event of a catastrophic loss of the topside facility. The valve is specifically placed below the maximum depth where cratering is expected to be a risk.

If there is a risk of methane hydrate (clathrate) plugs forming as the pressure changes through the valve due to Joule–Thomson cooling, then this is a reason to keep it low, where the rock is warmer than an appropriately-calculated temperature.

Most downhole safety valves installed as part of the completion design are classed as "tubing retrievable". This means that they are installed as a component of the completion string and run in during completion. Retrieving the valve, should it malfunction, requires a workover. The full name for this most common type of downhole safety valve is a Tubing Retrievable Surface Controlled Sub-Surface Valve, shortened in completion diagrams to TRSCSSV.

If a tubing retrievable valve fails, rather than go to the expense of a workover, a "wireline retrievable" valve may be used instead. This type of valve can fit inside the production tubing and is deployed on wireline after the old valve has been straddled open.

The importance of DHSVs is undisputed. Graphic images of oil wells in Kuwait on fire after the First Gulf War after their wellheads were removed, demonstrate the perils of not using the components (at the time, they were deemed unnecessary because they were onshore wells). It is, however, not a direct legal requirement in many places. In the United Kingdom, no law mandates the use of DHSVs. However, the 1974 Health & Safety at Work Act requires that measures are taken to ensure that the uncontrolled release of wellbore fluids is prevented even in the worst case. The brilliance of the act is that it does not issue prescriptive guideline for how to achieve the goal of health and safety, but merely sets out the requirement that the goal be achieved. It is up to the oil companies to decide how to achieve it and DHSVs are an important component of that decision. As such, although not a legal requirement, it is company policy for many operators in the UKCS.

While the DHSV isolates the production tubing, a loss of integrity could allow wellbore fluid to bypass the valve and escape to surface through the annulus. For wells using gas lift, it may be a requirement to install a safety valve in the "A" annulus of the well to ensure that the surface is protected from a loss of annulus containment. However, these valves are not as common and they are not necessarily installed at the same position in the well, meaning it is possible that fluids could snake their way around the valves to surface.

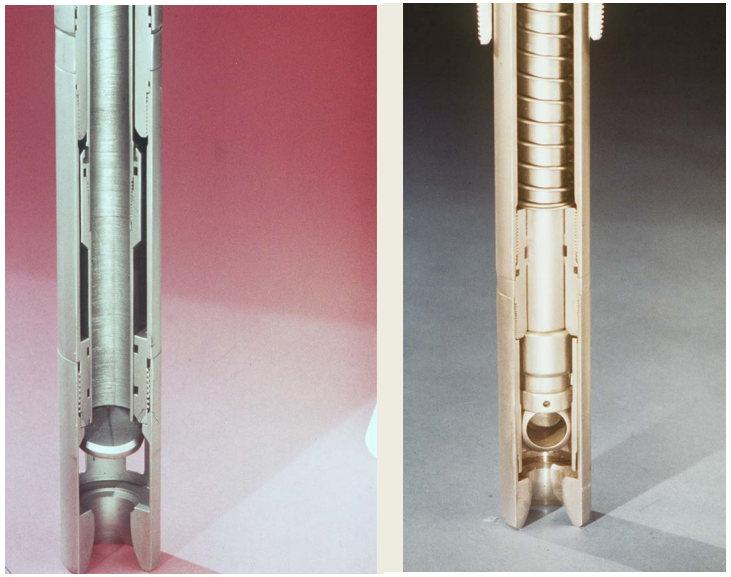

Field-proven Weatherford safety valve technology guards against catastrophic loss of well control. The Optimax Ultra Deep-Set Safety Valve shuts in a well in the event of uncontrolled flow. This rod-piston, flapper-type valve has heavy-duty springs and metal-to-metal seals to enhance reliability for a fail-safe closure at pressures up to 10,000 psi (68 MPa). The Optimax ultra deep-set safety valve delivers V1-rated reliability to your operation. This valve can be set as deep as 12,000 ft (3,658 m) to provide fail-safe closure at pressures up to 10,000 psi (68 MPa).

Weatherford engineers every Optimax safety valve for durability and reliability. We combined the quality you expect with the functionality you need to shut in a well. Our Optimax portfolio of safety valves lead the industry in design simplicity and reliability.

The ultra deep-set safety valve overcomes the challenges of nitrogen-charged safety valves with a design that uses highly reliable, field-proven technology. With two rod pistons acting in opposite directions, the Optimax valve is tubing-pressure insensitive and does not rely on nitrogen-charged chambers, which can bleed off over time. Optimax valves require only low operating pressures, which reduce costs on subsea trees and umbilicals. Its simple design eliminates sleeves or plugs that can be inadvertently actuated.

Each valve is validated through a testing program that exceeds API 14A requirements. The result is high performance and reliability in deepwater applications in temperatures between 35°F and 350°F (2°C and 177°C).

The safety valve can be run with one or two control lines, for greater operational flexibility. The valve can be remotely exercised using pressure applied through the second control line to help shift the valve. For deep-set applications, the Optimax model WUDP-10 valve provides the option of using a wireline-retrievable insert safety valve that operates on the tubing-pressure insensitive system principle.

A safety valve is a valve that acts as the protector of your equipment. Safety valves can prevent damage to your pressure vessels and even prevent explosions at your facility when installed in pressure vessels.

A safety valve is a type of valve that automatically actuates when the pressure of the inlet side of the valve increases to a predetermined pressure, to open the valve disc and discharge the fluid. The safety valve system is designed to be a fail-safe so that a wellbore can be isolated in the event of any system failure or damage to the surface production-control facilities.

In most cases, it is mandatory to have a means of closure for all wells capable of natural flow to the surface. The installation of a subsurface safety valve (SSSV) will provide this emergency closure capability. Safety systems may be operated on a fail-safe principle from a control panel located on the surface that was custom-built by PHC.

The SCSSV is controlled by a ¼” stainless steel control line that is attached to the outside of the well tubing string and installed when the production tubing is installed. Depending on the wellhead pressure, it may be necessary to keep as much as 10,000 psi on the control line to keep the valve open. PHC control panels feature the proven Haskel pump line that generates the required hydraulic pressure for optimal valve control.

The Halliburton NE™ tubing-retrievable safety valve (TRSV) is a single rod-piston non-elastomer flapper valve designed for general production with enhanced reliability and long life. The valve includes the non-elastomer hydraulic actuator design from the highly reliable SP™ line of safety valves. Along with the metal-to-metal (MTM) body joints and closure mechanism, the actuator places this valve in the premium category while keeping costs economical. The simple, compact design enhances the valve’s overall reliability and provides for trouble-free operation.

Surface Controlled Subsurface Safety Valve failure data from 14 North Sea fields have been collected and failure rates for the various valve types and makes calculated. Failure rates have been compared to well data in order to identify critical well parameters and give guidance to operators when selecting valves for new fields.

Finally, models are developed for calculating well safety and production availabilities. Input to these models is failure rates, testing and maintenance routines, frequency of other well service operations etc.

Most people involved in production of oil and gas from high pressure reservoirs will probably agree that the Down Hole Safety Valve is one of the most important components for controlling blowout risk. In particular this is the case offshore where one platform may be producing from more than 30 wells. In such situations it is very important to be able to shut off the wells with a down hole device if a hazardous situation should arise on the platform.

In spite of this importance, there are still endless arguments regarding what kind of safety valve to use, e.g. from which manufacturer, flapper or ball valve, or maybe to install two valves in series. No clear cut criteria for selecting valves for various types of fields and uses exists. The study documented this paper was aiming at recommending such criteria, based on an investigation of past safety valve performance in North Sea fields. In this area only surface Controlled Subsurface-Safety Valves (SCSSV) are used, and the study is therefore restricted to this type of valves.

The selection criteria that were sought, should reflect both well safety and production availability. Disregarding one of these factors will inevitably result in suboptimal solutions.DATA COLLECTION

To obtain a reasonably correct picture of past SCSSV performance, all major operators in the North Sea area were contacted, and asked to participate in the study by releasing their data regarding valve failure statistics and field parameters. Fortunately, most operators were willing to release their data, provided the information was published in a pooled manner. The information necessary wasValve type, make and dimensions

Field data (e.g. reservoir type, pressure, temp., H2S and CO2 content, GOR, oil gravity) From the 10 operators supplying data from a total of 14 fields, it was possible to obtain a sufficient amount of data for the following valvesWire line Retrievable (WR) valves:–

The safety valve lockout tool had parted downhole in the safety valve at 534 ft well depth. Video footage established that the ‘bean can’ mechanism (part of the safety valve lockout tool which keeps the flapper permanently in open position) had successfully locked out the downhole safety valve (DHSV). The sub-assembly housing on the bean can had fallen and was expected to be sitting in the 3.688-in nipple at 8155 ft.

PLUSCO 621-622 Safety Valve Sealant will improve the overall performance of the safety valve by insuring a continuous seal for extended operation. It eliminates line leaks, improves the hydraulic pump performance, maintains tighter seals and valve seating and reduces fluid friction in the system. The benefits of sealing, lubricity and operations efficiency are provided by PLUSCO 621-622 Safety Valve Sealant. Safety Valve Sealant will insure a continuous flow of the gas well without interruption or unnecessary shutdown.PLUSCO 621-622 Safety Valve Sealant is available in two grades depending on the severity of the leak in the system.

PLUSCO 621-622 Safety Valve Sealant is a high tech safety valve additive specifically designed for sealing hydraulic controlled surface or subsurface safety valves.PLUSCO 621 is designed for slow weeping leaks while PLUSCO 622 is for heavy pinhole type leaks.

8613371530291

8613371530291