drill string safety valve for sale

Packard safety valves are designed to either stab into the drill pipe or tubing at the rig floor or are used as part of the drill string to shut off a well kick. Use of these valves in the drill string enhances rig safety.

The Packard two-piece safety valve offers the convenience of a two-piece body for easy maintenance. Its full bore also allows the unrestricted flow of drilling fluid � reducing wear on critical parts while providing unrestricted access for downhole tools.

Packard International�s safety valves are built with enough length on each end to allow fully recutting the connections in the event of damage to the threads or shoulders where sealing takes place.

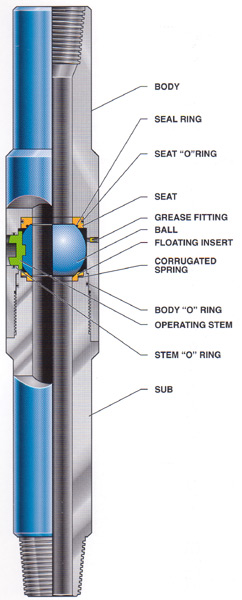

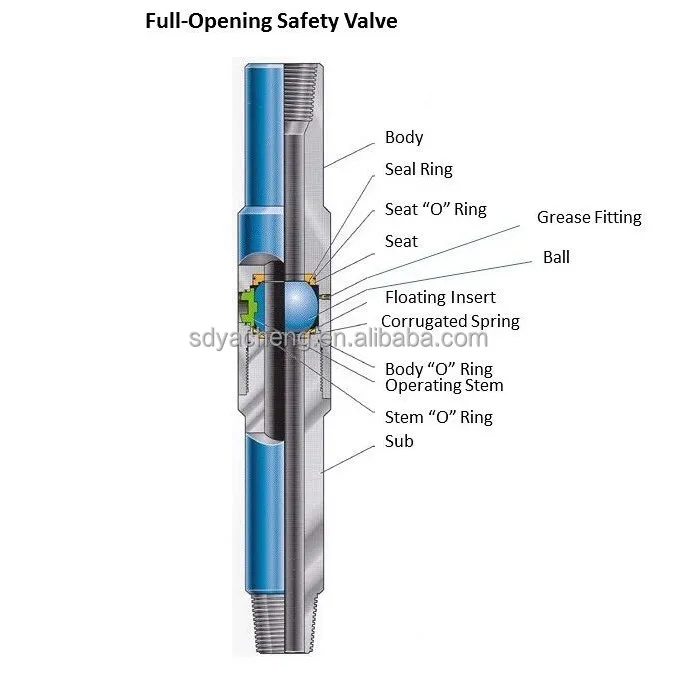

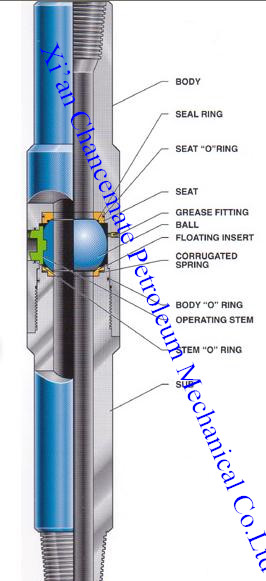

High and low pressure sealing is assured by the Teflon and metal sealing system of the ball and seats. The ball and lower seat float while the upper seat is fixed in the body. This floating/fixed design aids in low pressure sealing and enables the operator to pressure balance the valve under full rated working pressure.

Packard International�s safetyvalves are designed for even the harshest drilling conditions; however, it is suggested that parts most subject to wear and tear be replaced regularly.

For complete maintenance instructions and valve specifications, please phone 281-399-8771, e-mail support@packardint.com, or click the link below to download a PDF.

TIW is the original designer and manufacturer of ball type Safety and Kelly valves. Our strict adherence to API specifications as well as our own quality requirements ensures TIW valves are the highest quality valves in the market.

TIW Class I & Class II Kelly Valves may be utilized as a Drill Stem Safety Valve or as an Upper or Lower Kelly Cock and is designed to hold pressure from both directions.

TIW Kelly Valve Design and Quality System are certified by API.TIW Safety and Kelly Valves are also offered for H2S service, meeting all NACE standards. Standard Pressure rating is 10,000 PSI Test with higher pressure ratings available.

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale drill pipe safety valve on Alibaba.com. When you search for drill pipe safety valve and related items, you will be able to find many types of drill pipe safety valve varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of drill pipe safety valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

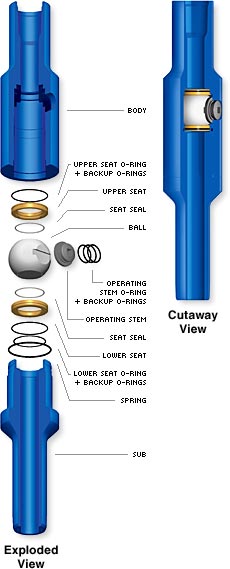

The WN-2 Ball Type Safety Valve is designed to be stabbed into the top joint of drill pipe or tubing at the rig floor and closed quickly in case a well kicks. Safety valves are not designed to rotate in the drill pipe string, rotate on a swivel or pull on a stuck string of tubing.

Like the kelly valve, the WN-2 Safety Valve is full opening. The ball-type design permits the valve to be compact, easy to handle, and yet have great strength. Standard test pressure is 10,000 pounds, but higher pressure ratings are available.

When ordering please specify threads, O. D. and I. D. WNCO SAFETY VALVES are available in virtually any size and configuration our customers may require.

Sub-drill exclusively represents Global Manufacturing Inc, an industry leading and world renowned US based manufacturer of Drill Stem Valves and Associated Products.

Global Manufacturingspecialise in the design and manufacture of a complete range of Drill Stem Valves, developed and engineered using FEA to be the highest quality and most reliable valve on the market.

Precision machined from the highest quality materials, Global Valves are competitively priced and reliable - designed to last the pace offshore in all types of well and operating conditions, including 20k designs for the next generation of drilling.

Sub-drill are the approved service facility for Global Manufacturing USA; we inspect, repair and test all types of Top Drive, IBOP’s, Full Open Safety, Kelly, Gray Type and Drop-In Check Valves to OEM standards. Sub-drill provides in-house inspection, repair, refurbishment and pressure testing facilities to the latest industry standards at its Aberdeen Westhill facility.

In addition to our in-house inspection, repair and test facilities, Sub-drill provide the means to test valves offshore using our compact portable Sub-drill DSV™.

The IBOP, also called Gray Valve or BVR, is a back pressure valve used in the drill string to prevent the well from flowing uncontrollably up the drill string. It is generally used in 2 ways:

Below the rig floor without a plug when connected in the drill-string. It can be left in the drill string as long as necessary to re-establish control of the well-pressure balance.

The RDCV, also called Dart Valve or a Back-Pressure Valve, controls backflow through the drill pipe during a kick or when tripping pipe into the hole against pressure. Check-valve compatibility should be checked with Kelly Cock free passage.

Full Opening Safety Valve (short for FOSV) is a ball type safety valve used to stop flow through the drill string when the drill string is being withdrawn from the well.

Our FOSV is dual body full-opening safety valve, so it does not interfere with the running of tools such as core barrels or survey instruments. It is designed to be stabbed into the top joint of drill pipe or tubing string at the rig floor and closed quickly in case a well kicks.

The ball-type design permits the valve to be compact, easy to handle, and yet have great strength. Standard test pressure is 10,000PSI, but higher pressure ratings are available.

M&M’s Top Drive Safety Valve Bottom Load™ lower valves have an extended pin nose profile that matches the mating ID profile of M&M’s Top Drive Safety Valve Bottom Load™ upper valves. These valve systems have the all-important, rig downtime saving, Bottom Load™ feature. When the time comes for scheduled routine maintenance, the lower valve only needs to be removed to allow quick and easy access to the upper valve’s internal components.

Along with its innovative design features and our CANISTER GUARD® technology, the Top Drive Safety Valve Bottom Load™ system allows for the quickest possible inspection and/or redress procedure. Since its inception over 20 years ago, M&M’s Top Drive Safety Valve Bottom Load™ system has saved countless hours of rig downtime.

M&M International is an original equipment manufacturer (OEM) of drill string and well control valves along with inside blowout preventers (IBOPs), crossover subs, swivels and other oilfield equipment.

M&M designs and manufactures the most efficient and user friendly drill string and well control valves on the market today. M&M incorporated their patented Canister Guard™ and Lite-Torc™ technology into the design making M&M Products the most reliable valve in the business.

Lite-Torc™ – improves the ability of valve so fitted to be closed under heavy flow at torque values manageable by one person with a standard 12” valve wrench. As well, once closed, well bore pressure can slowly be balanced by pump pressure to allow the valve to reopen with less than 30 ft lbs of torque.

M&M Internationals has been API licensed since 1992 and quality management system is well established and continually monitored for potential improvements. M&M is licensed under API Q1, and API Spec 7-1 and 7-2 for the monogramming of Upper and Lower Kelly Valves.

Full Opening Safety Valve (short for FOSV) is a ball type safety valve used to stop flow through the drill string when the drill string is being withdrawn from the well.

TIANHE FOSV is dual body full-opening safety valve, so it does not interfere with the running of tools such as core barrels or survey instruments. It is designed to be stabbed into the top joint of drill pipe or tubing string at the rig floor and closed quickly in case a well kicks.

The ball-type design permits the valve to be compact, easy to handle, and yet have great strength. Standard test pressure is 10,000PSI, but higher pressure ratings are available.

In 2006, Forum purchased the Baker SPD product line. Forum continues to manufacture the products formerly known as Baker SPD under the SPD name and offers a complete line of float valves, repair kits, and puller assemblies for a wide range of drilling situations and operating conditions. We are the premier provider of “Certified” drill pipe float valves that includes high- and low-pressure testing, serialization, and full material traceability, providing improved reliability and failure prevention.

High-performance drill pipe float valves are essential for consistent fluid control throughout drilling. Also known as non-return valves, this type of downhole safety valve prevents undesirable fluids from backing up into the drill string any time your crew is modifying connections.

Oteco valve bodies are manufactured for today’s increasingly harsh drilling environment. All valve bodies are cast out of ductile iron or a low-alloy carbon steel and are heat treated to a hardness equal to or less than 22 Rockwell C (≤ 22 Rockwell C 2 HR) to address the corrosive effects of hydrogen sulfide gas (H2S). Oteco’s integral valve bodies are manufactured from a one-piece casting and are not welded together the way some other competitors produce their bodies. This means that customers receive a superior and more reliable valve body.

All of Oteco’s plunger valves are machined from one solid piece of material to produce a more reliable float valve and reduce the risk of downhole valve failure.

All Oteco standard-service flapper valves are made of low-alloy steel and then case hardened for wear resistance, thus giving a longer operating life.

Inconel® springs come standard on all our valves. Inconel® springs are significantly more resistant to corrosion when compared with the standard service springs provided by most other manufacturers. Inconel® springs are also good for sour-gas (H2S) applications.

All Oteco drill-pipe float valves and replacement parts are manufactured to standard industry dimensions and interchangeable with other major manufacturer’s parts.

The Model F is a plunger-type float valve that provides a positive instantaneous shut off, providing constant fluid control while drilling. The Model F is a reliable and economical selection under standard drilling operations.

The Model FC Automatic-Fill plunger-type float valve incorporates a unique key assembly and slotted valve stem to hold the plunger open during run in of the drill pipe and allows the pipe to fill from the bottom, saving time, reducing mess, and avoiding hazards. The plunger is automatically released once circulation begins.

The Model FA Pressure-Monitoring plunger-type float valve has a special port running through the plunger of the float valve. This valve is used when monitoring the bit head for gas pressure and allowing differential pressure measuring when required. The port also permits partial automatic fill during run in.

The Model G is a flapper-type float valve that, when opened, offers an unobstructed bore through the float valve. The uniquely designed flapper closes rapidly to prevent shavings from entering the drill string when circulation stops and also assists primary BOP equipment in maintaining internal pressure control. The valve will fully open when the first joint is raised from the hole, preventing pulling wet joints.

The Model GA Pressure-Monitoring flapper-type float valve is indistinguishable from the Model G with the exception of a tungsten-carbide insert in the flapper valve. The insert has a quarter-inch orifice through the center that allows for differential pressure monitoring. The orifice also allows for partial automatic filling of the drill pipe during run in.

The Model GC Automatic-Fill flapper-type float valve incorporates a unique self-releasing key assembly that holds the flapper partially open during run in, allowing the pipe to fill from the bottom. This eliminates the need for filling the drill pipe from the top, saving time and money. The valve will fully open when the first joint is raised from the hole, preventing pulling wet joints while avoiding the environmental and safety risks related to having mud on the rig floor. The valve can be run with the automatic-fill option or in the standard, closed position.

The Model GCA Automatic-Fill/Pressure-Monitoring flapper-type float valve includes all the advantages of the Models G, GC, and GA. An unobstructed bore through the float valve, when open, permits automatic partial filling of the drill pipe from the bottom and measuring differential pressures when necessary.

Halliburton provides proven, high-performance tubing-retrievable and wireline-retrievable subsurface safety valves (SSSV) designed to reliably shut-in (fail safe) if a catastrophic event occurs, allowing operators to maintain safe operations.

8613371530291

8613371530291