drum safety valve in stock

Boilers are designed for a certain maximum operating pressure. If this pressure is exceeded, there is danger of an explosion unless this pressure is relieved. This danger is so great that it necessitates equipping all boilers with safety valves to maintain the boiler pressure within design limits. safety valve setting is a statutory requirement. as discussed above, there are safety valves. one is installed at super heater out let and other two are placed at steam drum . super heater safety valve is set at lower pressure than drum safety valve.

to set these safety valves boiler is light up . the safety valve to be set is kept on service and other two are gagged. pressure on the boiler is raised slowly as per normal operation procedure of boiler . fuel feeding rate is kept at minimum. the safety valve is required to lift and reset at desired pressure at per boiler pressure rating. accordingly it is adjusted to get the lift and reset pressure.

like this all the three safety valves are set. all the gagging are removed. percussion is to be taken during initial build up. the drum pressure gauge should be perfect and calibrated. if the safety valve does not lift beyond the set pressure then the pressure of the boiler is to be reduced and setting to be done again.

IF YOU LIKE THIS POST “BOILER STEAM DRUM SAFETY VALVE”PLEASE LIKE , SHARE AND YOU COMMENTS IS VERY VALUABLE SO PLEASE GIVE YOUR SUGGESTIONS IN COMMENT BOX please read once time if any mistake you find in this artical please suggest me through comment box or if this website contains all original article which are written by me if any article on this site find copyrighted please inform me through at joginder005@gmail.com……..THANK’S

The Consolidated 1700 series Maxiflow safety valves are field-proven and are designed to provide optimum boiler overpressure protection. Increases plant efficiency by reducing steam losses via improved seat tightness and rapid opening to full lift with rapid closing as vessel pressure is reduced.

The Consolidated 1700 series Maxiflow safety valves are used extensively in sub-critical, drum type boilers and super-critical, once-through boilers. Inlet pressure ratings from ASME 600 class thru ASME 4500 class.

We provide onsite safety relief valve diagnostic testing and repair services while helping you manage your overpressure protection assets for regulatory compliance.

Years ago, it was not uncommon to read news about tragic boiler explosions, sometimes resulting in mass destruction. Today, boilers are equipped with important safety devises to help protect against these types of catastrophes. Let’s take a look at the most critical of these devices: the safety valve.

The safety valve is one of the most important safety devices in a steam system. Safety valves provide a measure of security for plant operators and equipment from over pressure conditions. The main function of a safety valve is to relieve pressure. It is located on the boiler steam drum, and will automatically open when the pressure of the inlet side of the valve increases past the preset pressure. All boilers are required by ASME code to have at least one safety valve, dependent upon the maximum flow capacity (MFC) of the boiler. The total capacity of the safety valve at the set point must exceed the steam control valve’s MFC if the steam valve were to fail to open. In most cases, two safety valves per boiler are required, and a third may be needed if they do not exceed the MFC.

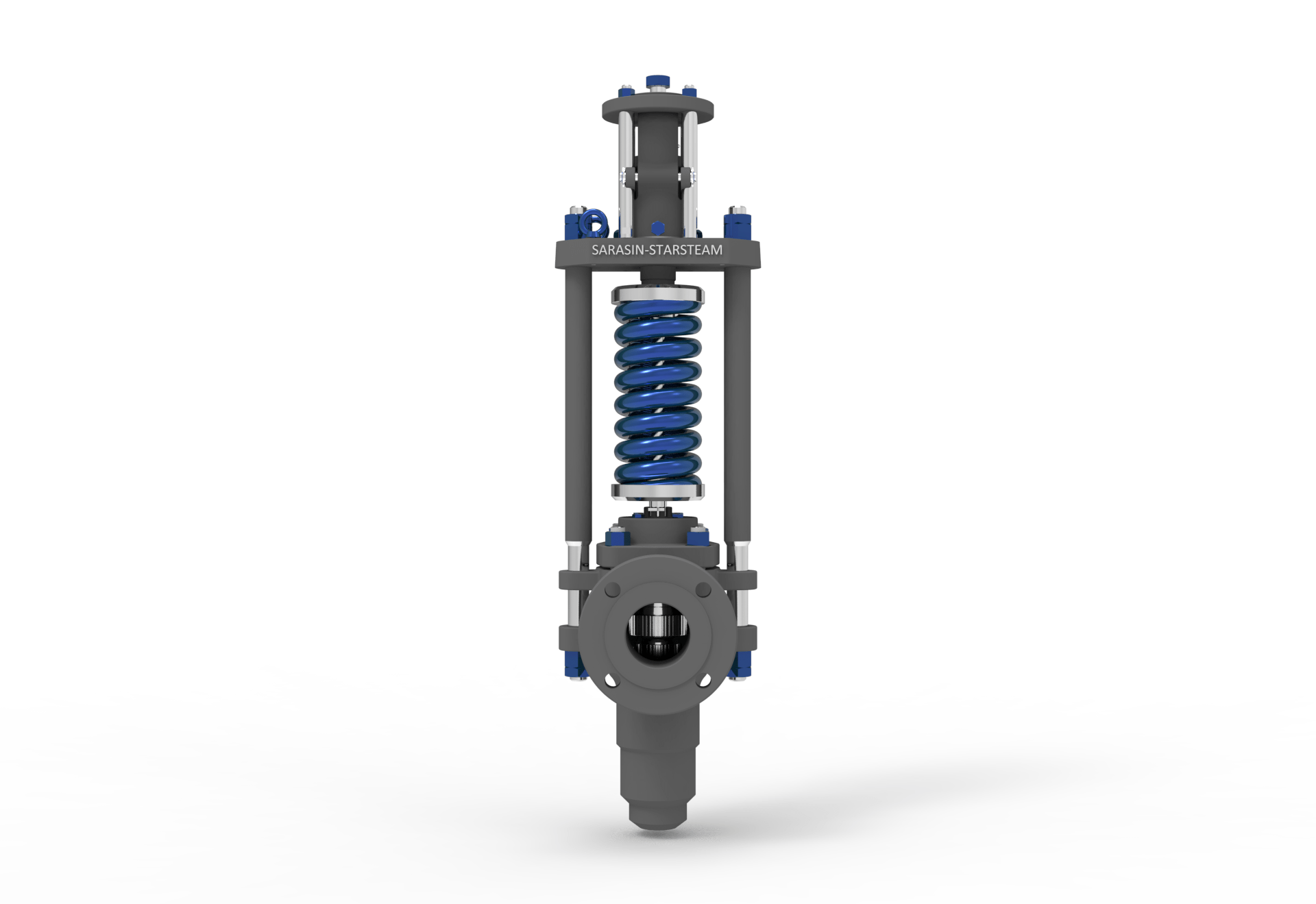

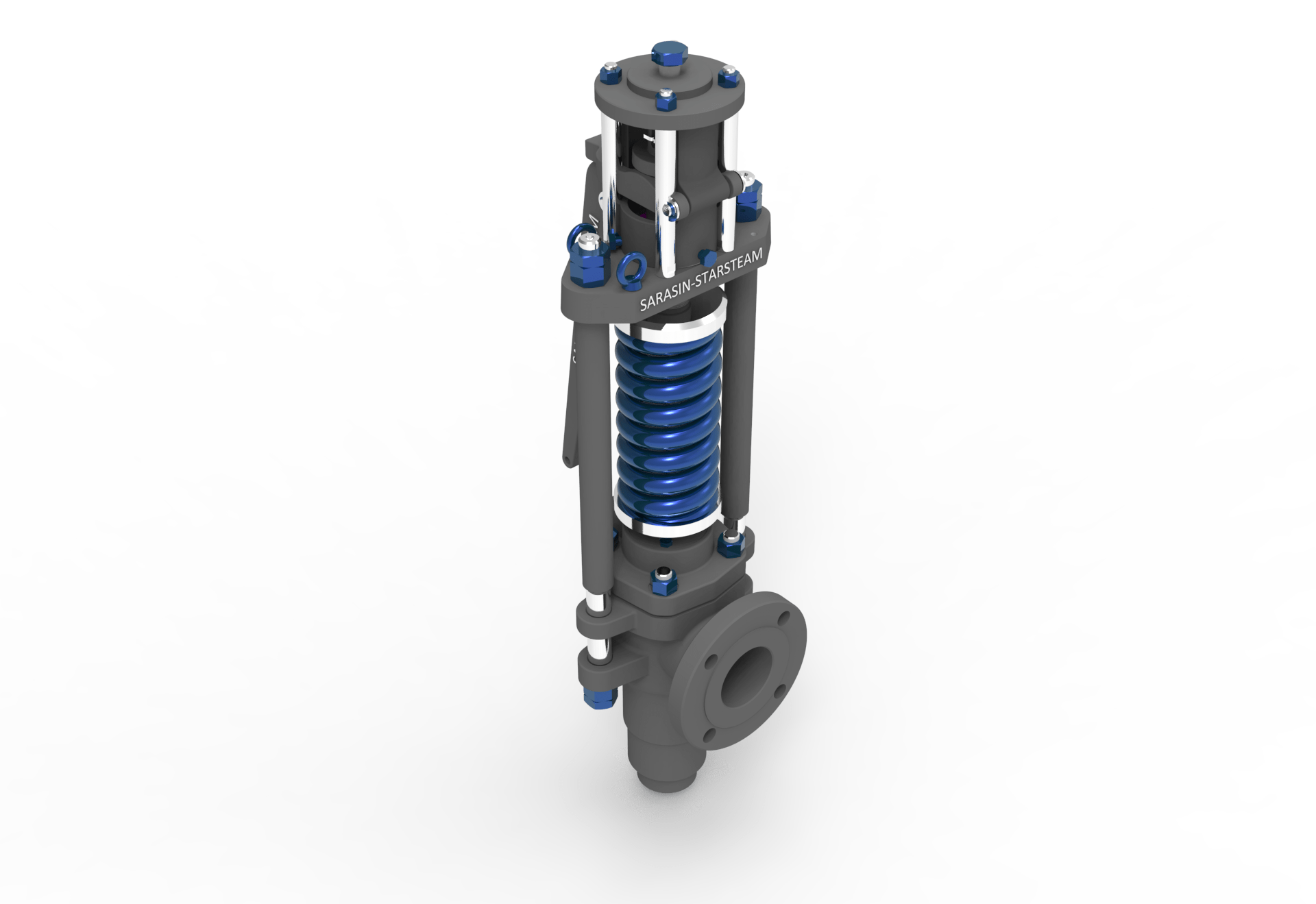

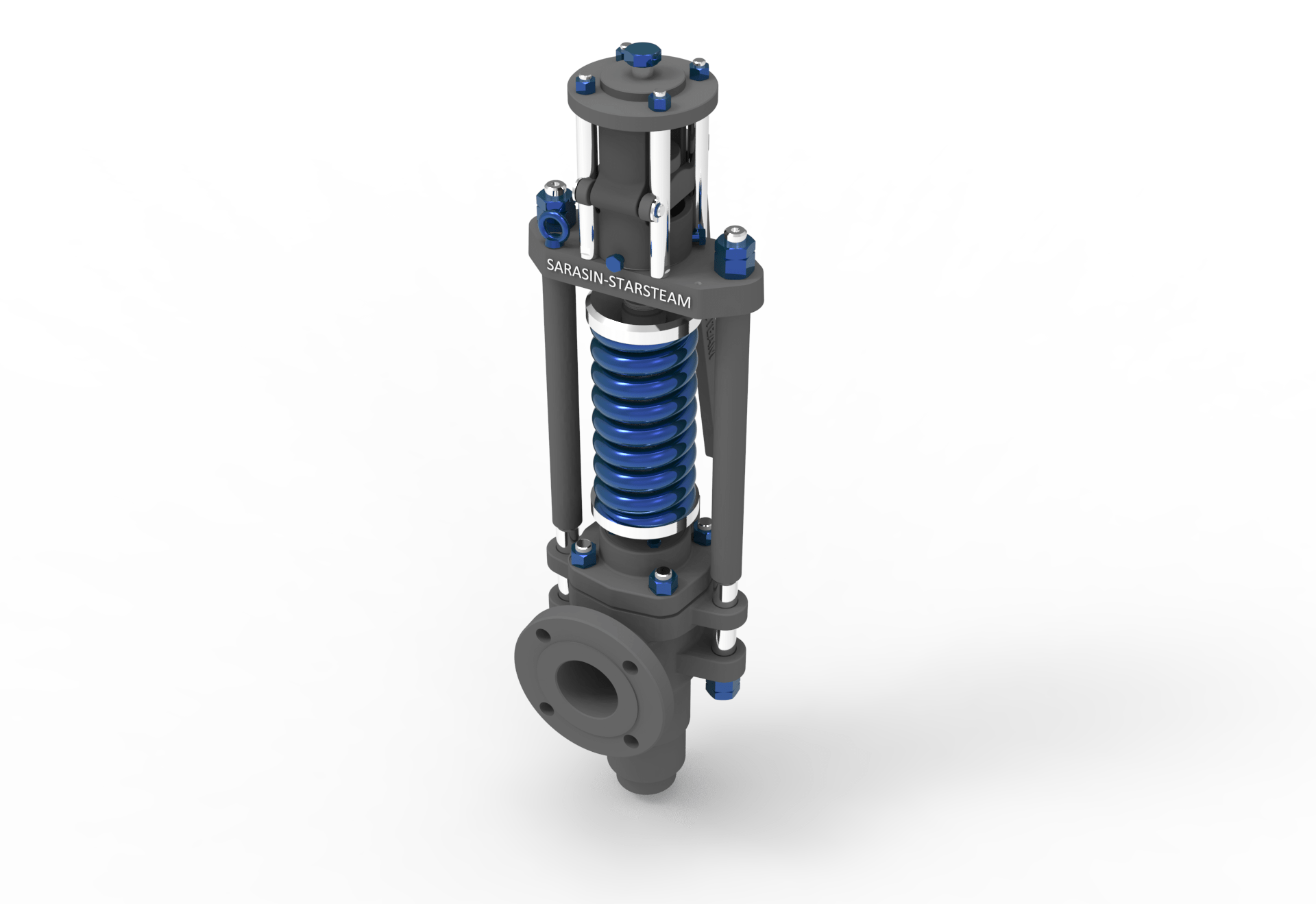

There are three main parts to the safety valve: nozzle, disc, and spring. Pressurized steam enters the valve through the nozzle and is then threaded to the boiler. The disc is the lid to the nozzle, which opens or closes depending on the pressure coming from the boiler. The spring is the pressure controller.

As a boiler starts to over pressure, the nozzle will start to receive a higher pressure coming from the inlet side of the valve, and will start to sound like it is simmering. When the pressure becomes higher than the predetermined pressure of the spring, the disc will start to lift and release the steam, creating a “pop” sound. After it has released and the steam and pressure drops below the set pressure of the valve, the spring will close the disc. Once the safety valve has popped, it is important to check the valve to make sure it is not damaged and is working properly.

A safety valve is usually referred to as the last line of safety defense. Without safety valves, the boiler can exceed it’s maximum allowable working pressure (MAWP) and not only damage equipment, but also injure or kill plant operators that are close by. Many variables can cause a safety valve on a boiler to lift, such as a compressed air or electrical power failure to control instrumentation, or an imbalance of feedwater rate caused by an inadvertently shut or open isolation valve.

Once a safety valve has lifted, it is important to do a complete boiler inspection and confirm that there are no other boiler servicing issues. A safety valve should only do its job once; safety valves should not lift continuously. Lastly, it is important to have the safety valves fully repaired, cleaned and recertified with a National Board valve repair (VR) stamp as required by local code or jurisdiction. Safety valves are a critical component in a steam system, and must be maintained.

All of Nationwide Boiler’s rental boilers include on to two safety valves depending on the size; one set at design pressure and the other set slightly higher than design. By request, we can reset the safeties to a lower pressure if the application requires it. In addition, the valves are thoroughly checked after every rental and before going out to a new customer, and they are replaced and re-certified as needed.

Automatic pressure relief ensures a safe workplace. No more worrying about pressure building up in your drums. These safety drum vents automatically relieve pressure between 3 and 8 psi (30 to 55 kPa). Vents are tested to allow 61 cubic inch (1 L) of water through a 3/8” (9.5-mm) pipe nipple in less than 6 seconds. Keep the vent in closed position to prevent flammable vapor from escaping. A built-in flame arrester will help absorb and dissipate heat for added safety. Vacuum relief is automatic on vertically installed vents and manual on horizontally installed vents.

Experitec is an authorized Anderson Greenwood™ and Crosby™ assembler and a National Board-Certified VR, Test Only, and ASME UV stamp holder. As such, we carry an extensive inventory of Anderson Greenwood and Crosby parts and assemblies right on the shelf. In addition, we have the ability to source pressure relief valves from a variety of manufacturers. This combination allows Experitec to repair all your pressure relief valves. Our vision is to serve our customers like no others. We can and will cater to your specific needs. Remember, don’t let the lack of a qualified PRV repair compromise the safety of your plant and your people.

Thermoglide design improves the gliding characteristics of internal parts thus enabling the valve to achieve its full lift and re-seat point within the fastest possible time

8613371530291

8613371530291