emergency safety valve pricelist

Relief and safety Valves are used in high pressure systems to control the pressure and keep balance of the system. The different between safety valves and relief valves is that the safety valves fully open or close under a certain pressure while the relief valves can open in proportion to the pressure in front of them. The safety and pressure relief valves are used automatically. They both operate under similar conditions. When the pressure builds up in a system, it has to be managed by releasing the material to flow through. These valves have a threshold pressure at which they open. The consolidated safety and safety relief valves comprise of a bonnet vent and bellow with springs.

The springs are set up for the threshold pressure and when the pressure exceeds the threshold, the spring is pushed into the bonnet vent and the bellow opens the valve. The Safety Relief Valves can be open and shut valves. They either open or shut off at any given pressure. This is mostly for the safety of an application not to explode under high pressure. The Pressure Relief Valve on the other hand releases the material after the threshold pressure, but not fully. If the pressure is slightly higher the threshold, then the valve opens slightly. If the pressure is very high above the threshold, it opens wider. It also functions in the same manner when the pressure drops down. The valve closes in proportion to the pressure. The safety valve shuts down at once only when the pressure is below the threshold.

Ready Stock of ASTM A351 CF8M Spring Loaded Safety Valve in wide range of Sizes, Stainless Steel Air Compressor Pressure Relief Valve Manufacturers In India

Relief Valves are designed to control pressure in a system While Safety Valves are used for controlling the pressure in a system they release pressure immediately in the event of an emergency or system failure

The Setpoint of relief valve is usually set at 10 Percent above working pressure limit while safety valve is usually set at 3% above working pressure limit.

If you are operating systems that can only be off for short periods of time, it is sensible to keep a spare valve to swap over and then the removed valve can be inspected and recertified.

Assured Automation"s FM Fire-Safe Thermal and Electro-Thermal ball valve and butterfly valve assemblies are designed to shut off automatically and control hazardous conditions. The heat actuated, U.L. listed thermal links automatically shut off or open the valve at predetermined temperatures. Ball and Butterfly assemblies are available with manual levers or gear operator which will allow the valve to operate manually at any time without affecting the fusible links or removing the spring loaded canister.

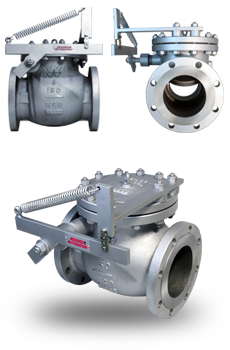

Assured Automation’s ESOV series ANSI flanged swing-check valves with fusible links are designed to provide a simple yet effective method of closing in an emergency or hazardous situation.

The valves are designed with an external spring load and held in the open position with the fire-sensitive fusible link. The valve will automatically close when the link melts due to fire or high temperatures. The external lever rotates the hinge pin which directs the disc into the flow of the liquid, gas or vapor.

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of pneumatic emergency shut off valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

Searching for pneumatic emergency shut off valve wholesale? Find these parts online at Alibaba.com. global wholesalers will provide you with any kind of pneum emergency off valve at favorable prices. Here you’ll find pne air components, filters pressure airators, pipe connectors of different sizes and shapes, pipesumatic andsolenoid valves with 2 to 5 ways and 2 to 3 positions, auto drain valves, brass pipes,ist other, like a compressor, evaporator, condenser coil and connector. Whether you’re looking for new or used equipment, the wholesale prices on China"s largest wholesale platform will prove meaningful. From theors of these parts and accessories, you can find what you need at our wholesalerersue. Alternaba,com"s wholesale store is the place to head when you need them. Find the gneget emergency.

Alibaba.com features a comprehensive range of high-quality, efficient, and durable pneumatic emergency shut off valve for distinct types of commercial and personal uses. Available in multiple variations and models, these products are ideal for all kinds of machinery and vehicle engines for optimal performance. The pneumatic emergency shut off valve varieties you can find on the site are made of sturdy materials that contribute to the long-lasting lifespan of the products and are unparalleled when it comes to offering flawless, consistent fuel flow to the engines. Grab these unique and robust pneumatic emergency shut off valve from the top brands and manufacturers in the industry for mind-blowing prices.Whether you are looking for perfect pneumatic emergency shut off valve to fit into your vehicle engine for smoother and consistent fuel flow or if you are looking for sturdy valves to fit into an irrigation system, heavy.

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale oil well safety valve on Alibaba.com. When you search for oil well safety valve and related items, you will be able to find many types of oil well safety valve varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of oil well safety valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

Use these valves for emergency relief where pressures must be relieved quickly to reduce damage that could result from overpressure in a system. Where the overpressure needs to be controlled more gradually ,such as in back pressure or pump bypass applications use our

Although the valve is typically installed in the position illustrated, it can operate in any position or orientation, vertical horizontal, etc as long as it can be easily accessed for making adjustments.

These valves do not carry the Canadian CRN or ASME approval stamp and should not be applied where this requirement must be met. However, the valves generally meet or exceed ASME design criteria with wall thicknesses that are much heavier than the minimums required. For an additional charge, valves can be ordered with material certs and with a certified hydro-test certificate and other tests to meet special documentation and acceptance requirements.

Avoid locating the valve where freezing can occur, and if unavoidable, take precautions to insulate or heat wrap valve and piping to keep from freezing.

Use these valves for emergency relief where pressures must be relieved quickly to reduce damage that could result from overpressure in a system. Where the overpressure needs to be controlled more gradually ,such as in back pressure or pump bypass applications use ourBack-pressure/Bypass valves which will reduce the probability of pressure spikes that often occur when relief valves are selected for pressure control applications. Standard metal seated valves meet ANSI/FCI Class IV seat leakage standards (0.01% of rated valve capacity, not bubble tight).

Although the valve is typically installed in the position illustrated, it can operate in any position or orientation, vertical horizontal, etc as long as it can be easily accessed for making adjustments.

Safety relief valve should only be used selectively where the materials chosen are compatible with the fluid used and will not cause corrosive buildup, crystallization or solidification in the close clearances between the piston and body bore, which could keep the poppet from opening freely. Use only clean, strained (#20 mesh min), or filtered liquids or gases so that the valve can operate without buildup of debris or solid matter which can cause the valve to malfunction. A basket strainer or high-pressure filter with the appropriate material and pressure rating can be purchased from Stra-Val.

Avoid locating the valve where freezing can occur, and if unavoidable, take precautions to insulate or heat wrap valve and piping to keep from freezing.

These valves do not carry the Canadian CRN or ASME approval stamp and should not be applied where this requirement must be met. However, the valves generally meet or exceed ASME design criteria with wall thicknesses that are much heavier than the minimums required. For an additional charge, valves can be ordered with material certs and with a certified hydro-test certificate and other tests to meet special documentation and acceptance requirements.

The American Wheatley Relief Valve series is designed to relieve pressure at a predetermined set in hot water heating systems. Intended for liquid systems, or emergency steam relief only. Constructed in accordance with ASME section IV, Latest Edition, rated for emergency steam discharge by National Board of Boiler and Pressure Vessel Inspectors. American Wheatley’s Relief Valve is Available in ¾” with male or female inlet, consult with our staff for availability.

safety valves, Safety Relief Valve, Industrial Safety Relief Valve, Safety Relief Valve Dealers, Safety Relief Valve Distributors, Safety Relief Valve Exporters, Safety Relief Valve Suppliers, Safety Relief Valve Manufacturers in india, Safety Relief Valve Price in India

safety valve, safety relief valve, pressure relief valves, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve

safety valve, safety relief valve, pressure relief valve, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions

We provide superior quality valves, industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves that are specially designed to offer high durability and optimum performance. Using materials like pure aluminum, cast iron and stainless steel trim these valves are made to high resistance to temperature and corrosion. Functionally different valves like Safety Valve, Safety Relief Valve, Pressure Reducing Valves, Breather Valves, Globe & Ball Valves, Pipeline Specialty Valves, Flush Bottom Valves and Float Valves are available with us.

Fluidyne carried out an extensive market research to manufature durable and effective safety relief valves, industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves that are highly suitable for most chemical, petrochemical, oil, pharmaceutical, phartilizer, power industries and more. These industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves have high reliability and are approved by factory inspectors, inspectors under Indian Boiler Regulation (IBR), B.V., Lloyds and Chief Controller of Explosives. Citizen Metal safety and relief valves are in used in above industries for over 50 years.Flanged Safety Relief Valves

Our range of small bore safety valves, industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves offer superior performance and maximum functionality. They are available in Screwed, Socket weld, Flanged Construction type or flanged-inlet, Screwed-outlet connection type. Their simplicity in construction makes them pretty cost effective and easy to use.

For Storage Tank, complete range of sizes :- 15 NB to 600 NB Flame and Detonation Arresters, Spark Arresters Free-Emergency-Conservation Vents Dip Gauges and Gauge HatchsVent nuts/Caps, Syphon bush, Fill caps, Lightning Arresters etc. Tyrus Valve, Vacuum Relief, Pressure Relief Valves. Available in : CS, CI, SS304, 316, AI etc. For more details on Tank Fittings, Flame / Spark Aresstors plz refer our section on "Safety Fittings"

Model PV - 1230 is one of our specially designed range of relief valves that has got connection flanged pallets of Al or Stainless Steel. This model comes with a tank accessory that is suitable for storage of chemicals and hydrocarbons. Model Pv 1230 is most suitable for low pressure and low vacuum operations.

Designed mostly like model PV 1220 our PV - 1240 range of vauts also offer high performance & durability. These efficient valves are commonly suitable for vacuum service. The disc available with these vaults is either weight loaded or spring loaded.

Safety Valves are designed and manufactured to meet the requirement of all a variety of applications as per API 526 and API 520. They also conforms to Standard VIII and the design requirement of Indian Boiler Regulations, they are of Full Lift type direct spring loaded, with a top guide, The full nozzle has the eliminating distortion of the seating surface, as body strain is not transmitted The Nozzle is made from a corrosion resistance stainless Steel material, When closed position, the fluid does not come in contact with the valve Body an therefore only subject to the outlet pressure which is very much lower pressure.

Similar to FTVC-520, but with closed bonnet & closed cap. Also available with same sizes and rating as FTVC - 520.Close Bonnet Safety Valve For Steam Application

Full lift safety relief valve, offers the combination of top guiding and unobstructed seat bore, producing a valve with maximum discharge capacity. Supplied with certificate confirming set lift pressure.

Tag : safety valves, Safety Relief Valve, Industrial Safety Relief Valve, Safety Relief Valve Dealers, Safety Relief Valve Distributors, Safety Relief Valve Exporters, Safety Relief Valve Suppliers, Safety Relief Valve Manufacturers in india, Safety Relief Valve Price in India, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions

Safety Relief Valves, Stainless Steel Forged Steel 304 Valve, Stainless Steel F321 Safety Relief Valves, F347 Safety Relief Valves, SS High Pressure Safety Relief Valves, Class 150, 300, 600, 900, 1/2 inch stainless steel Safety Relief Valves, 1/2" stainless steel Safety Relief Valves, 3/4 Size Safety Relief Valves, 4 inch stainless steel Safety Relief Valves, Industrial Safety Relief Valves, Stainless Steel 316 Safety Relief Valves Suppliers in India...Read more

Alloy Steel Safety Relief Valves, Chrome Moly Alloy A217 / SA217 Cast Valves, WC9 Alloy Steel Globe Valve, 4 Inch, 2500#, A350 LF3, A352 LC3, A182 F5A/F5, A217 C5, A182 F9, A217 C12, A182 F11, A217 WC6, A182 F22, A217 WC9, A182 F91, A217 C12A, 10 Inch, RF, WC9 Gate Valve, PSB, 12 Inch, 2500 LB, Alloy Steel Valves Dealers & Distributors in India.. Read more

Safety Relief Valves, Carbon Steel Safety Relief Valves, Carbon Steel Valve Material, ASTM A350 LF2 Safety Relief Valves, Carbon Steel ASTM A106 Safety Relief Valves, ASME B 16.10, ASME B 16.5, ASME B 16.25, ASME B 16.34 ASTM A105N Safety Relief Valves, Cast Carbon Steel Safety Relief Valves, API 600 Cast Steel Safety Relief Valves, Forged Carbon Steel Safety Relief Valves Exporters & Suppliers In India.. Read more

Hastelloy Safety Relief Valves, Hastelloy C276 Safety Relief Valves, Hastelloy C22 Safety Relief Valves, Hastelloy B2 Safety Relief Valves, Hastelloy C276/C22 Valves, ASTM B 435 Hastelloy X Safety Relief Valves, Hastelloy B2 Safety Relief Valves, ASME B16.34 Safety Relief Valves, UNS N10665 Hastelloy B2 Safety Relief Valves, UNS N10276 Hastelloy C276/C22 Manufacturer / Suppliers in Mumbai India. Read more

Wholesale Various High Quality Industrial Safety Relief Valves Products from Citizen Metals, Largest Suppliers of Alloy 20 Safety Relief Valves, Alloy 20 Safety Relief Valves Dealers, Alloy 20 Check Valve, UNS N08020 Alloy 20 Safety Relief Valves, Alloy 20 Safety Relief Valves Suppliers, Alloy 20 Safety Relief Valves Manufacturer, Alloy 20 Safety Relief Valves Manufacturers in India. Read more

We supply broad range of Nickel 200/201 Safety Relief Valves, Leading Suppliers of Nickel 200/201 Valves, Ni-200 Safety Relief Valves, Ni-201 Safety Relief Valves, Uns N02200 Safety Relief Valves, Uns N02201 Safety Relief Valves, Nickel 200/201 Safety Relief Valves Dealers, Safety Relief Valves Suppliers, Nickel 200/201 Safety Relief Valves Manufacturer, Nickel 200/201 Safety Relief Valves Manufacturers in India. Read more

we supply Monel 400 Valves with high quality and best affordable rate., Monel 400 Safety Relief Valves, Monel DIN 2.4360, 2.4375 Safety Relief Valves, Monel UNS N04400 Safety Relief Valves, Monel UNS N05500 Safety Relief Valves, Monel Safety Relief Valves, Monel K500 Safety Relief Valves, Monel 400 Safety Relief Valves Distributors in India... Read more

We specialize in the oil & gas industries and offer specialty Duplex Steel Safety Relief Valves, UNS S31803 Safety Relief Valves Suppliers in India, DIN 1.4410 Super Duplex Steel Safety Relief Valves, ASME B 16.10 UNS S32760 Safety Relief Valves, ASTM A351 Duplex Steel UNS S31803, ASME SA494 Duplex Steel UNS S31803, Duplex Steel UNS S31803 Class 900 Safety Relief Valves Exporters in India. Read more

Safety Relief Valves, 254 Smo Safety Relief Valves, Cryogenic 254 SMO gate valve, ASME B16.34 SS 254 SMO Safety Relief Valves, Stainless Steel 254 SMO Safety Relief Valves, ASTM A351 SS SMO 254 Safety Relief Valves, ASME B 16.10, ASME B 16.5, ASME B 16.25, ASME B 16.34, 254 SMO Industrial Valves, Stainless Steel 254SMO Safety Relief Valves Suppliers in India.. Read more

Safety Relief Valves, 904l Stainless Steel Safety Relief Valves, 904l Stainless Steel Industrial Safety Relief Valves, SS 904L ASTM A351 Safety Relief Valves, ASME B 16.10 Safety Relief Valves, ASME B 16.5, ASME B 16.25, ASME B 16.34, UNS N08904, 1.4539, BS 904S13, JIS SUS 890L Safety Relief Valves

Safety Relief Valves, Inconel Safety Relief Valves, Inconel 600 Safety Relief Valves, INCONEL WERKSTOFF NR. 2.4816 Safety Relief Valves, Inconel 600N06600 Safety Relief Valves, Inconel 2.4816 Safety Relief Valves, UNS N06600 Safety Relief Valves, Inconel 600 Safety Relief Valves, API 600/ BS1414, ALLOY 600 Safety Relief Valves, ASME B 16.5 Safety Relief Valves Dealers in India.. Read more

We are the one of the top most manufacturers of different types of Industrial Safety Relief Valves, We have a large inventory of Safety Relief Valves in a variety of options., Largest Suppliers of Titanium Gr2(B367 Gr C2) Safety Relief Valves, Titanium Gr3(B367 Gr C3) Safety Relief Valves, Titanium TA1, TA2, Titanium Gr.5, Gr6 Safety Relief Valves,Gr7 ,Gr12, Titanium TC4,TA9,TA10 Dealers in India.. Read more

Brass Safety Relief Valves, brass Safety Relief Valves price list in India, brass Safety Relief Valves 1/2, 1 inch brass Safety Relief Valves, brass Safety Relief Valves 3/4, brass Safety Relief Valves price list india, 3 inch brass check valve, brass Safety Relief Valves price list, 1/2 inch Safety Relief Valves, 4 brass Safety Relief Valves, 3/4 brass Safety Relief Valves, 4 inch brass Safety Relief Valves, 2 inch brass Safety Relief Valves Read more

Experience Of 50 Years In Copper Knife Gate Valve, We have a large inventory of Copper Safety Relief Valves, Copper 90/10 Safety Relief Valves, Copper 70/30 Safety Relief Valves, Copper Cu-Ni 70/30 Safety Relief Valves, Copper 90/10 Safety Relief Valves Dealers, Copper 70/30 Safety Relief Valves Suppliers, Copper Cu-Ni 70/30 Safety Relief Valves Manufacturer, Copper Cu-Ni 90/10 Safety Relief Valves Manufacturers in India. Read more

Tags : safety valve, safety relief valve, pressure relief valve, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch Dealers, Distributors, Exporters, Suppliers india, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions,

Tags : safety valve, safety relief valve, pressure relief valve, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions

With thorough understanding of this concerned industry, we have established ourselves as prominent manufacturer and supplier of a wide range of Emergency Pressure Relief Valve and Manhole Cover. Considering needs of several industries, we offer these valves in a range of sizes and other allied specifications. Used for numerousread more... Brochure

We are prominent in offering our customers Emergency Relief Valve, which is well recognized in the market for its technically appropriate designing. This reliable and high quality valve is utilized in conservation vents for excretion of sludge and rust load from compressed air systems. Consisting of high sturdy construction toread more...

We are offering Emergency Relief Items to our esteemed clients, under the wide array of humanitarian aid and development solutions. Being a reckoned name, we have assorted qualitative products under this category, such as blankets, hygiene kit, semi collapsible jerry cans, shelter kit, sleeping mat, tarpaulins and several otherread more...

In recent years, the demand forfire-safe fusible link shut-off valves in industrial processing has increased with the improvement of the operating environment for industrial production, the priority is to protect the workers’ lives and the property of owners. Especially under the environmental and safety regulations, THINKTANK’s sales offire-safe fusible link shut-off valves are increasing year by year. The unique design of Fire-safe valves ensures that valves close tightly to prevent leakage of media in the tremendous heat of an industrial fire. The use of heavy-duty valve bodies, bolts, and UL-approved fuse plates imported from the US adds a great safety factor in different details.

Ball valves are available with metal seals, RPTFE, TFE, and other high temperature resistant materials. All fire ratings can be ordered to meet the requirements of NACE MR-01-75.

The fire-safe ball valve is a unique design that combines a complex sealing design, in case to minimize medium emissions and tight shut off the leakage in a fire situation. This valve has the ability to keep a fail-safe valve position at high temperatures.

The fire-safe ball valves meet the requirements of main standards including API 607, EXES 3-14-1-2A, BS 6755-PT2, BS5146 APP.B, and BS 5351 Anti-Static, etc.

All THINKTANK fire safe valves are designed with a thrust bearing and gasket with carbon-filled TFE or a ball inside of the stem. This excellent sealing material can meet a wide range of operating conditions. Over 3inches fire safe ball valves, the valve stem is made of SS316 material, and it has a top and bottom stem to fix the ball.

When the fire safe ball valve exposes to high-temperature fire conditions, the soft seat material will melt while the resilient metal seat will compensate for the sealing to tight shutoff.

In the event of a fire, the process fluid is contained within the valve. If the heat of the fire thrusts the bearing into sublimation, the blowout preventer rod forms a metal-to-metal seal with the valve body. The use of standard carbon-filled TFE packing or a steel ball and spring design inside the stem effectively prevents the bonnet from sealing. The use of spring-loaded metal seat compensation makes the valve body seal stable and keeps the media from external leakage in intense temperatures.

THINKTANK’s fire safe ball valves as manually operated or automated valves have excellent performance, the valve body is designed with two-piece, three-piece flanged, or threaded ends.

Fire Safe 2-piece forged ball valve commonly used for the oil and gas industry, and body material available in carbon steel, stainless steel, and other alloy steel. Valve Size: ½” to 8″

When the media is liquid oxygen, liquid nitrogen, and other liquefied gases, the valve is at extremely cryogenic application, we need specially designed ball valves to meet the equipment for reliable operation, and minimal heat exchange between the fluid and the environment.

For most cryogenic liquefied gases, with cryogenic temperatures as low as -450F, the valve will operate hundreds of degrees Fahrenheit below ambient temperature. Therefore, our ball valves and bonnets need to be designed with thermal expansion in mind, not only by completely cleaning and degreasing all parts, but also by taking care that the bolts are spring-loaded, the balls are pressure relievable, and the seats have double seals.

At the same time, a special packing design prevents media leakage along the stem axis, and the packing gland compresses the packing to ensure a tight seal between the stem and the body. In extreme cryogenic conditions, we use a longer stem and design the packing gland to be farthest from the cryogenic temperature. The bonnet is bolted to the valve body and uses a locknut with a resilient washer to ensure a secure connection to the valve body.

A pressure relief hole is typically designed at the upstream end of the ball to prevent overpressure due to thermal expansion. Therefore, cryogenic valves have specific inlet and outlet ends, and we will indicate the flow direction on the nameplate and valve body.

In the cryogenic environment, moisture condensation will freeze on the surface of the ball or cause thermal contraction of the ball valve material, and the valve torque will increase sharply, so in the selection and calculation, the safety factor of torque should be considered so as not to cause too little torque of the actuator and not to open the valve.

Trunnion ball valves are widely used in natural gas storage systems, gas transmission, LNG, subsea refining, desalination CO2 services, and power generation applications.

When the ball passage is in the same direction as the pipeline, the valve is in the open state and the medium can pass downstream. When the ball passage rotates 90 ° with the pipeline, the valve is in a closed state, and the media can not pass.

Since the ball valve only needs closing by rotating 90°, so the ball valve has the function of a fast closing. It is easy to monitor the open or closed status of the valve by the indication of the handle or limit switch. Soft seat ball valves, which also have a tight seal for a long service time, can achieve zero leakage.

While the trunnion ball valve has all the advantages of a normal ball valve, its design features a trunnion fixed at both the top and bottom of the ball, providing a positive seal on the upstream and downstream seats. So regardless of pressure, double block and bleed, or double isolation and bleed function is possible.

This special design reduces the torque required for valve action and is more suitable for large bore and high pressure operation, making the trunnion design ideal for the oil and gas automatic industry.

The standard feature of emergency stem sealant injection allows the valve’s stem housing to be adapted to a grease fitting to inject sealant in case of emergency, providing protection against unplanned spikes in operating conditions.

The emergency sealant injection feature allows a grease fitting to be used at the end connection of the valve to inject the sealant. This will produce a positive seal in the event of leakage from the valve seat due to impurities or unexpected increases in operating conditions. Double Block and Bleed

This safety feature eliminates pressure buildup due to high pressure media trapped in the valve cavity, even when the valve is in the fully closed position.

According to API 607 fire-safe standard, there are secondary metal seat designs in trunnion ball valves. The secondary graphite body seals and flexible graphite packing respectively prevent fluid leakage through the body joints and stuffing box.

A vent port at the bottom of the valve releases any liquid trapped in the cavity of the closed valve body. A vent port at the top of the valve body cavity removes residual gas from the cavity of a completely closed valve body. Both play a critical safety role in a dual block and bleed and/or dual isolation and bleed valve configuration. Double Seals on Body Joints

An anti-static device ensures that there’s electrical continuity between the ball, the stem, and the body, so the sparks created by a lightning strike or static discharge won’t create sparks inside the valve. ISO 5211 Actuator Mounting Pad

In industrial process control, we will see many kinds of ball valves, in general, we are divided into two categories, floating ball valves and trunnion ball valves. This article will tell you when to use which type of ball valve, and what is the difference between them? Design differences

The floating ball is fixed to the valve body by a single stem only, and the ball is floating on the valve seat. Trunnion ball valves are connected and centered inside the valve body by a shaft/stem at the top and a shaft/trunnion at the bottom. Torque

In the floating ball design, the ball is pushed against the downstream seat by in-line pressure, resulting in tightness. When operated from the closed position to the open position, the ball is rotated against the in-line pressure (∆p) and the frictional force of the seat. In other words: the torque required to open and close the ball valve is caused by the line pressure and the nature of the valve seat. As the operating pressure (∆p) and/or valve size increase, the amount of torque required increases significantly. Especially when the seat is a metal seal, the torque can be very high.

Trunnion ball valves are designed with the ball fixed in the center, the ball is held between the stem and the trunnion, which is fixed at the bottom of the valve body. During operation, the inline pressure fits the seat tightly to the ball. Instead of relying on the inline pressure (∆p) and the seat to rotate, only the pressure from the seat to rotate is needed to achieve a tight close.

Therefore, the drive torque required for a trunnion ball valve is usually lower than that of a floating ball valve of the same size and pressure. For example, a DN250 trunnion ball valve has a much smaller actuator than the same DN250 metal-seated floating ball valve, it optimizing the overall package cost. In addition, the trunnion seat design has better stability, which makes it more suitable for extreme conditions, especially for high pressure service conditions.

Trunnion ball valves are more suitable for high pressure applications and larger pipelines than floating ball valves. Another advantage of the trunnion design over the floating design is that the trunnion usually includes a drain or bleed connection, making it suitable for use as a double safety device. It automatically acts as a relief valve whenever the pressure in the central cavity is higher than the spring force of the valve seat. When it happens, the seat spring is automatically released so that the excess pressure is discharged back into the mains. For these reasons, trunnion ball valves are commonly used in offshore and oil and gas applications.

Although trunnion ball valves require relatively much less torque than floating ball valves, this means that the cost of purchasing actuators is much lower. However, in terms of the cost of the ball valve alone, trunnion ball valves are significantly more expensive than floating ball valves, so as a professional manufacturer, we will be able to advise on the correct ball valve design when selecting and evaluating costs. Please do not hesitate to contact us if you have any questions.

8613371530291

8613371530291