evt safety valve testing pricelist

The Electronic Valve Tester, (EVT), is a digital computerized, hydraulic assisted device, designed to test and set safety/relief valves while in service. The EVT is portable and can be used under normal operating conditions without over pressuring the system.

Our Factory and National Board certified technicians, provide total safety/relief valve evaluation utilizing EVT technologies... at your convenience. The Electronic Valve Tester has been approved by the ASME for set point evaluation and or adjustment.

EVT service eliminates the need to overpressure the system for testing. Under normal operating conditions, we save test medium and unnecessary stress on the overall system.

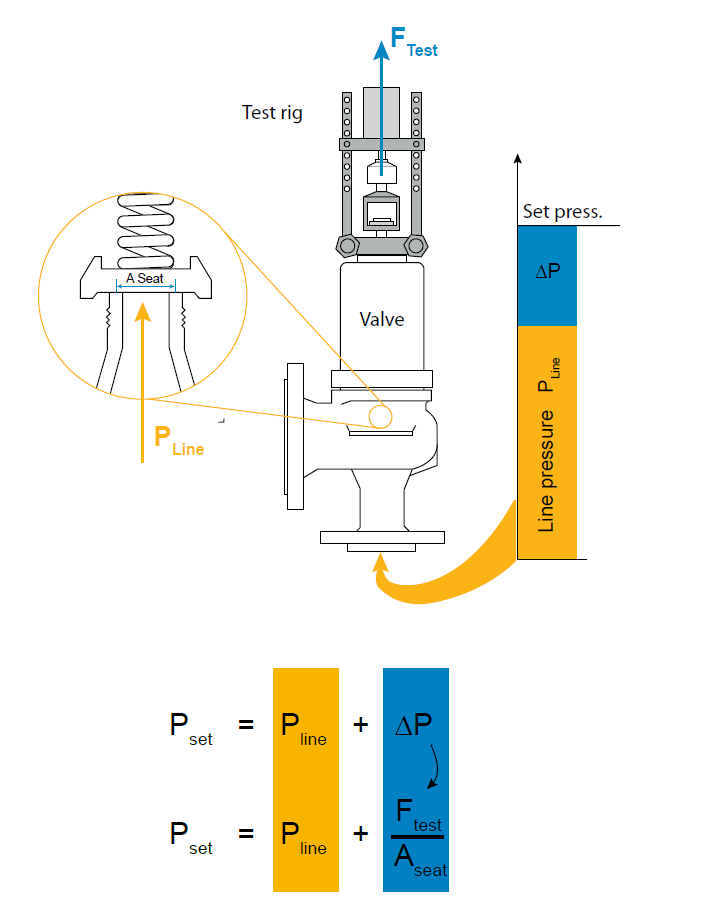

The EVT-Pro device simultaneously examines two critical variables of the relief device — the upward force applied to the spindle and the actual system pressure. Using sophisticated sensors, including an acoustic device, EVT-Pro testing accurately determines the pressure relief valve’s set pressure. It can also immediately sense and automatically close a relief device should it remain open during a test – a unique safety feature built into the software and hardware.

Stainless Steel Safety Valve is a product used as a safety mechanism that is deployed in applications to prevent them from bursting under pressure. These valves are normally set at a pressure which is 10% above the working pressure of the system. This is referred to as the set pressure, at which the oozing of the steam starts. The Stainless steel air safety valves are fitted with the pipelines and that is how it is installed. When the pressure goes above the threshold level, the valve opens up and relieves the system of pressure preventing damage. With the system pressure reaching blow off pressure the safety valve opens to its full lift to discharge full capacity.

The safety pressure relief valves are used in industries involving many chemical, oil, and gas plants. They ensure efficiency and safety but they’re susceptible to leaks. In case of a leak in Ss safety relief valve, systems become over pressurized leading to their failure. Leaking pressure relief valves can’t regulate the overall pressure within the pipelines. When a valve is leaking, shutting down the system forms the first thing we should do. After that, you need to determine the cause of the leak after which necessary repairs need to be done. To prevent future leaks, a leak detection and repair (LDAR) program is also implemented by the industries.

The Stainless steel safety relief valves form the crucial pieces of safety equipment that is used in pipeline systems and industries. It should’ve no margin for error and thus needs to be regulated regularly. You need to know when to replace or repair it. The safety relief valves need to be repaired every three to five years but it should be tested every 12 months meanwhile. Preventive measures are the best way to extend the life of your valves is through preventative maintenance. Keep checking your valve for leakage after discharge and test it with Electronic Valve Testing (EVT) services.

ASME stands for American Society of Mechanical Engineers (ASME) is a group that assigns codes to different materials used in industries. It produces approximately 600 codes and standards that cover many technical areas. ASME safety relief valve is one such standard valve used in industries for pipelines and plumbing materials. When kept in very good condition with regular repairing the relief valves can last up to 30 long years but it is very rarely possible. In general, the Stainless steel safety exhaust ball valves need to be replaced or repaired every three to five years because they might cause leakage and failure.

Are you looking for ss pneumatic safety valve dealers in the middle east and Asia? Find very few but genuine stockist of stainless steel air safety valve who offers various sizes at the cheapest price in GCC countries

The air safety valves come with a lot of advantages including easy machining. It is easy to use, repair and works great for a good amount of time without any problems. However, the valves have some drawbacks on their side as well. Some of these are: –

Choose from the list of verified a351 cf8 304 spring loaded safety valve stockists in the United Arab Emirates before ordering, compare response times and prices of cf8 stainless steel pressure safety valves in the Bahrain

Stainless steel SA-351 CF8 comes under the category of type 304 Stainless Steel that offers a range of austenitic chromium-nickel alloys with good strength and ductility. Such a steel is used in the A351 Cf8 304 spring loaded safety valve. CF8 is used for good cavitation resistance and is used primarily for water handling. Cf8 stainless steel pressure safety valve also is a subtype of the same type of steel. The valves range from low end to high end prices. They are available in Indian markets at prices ranging from ₹1,500 to ₹6,600. It can be easily replaced in up to 15 minutes of time and once fitted, they’re good to go.

Control Valve Testing is the best way to make sure your current system is performing to an optimal standard. If you’re curious about where your valves are falling short or how you can improve their performance, Pioneer has the solution to get your safety relief valves where they need to be. At Pioneer, we provide specialized equipment to help your pressure relief valves adhere to required standards and certifications. The EVT-Pro from GE offers cutting-edge testing, diagnostics, and reporting for your valves for comprehensive evaluation. The EVT-Pro works for all brands of pressure relief valves.

The Electronic Valve Tester, (EVT), is a digital computerized, hydraulic assisted device, designed to test and set safety/relief valves while in service. The EVT is portable and can be used under normal operating conditions without over pressuring the system.

Our Factory and National Board certified technicians, provide total safety/relief valve evaluation utilizing EVT technologies... at your convenience. The Electronic Valve Tester has been approved by the ASME for set point evaluation and or adjustment.

EVT service eliminates the need to overpressure the system for testing. Under normal operating conditions, we save test medium and unnecessary stress on the overall system.

The valve controls filling of a tank to an adjustable level. The altitude pilot is fitted on the main valve at the bottom of the reservoir. The pilot is connected to the reservoir level through a sensing line (sensing line not included). This valve can be used instead of a float controlled valve when a non intrusive control pilot is required. In many cases installation of this valve is simpler compared to a float pilot valve. The on-off function means the reservoir can be intermittently supplied from a pump-ing station or fire protection tank.

8613371530291

8613371530291