fire safety valve fusible link free sample

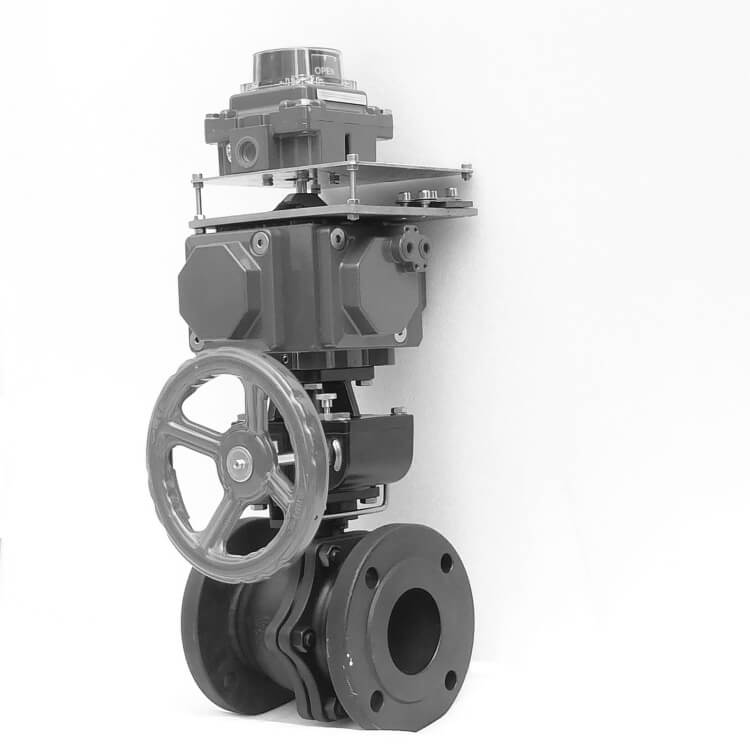

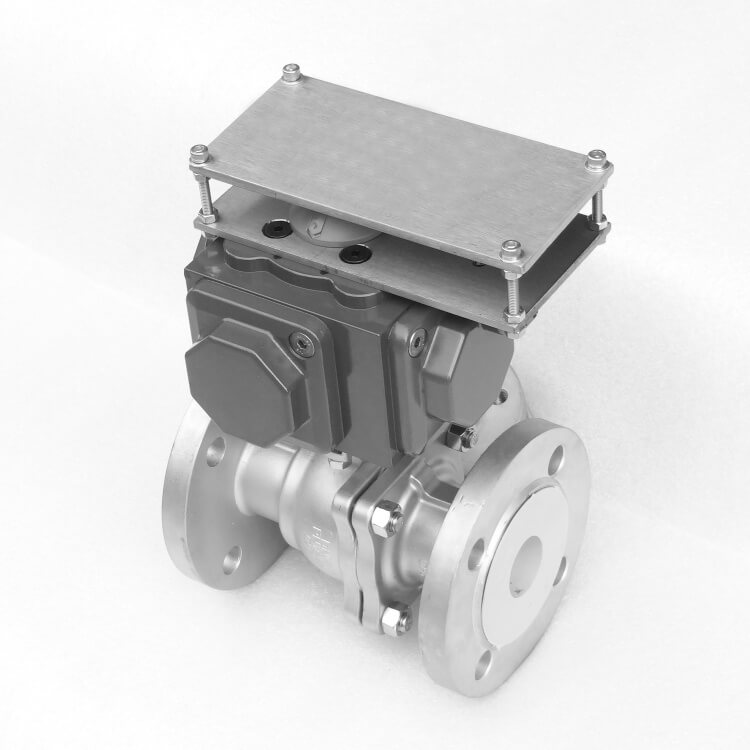

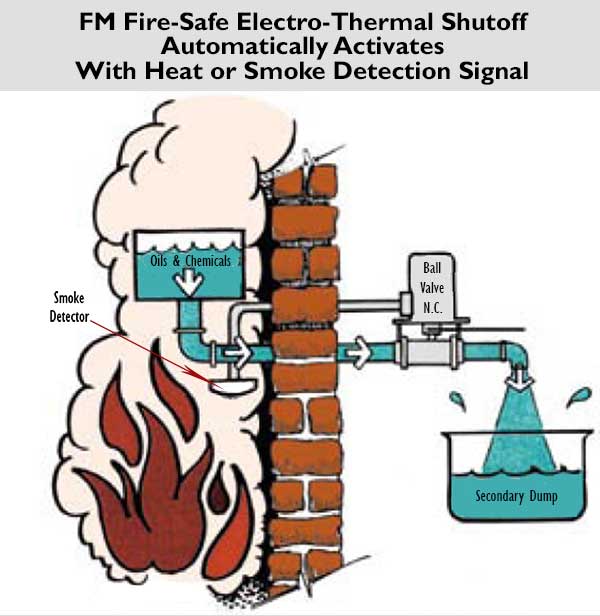

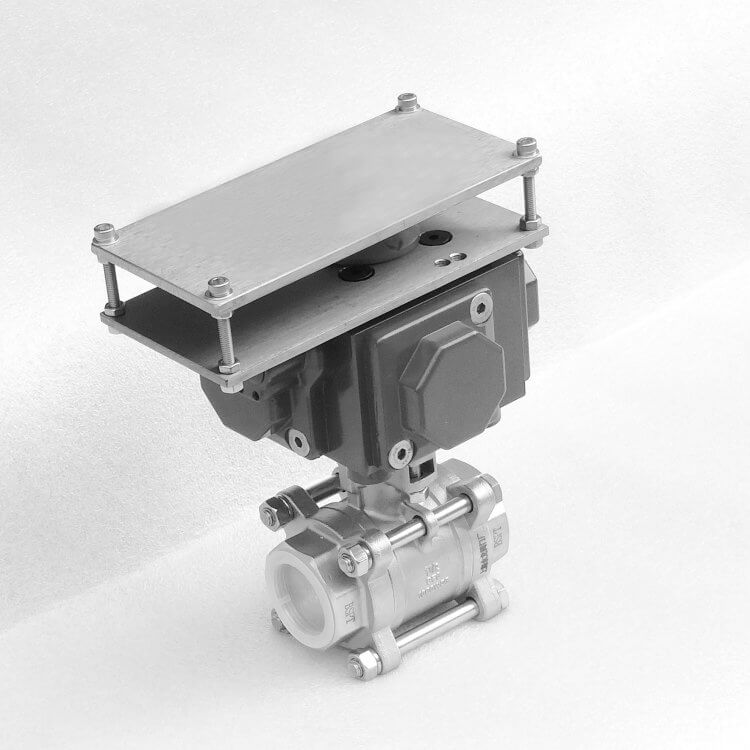

Assured Automation"s FM Fire-Safe Thermal and Electro-Thermal ball valve and butterfly valve assemblies are designed to shut off automatically and control hazardous conditions. The heat actuated, U.L. listed thermal links automatically shut off or open the valve at predetermined temperatures. Ball and Butterfly assemblies are available with manual levers or gear operator which will allow the valve to operate manually at any time without affecting the fusible links or removing the spring loaded canister.

A fire-safety shut-off valve, also known by thermal shut-off valve or simply afusible link valve, is a safety device designed to provide automatic valve shut-off in the event of a fire. Fire-safety valves of this type are designed for facilities that utilize flammable or toxic gases and chemicals in their production or for fuel systems of all types.

The fusible link is an FM and/or UL approved two-part linkage held together by a specialized heat-sensitive solder. These link(s) hold the fire safety valve open by keeping tension on a spring pack through a trigger assembly.

A fire safety shut-off valve is comprised of five main components – API 607 fire-safe valve, spring pack, mounting hardware, trigger assembly, and fusible link. The last four of these components work in unison to close the API 607 valve should a fire be detected within a facility.

The fusible link portion is the linchpin of the assembly and keeps the fire safety valve open by keeping tension on a spring pack through the trigger assembly. When a fire breaks out, the link separates when its rated temperature is met, releasing the spring pack and allowing it to close the valve.

The API 607 standard is a specification for the fire testing of quarter-turn valves. For fire-safety valve with fusible links, this means that the valves have a primary drop-tight seat, typically made of TFE, along with a secondary seat made of metal for isolation in a fire. The secondary seat is coupled with graphite seals for further protection. This means the top works of the shut-off valve can be paired with any quarter-turn API 607 fire safe valve – ball valve, butterfly valve, or plug valve.

Fusible link fire-safety valves are used in a variety of industries within an organization’s overall fire safety system for widespread fire protection. Most modern facilities have at diesel generators and day tanks that that requires this type of safety valve at a minimum. Other locations where flammable or toxic media are part of the production process, this valve type is placed at strategic locations throughout facilities including storage tanks, pumps, entryways into a building, and at key piping junctions. Entryways into buildings are especially key so that have employees, customers, and patients have as much time for notification and evacuation as possible.

A fire safety valve should be used as a safety precaution on any system that utilizes flammable or hazardous media. Designed to save lives and enable quick resumption of operations after a fire has been handled, fusible link assemblies are necessary for the safe daily operations of many commercial operations, plants, and manufacturing facilities. Many of these operations will find that insurance for their business is not available without a fire safety valve with fusible link.

BI-TORQ has been designing this type of assembly for over two decades. Let’s have a conversation about your fire safety needs and how our products can provide safety for your workers and operation. Contact us for more information on fire safety valves with fusible links, or to discuss any of our wide range of valve solutions.

All of our links are 100% original manufacturer parts from Ansul. Links ordered will come dated for the current year; however, on occasion we will have pre-current year links available, options will vary per availability.

The AP-C Style also commonly called the ML Fusible Links are available for individual purchase or in packages of 10 (besides the 500 degree Fusible links). The SL Style also commonly called the K links are available for individual purchase in packages of 25.

Ansul® is a global premium brand of Tyco Fire Protection Products. Ansul special hazard fire protection products are designed and manufactured to strict standards and tested under the scrutiny of national and international independent testing laboratories and approval agencies.

Ansul fire protection products were introduced to the marketplace in 1939 featuring the first cartridge-operated, dry chemical fire extinguisher. As technology changed and dangerous new hazards emerged, Ansul product engineers worked hand-in-hand with many industries to protect their people and property from fire. Today, the Ansul Fire Technology Center and Center of Excellence houses one of the most extensive fire research and testing facilities in the world. No other fire protection brand is supported by such extensive broad-based research and test facilities with so many scientists and engineers devoting 100% of their time preparing for the fire protection and safety needs of the future.

Every year, the Ansul Fire School trains hundreds of customers from around the world in the basics of hands-on firefighting with portable and stationary fire equipment using a variety of fire extinguishing agents. Since 1940, the school has trained thousands of first responders from high hazard/high risk industries such as aviation, mining, oil & gas, chemical, utility, fire service, and metal processing.

Authorized Ansul distributors regularly attend intense product training programs where they are instructed and tested in the design, installation, and service of Ansul fire suppression equipment. This continuously develops an experienced global network of authorized distributors who are supported by dedicated field-sales representatives and a professional technical and customer services staff.

Guide to OSVs - Oil Line Safety Valves: this article describes check valves and fusible link oil safety valves used on oil piping at heating appliances as both a fire safety device and to assist in oil burner servicing.

We explain the purpose of OSVs, which way to turn the OSV or oil line safety valve to open or close it, and we describe common oil line valve installation or use mistakes.

How & Where do We Install a Fusible-Link Firomatic™ Type Oil Safety Valve? This article series explains the installation & use of OSBs, or Fusible Link Oil Safety Valves. We describe and explain the differences in function and use among fusible link fire safety valves (OSVs) like the Firomatic®, vacuum operated OSVs like the Webster OSV and Suntec PRVs, oil line check valves, Tiger Loop and other oil system air removing devices, and oil delay valves or quick-stop valves that are also referred to as oil safety valves.

We explain where each valve is installed and what it does. We include oil safety valve and check valve troubleshooting advice, and we describe defects in heating oil piping & control valves.

The OSV or oil safety valve controls flow of fuel oil to the oil burner of oil-fired heating boilers, furnaces, and water heaters. This inline oil valve is intended to close automatically and thus stop the flow of oil in the oil line in the event of a fire.

Some suppliers use other names for this valve including the "Firomatic" valve (R.W. Beckett) or the "Oil Safety Valve OSVA-38" (Capital City Tool, Inc.).

Fusible Fire Safety Valves are designed to reduce fire damage by shutting off the flow of oil from the oil tank in the event of a fire. These valves conform to UL/ULC 842 and are listed in the US and Canada. They are required by code in residential oil heating installations in conformance with NFPA 31. - R.W. Beckett [4a]

Because the valve includes a fusible link (a lead or other soft metal core), in event of a fire the fusible link melts and the internal spring pushes the valve stem down, closing the valve and stopping oil flow.

Sometimes additional stop valves or OSVs may be installed at other locations (such as at the outlet of an above ground oil storage tank), but the critical location is at the oil burner since that"s a more likely location at which a fire may occur.

Watch out: the Firematic™ fusible-link automatic oil line shutoff valve (photo at left) should only be present on the oil supply line. We explain below

that installing an OSV on the return line of a two pipe oil system can lead to disaster. Instead, where it is necessary to prevent leakage from the return oil line during oil burner servicing we can install a simple one-way check valve on the oil return line (if the oil burner"s fuel unit manufacturer permits.)

Our photo at below left shows an example of a Firematic™ safety valve right at the oil burner. Synonyms people use for this valve include OSV, fire safety valve, oil line valve, Fire-o-Matic valve, Fusible link valve, oil line shutoff valve, oil safety valve, and Fireomatic valve.

In particular, the OSV shown here is installed between the oil filter canister and the fuel unit intake port. That means that it would be impossible to service the oil filter without spilling heating oil unless the service technician finds another oil line shutoff valve somewhere between the oil tank and the inlet side of the oil filter.

With the shutoff valve between the filter canister and the oil burner (above right), changing the oil filter in the canister will require the service tech to go to the more distant oil tank to find and close a valve in that location (if one is even present).

The technician moved the Fire-o-matic OSV to its proper location at the inlet side of the oil filter, and he also installed a Firomatic oil line check valve between the oil filter and the oil burner.

This is an important fire-safety detail as in event of a fire a closed valve on the return line (if it closes before the OSV on the supply line) could cause blowing seals on the oil pump or a blown oil line fitting, spewing fuel oil over the building fire.

In sum, the proper place for the fusible link oil valve (Fire-o-Matic Safety Valve™ for example) is on the oil supply line just before the inlet to the oil filter canister (red arrow, below left), not between the canister and the oil burner as shown at below right (orange arrow).

Regarding "the best location of an oil filter", NFPA 31 (2011): 7.5.8, for indoor tanks up to 330 gallons, requires that a thermally activated shutoff valve be placed inline as close as practical to the outlet from a tank and that a proper filter or screen be installed downstream and WITHIN SIX INCHES of the required thermally actuated valve. If it"s required in the code, it doesn"t have to "the best" - it just has to comply with the code.

With respect, Firebear, it is a fundamental error to suggest that "complying with code" is all that we need to think about in building and mechanical systems. Building codes specify the minimum requirements for acceptable practice. Often there are powerful reasons to do a better job than the bare minimum that"s required.

Many oil heat technicians sensibly want to install a fusible-link oil supply line valve at the oil burner, not only because this makes servicing the oil burner easier but because it also recognizes that the most-likely location of a fire is at the oil burner rather than possibly at a more distant oil storage tank.

The photograph above shows the right location for this safety device: at the input end of the oil filter. This permits the service technician to conveniently turn off the oil supply inorder to change the oil filter cartridge.

The writers of NFPA 31 (2011) 7.5.8 as specified above were focused on safety including wanting to avoid oil spills from the tank, but they might also have recognizede that putting an oil filter at the oil tank protects the oil line (between tank and oil burner) from sludge-clogging.

In our OSV photos below, the first photo (below left) shows the oil line safety valve in the OPEN position - oil will flow when the threaded portion of the valve shaft extends fully up through the rotatable knob pointed to by my pencil.[Click any image to see an enlarged version. Thanks to reader Bernie Daraz for pointing out the need for these two photos]

In our heating oil line valve photo at above right the valve has been manually CLOSED - no oil will flow. The threaded valve stem has disappeared down into the valve body and has shut off the valve and oil flow.

Watch out: if (for example in case of a fire) the fusible link inside of an OSV has melted permitting the spring to close the valve, then from outside the valve may look as if it is in the open position - the threaded stem will still be poking out - but the valve has snapped and closed internally. Most likely you"ll know this also because there will have been a fire or other horrible event that melted the OSV fusible link.

Watch out: A simple oil line shutoff valve may not be a fusible-link safety valve. The simple shutoff valve might be any plumbing valve that can manually stop oil flow in the line, but it is not a safety device.

Make sure you"ve installed a fusible-link safety valve at each location where it"s most needed - at each oil burner. Even when one of these valves is installed at the oil tank the proper place for this protection is on the fuel oil supply line

In the event of a fire, if the return oil line valve closes before the supply line oil valve your oil burner pump may burst the oil line or it may cause a fuel pump gasket or seal to fail, leading to uncontrolled oil flow and perhaps worse, spray heating oil everywhere, possibly feeding the building fire.

Thanks to Dave Ferris for this fire safety tip and thanks to reader Rick Johnston for adding clarification. (Note that not oil burners use both an oil supply and oil return line between the oil tank and oil burner.)

Watch Out: If the oil line fire safety valves are missing or are not at the right location, we recommend immediate installation of a Fire-o-matic™ type oil line safety

Recommended (red arrow, photo above left): an automatic oil line shutoff valve on the oil supply line right at each and every individualoil burner: (a type that will shut off oil supply to the heating equipment in the event of a fire, such as a Fire-o-Matic™ valve) is shown in our photo at left.

By every oil burner, we mean for example that if your heating system and also your hot water heater each has its own oil burner then each burner should have an oil safety valve. (As in our photo above left).

A common but poor practice is to install an oil valve just at the oil tank or perhaps installing a single oil safety valve at the oil burner for the heating boiler but omitting the oil safety valve for the oil fired water heater in the same building.

A second oil line shutoff valve on the oil supply line at the oil tank (photo above right) is ok as long as you have also provided the first oil safety valve at the oil burner(s).

Some service technicians install a second oil safety valve at the oil tank or at another remote location away from the oil burner, such as at the building wall where an outdoor oil tank line enters the building, or right at the oil tank (photo at above right - this oil tank valve is leaking).

This second valve is helpful if it becomes necessary to replace the oil line between oil tank and oil burner. Although our photo above shows a fusible link oil valve at the oil tank, the oil line shutoff valve at the oil tank or at a location remote from the oil burner or other more likely fire sources can be a normal plumbing stop valve.

However a common exception we see in the field is an OSV at the oil burner and a second OSV (or perhaps a simple shutoff valve, not thermally linked) at the oil tank end of the oil line.

The concern is that should a fire occur in the building, and should an OSV on the oil return line close before the OSV on the supply line, the fuel unit may over-pressurize the oil lines, causing a burst oil line that then sprays high-pressure oil into the fire, increasing its size and spread-rate.

Use an oil line check valve instead. Or if the heating equipment manufacturer recommends against using a check valve in the oil piping system (Suntec prohibits, Webster recommends) then leave it out.

Our photo (left, red arrow) illustrates this hazard: you will see fusible link safety valves on both the oil feeder line (blue arrow, left side of photo before the oil filter canister) and the oil return line (red arrow, right side of the photograph).

Unlike a fusible link OSV that shuts in response to high temperature to provide fire protection at the oil burner, a vacuum operated OSV opens only in response to a "sustained vacuum" created at its outlet end when the oil burner"s fuel unit pump is drawing oil from the supply.

Vacuum-operated safety valves offer protection against oil line leaks and against overpressure conditions on the supply side of the fuel unit. They are not a fire-safety valve.

If two oil lines are used to supply an oil burner, (a supply and a return) install an oil safety valve or OSV or fusible link oil line shutoff valve only on the oil supply line at the oil pump on the oil burner.Do NOT install an automatic oil line shutoff on the return oil line between the oil burner and the oil tank.

If a protection against oil back-flow at the return line is a concern, and if the manufacturer recommends it, use a check valve instead. Check valves like this one permit oil to flow just in one direction. They do not close down in event of a fire. Installed on the oil return line a check valve permits oil to flow from the oil pump in one direction only: back to the oil tank.

The Firomatic® oil line valve can be installed in ANY position - (vertical, horizontal, upside down) at least that"s what we were taught and what we have seen - the valve is spring loaded.

In a fire the fusible link, a lead core, melts at 165°F and a spring in the valve assembly snaps the valve shut to assure that the heating system does not feed oil to a building fire. It has to work in any orientation.

This list provides some of the companies produce fusible-link inline oil safety valves (OSVs). The footnote links point to the companies" contact information in our REFERENCES section, but generally you would purchase an OSV from your local heating equipment supplier or plumbing supplier.

AFL Industries, AFL OIL STOP VALVE PRODUCT BULLETIN [PDF] AFL Industries, 1101 West 13th St., Riviera Beach FL 33404 USA, Tel: 561-844-5200 includes OSV installation instructions for the contractor.

Bursey, Charles, "The Oil Safety Valve (Service)", Charles Bursey, Sr., Fuel Oil News, February 2006 (Still trying to get the full article - October 2008 - DF) Charles W. Bursey Sr. can be reached at F.W. Webb Co. www.fwwebb.com/

Cleanburn Energy CLEANBURN MULTI-OIL FURNACE OPERATORS MANUAL [PDF] (2009) Clean Burn Energy Systems, CLEAN BURN, INC. 34 Zimmerman Road Leola, PA 17540 U.S.A. includes Oil Safety Valve Installation Instructions

R.W. Beckett (U.S. & Canada) Firomatic Fire Safety Valves Beckett Corporation produces /distributes a wide range of oil burners & oil burner accessories * equipment including the oil safety valve (OSV) referred to as Firomatic® fusible fire safety valves, oil line check valves, and fusible link thermal switches

Fusible fire safety valves are designed to reduce fire damage by shutting off the flow of oil from the oil tank in the event of a fire. These valves conform to UL/ULC 842 and are listed in the U.S. and Canada. They are required by code in residential oil heating installations in conformance with NFPA 31.

All[Firomatic® fire safety] valves are embossed with the direction of oil flow and include unique part number identification ring on each valve. The seal stem uses a double seal washer/o-ring system with high grade Viton® equivalent materials suitable for No. 2 fuel oil, kerosene, and jp to 205 biodiesel blend.

Oil under pressure or vacuum is supplied to the inlet of the PRV valve. Vacuum is required at the outlet of the PRV valve to open it and to allow oil to flow. When a burner starts, the pump will supply the vacuum necessary to open the valve. Any leak in the system which prevents vacuum from being exerted on the outlet port of teh valvewill prevent oil from flowing.

ISP Automation, Firomatic Globe Type Oil Line Valves & Lever Type Fusible Link Control Valves: ISP Automation, Inc., 1035 Old Georges Road, North Brunswick, NJ 08902, Phone: 866-383-3481, FAX 866-383-3482, Email: support@ispautomation.com http://www.ispautomation.com/

Webster "Service Technician"s Handbook, Webster Fuel Pumps & Valves" [handbook]. Webster Fuel Pumps & Valves, Capitol City Tool, Inc., http://www.websterfuelpumps.com/ , Division of Capital City Tool, Inc., Op. Cit.

Webster, OSV SERIES OIL SAFETY VALVES DIMENSIONS & SPECIFICATIONS [PDF] Fuel oil safety valves, Webster Fuel Pumps & Valves, web search 10/12/2011 original source http://www.websterfuelpumps.com/pdffiles/osv1.pdf

Webster, "Dimensions & Specifications, OSV Series Oil Safety Valves, OSVA 38, OSVA 50", Webster Fuel Pumps & Valves, (1980), Op. Cit. retrieved 2/24/2014, original source: http://www.websterfuelpumps.com/pdffiles/osv1.pdf

The current fusible link valve product properly named Firomatic is so widely also called "Firematic" and "Fireomatic" that we include those terms to assist readers in finding this information. Who manufactures the Firomatic fusible link valve? R.W. Beckett. Who manufactures vacuum-operated OSVs? Webster & Suntec (the PRV). We explain the differences among these products in this article series.

RW BECKETT RECALL for FIROMATIC 1/2" FEMALE PIPE THREAD FUSIBVLE SAFETY VALVE [PDF] P/N 12130 - the stem may not travel far enough to shut off the flow of fuel if exposed to trip point temperature. Posted until 4/1/2017, retrieved 2019/10/09 original source: https://static.globalindustrial.com/site/pdf/RW_Beckett_Firomatic_Female_Pipe_Thread_Recall.pdf

Excerpt: Recently, we became aware of a design deficiency in our ½” ‘Firomatic’ Fusible Safety Valve part number 12130. This bulletin covers ONLY the ½” FPT version p/n 12130, previous p/n B200F.

Under certain conditions, if the valve is exposed to temperatures exceeding the handle’s temperature rating and the valve ‘fires’ or actuates, the stem may not travel far enough to properly seat the valve and shut off the flow of fuel. This could result in a dangerous situation if there is a ruptured fuel line downstream of the valve. There have been no reports of this situation arising, but the potential for this issue to occur does exist. This does not affect the valve’s operation when used as a manual shut off valve.

The current design of the 12130 – ½” FPT valve and handle assembly was in production prior to R W Beckett’s acquisition of the Firomatic® product line. We have been unable to determine exact dates for any changes made to the design by previous manufacturers. Therefore this bulletin covers all Firomatic® ½” FPT valves, whether using our part number 12130 or the obsolete part number B200F, used by Highfield Manufacturing. Suspect valves can be identified by the name ‘Firomatic’ cast into the body of the valve. See illustration below.

A re-design of the 12130 valve will be available pending agency approvals and manufacturing process lead times. We are anticipating the re-designed valve to be available by January 1, 2017.

RW BECKETT RECALL for FIROMATIC 1/2" FEMALE PIPE THREAD FUSIBVLE SAFETY VALVE [PDF] P/N 12130 - OLDER COPY - the stem may not travel far enough to shut off the flow of fuel if exposed to trip point temperature. Posted until 4/1/2017, retrieved 2019/10/09 original source: https://static.globalindustrial.com/site/pdf/RW_Beckett_Firomatic_Female_Pipe_Thread_Recall.pdf

It might matter tremendously which way your OSV or oil safety valve is installed and in any event we ought to follow the manufacturer"s instructions including the flow arrow.

Those Webster OSVs include an internal valve that is designed to OPEN in RESPONSE to the FUEL UNIT OPERATION. So if the valve is installed backwards that feature will not work and the fuel unit may not pump oil properly to the burner nozzle.

Fusible Fire Safety Valves are designed to reduce fire damage by shutting off the flow of oil from the oil tank in the event of a fire. These valves conform to UL/ULC 842 and are listed in the US and Canada. They are required by code in residential oil heating installations in conformance with NFPA 31.

All valves are embossed with the direction of oil flow and include unique part number identification ring or each valve. The seal stem uses a double seal washer/ o-ring system with high grade Viton® equivalent materials suitable for No. 2 fuel oil, Kerosene and up to 20% Biodiesel blend.

I have shut off at the tank that is pointed in the correct direction and a second shut off at the burner end that is pointed in the wrong direction. it works properly as a shut off but will it work propoerly incase of fire? if it doesn"t matter then whats the purpose of the arrow?

Watch out: That"s because in the event of a fire a lead core in the valve is intended to melt to allow the valve to close - to stop feeding oil to a possible building fire. So if the valve is jammed it"s unsafe.

My concern is the stem does not go back into the valve or come out of it any further than it currently is no matter which direction I turn the valve or how many turns I make. Since the valve does not STOP turning in either direction, I"m concerned the valve is faulty.

If the stem pokes up out of the valve handle you"ve screwed the valve "down" and it is "open" to pass oil. Remember that these valves are threaded opposite of most others.

The knob on my OSV does not tighten up no matter how many times I turn it in either direction. The threaded stem in the center is protruding out about 2mm so I"m not sure if the valve is fully opened or closed. Is there a fix for this or do I need to replace the OSV?

If you have a fusible link valve that doesn"t seem to turn off you might try tapping the exposed end of the valve stem. I have found a stuck, or slow to close OSV on a few rare occasions. A gentle tap, not hard enough to damage threads, loosens it after which I open and close the valve a few times to convince myself it now moves freely. A burr on the brass interior or more likely internal sludge or debris could be the culprit.

Because at the oil burner the OSV is likely to be used at least once a year during service, that"s a good opportunity to discover if the valve is not closing fully.

In my opinion painting a fusible link is potentially unsafe - paint may interfere with mechanical operation of the valve. Most likely the manufacturer will agree, though they may not have imagined that event.

there must be an exception to the rule. my firematic valves open counter-clockwise and close clockwise and are definitely firematic valves because of their construction. they are just like the photos above but turn in the opposite direction you describe

Also, how do you recommend trouble shooting this? There are several valve one at each end of the supply line and one before the tigerloop that I could close for a few hours and see if it solves the problem (that would atleast narrow it down to a few fittings)

On a manual 1" fireomatic valve where the bonnett section joins the valve body, is that a brass on brass fit or is there suppose to be an o-ring or gasket? Does the OEM (Fireomatic) permitt valve disassembly for installation purposes? Thanks.

Mike I"ve installed these valves but have not tried disassembling one. If your unit is from Beckett, who currently provides the Fireomatic oil safety valve as well as the "New England Safety Switch" that uses a similar mechanism, then you might give them a call to ask.

Is there a inspection protocol for these valves like Morrison has on there fusible link valves (some quarterly inspections some yearly) and are they fine to use on gasoline lines I see only oil mentioned.

Watch out: do not use an oil line safety valve in ANY application other than those listed by UL and by the manufacturer - in this case, on heating oil supply lines.

Continue reading at OIL LINE SAFETY VALVE TURN DIRECTION to OPEN or SHUT or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

OIL LINE SAFETY VALVES, OSVs at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Note: appearance of your Comment below may be delayed: if your comment contains an image, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

[1]AUDELS OIL BURNER GUIDE, INSTALLING, SERVICING, REPAIRING, [PDF online copy of this book] Frank D. Graham, Theo. Audel & Co., New York 1946, 1947, 1955 (out of print, copies occasionally available from antique book dealers and on EBay). Use THIS LINK to read a free online copy of this helpful classic textbook.

[17] Newmac Furnaces & Boilers, "Installation, Operating, and Service Manual, Oil Fired Boiler Model NBR-2001 NBR 2002", (2007) Newmac Manufacturing, Inc., Debert Air Industrial Park, Lancaster Crescent, PO Box 9, Debert, Nova Scotia, BOM 1GO Canada, Tel: 902-662-3840, retrieved 2/23/2014

Thanks to Rick Johnston for pointing out that the more likely cause of a fire safety valve in the return oil line is a burst seal on the fuel unit 4/6/2009

Thanks to reader Bernie Daraz for suggesting the need for clear photographs illustrating the OSV or oil line safety valve in the open and closed positions. Personal correspondence 2/15/2013.

Thanks to reader T.R. for suggesting clarity on where oil safety valves should or should not be installed and for discussing the proper hook-up location for the Tigerloop and similar oil line prime protection & air removal devices. April 2011.

Thanks to reader Anonymous by request 2/23/2014, for requesting clarification of the safety hazards involved in placing an OSV on the return line of a two-pipe oil system.

Q3: How long is your product warranty?All valves from THINKTANK are covered with a 12 Months warranty from the date of installation or 18 Months warranty from the shipment date, whichever comes earlier.

Q5: What is your hot items?The most popular are globe type control valves, self-operated pressure regulating valves and other valves made of special materials. Both aluminum bronze, duplex steel materials and other special steel can be customized. We provide confidential production agreements for many brands and distributors, which can replace the valves on-site FISHER, FLOWSERVE, KOSO, MASONEILAN and other international brands.

A crucial component in any fire protection system our customized fusible link shut-off valves (also referred to as “thermal shut-off valves”) are ideal for any pipeline handling flammable liquids. With OSHA, Factory Mutual (FM) and insurance companies increasingly requiring that automatic shut-off valves be used in these applications, the need for our product is greater than ever.

Our complete line of API 607 certified quarter-turn valves suit a wide range of applications. Carbon and stainless steel ball valves are available in 1/4” through 6” sizes with ANSI flanges and NPT, socket weld or BSP ends. Fire safe high performance butterfly valves come in 2” through 24” sizes.

One of the more recent developments in industrial tools to prevent fire is the introduction of fire safety valves. These valves are designed to prevent a fire from spreading if the fuel valve gets damaged or causes a leakage.

A valve is a device that adjusts, directs, or controls the flow of a fluid by opening, closing, or partially blocking various passageways. Valves are technically a type of fitting but are usually discussed separately. In an open valve, fluid flows from higher pressure to lower pressure. The simplest kind of valve is simply a freely hinged flap that drops to obstruct flow one way but is pushed open by fluid flowing the opposite way. This ancient valve is called a check valve, as it stops or "checks" the flow in one direction. Modern valves may regulate pressure or flow downstream and operate on sophisticated automation systems.

Valves have industrial applications for controlling processes, residential uses such managing water flow to dish and clothes washers and taps in the home. They are found in almost every industrial process, including mining, water and sewage processing, power generation, food manufacturing, processing of oil, gas and petroleum, chemical and plastic manufacturing, and many other fields.

Fire-safe valves are spring-loaded valves that are thermally actuated. In case of fire, they close automatically and stop the fuel flow. The fuel flow from the crankcase of the engine and the reserve oil supply gets hindered, thus minimizing the chances of leakage.

Spring-loaded valves help with preventing the flow of fuel such as oil, gas, petrol, and other combustibles, and are useful and effective against any damage. The benefits of using fire-safe valves in a system are the protection of human life, lower insurance rates, and the protection of equipment and the building.

It is because of these benefits that the use of these valves is highly recommended and appreciated. These days, many companies offer an extensive range of fire-safety valves to provide protection even in high temperature and high-pressure conditions.

A fire safety valve aims to keep ignitable fluids away from a flame. These valves close when exposed to heat, separating a flammable liquid from the heat source. They close in the midst of overheating of the pipeline, brought on by fire or similar events. The obligation to use fire safety valves is subject to any tenets, regulations, and laws concerning the unique methodology, plant, pipeline, or vessel.

Fire-safe ball valves use a combination of a floating ball, graphoil seals, and metal-to-metal seating to provide tight shut-off while preventing external stem leakage. In normal working conditions, the ball rests against two seats, ensuring bubble-tight closure. When the valve is exposed to a temperature above the limits the seats can withstand (for example, +450°F), the seats become deformed and are subject to extrusion. When the seats have been completely destroyed, the ball in the valve will come to rest firmly against the end cap, producing a metal-to-metal closing. Stem seals, which have high temperature-resistant properties, further restrict leakage in conjunction with a blow-out-proof anti-static stem, so that the flammable fluid stays separate from the heat source that may ignite it.

A fire-safe valve may also be made up of four main mechanisms: a spring pack, a trigger assembly, mounting hardware, and a fusible link. The components work in unison to close the valve should a fire be detected within a facility. The fusible link is the key part of the assembly. It keeps the valve open by maintaining tension on a spring pack through the trigger assembly. When a fire breaks out, the fusible link separates once it is heated to a certain high temperature, which releases the spring pack and allows it to close the valve.

A fire-safety valve with fusible links has a primary drop-tight seat, usually made of TFE, along with a second seat made of metal for isolation in a fire. The secondary seat also has graphite seals for further protection. This means that the shut-off valves can be paired with any quarter-turn ball valve, butterfly valve, or plug valve.

This article presents an understanding of fire safety valves. For more information on related products, consult our other guides or visit the Thomas Supplier Discovery Platform to locate potential sources of supply or view details on specific products.

Overview of Fusible Link Assemblies Automatic shutoff in case of fire or exposure to elevated heat conditions Used in process lines to contain the media in a safe location or in fire suppression systems Used with API 607 ball and butterfly valves (1/4” through 24” sizes) For pipelines conveying flammable media in either liquid or gas form Valve can be operated even while spring pack is armed Remote shut-off options Torque output options to 21,000 inch pounds

Specialty Safety Products: Fire Safe Valves Applications and Industries Served Tank Farms Biodiesel, Ethanol and Alternative Fuels Petrochemical Oil and Gas Pipelines Boiler Systems Paint and Toxic Chemicals Hospitals/Generator Systems To meet insurance, FM or OSHA requirements Release of fire retardants (Fail OPEN) ANY plant with flammable liquids or gasses

Main Features Automatic shut-off in case of fire API 607 fire safe design/approval on all valves Full FM approval Ball valves from ¼” through 4” with NPT, socket weld or 150# flanged ends Butterfly valves from 2” through 24” in lug or wafer style connections Valve can be operated even while spring pack is armed Heavy duty all stainless steel arming plate Patented clock spring design Industrial-style ball and butterfly valves in carbon steel or stainless steel with multiple seat options

Specialty Safety Products: Fire Safe Valves How fire safe fusible link valves work Fusible link The spring pack is armed in the full CCW position. Note: the valve can still be opened and closed manually even while the spring pack is armed. The fusible link holds the spring pack in the designated position (for fail open or fail close). When the soldered fusible link breaks, spring pack will rotate the drive coupler and tripper arm clockwise no matter what position the handle is in. Most applications are fail closed; once the valve is in the closed position, it will cut off the flow of flammable media to the pipeline. spring pack Tripper arm SS arming plate

Specialty Safety Products: Fire Safe Valves What makes a valve “fire safe”? Integral tongue & groove Graphoil body seals prevent any leakage past the ball or disc; graphoil stem packing prevents leakage through the top of the valve Tongue and groove body seal design Blow-out proof stem Seats can be TFE, RTFE, PEEK, Nova or Delrin Meets API (American Petroleum Institute) 607 standards for withstanding extended high temperature conditions without leakage at full pressure rating Metal-to-metal contact reduces threat of leakage Graphoil seal

Specialty Safety Products: Fire Safe Valves Our design versus others you might encounter True “industrial style” full port ball valve, not a check valve Higher pressure ratings Can be manually operated Easy to re-set in the field Simple maintenance and repair of valves in the field No need to remove ball valves from the pipeline for repair/maintenance Can be retrofit to customer-owned or plant-specified valves

Options Valve monitoring Remote shut off On-site installation with our technicians Retrofit to customer-owned valves Proximity sensors/limit switch options for open and closed positions Remote shut-off of fusible link from 24VDC power source

Specialty Safety Products: Fire Safe Valves FUSIBLE LINK ASSEMBLIES FOR FIRE PROTECTION FUSIBLE LINK PACKAGES Ball valves with NPT ends ½” - 2” 2000PSI RTFE, TFE, Delrin and Peek seat options API607 fire safe Carbon steel or SS construction Ball valves with flanged ends ½” - 4” 150# ANSI flanged RTFE seats and graphoil seals

FUSIBLE LINK ASSEMBLIES FOR FIRE PROTECTION BT-Series FOR VALVES UP TO 21,000# TORQUE LT-Series FOR VALVES UP TO 150# TORQUE MT-Series FOR VALVES UP TO 830# TORQUE HT-Series FOR VALVES UP TO 1800# TORQUE

FUSIBLE LINK ASSEMBLIES FOR FIRE PROTECTION Also available for retrofit to any API607 ball or butterfly valve Here are a few of the valve manufacturers we have made fusible link assemblies for: ABZ BRAY DEZURIK FNW FLO-TITE FLOW-TEK HABONIM JAMESBURY MARWIN SHARPE VALVE SVF FLOW CONTROLS TYCO FLOW CONTROLS

FUSIBLE LINK ASSEMBLIES FOR FIRE PROTECTION Here are a just a few of the END USERS who use our product: Abbott Pharmaceutical Archer Daniels Midland Briggs & Stratton BP Products Cardinal Health Cargill Consumer Energy Elgin Sweepers Georgia Pacific Gillette Harley-Davidson Honda La Farge Marathon-Ashland Nissan North America Procter & Gamble Rustoleum Toyota

Specialty Safety Products: Fire Safe Valves SAMPLE APPLICATION #1: Marathon-Ashland Location: Canton, OH Application: fusible link assemblies designed to fail close at a diesel truck re-fueling station Marathon had been using a competitor’s non-industrial style fusible link on a 3” pipeline and they were not holding up in the application because of constant cycling Our assemblies have been in line for over 5 years without failure or maintenance

Specialty Safety Products: Fire Safe Valves SAMPLE APPLICATION #2: SKF USA Location: Armada, MI Application: fusible link assemblies designed to fail close on EDM (Electrical Discharge) machines that are used to remove material and reshape precision steel parts to obtain desired finish and accuracy High flash points of electrodes/liquid in process recently resulted in a fire at another one of SKF’s locations. FM inspectors now require BI-TORQ fusible link valves on each port off of their dielectric tanks Four assemblies were installed last month and approved by FM and OSHA inspectors

Optional Fusible Plug A cost-effective option when plant air is available Used with a spring return pneumatic actuator Functions open-closed as a standard pneumatically actuated valve. Plug allows air to vent to atmosphere, causing springs to turn actuator CW to close

Specialty Safety Products: Fire Safe Valves AUTOMATED VALVES FOR FIRE PROTECTION PNEUMATICALLY ACTUATED API607 FIRE RATED BALL VALVES Spring return or double acting rack and pinion design ISO direct mounting of valves and accessories NAMUR pattern for solenoid mounting ½” through 4” WCB or SS ball valves with NPT or ANSI flanged ends ELECTRICALLY ACTUATED API607 FIRE RATED BALL VALVES On-off or 4-20mA modulating electric actuators 120VAC, 220VAC, 24VAC, 12VDC and 24VDC Variety of options, including heaters and thermostats, timers, relays, auxiliary switches and more ½” through 4” WCB or SS ball valves with NPT or ANSI flanged ends

OTHER PRODUCTS FROM BI-TORQ Valve Automation Butterfly valves Electric actuators InstruPak automated ball valves Pneumatic actuators Knife gate valves Custom mounting kits

According to a report posted on the US Homeland Security’s US Fire Administration website, the United States has one of the highest fire death rates per capita among Western Nations. To understand what can be done to improve fire safety, we examine US and European fire safety systems differences.

We know US fire deaths occur predominately in homes during the winter months when the number of cooking and heating fires increases. According to the National Fire Protection Association (NFPA), the U.S. fire departments face 2,110 home fires per year where natural gas is the first material ignited, and 1,170 home fires each year where LP-gas is involved with the start of a fire. Most home gas fires originate in the kitchen at the stove or gas range.

Although heat is generated from any number of fuel sources (gas, electric, oil, wood, coal), this article focuses on current European practices for gas fire safety, starting at the curb, to the gas meter and then throughout the home.

A universal shut-off valve designed to remain tight at high temperatures. If a fire does occur and the gas expands from the heat, the valve is able to withstand the additional gas pressure, preventing the gas from exploding.

An excess flow valve to stop gas flow when the flow rate dramatically changes. For example, if a back hoe damages the piping, the excess flow valve will automatically shut off the gas flow.

A combined active and passive mechanism which includes both a manual shut-off valve and an automated thermal shut-off fusible device, such as the TECO Americas FireBag®. This automatic shut-off device is triggered by a fusible plug and piston and it does not need a fire or heat detector to set it off. The TECO Americas’ FireBag is designed for rugged applications, and it can undergo mechanical or thermal stress without misshaping. Since the FireBag is virtually maintenance free, it does not require regular inspections like active safety devices.

Typical gas meter installations in Europe include two passive safety devices and a plug to safely test gas pressure and tightness. The gas meter is equipped with an excess flow valve and a shut-off valve armed with an automatic thermal shut-off device.

European standards (UNI TS 11147 February 2007) require a pressure plug placed right after the meter. To test gas pressure safely and quickly – in 30 seconds or less – the meter is equipped with a double safety valve to avoid risk of gas leakage. TECO America’s CheckPoint was designed to meet this European standard. It includes an intercepting ball valve, and a pressure plug with the second safety valve which is installed with a safety handle that cannot be inadvertently turned. This double valve design allows pressure tests to be performed while the gas installation is operating.

Unlike their U.S. counterparts, some European countries such as Germany have mandated safety fusible devices for all gas appliances that use natural gas, propane, and butane gas for over 17 years.

The internal fusible device is located in the gas line connected to the gas appliance. Due to their low cost, the internal fusible device can be used economically at each gas appliance. External fusible devices are significantly more expensive and they are normally used for liquid fuels or used with remote sensing devices. The external fusible devices normally have a manual override or resettable feature.

In Europe, as in the United States, inside gas lines are maintained by licensed plumbers hired by the home owner. In the US, the NFPA standards require gas appliances to be equipped with manual gas shut-off valves. These manual shut-off valves are not considered emergency valves, and are not required to be easily accessible. Few home cooks are knowledgeable about the location of these valves, and would not be inclined to search for the valve when a gas fire does occur. For these reasons, European lines feeding gas appliances throughout the home are protected with passive fire safety devices, such as the FireBag automated thermal shut-off device which can be provided with the shut-off valve as well:

Basement gas appliances may include a furnace, water heater and dryer. In Europe the gas lines include dual-equipped shut-off valves at the appliance connection. The valve can be equipped with a safety handle for manual manipulation and the automated thermal shut-off device for passive fire safety.

Kitchen gas appliances may include ovens and ranges. The gas appliance is already equipped with a manual shut-off valve, so there is no need to install an additional valve prior to the gas appliance connection. The inexpensive FireBag passive automatic shut-off is installed in the gas line. The FireBag is manufactured in straight line versions and with elbow connections for flexible pipes.

Decorative gas fireplaces, gas logs or space heaters are equipped with passive safety devices by inserting the inexpensive thermal shut-off device in the gas line.

Outdoor patio gas appliances are also protected with automatic thermal gas shut-off devices. Gas grills are protected with extensible hoses equipped with a device such as the FireBag.

U.S. state public utility commissions and state and municipal building codes frequently reference the NFPA, and also may require safety regulations that exceed the NFPA standards. Currently the NFPA does not require passive gas safety devices, although recommendations have been made to the NFPA Technical Committee on National Fuel Gas Code.

The Technical Committee met in February 2010, to discuss revisions for the 2011 edition of the NFPA National Fuel Gas Code (NFPA 54). The committee met again in October 2010 to act on the proposed revisions. A revision for passive safety devices was requested: “for each appliance, a fusible link automatic shutoff valve shall be installed within two feet of the equipment manual shutoff valve and upstream all other components of the fuel train.”

The proposed revision was rejected for lack of data demonstrating “building fires are aggravated by the release of gas from heat damaged piping system components.”

Peter Holmes from the State of Maine’s Gas, Oil and Solid Fuel Board reports he has experienced “several fires in recent years which were greatly aggravated by the release of gas from heat damaged piping system components.”1

Although the 2010 San Bruno, CA and 1981 San Francisco pipeline ruptures and their subsequent fires were exacerbated by the lack of automatic passive thermal gas shut-off devices, current fire reporting does not track when fires could be better contained if passive thermal shut-off devices were installed.

Currently the NFPA only requires manual gas shut-off valves gas appliances in the U.S. The requirement in 9.6.4 for manual shut-off valves is intended solely to isolate an appliance for servicing, removal, or replacement without shutoff off the gas supply to other appliances. Since this valve is not an emergency shut-off valve, it is not required to be readily accessible.

Some U.S. cities, counties and states do have regulations requiring automatic gas shutoff devices. However, these regulations focus primarily on gas shutoff for excess gas flow and earthquakes. The State of California requires excess flow gas shutoff valves and earthquake actuated gas shutoff valves be installed on building gas houseline piping, (the gas pipe connecting appliances to the gas meter) after the utility gas shutoff valve, the pressure regulator (if installed), the meter(s), and the service tee. Californian homes are, therefore, protected from gas pipe breakages and earthquakes — but not from fire.

A number of regulations exist for passive, automatic safety devices that supply oil supply to and within the home. Yet, similar protection is not required for gas service in the U.S. For example, the NFPA 31 standard for the installation of oil-burning equipment requires fusible fire safety devices in residential oil heating installations. State fire codes such as those in Maine and Massachusetts, require automatic fusible valves in oil supply lines at oil tanks and burners. 2, 3

It is critical that both gas and oil supply lines are able to terminate automatically the fuel supply in the event of fire to minimize fire damage and save lives. Homes are protected by external gas shut-off valves which are accessible to fire departments. However, passive fire safety devices can provide additional protection. Internal fusible devices that automatically shut-off the flow of gas when the ambient temperature reaches a critical level can provide this protection at minimal cost.

Most people experience the benefits of fusible links through the emergency ceiling sprinkler systems commonly installed in office buildings. The sprinkler’s fusible device triggers the flow of water when fire is detected in order to rapidly extinguish the fire. Fusible links, thermal fuses, and fusible devices are all used to shutoff fuel sources in the event of fire. Recent fire safety improvements incorporate these fusible techniques.

Cost must be considered, however, in the application of safety devices. Sprinklers have become ubiquitous because they can be manufactured cheaply. Fuel shutoff devices are available in both internal fusible devices which are less expensive and external fusible devices which are more expensive.

Internal fusible devices are frequently used with natural, propane and butane gas systems because of their relative affordability. Their low cost allows them to be used with each gas appliance. External fusible devices are significantly more expensive and are more frequently used for liquid fuels or with remote sensing devices. The external fusible devices normally have a manual override or resettable feature.

A mechanical fusible link involves two metal strips that are held together with a material that melts at a specific temperature, separating the metal strips. Warehouse fire wall doors are typically controlled by fusible links, which trigger automatic door releases during fires. Once triggered, the links need to be replaced, since they cannot be reset.

Fusible fuses are safety devices typically used to control electrical current for heat producing appliances such as coffeemakers and hair dryers. A search for “thermal fuse” on the eHow.com website offers homeowners at least 506 instructional videos on replacing fusible fuses on appliances with heating elements, once the fuse has been triggered.

Fusible devices automatically shut-off fuel supply in the event of fire to meters and fuel-consuming appliances, such as heaters, boilers, ranges, varnishing booths, gas motors, and ovens. This passive safety device contains a fusible alloy which melts when the outside temperature reaches a trigger temperature, releasing the plug to completely close the flow of fuel.

The FireBag® is a thermal-activated shut-off device for propane, natural and butane gas. It automatically turns off the gas supply in a fire, preventing explosions and the spreading of fire. When the outside temperature reaches 203-212°F (95-100°C) the metal alloy that keeps the plug and cartridge together melts and the spring pressure pushes the plug against the gas opening closing it completely. No fire or heat detectors are required to automatically intercept gas flow. Once triggered, the shut-off device works up to 1,697°F (925°C) for one hour.

The FireBag is compatible with other safety devices (e.g. gas leak detectors), working even when the cause of the fire is not inside the system. Since it is a passive device, it does not require regular inspections and is virtually maintenance-free. It is not affected by external factors and works even during servicing operations.

Electro-thermal link’s are designed to minimize property damage by providing an instantaneous fusible link response and separation in the event of fire. Electro thermal links are incorporated into safety control systems where a fire hazard may occur, for example above a burner of an air heater, boiler or generator. The fire will melt the internal fusible metal link interrupting the electrical supply to a valve or alarm for example.

The link consists of a purpose built enclosure with a perforated cover having a temperature sensitive fuse. The unit should be mounted so that the perforated cover faces downwards and ventilation holes in the sides must not be obstructed.

8613371530291

8613371530291