fire safety valve fusible link for sale

Assured Automation"s FM Fire-Safe Thermal and Electro-Thermal ball valve and butterfly valve assemblies are designed to shut off automatically and control hazardous conditions. The heat actuated, U.L. listed thermal links automatically shut off or open the valve at predetermined temperatures. Ball and Butterfly assemblies are available with manual levers or gear operator which will allow the valve to operate manually at any time without affecting the fusible links or removing the spring loaded canister.

Assured Automation"s FM Fire-Safe Thermal and Electro-Thermal ball valve and butterfly valve assemblies are designed to shut off automatically and control hazardous conditions. The heat actuated U.L. listed thermal links automatically shut off or open the valve at predetermined temperatures. All valves come with a removable handle. The ball valves have the ability to use this handle to operate the valve manually at any time without affecting the fusible links or removing the spring loaded canister. The Butterfly valves require that the spring-loaded canister is removed for manual operation.

Fusible link valves are a type of valve that is used in shutoff applications as a safety measure. These valves are designed to be used in control systems that deal with flammable, combustible, or toxic materials. The fusible link refers to the part of the valve that is designed to fail. In the event that a certain preset temperature is exceeded, this link releases the tension on a spring, which closes the valve and prevents any process media from flowing past the point in the pipeline where the valve is located.

Fusible link valves mainly consist of a valve connected to a high tension spring. When the valve is opened, the spring is compressed. The link keeps the valve open and the spring tensed. The fusible link is designed to fail at a certain temperature. In case of a fire, the link breaks, releasing the tension on the spring and slamming the valve shut. This keeps any flammable or toxic media contained in the pipeline, reducing the spread of fire and helping prevent unnecessary damage, injury, or loss of life. In terms of safety, this type of valve is an integral part of safety systems and can help a company ensure the least amount of damage or loss in the event of a fire.

Fusible link valves should be used in conjunction with fire-safe valves. These are normally either ball valves or butterfly valves. It is important to make sure the valve used is rated as fire-safe, since it will be used for containment of flammable liquids. These valve assemblies can usually be found on storage tanks, mixing tanks, or transport vessels that require automatic shutoff in the event of a fire.

There are many different applications that benefit from the use of fusible link valves. These applications include petrochemical, pharmaceutical, tank farms, fueling stations, airports, biodiesel, diesel fuels, fire suppression systems, paint applications, and natural gas lines. Any one of these applications requires a fail-closed safety shutoff, which this type of valve can supply. In fact, most insurance companies require the use of these valves before they will provide insurance coverage for the plant or application.

In addition to fail-close applications, fusible link valves can also be used in fire safety protection systems as fail-open valves. This is useful in application where the valve is used to transport water or fire suppression media to the site of a fire when it is necessary. This ensures that the flow of water or fire suppression media is uninterrupted even if the valve fails. These fluids can be used to extinguish a fire or cool a storage tank, among other uses.

In recent years, the demand forfire-safe fusible link shut-off valves in industrial processing has increased with the improvement of the operating environment for industrial production, the priority is to protect the workers’ lives and the property of owners. Especially under the environmental and safety regulations, THINKTANK’s sales offire-safe fusible link shut-off valves are increasing year by year. The unique design of Fire-safe valves ensures that valves close tightly to prevent leakage of media in the tremendous heat of an industrial fire. The use of heavy-duty valve bodies, bolts, and UL-approved fuse plates imported from the US adds a great safety factor in different details.

Ball valves are available with metal seals, RPTFE, TFE, and other high temperature resistant materials. All fire ratings can be ordered to meet the requirements of NACE MR-01-75.

The fire-safe ball valve is a unique design that combines a complex sealing design, in case to minimize medium emissions and tight shut off the leakage in a fire situation. This valve has the ability to keep a fail-safe valve position at high temperatures.

The fire-safe ball valves meet the requirements of main standards including API 607, EXES 3-14-1-2A, BS 6755-PT2, BS5146 APP.B, and BS 5351 Anti-Static, etc.

All THINKTANK fire safe valves are designed with a thrust bearing and gasket with carbon-filled TFE or a ball inside of the stem. This excellent sealing material can meet a wide range of operating conditions. Over 3inches fire safe ball valves, the valve stem is made of SS316 material, and it has a top and bottom stem to fix the ball.

When the fire safe ball valve exposes to high-temperature fire conditions, the soft seat material will melt while the resilient metal seat will compensate for the sealing to tight shutoff.

In the event of a fire, the process fluid is contained within the valve. If the heat of the fire thrusts the bearing into sublimation, the blowout preventer rod forms a metal-to-metal seal with the valve body. The use of standard carbon-filled TFE packing or a steel ball and spring design inside the stem effectively prevents the bonnet from sealing. The use of spring-loaded metal seat compensation makes the valve body seal stable and keeps the media from external leakage in intense temperatures.

THINKTANK’s fire safe ball valves as manually operated or automated valves have excellent performance, the valve body is designed with two-piece, three-piece flanged, or threaded ends.

Fire Safe 2-piece forged ball valve commonly used for the oil and gas industry, and body material available in carbon steel, stainless steel, and other alloy steel. Valve Size: ½” to 8″

When the media is liquid oxygen, liquid nitrogen, and other liquefied gases, the valve is at extremely cryogenic application, we need specially designed ball valves to meet the equipment for reliable operation, and minimal heat exchange between the fluid and the environment.

For most cryogenic liquefied gases, with cryogenic temperatures as low as -450F, the valve will operate hundreds of degrees Fahrenheit below ambient temperature. Therefore, our ball valves and bonnets need to be designed with thermal expansion in mind, not only by completely cleaning and degreasing all parts, but also by taking care that the bolts are spring-loaded, the balls are pressure relievable, and the seats have double seals.

At the same time, a special packing design prevents media leakage along the stem axis, and the packing gland compresses the packing to ensure a tight seal between the stem and the body. In extreme cryogenic conditions, we use a longer stem and design the packing gland to be farthest from the cryogenic temperature. The bonnet is bolted to the valve body and uses a locknut with a resilient washer to ensure a secure connection to the valve body.

A pressure relief hole is typically designed at the upstream end of the ball to prevent overpressure due to thermal expansion. Therefore, cryogenic valves have specific inlet and outlet ends, and we will indicate the flow direction on the nameplate and valve body.

In the cryogenic environment, moisture condensation will freeze on the surface of the ball or cause thermal contraction of the ball valve material, and the valve torque will increase sharply, so in the selection and calculation, the safety factor of torque should be considered so as not to cause too little torque of the actuator and not to open the valve.

Trunnion ball valves are widely used in natural gas storage systems, gas transmission, LNG, subsea refining, desalination CO2 services, and power generation applications.

When the ball passage is in the same direction as the pipeline, the valve is in the open state and the medium can pass downstream. When the ball passage rotates 90 ° with the pipeline, the valve is in a closed state, and the media can not pass.

Since the ball valve only needs closing by rotating 90°, so the ball valve has the function of a fast closing. It is easy to monitor the open or closed status of the valve by the indication of the handle or limit switch. Soft seat ball valves, which also have a tight seal for a long service time, can achieve zero leakage.

While the trunnion ball valve has all the advantages of a normal ball valve, its design features a trunnion fixed at both the top and bottom of the ball, providing a positive seal on the upstream and downstream seats. So regardless of pressure, double block and bleed, or double isolation and bleed function is possible.

This special design reduces the torque required for valve action and is more suitable for large bore and high pressure operation, making the trunnion design ideal for the oil and gas automatic industry.

The standard feature of emergency stem sealant injection allows the valve’s stem housing to be adapted to a grease fitting to inject sealant in case of emergency, providing protection against unplanned spikes in operating conditions.

The emergency sealant injection feature allows a grease fitting to be used at the end connection of the valve to inject the sealant. This will produce a positive seal in the event of leakage from the valve seat due to impurities or unexpected increases in operating conditions. Double Block and Bleed

This safety feature eliminates pressure buildup due to high pressure media trapped in the valve cavity, even when the valve is in the fully closed position.

According to API 607 fire-safe standard, there are secondary metal seat designs in trunnion ball valves. The secondary graphite body seals and flexible graphite packing respectively prevent fluid leakage through the body joints and stuffing box.

A vent port at the bottom of the valve releases any liquid trapped in the cavity of the closed valve body. A vent port at the top of the valve body cavity removes residual gas from the cavity of a completely closed valve body. Both play a critical safety role in a dual block and bleed and/or dual isolation and bleed valve configuration. Double Seals on Body Joints

An anti-static device ensures that there’s electrical continuity between the ball, the stem, and the body, so the sparks created by a lightning strike or static discharge won’t create sparks inside the valve. ISO 5211 Actuator Mounting Pad

In industrial process control, we will see many kinds of ball valves, in general, we are divided into two categories, floating ball valves and trunnion ball valves. This article will tell you when to use which type of ball valve, and what is the difference between them? Design differences

The floating ball is fixed to the valve body by a single stem only, and the ball is floating on the valve seat. Trunnion ball valves are connected and centered inside the valve body by a shaft/stem at the top and a shaft/trunnion at the bottom. Torque

In the floating ball design, the ball is pushed against the downstream seat by in-line pressure, resulting in tightness. When operated from the closed position to the open position, the ball is rotated against the in-line pressure (∆p) and the frictional force of the seat. In other words: the torque required to open and close the ball valve is caused by the line pressure and the nature of the valve seat. As the operating pressure (∆p) and/or valve size increase, the amount of torque required increases significantly. Especially when the seat is a metal seal, the torque can be very high.

Trunnion ball valves are designed with the ball fixed in the center, the ball is held between the stem and the trunnion, which is fixed at the bottom of the valve body. During operation, the inline pressure fits the seat tightly to the ball. Instead of relying on the inline pressure (∆p) and the seat to rotate, only the pressure from the seat to rotate is needed to achieve a tight close.

Therefore, the drive torque required for a trunnion ball valve is usually lower than that of a floating ball valve of the same size and pressure. For example, a DN250 trunnion ball valve has a much smaller actuator than the same DN250 metal-seated floating ball valve, it optimizing the overall package cost. In addition, the trunnion seat design has better stability, which makes it more suitable for extreme conditions, especially for high pressure service conditions.

Trunnion ball valves are more suitable for high pressure applications and larger pipelines than floating ball valves. Another advantage of the trunnion design over the floating design is that the trunnion usually includes a drain or bleed connection, making it suitable for use as a double safety device. It automatically acts as a relief valve whenever the pressure in the central cavity is higher than the spring force of the valve seat. When it happens, the seat spring is automatically released so that the excess pressure is discharged back into the mains. For these reasons, trunnion ball valves are commonly used in offshore and oil and gas applications.

Although trunnion ball valves require relatively much less torque than floating ball valves, this means that the cost of purchasing actuators is much lower. However, in terms of the cost of the ball valve alone, trunnion ball valves are significantly more expensive than floating ball valves, so as a professional manufacturer, we will be able to advise on the correct ball valve design when selecting and evaluating costs. Please do not hesitate to contact us if you have any questions.

BI-TORQ Valve Automation, a division of Strahman valves since 2015, has been serving industrial, commercial and municipal accounts since 1981. Our experience with a wide variety of valve and actuator manufacturers gives us a strong knowledge of the industry, while our product depth allows us to provide valve automation components for virtually any application. Our experienced technical sales staff, designers and long-time employees will ensure that we will provide the right product for your application.

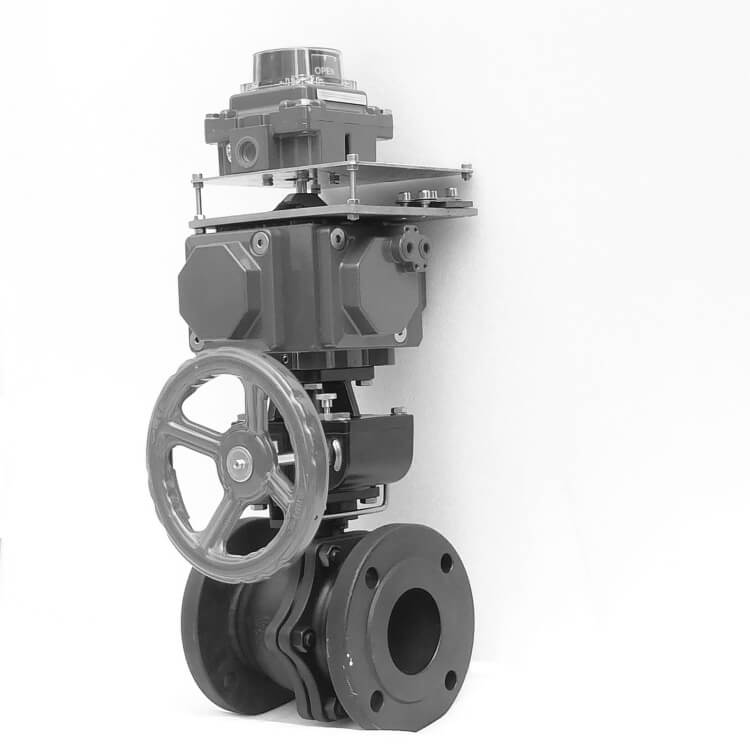

Howell provides Firesafe API 607 ball and butterfly valves with BI-TORQ® fusible link assemblies. These thermal shutoff valves are designed for automatic shutoff in case of a fire. They are used in applications requiring media containment in systems conveying flammable gases or liquids, solvents, alcohols, toxic fluid or any other potentially dangerous media.

Q3: How long is your product warranty?All valves from THINKTANK are covered with a 12 Months warranty from the date of installation or 18 Months warranty from the shipment date, whichever comes earlier.

Q5: What is your hot items?The most popular are globe type control valves, self-operated pressure regulating valves and other valves made of special materials. Both aluminum bronze, duplex steel materials and other special steel can be customized. We provide confidential production agreements for many brands and distributors, which can replace the valves on-site FISHER, FLOWSERVE, KOSO, MASONEILAN and other international brands.

A crucial component in any fire protection system our customized fusible link shut-off valves (also referred to as “thermal shut-off valves”) are ideal for any pipeline handling flammable liquids. With OSHA, Factory Mutual (FM) and insurance companies increasingly requiring that automatic shut-off valves be used in these applications, the need for our product is greater than ever.

Our complete line of API 607 certified quarter-turn valves suit a wide range of applications. Carbon and stainless steel ball valves are available in 1/4” through 6” sizes with ANSI flanges and NPT, socket weld or BSP ends. Fire safe high performance butterfly valves come in 2” through 24” sizes.

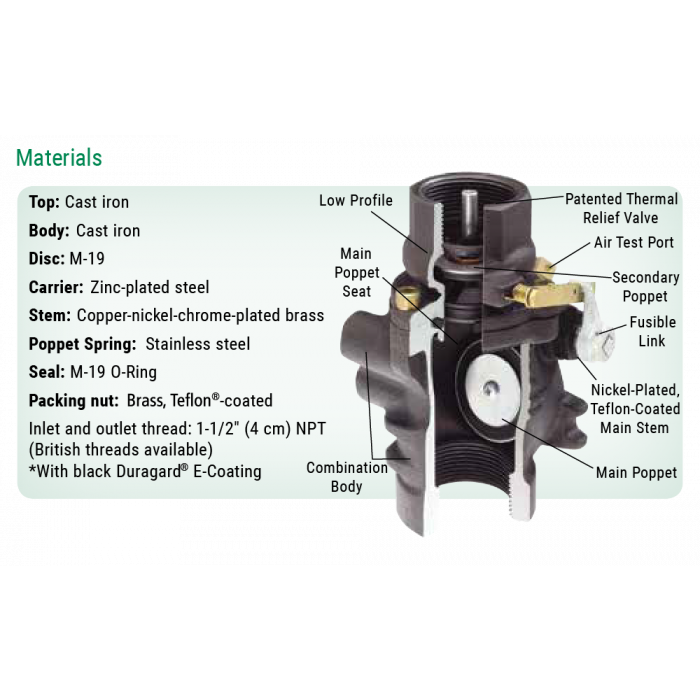

OPW 10 Series Emergency Shut-off Valves are installed on fuel supply lines beneath dispensers at grade level to minimize hazards associated with collision or fire at the dispenser. If the dispenser is pulled over or dislodged by collision, the top of the valve breaks off at the integral shear groove, activating poppets and shutting off the flow of fuel. Single-poppet models shut off supply flow, while double-poppet models shut off supply as well as prevent release of fuel from the dispenser’s internal piping. The base of the emergency valve is securely anchored to the concrete dispenser island through a stabilizer bar system within the dispenser sump or pan to ensure proper shearing action. The valve base is secured to the stabilizer bar using a three-point boss mount system or a U-Bolt Kit (not included) 10UBK-015 (1-1/2") and 10URK-0200 (2 sold separately). Valve inlet (bottom) connections are female pipe threads and outlet (top) connections are available with female threads, male threads or a union fitting. Other options include suction system models with a normally closed secondary poppet which maintains prime, and models with external threads on the inlet body which connect to secondary containment systems.

High Flow Capacity – The primary poppet is held out of the flow stream while the secondary poppet is held normally open to minimize head loss across the valve and to protect the poppet seals from damage and erosion. True 1-1/2" (4 cm) and 2" (5 cm) body sizes ensure maximum flow.

Main Poppet Seat Integral to the Top Assembly – Having the main poppet seat as an integral part of the valve top assures a new, clean seating surface is installed each time the top is replaced. This design also ensures that the integrity of the seal between the valve top and bottom is verified during line testing and allows full inspection of the main poppet when the top is removed.

Patented Thermal Relief Valve – Relieves excessive pressure over 25 psi caused by thermal expansion of fuel in the dispenser piping system in the event of fire (double-poppet models only).

Low-Profile Tops – Female and Union-top double-poppet valves have a low-profile top to allow upgrading from OPW single-poppet valves without changing existing piping.

Multiple Mounting Options – Valves are boss-mounted to stabilizer bars in sumps and pans or mounted to bars embedded in the island with optional U-Bolt kits 10UBK-015 (not included). Versatile Combination Body (boss mount/U-Bolt mount) models are available to accommodate most mounting applications with one valve style.

Underwriters Laboratories – Listed for use with gasoline and 85% and 100% methanol. All OPW 10 Emergency Shut-Off Valves meet requirements of UL STANDARD 842.

Our Fire-Safe Thermal Shut-off Assemblies are engineered for automatic shut-off in case of a fire. They are ideal for flow shut-off protection in systems conveying flammable gasses or liquids such as fuel, solvents, alcohols, toxic chemicals, or other potentially dangerous media.

Two Classifications:Thermal Shut-Off Fusible Link Packages (FLP Ball ValvesandFLP Butterfly Valves): “sentry-type” protection for local isolation. FM approved actuators on assemblies through 3,960 in/lbs of torque and designed for fire-safe certified quarter-turn ball, butterfly, or plug valves with torques up to 21,000 in/lbs depending on media, pressure, and other conditions. This series is ideal for customers or end-users who must use plant-specified valves. We have also designed adapter kits for leading valve manufacturers to create a high-quality package for API 607 fire-safe certified valves. Customers send specified valves to our facility, where we assemble and test by our experienced team so that they are ready to install in line when they arrive on your dock. And upon request, we can also offer start-up and commissioning.

Thermal-Electric (TES Series): provides local thermal protection. This series allows a single operator to transmit a low-voltage signal to a thermal-electric fusible link via a command device or PLC. The voltage causes the link to yield, releasing the spring and closing the valve. The TES design can control a single assembly or an entire bank and doubles as a thermal shut-off, which will trigger when the surrounding temperature exceeds the link’s rating. The TES system has revolutionized fire safety systems by allowing isolated and group valve shut-offs from one operating location in the event of an emergency, without the need for compressors, pneumatic lines, and other expensive and time-consuming apparatus. This series is not FM Approved.

BI-TORQ Valve Automation, dedicated to providing only the highest quality, dependable shut-off valves for critical applications. From automatic shut-off valves for oil and gas refineries to thermal shut-off valves for your facility’s fire protection systems, we have the equipment, expertise, and experience necessary to ensure that your system operates with the utmost safety and efficiency.

To automatically shut off the flow of diesel fuel, fuel oil, kerosene, and oil in case of fire, these valves automatically close and the handle permanently fuses in place when the ambient temperature reaches 165° F. To reuse the valve, replace the handle (sold separately).

OPW 10 Series Emergency Shut-off Valves are installed on fuel supply lines beneath dispensers at grade level to minimize hazards associated with collision or fire at the dispenser. If the dispenser is pulled over or dislodged by collision, the top of the valve breaks off at the integral shear groove, activating poppets and shutting off the flow of fuel.

Manufacturer of FM Approved, Heat-Actuated Fail-Safe Fusible Link Valves. Designed for installation in the withdrawal lines of flammable or combustible liquid storage tanks. The tank withdrawal line typically supplies fuel to peripheral support and emergency equipment such as generator sets and pump engines found in but not limited to commercial, construction and industrial applications. The valve is held in the open position by a heat-activated element mechanism. In the event of exposure to an external fire source, the element is activated and the valve is closed securely by an internal spring, and the flow of liquid through the line is stopped. NPT threaded connections. Materials include cast bronze housing; Buna-N or TFE soft good materials.

The kit for lever fire valves above contain: 1 x tension spring, 1 x 9m roll of cable, 2 x 22mm pulley assembly, 1 x pack wire crimps, 1 x 160°F fusible link & 1x screw eye cable fixing hook.

8613371530291

8613371530291