full opening safety valve manufacturer

Packard Safety Valves are designed to either stab into the drill pipe or tubing at the rig floor or are used as part of the drill string to shut off a well kick. Use of these valves in the drill string enhances rig safety.

The Packard two-piece safety valve offers the convenience of a two-piece body for easy maintenance. Its full bore also allows the unrestricted flow of drilling fluid; reducing wear on critical parts while providing unrestricted access for downhole tools.

Packard International"s Safety Valves are built with enough length on each end to allow fully recutting the connections in the event of damage to the threads or shoulders where sealing takes place.

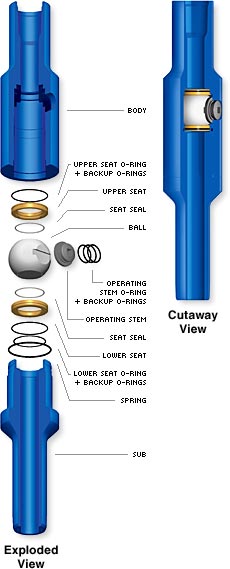

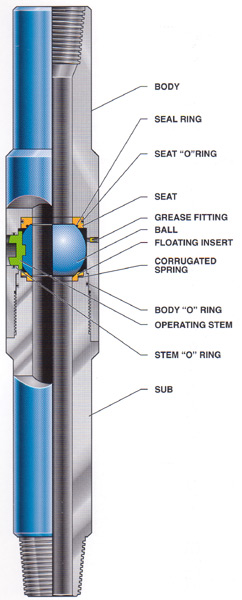

High and low pressure sealing is assured by the Teflon and metal sealing system of the ball and seats. The ball and lower seat float while the upper seat is fixed in the body. This floating/fixed design aids in low pressure sealing and enables the operator to pressure balance the valve under full rated working pressure.

Full Opening Safety Valve (short for FOSV) is a ball type safety valve used to stop flow through the drill string when the drill string is being withdrawn from the well.

TIANHE FOSV is dual body full-opening safety valve, so it does not interfere with the running of tools such as core barrels or survey instruments. It is designed to be stabbed into the top joint of drill pipe or tubing string at the rig floor and closed quickly in case a well kicks.

The ball-type design permits the valve to be compact, easy to handle, and yet have great strength. Standard test pressure is 10,000PSI, but higher pressure ratings are available.

TIW is the original designer and manufacturer of ball type Safety and Kelly valves. Our strict adherence to API specifications as well as our own quality requirements ensures TIW valves are the highest quality valves in the market.

TIW Class I & Class II Kelly Valves may be utilized as a Drill Stem Safety Valve or as an Upper or Lower Kelly Cock and is designed to hold pressure from both directions.

TIW Kelly Valve Design and Quality System are certified by API.TIW Safety and Kelly Valves are also offered for H2S service, meeting all NACE standards. Standard Pressure rating is 10,000 PSI Test with higher pressure ratings available.

Distributor of hydraulic press safety, quick opening safety, rotary and safety valves. Amerigear®, Boston Gear®, Carlisle®, DeMag®, Desch® and IMI Norgren®, pneumatic, double action, quick release and flow control valves also provided. Repair and preventative maintenance services are offered. Value added services such as custom barcoding, CAD capabilities, OEM assembly, plant surveys and third party logistics are also available. Serves the metal processing, metal service center, paper mill and paper converting, canning, grinding, commercial laundry, marine, oil and gas and material handling industries. Vendor managed inventory (VMI) programs available. Kanban delivery.

Two types of stabbing valves that must be prepared for well control are Full Opening Safety Valve (TIW valve) and Inside BOP valve (Gray Valve). We would like to describe what the differences between two valves are.

Full Opening Safety Valve or TIWvalve is a ball valve designed for high pressure condition and it can hold pressure from both directions. It is called “Full Opening” because when the ball valve is opened; the flow path through the valve has a smooth inside diameter. One thing that you need to remember is that the term “Full Opening” does not mean that the ID of the valve is the same of drill pipe ID. ID of the valve is typically smaller than the pipe in the hole.

The valve should be always located on the rig floor and left in the open position. Additionally, you need to ensure that personnel on the rig have a right wrench to close the valve. The valve left in the open position is critical because the valve can stabbed quickly into drill string if the well flows through drill pipe.

For good drilling practices, you must have all size full opening safety valves which can be screwed into each size of drill pipe, drill collar, tubing, etc on the rig. When there is any string in the hole, the correct connection of the valve must be ready on the rig floor to stab in. Furthermore, it is a good practice to perform well control drill during tripping operation in order to ensure that the crew are familiar with the stabbing procedure.

This valve is a non-return valve (check valve) allowing pumping through the valve into the drillstring but it prevents upward flow and the more widely used type is “dart-type”. The dart is used to hold the tool open therefore it is possible to stab the valve while the fluid is flowing through the drillpipe. With the IBOP valve installed in the drill string, it allows you to strip in hole without mud flowing through the drillsting. The IBOP valve should not be used for shut the well in while tripping.

Alibaba.com offers 37 full opening safety valve for drilling products. About 75% % of these are mining machine parts, 10%% are valves, and 8%% are other oil field equipments.

A wide variety of full opening safety valve for drilling options are available to you, such as energy & mining, construction works and manufacturing plant.You can also choose from 1.5 years, 6 months and 3 years full opening safety valve for drilling,As well as from bearing, {2}, and {3}. and whether full opening safety valve for drilling is russia, kazakhstan, or egypt.

... -start valve with Series MX2 air treatment units without the need for additional connection interfaces. The soft-start valve is positioned upstream of the safety valves, ...

Two hands safety valve, which allows a safety use of two hands pneumatic controls (for example two push-button 3/2 N.C. to a certain distance) excluding false signals in case of push-button ...

The SI2 safety valve prevents the allowed operating pressure from being exceeded by more than 10%. If, after opening, the adjusted response pressure falls ...

... stainless steel full-lift clean service safety valve designed to AD Merkblatt A2 and TRD 421 standards and suitable for pure steam, vapour and inert gases.

Insert style flow control valves are comprised of a precision orifice in parallel with a check valve, combined into a single component. Each is designed for easy installation into metal housings using ...

Press-in style flow control valves are comprised of a precision flow orifice in parallel with a check valve, combined into a single component. Each part is designed for easy installation into plastic ...

If you have been searching for a safety release valve that you can use to reduce short-term pressure surges successfully and diminish the effects of gas leaks, this is the product for you. With a pe of ...

... have been type tested as well. These pressure regulators have safety valves which will slam shut in the event of emergencies, such as the gas reaching too high a pressure level. The valve ...

This product has hydraulically actuated class A gas safety valves to EN 161 used for automatic shut-off. It shuts off when unstimulated for gas and air, or even biologically produced methane. It has AISi ...

The S 104 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

The S50 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

The S100 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

... Pressure Safety Valve + Rupture Disk is protected and may be utilized autonomously as essential security gadgets or in conjunction. There are 3 possible combinations. The first combinations ...

Excavator pipe-rupture valves prevent uncontrolled cylinder movement in the event that a pipe or hose bursts. The ESV valve fulfills all of the requirements of the ISO 8643 and EN 474-5 standards for ...

Material: Body- CF8M; Valve Seat- CF8M Métal Seat, PTFE Soft Seat available Orifice Size: fc"(15mm), 3/4M(20mm), l"(25mm), l1/4,’(32mm)I ltë”(40mm), ...

The Safety valves from ATOS are designed to guarantee protection for application on various devices, especially those that monitor spool position. They are also recommended for hydraulic ...

The M&M International CANISTER GUARD® encapsulates its internal spring loading within the canister itself, which is a significant feature that cannot be overstated. During disassembly of one-piece valves made by other manufacturers, the internal spring must be compressed prior to removal of the locking mechanism. Considering the application, it is typical for mud, cement, debris, and/or corrosion to accumulate in this area. This makes it difficult or even impossible to compress the spring enough to remove the locking mechanism from valves of this kind, even when using the special tools required by the competitor manufacturer. These and other issues can make field dressing impractical and shop dressing a much longer and more expensive process than necessary. M&M International’s CANISTER GUARD® technology completely eliminates these issues, saving both time and money.

M&M International’s CANISTER GUARD® reduces the need for customer locations to keep large spare valve parts inventories on hand. In most cases, CANISTER GUARD® valves utilize identical parts within each size range. This low inventory ability allows a customer to operate with one spare canister and one or two spare operating stems in inventory, if necessary.

M&M’s Top Drive Safety Valve Bottom Load™ lower valves have an extended pin nose profile that matches the mating ID profile of M&M’s Top Drive Safety Valve Bottom Load™ upper valves. These valve systems have the all-important, rig downtime saving, Bottom Load™ feature. When the time comes for scheduled routine maintenance, the lower valve only needs to be removed to allow quick and easy access to the upper valve’s internal components.

Along with its innovative design features and our CANISTER GUARD® technology, the Top Drive Safety Valve Bottom Load™ system allows for the quickest possible inspection and/or redress procedure. Since its inception over 20 years ago, M&M’s Top Drive Safety Valve Bottom Load™ system has saved countless hours of rig downtime.

Curtiss-Wright"s selection of Pressure Relief Valves comes from its outstanding product brands Farris and Target Rock. We endeavor to support the whole life cycle of a facility and continuously provide custom products and technologies. Boasting a reputation for producing high quality, durable products, our collection of Pressure Relief Valves is guaranteed to provide effective and reliable pressure relief.

While some basic components and activations in relieving pressure may differ between the specific types of relief valves, each aims to be 100% effective in keeping your equipment running safely. Our current range includes numerous valve types, from flanged to spring-loaded, threaded to wireless, pilot operated, and much more.

A pressure relief valve is a type of safety valve designed to control the pressure in a vessel. It protects the system and keeps the people operating the device safely in an overpressure event or equipment failure.

A pressure relief valve is designed to withstand a maximum allowable working pressure (MAWP). Once an overpressure event occurs in the system, the pressure relief valve detects pressure beyond its design"s specified capability. The pressure relief valve would then discharge the pressurized fluid or gas to flow from an auxiliary passage out of the system.

Below is an example of one of our pilot operated pressure relief valves in action; the cutaway demonstrates when high pressure is released from the system.

Air pressure relief valves can be applied to a variety of environments and equipment. Pressure relief valves are a safety valve used to keep equipment and the operators safe too. They"re instrumental in applications where proper pressure levels are vital for correct and safe operation. Such as oil and gas, power generation like central heating systems, and multi-phase applications in refining and chemical processing.

At Curtiss-Wright, we provide a range of different pressure relief valves based on two primary operations – spring-loaded and pilot operated. Spring-loaded valves can either be conventional spring-loaded or balanced spring-loaded.

Spring-loaded valves are programmed to open and close via a spring mechanism. They open when the pressure reaches an unacceptable level to release the material inside the vessel. It closes automatically when the pressure is released, and it returns to an average operating level. Spring-loaded safety valves rely on the closing force applied by a spring onto the main seating area. They can also be controlled in numerous ways, such as a remote, control panel, and computer program.

Pilot-operated relief valves operate by combining the primary relieving device (main valve) with self-actuated auxiliary pressure relief valves, also known as the pilot control. This pilot control dictates the opening and closing of the main valve and responds to system pressure. System pressure is fed from the inlet into and through the pilot control and ultimately into the main valve"s dome. In normal operating conditions, system pressure will prevent the main valve from opening.

The valves allow media to flow from an auxiliary passage and out of the system once absolute pressure is reached, whether it is a maximum or minimum level.

When the pressure is below the maximum amount, the pressure differential is slightly positive on the piston"s dome size, which keeps the main valve in the closed position. When system pressure rises and reaches the set point, the pilot will cut off flow to the dome, causing depressurization in the piston"s dome side. The pressure differential has reversed, and the piston will rise, opening the main valve, relieving pressure.

When the process pressure decreases to a specific pressure, the pilot closes, the dome is repressurized, and the main valve closes. The main difference between spring-loaded PRVs and pilot-operated is that a pilot-operated safety valve uses pressure to keep the valve closed.

Pilot-operated relief valves are controlled by hand and are typically opened often through a wheel or similar component. The user opens the valve when the gauge signifies that the system pressure is at an unsafe level; once the valve has opened and the pressure has been released, the operator can shut it by hand again.

Increasing pressure helps to maintain the pilot"s seal. Once the setpoint has been reached, the valve opens. This reduces leakage and fugitive emissions.

At set pressure the valve snaps to full lift. This can be quite violent on large pipes with significant pressure. The pressure has to drop below the set pressure in order for the piston to reseat.

At Curtiss-Wright we also provide solutions for pressure relief valve monitoring. Historically, pressure relief valves have been difficult or impossible to monitor. Our SmartPRV features a 2600 Series pressure relief valve accessorized with a wireless position monitor that alerts plant operators during an overpressure event, including the time and duration.

There are many causes of overpressure, but the most common ones are typically blocked discharge in the system, gas blowby, and fire. Even proper inspection and maintenance will not eliminate the occurrence of leakages. An air pressure relief valve is the only way to ensure a safe environment for the device, its surroundings, and operators.

A PRV and PSV are interchangeable, but there is a difference between the two valves. A pressure release valve gradually opens when experiencing pressure, whereas a pressure safety valve opens suddenly when the pressure hits a certain level of over pressurization. Safety valves can be used manually and are typically used for a permanent shutdown. Air pressure relief valves are used for operational requirements, and they gently release the pressure before it hits the maximum high-pressure point and circulates it back into the system.

Pressure relief valves should be subject to an annual test, one per year. The operator is responsible for carrying out the test, which should be done using an air compressor. It’s imperative to ensure pressure relief valves maintain their effectiveness over time and are checked for signs of corrosion and loss of functionality. Air pressure relief valves should also be checked before their installation, after each fire event, and regularly as decided by the operators.

Direct-acting solenoid valves have a direct connection with the opening and closing armature, whereas pilot-operated valves use of the process fluid to assist in piloting the operation of the valve.

A control valve works by varying the rate of fluid passing through the valve itself. As the valve stem moves, it alters the size of the passage and increases, decreases or holds steady the flow. The opening and closing of the valve is altered whenever the controlled process parameter does not reach the set point.

Control valves are usually at floor level or easily accessible via platforms. They are also located on the same equipment or pipeline as the measurement and downstream or flow measurements.

An industrial relief valve is designed to control or limit surges of pressure in a system, most often in fluid or compressed air system valves. It does so as a form of protection for the system and defending against instrument or equipment failure. They are usually present in clean water industries.

A PRV is often referred to as a pressure relief valve, which is also known as a PSV or pressure safety valve. They are used interchangeably throughout the industry depending on company standards.

The IBOP, also called Gray Valve or BVR, is a back pressure valve used in the drill string to prevent the well from flowing uncontrollably up the drill string. It is generally used in 2 ways:

The RDCV, also called Dart Valve or a Back-Pressure Valve, controls backflow through the drill pipe during a kick or when tripping pipe into the hole against pressure. Check-valve compatibility should be checked with Kelly Cock free passage.

8613371530291

8613371530291