gagging tool for safety valve made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

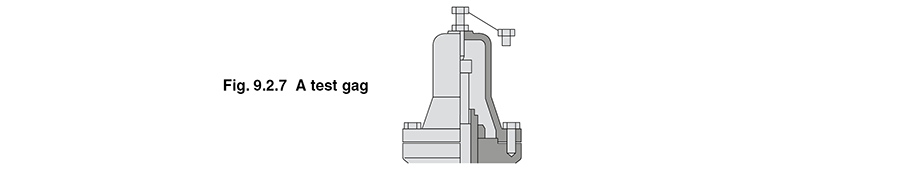

Test Gag is a bolt used for the spindle block of the pressure relief valve (PRV) to allow the PRV to be closed during the pressure test. The bolt should be tightened when the system has 80% of the pressure used. test (test pressure) to ensure that the PRV is closed at the test Pressure:

Warning: All pipe plugs must be blocked or anchored adequately against a force equal to the head pressure times the cross-sectional area of the pipe. Debris or protrusions in the pipeline can damage a seal or rupture inflatable plugs. NEVER use an inflatable plug when its failure could cause injury or catastrophic damage or as the only means of protection for personnel working downstream. NEVER use a test pressure greater than the capacity of the weakest pipe or component in the system. Actual conditions vary so user must accept full risk and responsibility for the selection and use of any product. Please review our Warranty, Terms and Conditions.

Note 1: Mechanical and Molded Rubber Plugs are generally used for testing because fabricated Multi-Flex® style plugs may allow some seepage unless customized for a positive seal.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

IMO your question is more suitable for PSV forum http://www.eng-tips.com/threadminder.cfm?pid=1203 . Of course some of us in this forum have experiences in safety valve.

See some hint from some expert whom have done this http://www.eng-tips.com/viewthread.cfm?qid=180240 . Moral of the story, this is a risky job with some uncertainties, be cautious for operator to position themselves when performing this. If your safety valve is open loop, do not position any parts of someones" body in front or near the outlet

For gaging as well as adjusting it in relatively safe manner, Trevi-test is one way to do it. similar video by Tru-test https://www.youtube.com/watch?v=gAwS-tjbLeg

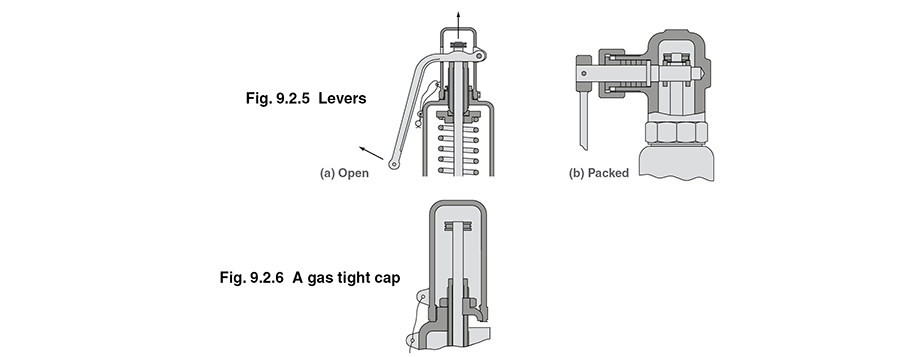

Be cautious that you or the commissioning personnel should correspond both safety valves" setting pressure vs the testing pressure. If its gagged (set the screw to prevent it from opening)at X Psi, then the testing pressure is not advisable to exceed 5% of X. this potentially bent the spindle. And if this happened, as per safety regulation the damage parts shall be renewed with UV stamped (read: original) manufacturer parts (if your safety valve manufacturer and your boiler are referring to ASME).

We are one of the reputed suppliers of specialized instruments like Pressure Switches, Differential Pressure Switches, Temperature Switches (weather proof as well as explosion proof), RTD / Thermocouples, Pressure Indicators / Temperature Indicators, Differential Pressure Indicators, Pressure Relief Valves, Volume Boosters, I / P Converters and other instruments and instrument accessories.

With Farris, a trustworthy valve is only part of our promise. Farris provides customers with total pressure relief management solutions that support a facility’s entire lifecycle, transforming the way you ensure plant safety:

Now you can accurately size and select a pressure relief valves for any combination of process applications with SizeMaster™ Mark IV pressure relief valve engineering software. This program for Windows® (all versions) brings unprecedented integration of standard engineering practice to the task of sizing and selecting pressure relief valves.

With SizeMaster Mark IV software, you can define as few as one or as many as 64 different sizing scenarios including blocked flow, fire, thermal and tube rupture, from a scenario matrix grid. Selection of the pressure relief valve is automatically based on the relief area of the worst case scenario. Various Wizards make the most complicated task simple; for instance, the Capacity Wizard allows you to determine accurate vapor generation for vessels of all types.

Quicksize Database Tube Rupture Scenario English/Metric Dimensional Drawings API-Omega 2-phase flow calculations Noise and reaction force calculations Multiple valve sizing Standard Windows user interface functions Developed under ISO 9001-2000 guidelines Supports network database access Database administration tools Interactive product catalog Internal client/project database Complete revision control with definable database access English/metric units definable by job level Import/export capabilities Online help including a variety of tutorials

All sizing equations and selection algorithms are based on ASME Code requirements, API standards and best engineering practice as determined by Farris Engineering. The equations and flow algorithms are internally calculated within an innovative worksheet engine. This worksheet engine also checks parameters and any intermediate calculations against standards’ constraints, letting you know about any non-compliance issues it encounters. All equations, calculations and internal algorithms can be displayed on screen or printed for review.

The engineering worksheet engine also checks your parameters and all intermediate calculations against the standards’ constraints, and it tells you about any non-compliance that it encounters, such as attempting to size a conventional valve when a bellows valve is required.

Once SizeMaster calculates the orifice area required to relieve your process scenarios, SizeMaster guides you through the selection of the appropriate Farris pressure relief valve and its materials and other options.

SizeMaster includes catalogue information for Farris 2600, 2700, 3800, 6400, 6600, 4200, 2800 , and 7200 series pressure relief valves, including their black and white drawings. While you are selecting a Farris type number for a tag, SizeMaster ensures that you don’t pick a valve that is not applicable to your process parameters (such as a liquid-service valve for a vapor scenario), and on-line help is available to assist in the determination of each of the digits of the Farris type number, based on your process scenarios.

From its Quick Size and Capacity Wizards through to its consistently standard Windows user interface, SizeMaster makes the job of sizing and selecting pressure relief valves easy, and its worksheet management and workflow auditing facilities let you ensure that your results are correct.

8613371530291

8613371530291