gas cylinder safety valve manufacturer

Distributor of gas valves including natural gas valves, gas compressor valves, gas cylinder valves & 2-way sub-miniature diaphragm isolation valves. Types include modular design valves & 4-port floating seal direct acting valves. Modular design valves are available orifice sizes ranging from 1/32 in. to 3/16 in. with operating pressures ranging from 15 psig to 400 psig. 4-port floating seal direct acting valves are available in orifice sizes of 1/16 in. with gas pressure ratings of 124 psig, liquid pressure ratings of 100 psig & power ratings of 10 kW & 15 kW. Applications for 2-way sub-miniature diaphragm isolation valves include analytical instrumentation, mass spectography & gas chromatography. JIT delivery available.

Residual Pressure Valve (RPV) valves have been cycle tested to conform to GCE´s own stringent standards exceeding ISO 10297 and ISO 15996 to provide a Class Leading 15 year maintenance-free Service Life

Laser marked Batch and Part Numbers on the valve body, for easy identifi cation and traceability, all provide Operational Ease of Use for GCE´s customers

compressed gas solutions serving blue-chip bulk and specialty gas manufacturers, distributors and storage & delivery system providers (OEMs). The Sherwood brand includes valves and accessories for all segments including industrial gases, acetylene, medical, hydrogen, refrigerant recovery, propylene, alternative energy and more.

Evergreen Midwest Co. is dedicated to serving the manufacturing industry with the highest quality industrial valves available today. Valves, being critical machinery components, need to be built with maximum dexterity and strength. All valves available for sale on our website are manufactured by well-known & trusted brands Sherwood ValveandRego Products. After decades of industry experience, we are proudly a leading supplier of exceptional valves from these manufacturers. These include globe valves, gate valves, ball valves, pressure regulators, safety relief valves, check valves - the list goes on. We serve a complete range of these critical cylinder components for almost all subcategories of the compressed gas industry, cryogenic markets, and specialty gas markets, as well as the medical, chemical, welding, life-support, cryogenic, and semi-conductor fields.

All the valves that we sell are manufactured in the United States and follow strict and automated manufacturing and testing processes. Our valves also adhere to the necessary international industrial valve standard regulations, therefore meeting the safety levels required for a variety of applications. We are teamed up with technology experts and experienced professionals to guide users with the functioning and repair mechanisms.

If you have been searching for a safety release valve that you can use to reduce short-term pressure surges successfully and diminish the effects of gas leaks, this is the product for ...

... regulators have safety valves which will slam shut in the event of emergencies, such as the gas reaching too high a pressure level. The valve works to protect any fittings ...

This product has hydraulically actuated class A gas safety valves to EN 161 used for automatic shut-off. It shuts off when unstimulated for gas and air, ...

The S 104 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

The S50 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

The S100 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

... Pressure Safety Valve + Rupture Disk is protected and may be utilized autonomously as essential security gadgets or in conjunction. There are 3 possible combinations. The first combinations ...

It"s a Safety valve in according with Directives ATEX 20K/34/EU. Technical Norm Fire Prevention 41/256 31/10/2019. d.P.R. 10/520 19/03/1955 and subsequent amendments.

130 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function, ...

V651 Series safety relief valves are produced as safety and relief type. Safety valves are pressure relief elements used to evacuate excessive pressure ...

PVS type slam shut valves are pilot-operated relief valves in which the opening and the closing of the main plug is controlled by a pilot device which is very ...

This range of spring loaded conventional and balanced safety relief valves is specifically designed for overpressure protection of unfired pressure vessel (ASME Section VIII application). ...

The EMERSON BM7 SERIES is a disk slam-shut valve characterized as automatic isolating elements, which are suitable for installation as safety devices in regulating stations. This device has a high operation ...

... control and regulate the gas, air flow to burners and other combustion devices. HMV is a unique safety valve that can be supplied for the requiremen of handling higher ...

Type 50 is a safety valve for universal use. It can be used for nearly any industrial application, e.g. in shipping and pipeline construction, the chemical and petrochemical industries, ...

The RIEGER Safety valve Type SH prevents excessive pressure in steam and gaseous media in plant components and tanks. The set pressure is generally higher than the operating pressure of the system.

... sewage, gas, glycol, diathermic oil, industrial water, steam and other natural and aggressive media, depending on theresistance of materials usedfor the construction ofthe valve.

NingBo ZhengXin(ZX) pressure vessel Co., Ltd. is a leading manufacturer of high pressure gas cylinders and valves located in No.1 JinHu East Road, HuangJiaBu Town, YuYao City, China, with its sales office in Shanghai, China. Over 20 million reliable cylinders are made by ZX and in ...

SS Gas Lab Asia (SSGLA) is a leading manufacturer-exporter of carbon dioxide (CO2) generation and recovery, biogas generation and upgradation, nitrous oxide generation and dry ice process plants. SSGLA also supplies allied systems like CO2 storage tanks &transportation tankers for CO2 vaporizers, manifold systems etc. for ...

MATAR Srl. is a high pressure gas containers player, updated to the most modern technologies. Cylinders selling, testing and refurbishing – Valves and caps – Ultra light rolls-on, modules and trailers for compressed gas transport. Family owned company, MATAR is born in 1982 as aluminium ...

Since 1999 we’ve been bringing our extensive knowledge, great service and an unrivalled safety record to the global valve and ancillaries market. Herose supply the top international industrial gas companies and original equipment manufacturers (OEM), and our products are used in over 100 countries. You’ll ...

Tekno Valves, established in 1971, is an ISO 9001 and TPED certified cylinder valve manufacturer of industrial, medical, and specialty gases. Our cylinder valves are tested and approved to global standards. Our integrated design and manufacturing facility in India is equipped with state-of-the-art CNC equipment ...

The GCE Group is Europe’s leading gas equipment company. We are proud member of ESAB Corporation and our today’s extensive product portfolio service our customers in following business areas: -Cutting & Welding Technologies -Valves -Central Gas Systems -Healthcare -Homecare The GCE Group headquarter is located ...

Established in 1949, with over 70 years of experience, Habonim is committed to engineering, manufacturing, and supplying superior products and providing excellent personal service to our customers. We take pride in incorporating quality, innovation, reliability, and safety into our products. We provide the best professional ...

MSR-Electronic is a manufacturer of fixed gas warning systems with decades of experience in the field of building automation and gas measurement technology. The international company with headquarters in Germany has a wide range of methods for the detection of toxic and combustible gases. On ...

M/s. Vadilal Chemicals Limited is a part of Vadilal Group (Known for Vadilal Ice-Cream in worldwide) which have over 30 years of experience in specific Gas Industry. Our presence in INDIA as a leading company with 10 plant / branches. Calibration gases are traceable to ...

Cyl-Tec, Inc.® has come to be known as a prominent leader and innovator in the compressed gas industry who really understands and fulfills what matters most to customers – on-time delivery, reliable products, and personal service. This family-owned business began in 1991 as a gas ...

RealGaz operating on the gas sales market of Azerbaijan since 2003 year. Sales and services of industrial, technical, medical and specialty gases, as well as gas mixtures. Accredited laboratory for the analysis of all gases, which we produce at our plant and have for sale. With a higher ...

FasTest’s high-pressure, gas filling connectors have a proven track record with over two decades of service in the field. FasTest gas quick connectors provide a simple single handed approach to filling cylinders. Under pressure, a secure, leak-tight seal is established with our patented safety locking ...

PTEC – the company for innovative products PTEC GmbH – a Worthington Industries company since Jan. 2021 – stands for comprehensive and reliable project supervision in mobile and stationary natural gas and hydrogen applications. We are a single source for consultation, engineering, prototyping, type approval, ...

The GCE Group is Europe’s leading gas equipment company. We are proud member of ESAB Corporation and our today’s extensive product portfolio service our customers in following business areas: -Cutting & Welding Technologies -Valves -Central Gas Systems -Healthcare -Homecare The GCE Group headquarter is located ...

ABOUT GAS INNOVATIONS Gas Innovations has become a world leading provider of high purity hydrocarbons in the refrigerant, pharmaceutical, industrial, electronics, and agricultural chemical industries. Ancillary services and products offered are technical consultation, equipment and turnkey logistics to satisfy your business needs by being strategically located at the ...

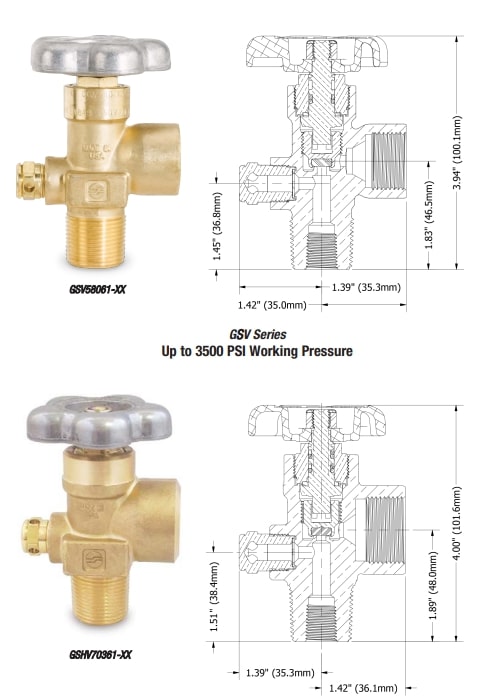

Founded in 1963, Control Devices is a leading designer and manufacturer of specialty valves and other high-quality flow control products. Control Devices’ ISO 9001:2008 certified facility boasts a dedicated and skilled work force utilizing automatic machining, assembly and final test equipment to support our production ...

Cavagna Group is a key industrial partner and enabler for the treatment, distribution, control, and metering of all types of gases. Founded in 1949 in Italy, and still run as a family business, for over 70 years Cavagna Group has been operating globally, with eleven ...

The Cavagna Group™ offers the most complete and reliable line of products in the sector, supported by a never-ending commitment to research and engineering. We design, manufacture and distribute a wide range of valves and regulators for different types of high-pressure gas applications worldwide. From ...

Dayan Gas Co. is member of Dayan Chemical Group. Dayan Gas is supplier and producer of cylinders, CNG tanks, industrial gases, pure gases, gas mixture, liquid gases, refrigerant gases and regulators. Dayan gas Co. is a private company which imports & exports industrial gases and ...

Equigas Group is dedicated to providing customers with impeccable service, high quality products, and customer minded warranties for the Americas and the Caribbean. Equigas International, Inc. is the subsidiary of the group that serves the Cryogenic & Compressed Gas, Specialty Gases, Medical Gases and LNG ...

WITT is a manufacturer of Pressure relief valvesor Safety relief valves for technical gases. They are designed to protect against overpressure by discharging pressurized gases and vapors from pipelines, pressure vessels and plant components. Safety relief valves (SRV) are often the last line of defense against explosion – and such an explosion could be fatal. Other common names for safety relief valves are pressure relief valve (PRV), safety valve, pressure safety valve, overpressure valve, relief valve or blow-off valve.

WITT safety valves are very precise. They are individually preset to open at a predetermined pressure within the range 0.07 to 652 Psi. Their small size and orientation-independent installation allow a wide range of connection options. WITT relief valves also stand out due to their high blow-off flow rates of up to 970m³/h. They can be used within a temperature range of -76° F to +518°F and even with very low pressures.

For maximum safety, WITT undertakes 100 % testing of each safety relief valve before it is delivered. In addition, WITT offers individual testing of eachsafety valveby the TÜV, with their certificate as proof of the correct set pressure.

WITTsafety relief valvesare direct-acting, spring-loaded valves. When the preset opening pressure is reached, a spring-loaded element in the valve gives way and opens, and the pressure is relieved. Once the pressures are equalized, the valve closes automatically and can be reactivated any time the pressure rises again. Depending on the application and the nature of the gas, the safety relief valvescan either discharge to atmosphere, or via a connected blow-off line. The opening pressure of the safety valves is preset by WITT at the factory according to the customer’s requirements.

Safety relief valvesare used in numerous industries and industrial applications where, for example, gases pass through pipelines or where special process vessels have to be filled with gas at a certain pressure.

For most industrial applications using technical gases, brass is usually the standard material of construction of thesafety relief valvebody/housing. For the use of pressure relief valves with aggressive and corrosive gases, the housings are made of high-quality stainless steel (1.4541/AISI 321, 1.4404/AISI 316L, 1.4305/AISI 303 or 1.4571/AISI 316Ti). The use of aluminium as a housing material is also possible.

Depending on the type of gas used and individual customer requirements, various sealing materials and elastomers are available to ensure the safety of your systems under even the most difficult conditions.

WITT pressure relief valves are available with different connections. In addition to the standard versions with the usual internal or external threads, special versions with KF or CF flanges, VCR or UNF threads can also be ordered. Special adapters for connecting the safety relief valve to a blow-off line are also available.

SMARTOP cylinder valves for industrial and specialty gases have built-in caps and easy-to-use on/off levers to help stop gas loss, improve safety, save time and money.

Now you can simplify your cylinder gas use while improving safety with innovative SMARTOP cylinder valve technology, from Airgas, an Air Liquide company. SMARTOP has a built-in cap, easy-to-use on/off levers, at-a-glance pressure valves and more for the enhanced safety and performance you want.

Are you tired of wasting gas, losing cylinder caps and all of the ergonomic and safety risks associated with daily cylinder use and handling? Now you can get the most out of every cylinder with SMARTOP, our innovative cylinder pressure relief valve developed exclusively for ARCAL™ premium welding gases and ALPHAGAZ™ pure analytical gases.

Our supply chain management solutions can enhance efficiency, continuity and safety — especially when managing your gas supply. EZ-GAZ™ is a unique digital gas monitoring service that alerts you when your preset gas pressure level is detected, no matter where you are.

Call your Airgas account manager or provide your information below to have an Airgas representative contact you about SMARTOP™. Ready to talk now? Contact us at 800-909-8058.

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale gas cylinder safety valve on Alibaba.com. When you search for gas cylinder safety valve and related items, you will be able to find many types of gas cylinder safety valve varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of gas cylinder safety valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale gas cylinder safety valves on Alibaba.com. When you search for gas cylinder safety valves and related items, you will be able to find many types of gas cylinder safety valves varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of gas cylinder safety valves that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

Pressure relief devices (PRDs) are installed on gas valves for high- and low-pressure cylinders to minimize the risk of cylinder rupture. It’s crucial that the person who’s filling the cylinder verifies that the PRD is correct for the product. If each filler makes sure to take care of this responsibility on his or her own, everyone can be sure that this process runs smoothly and that safety is ensured.

• Rupture Disk Devices:This device is a flat disk that’s typically made of metal and designed to burst at a predetermined pressure in order to permit the release of gas. The rating is usually stamped on the face of the device. It should be used for compressed air, argon, helium, nitrogen, and oxygen.

• Fusible Plug Devices:This device is a plug made of fusible metal that’s designed to yield or melt at low temperatures. The rating of the metal’s temperature is stamped onto the device. The gas that uses this type of device is acetylene.

• Combination Rupture Disks:A rupture disk is backed by the previous fusible plug. If there’s a fire, the fusible metal will melt, and the cylinder overpressure will be relieved when the disk bursts. The burst pressure of the disk and the melting point of the plug are marked with the rating. This type of device is most commonly found with medical-grade gas cylinders.

• Pressure Relief Valves:A spring-loaded valve opens when the cylinder pressure exceeds the pressure setting of the spring to discharge contents. Once the cylinder pressure decreases to the valve’s pressure setting, the valve will normally reseat without leakage.

Care should be taken when handling and storing compressed gas cylinders and to avoid plugging the PRD channels and parts in any way that could affect the functioning of the device.

All pressure relief devices must be examined internally for corrosion, damage, rust, plugging of relief device channels, or mechanical defects such as leakage or the extrusion of fusible metal. If there’s any question about whether the PRD is suitable, the cylinder shouldn’t be filled until the device is appropriate.

Pressure relief devices ensure safety and reduce the risk of a disastrous event. Safety is the top priority at CPV Manufacturing, and that’s why customers rely on our products. CPV designs and manufactures products that exceed the requirement of industry and customer specifications.

Almost all compressed gas containers are fitted with pressure relief devices. A pressure relief device is a pressure- and/or temperature-activated device used to prevent the pressure from rising above a predetermined maximum, and thereby prevent rupture of a normally charged cylinder when subjected to a standard fire test as required by Title 49 of the U.S. Code of Federal Regulations (49CFR 173.34(d)), or equivalent regulations of Transport Canada.

The Compressed Gas Association, in pamphlet CGA S-1.1, has classified pressure relief devices according to type using the letter designation CG followed by a numeral. Each of these types described are in the following subsections (reference CGA S-1.1).

A rupture disk (synonymous with the name burst disk within the industry) is a pressure-operated device which affords protection against development of excessive pressure in cylinders. This device is designed to sense excess

pressure in a cylinder and will function when the cylinder is of sufficient magnitude to cause the rupture or bursting of the rupture disk element, thereby venting the contents of the cylinder. The rupturing of the rupture

Rupture disk devices installed on compressed gas cylinders may be either an integral part of the cylinder valve assembly or may be installed on the cylinder as an independent attachment. The materials of construction selected must be compatible with the fluid in the cylinder as well as the cylinder valve materials with which the rupture disk device comes in contact in order to minimize corrosion.

One of the most common types of rupture disk devices consists of a gasket and a rupture disk and a rupture disk holder. These components are only supplied as factory-assembled devices designed to be replaced as a unit. The gasket is the part which provides the proper seal to prevent leakage of the cylinder contents past the rupture disk assembly and may be constructed of metallic or nonmetallic materials.

The rupture disk is the operating part of the pressure relief device and, when installed in a proper rupture disk holder, is designed to burst at a predetermined pressure to permit discharge of the cylinder contents. Such disks are usually made of metallic materials and may be of flat, preformed, reinforced, grooved or scored construction. Nonmetallic materials are also used for specific applications.

The rupture disk holder is the part of the pressure relief device which contains the opening, against which the rupture disk mates. The rupture disk holder usually also contains the discharge porting or passages, beyond the operating parts of the device, through which fluid must pass to reach the atmosphere. In many cases, the discharge holder is provided with radial vent holes through which the fluid in the cylinder vents to the atmosphere. This radical discharge design provides an anti-recoil feature, which minimizes rocketing of compressed gas cylinders during discharge of the contents through the pressure relief device. Other types of discharge ports may also be provided in rupture disk holders to suit specific application requirements.

B. Tightening of the rupture disk assembly to the cylinder valve or to the cylinder itself should be in accordance with the manufacturer’s instructions. Tightening to a torque less than the manufacturer’s recommendations may result in a leaking device or a device that may rupture at a lower pressure than specified. Conversely, over tightening can also result in disk actuation at a lower pressure than specified due to excessive twisting action, which may create wrinkles or distortions in the disk, which may cause premature failure of the disk and inadvertent release of the pressure contents. Either of these premature releases could cause serious injury or death.

WARNING Components of devices designed to rupture in shear are very similar in appearance to those designed to rupture in tension but are not interchangeable because they have completely different modes of actuation. If components are inadvertently interchanged, i.e. a disk designed to rupture in shear is installed in a rupture disk holder designed to rupture in tension, a serious cylinder failure incident could result that could lead to loss of life due to the significant increase in pressure required to rupture the disk. Conversely if a disk designed to rupture in tension is installed in a rupture disk holder designed to rupture in shear, premature rupture could occur with complete loss of contents due to significant reduction in rupture pressure of the disk. That may lead to fire, personal injury or death.

A rupture disk is a pressure-operated device which affords protection against excessive pressure. It protects against excessive pressure when the properties of the gas, cylinder design, and percentage of charge in the cylinder are such that exposure to excessively high temperatures will cause an increase in internal pressure sufficient to actuate the rupture disk before the cylinder loses its integrity and weakens. The rupture disk also

A rupture disk is a non-reclosing device. Once the disk has ruptured, there is no way to prevent the complete release of the contents of the cylinder. This device does not provide good protection against pressures caused by exposure to excessively high temperatures when the cylinder is only partially charged. The pressure rise may not be sufficient to actuate the rupture disk before the cylinder loses its integrity and weakens.

Consideration should be given to environmental conditions to which the cylinder may be exposed. Severely corrosive atmospheres may contribute to premature rupture of the disk. To prevent corrosion of the rupture disk, care must be taken to select materials of construction that do not interact with either the contents of the cylinder or the anticipated environmental conditions.

A fusible plug is a thermally operated pressure relief device which affords protection against excessive pressure developed by exposure to excessive heat. Once sufficient heat melts the fusible alloy, the entire contents of the cylinder will be vented. The CG-2 fusible alloy has a nominal melt temperature of 165˚ F (73.9˚ C); the CG-3 fusible metal has a nominal melt temperature of 212˚ F (100˚ C).

Fusible plugs can be installed on the cylinder as independent devices or fusible alloy can be cast directly into a suitable orifice in the cylinder valve body. In some cases, a fusible plug may be installed as a separate device

WARNING No attempt should be made to repair fusible plug devices. They are not repairable and attempts to repair will destroy the integrity of the fusible alloy causing leakage of gases that may lead to fire, personal injury or death.

Industry practice limits the application of these style fusible plugs to cylinders with 500 psig (3447 kPa) service pressure or less to minimize the possibility of cold flow or extrusion of the fusible alloy. A fusible device is a

In this type of device, the rupture disk portion (CG-1) is directly exposed to the internal cylinder pressure, and so it is directly upstream of the fusible metal. In general, the same components that make up the CG-1 device are

A pressure relief valve is a spring-loaded pressure-operated device designed to relieve excessive cylinder pressure, reclose, and reseal to prevent further release of product from the cylinder after excessive pressure is removed and valve resealing pressure has been achieved.

The primary advantage of using the pressure relief valve is that functioning of this type of device may not release all of the contents of the cylinder but is designed to reseal after resealing pressure has been achieved. This characteristic, in fire conditions, will minimize feeding the fire in the case of flammable or combustible cylinder contents.

Pressure relief valves are designed to maintain the pressure in the cylinder at a limit as determined by the spring force. Therefore, such devices do not protect the cylinder against possible rupture when continued application of external heat or direct flame impingement weakens the cylinder wall to the point where its rupture pressure is less than the operating pressure of the relief valve.

If you require assistance in selecting a Pressure Relief or Safety device for a specific application, please contact Sherwood Customer Service at 888-508-2583 with the following information: Part number of the valve assembly being repaired, if applicable; Type of gas service in which cylinder will be used; and service or test pressure of the cylinder.

We"re committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for Gas Cylinder Safety Valve, Stainless Steel Marine Hardware, 6 Inch Stainless Steel Boat Cleats, Stainless Steel Hardware Fittings,Boiler Safety Valve. Welcome around the world consumers to speak to us for organization and long-term cooperation. We"ll be your reputable partner and supplier of auto areas and accessories in China. The product will supply to all over the world, such as Europe, America, Australia,Vietnam, Thailand,Bhutan, Montpellier.Welcome to visit our company and factory, there are various products displayed in our showroom that will meet your expectation, meanwhile, if you are convenient to visit our website, our sales staff will try their efforts to provide you the best service

11 Gas Cylinder Safety Guidelines E. General use requirements Gas Cylinder Use • Never apply excessive force when trying to open valves. • Never allow flames or concentrated heat sources to come in contact with a gas cylinder. • Never allow a gas cylinder to become part of an electrical circuit. • Never partially open a cylinder valve to remove dust or debris from the cylinder inlet. • Never use cylinder gas as a compressed air source. • Never use adapters or exchange fittings between tanks and regulators. • Never use Teflon TM tape on Compressed Gas Association (CGA) fittings (straight thread) where the seal is made by metal- to-metal contact. Use of Teflon TM tape causes the threads to spread and weaken, increasing the likelihood of leaks. Small pieces of tape can also become lodged in the valve mechanism resulting in possible valve failure. • Never attempt to open a corroded valve; it may be impossible to reseal or it may break and release the cylinder’s contents. Valve and Regulator Use • Ensure the regulator pressure control valve is relieved (i.e., closed) before attaching it to cylinders. • Close valves on gas cylinders when a system is not in use. • Remove all pressure from regulators not currently used (by opening equipment valves downstream after the regulators are closed). • Use pressure relief valves in downstream lines to prevent high pressure buildup in the event that a regulator valve does not seat properly and a tank valve is left on. • Vent relief valves to a fume hood or ventilated gas cabinet, when using flammable or toxic gases. • Pressurize regulators slowly and ensure that valve outlets and regulators are pointed away from all personnel when cylinder valves are opened. • Leave the wrench in place on the cylinder valve, when needed, to open the main valve. Use adequately sized wrenches (12 inches long) to minimize ergonomic stress when turning tight tank valves. Cylinders with “stuck” valves should be returned to suppliers to have valves repaired. • Fully open valves during cylinder use. A fully open valve

Lintgen, Luxembourg 10 August 2021 – Rotarex SRG a business unit of Rotarex SA announced that the entire Cryotec range including the Refrigerant Valves and Components is taken over and managed by Rotarex SRG in Gladenbach, Germany.

SRG Schulz + Rackow Gastechnik has a long history and experience of more than 85 years in the design and manufacturing of valves, regulators and equipment for various applications, such as Cylinder and Bulk Tank Storage, Automotive solutions, Cont...

Pressure regulators reduce the high pressures of the stored gas in the cylinder to lower pressures that can be safely used in an operating system. Proper regulator selection is critical for both safety and effectiveness of operating systems. Regulators are designed to control pressure; they do not measure or control flow, unless equipped with devices such as a flow meter specifically designed for such purposes.

Regulator connections to cylinder valves must be completely free of dirt, dust, oil, and grease. "Crack" the valve slowly (by opening the valve slightly and then reclosing it) before attaching the regulator in order to blow out dust and debris from the opening. Note: Cylinders containing highly toxic gases should not be "cracked".

Regulators are attached to the cylinder, or manifold, at the inlet connection. This connection should be tested for leaks with a non-petroleum based product. Note that many soaps contain petroleum! The connection is marked with a Compressed Gas Association (CGA) number and will be left-hand or right-hand threaded to match the nut or fitting. This prevents a piece of incompatible gas equipment from being connected to the wrong gas supply.

Opening a Regulator - Stand on the valve side of the cylinder at arms length so you do not have to reach in front of the regulator face. Turn your head away from the regulator and open the valve, turning counter clockwise, to blow out dust and debris, and then reclose the valve.

Changing a Regulator - Close the valve and drain the regulator by backing out the adjusting screw. Disconnect the regulator, making sure not to touch the nut and gland areas. Connect the regulator to the new cylinder.

Closing a Regulator - Turn the valve clockwise to close the valve. Drain the regulator by turning (opening) the adjusting crew to release any gas. Reclose the adjusting screw.

Recommendation: To provide easier access and additional safety, purchase wall-mounted regulators which connect to the supply cylinder by hose. This will reduce the handling of the regulator and reduce the likelihood of damage.

Diaphragm Valve - This valve uses a two piece stem separated by non-perforated diaphragms. These diaphragms prevent leakage along the valve stem. The lower part of the stem is encased in a spring, which forces the stem away from the seat whent eh valve is opened. The upper stem is threaded into the diaphragm retainer nut. When the handwheel is rotated to the closed position, the upper stem pushes on the diaphragms, which deflect downward, forcing the lower stem against the valve seat. Advantages of this type of valve are that they provide superior leak integrity and have no threads or lubricants in the gas stream to generate particles or contaminants. This type of valve is required for mos

Compressed gas cylinders shall have a pressure relief device installed to prevent the rupture of a normally pressurized cylinder when inadvertently exposed to fire of high temperatures. There are four basic types of pressure relief devices:

Rupture Disk Devices - A flat disk typically made of metal that is designed to burst at a predetermined pressure to permit the release of gas. The pressure rating of the disk is typically stamped onto the face of the device. Examples of gases using this type of device include compressed air, argon, helium, nitrogen, and oxygen.

Fusible Plug Devices - A plug made of fusible metal designed to yield or melt at low temperatures (usually 165 or 212 degrees F). The temperature rating of the fusible metal is stamped onto the face of the device. An examples of a gas that uses this type of device is acetylene.

Combination Ruture Disks/Fusible Plug Devices - A rupture disk backed by a fusible plug. In the event of a fire, the fusible metal melts and cylinder overpressure is relieved by the bursting of the disk. The burst pressure of the disk and the melting point of the plug will be marked with the ratings. Medical grade gas cylinders typically have this type of pressure relief device.

Pressure Relief Valves - A spring-loaded valve opens when the cylinder pressure exceeds the pressure setting of the spring to discharge contents. Once the cylinder pressure decreases to the valve"s pressure setting, the valve will normally reseat without leakage.

8613371530291

8613371530291