gas oven safety valve leaking manufacturer

Their are several different gas safety valves. On ovens with ignitors, if the ignitor is weak then the oven will not light off, but what if the igniter is new and the oven will not come on?

NOTE:Never put 120 volts to the safety valve in an attempt to make it come on. All you will do is kill that valve"s bi-metal. It has to be hooked in line with the igniter to work properly. Why? The ignitor takes up most of the power. The power goes through the safety valve as 120 volts but because the amperage is all being hogged by the ignitor, the gas valve opens up and allows gas to flow out into the burner and ignite. Unless it is leaking most of the time the gas safety valve is NOT the problem.

On ovens with pilot lights or standing pilots most of the time it IS the safety valve because the little thermocouple that mounts on the pilot goes bad and won"t open the safety valve.

Some ovens offer a seperate safety feature called a flame switch. What it amounts to is the thermocouple mounted on the pilot light goes to the flame switch which will have continuity as long as it is heated by the pilot light.

NOTE: If you do have to replace the gas valve remember this: It will not come preset. You will have to adjust the flame height with a wrench. It is a good idea to set the 2 valves side by side, adjust the orifice height on the new valve to the same height as the old one and then you need only to tweak it a tad. If the flame is too low it will take 2 hours to bake a pie shell. too high and the bottom will be cooked before the rest. It is best to adjust the flame to about half way up the flame spreader.

These valves do not fail very often. Normally the problem is with the ignitor not drawing enough amperage to open the valve. Even if the ignitor is glowing orange it is likely still the cause of the burner not igniting. Technicians refer to this as a "weak" igniter.

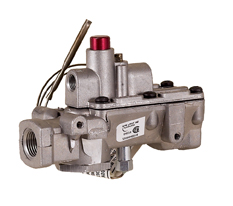

Dual gas safety valve assembly. The gas oven safety valve works with the oven igniter to provide gas to the burner. If the safety valve fails, the oven won’t heat. Since safety valves rarely fail, be sure to check more commonly defective parts before replacing the safety valve.

These valves do not fail very often. Normally the problem is with the ignitor not drawing enough amperage to open the valve. Even if the ignitor is glowing orange it is likely still the cause of the burner not igniting. Technicians refer to this as a "weak" igniter.

These valves do not fail very often. Normally the problem is with the ignitor not drawing enough amperage to open the valve. Even if the ignitor is glowing orange it is likely still the cause of the burner not igniting. Technicians refer to this as a "weak" igniter.

These valves do not fail very often. Normally the problem is with the ignitor not drawing enough amperage to open the valve. Even if the ignitor is glowing orange it is likely still the cause of the burner not igniting. Technicians refer to this as a "weak" igniter.

These valves do not fail very often. Normally the problem is with the ignitor not drawing enough amperage to open the valve. Even if the ignitor is glowing orange it is likely still the cause of the burner not igniting. Technicians refer to this as a "weak" igniter.

These valves do not fail very often. Normally the problem is with the ignitor not drawing enough amperage to open the valve. Even if the ignitor is glowing orange it is likely still the cause of the burner not igniting. Technicians refer to this as a "weak" igniter.

Thank you for your inquiry. The oven safety valve is one part that may fix the issue, but there are some other parts that you will need to check to see which one is causing the issue. You will need to check the igniter, the electronic control board and the temperature sensor. I hope this helps. Thank you and have a great day!

Can this oven valve work on my range? The range was plugged into the wrong outlet and it shorted out, the igniter glows when the stove is turned on however the burner isn"t lighting. I was told the the valve needs to be replaced.

Thank you for your question. This is not the correct safety valve for your appliance. I have listed the correct valve below for you. I hope that helps. Good luck with your repair.

Oven doesn"t heat. Igniter glows when gas is turned on, voltage on value starts near zero and slowly ramps up to just under 3 volts, but gas never ignites. The slow ramp seems normal to allow igniter to get hot, but not sure what the valve"s voltage should be to have it open. Valve coil is not open per ohm meter. Sounds like a bad valve? Thanks.

Hello Curt, Thank you for your inquiry. It sounds like it could be either this part or the pressure regulator. When the ignitor heats up to a certain temperature, it is supposed to trigger the valve to open and let the gas in to ignite and the regulator cuts it off at a certain pressure. Hope this helps!

Hello Sal, thank you for your question. You can test the gas valve to see if it has gone bad. You will need to test this with a multimeter. Here is a video that will show you how to test that valve.

Hello Steve, thank you for your question. The oven safety valve part number WB19K31 will work with either NAT or LP gas. The part itself can be switched over without any additional parts. Please check your owners manual on steps to change that over. I hope this helps!

In the oven a wire from the igniter shorted (had to pry the wire off the wall) to the frame. Would the control valve or the thermostat also be damaged. Where is the thermostat located on the stove. I noticed that the plastic on one of the knife connection on the control valve was missing

Hello Robert, thank you for writing. It is doubtful that the Oven Safety Valve or Oven Thermostat were also damaged when this occurred. The Oven Thermostat (part PS235170 on your model) is located behind the Manifold Panel (control panel). We hope this helps.

Hi there, i have a GE gas range (model jgbp28sem1ss) and need to replace the safety valve for the part of the oven that bakes. Is this the correct part? Thanks

The valve pictured needs to be replaced immediately please. That type of valve is not only out of code but few know that it needs regular grease maintenance every few years, now ask yourself has this been greased in the last 10 years or 20? I think not. Spend the time and put a ball valve so in an emergency you will not have to find a tool to shut it off if the appliance developes a leak. My mother in law had a 5 year old gas stovetop go poof on her last year, luckily it just scared the pants off her but the inner explosion was forceful enough to unseal the stovetops gasket connecting the factory upper half to lower half. Leak was caused by maids over cleaning and getting cleaner over the years down into casing by spraying stovetop with cleaner. The cleaner along with any spills caused the dissimilar metals of the gas tube and appliance casing touching and caused a hole is my best theory after dismantling and inspection of the unit. Be safe replace it and make sure to add a auto off check valve also. But hey its only the life of you and your family we are talking about over 10 dollars in parts.

When our field technicians go out to homes to investigate gas leaks, check appliances, and respond to other routine service calls, the most common problem they come across is old, leaking or improperly installed valves and connectors.

In many cases in the past, our technicians had to turn off gas to the appliance and potentially the entire house for safety reasons, pending repairs by the homeowner. This posed a significant inconvenience for residents, as not only did they lose gas service (for heating and cooking, etc.), they must find a qualified plumber to fix the unsafe condition. After the repair was made, it could require another visit by one of our technicians to restore service.

The Parts Replacement Program is borne out of our company’s commitment to continually improve customer satisfaction by providing residents a one-stop shop to meet their utility needs, and to quickly address any potential customer safety issues on the spot.

Gas leaks are a serious matter. Gas line repairs should only be done by a licensed and certified plumber. If your home uses gas, it is always in your best interest to receive regular gas line inspections.

You may have a gas leak in your home or beneath your lawn and not be aware of it until it’s too late. Gas companies are aware of thousands of leaks that go un-repaired because they present no immediate problem.

Gas distribution lines are part of America’s aging infrastructure. Decades-old copper and, in some places cast-iron, gas lines deteriorate from the corrosive effects of the gas, plus water and minerals in the soil. Gas escapes and collects in underground voids or eventually makes its way to the surface.

Government agencies and gas companies grade gas leaks in terms of severity and threat as Grade 1, Grade 2 or Grade 3. Definitions are similar from state to state. The agency that regulates natural gas in Texas, the Texas Railroad Commission, defines them as:

Grade 3 – A leak that is non-hazardous at the time of detection and can reasonably be expected to remain non-hazardous. These are reevaluated within 15 months or at the next scheduled survey, if sooner, until the leak is regraded or no longer results in a gas reading.

If you smell gas outside and away from your home a distance of 15 feet or more, notify the gas company. To get a better idea of the location start sniffing to see where the smell is strongest. Good visual cues are dead or dying plantings or a circular brown patch in your lawn.

Look for areas of heavy insect activity. Some insects are attracted to the smell of the Mercaptan odorant added to help detect the naturally odorless gas. Listen for a hissing sound, which could indicate a gas leak.

Do not dig or attempt to repair a suspected leak. That’s a job for either the gas company or a licensed plumber, depending on the location of the leak and the location of your gas meter (see details below under “Gas riser” and “Gas pressure regulator”).

You or someone in your family may develop physical symptoms that may have resulted from exposure to natural gas. These include nausea, headaches, fatigue, difficulty breathing, dizziness, and drowsiness. These might indicate a gas leak near or inside your home.

Gas may leak out anywhere in the distribution system, especially around valves and fittings. Some areas have proven more problematic than others. Here are the ones we see most often:

1. Gas riser – The gas riser is the pipe that emerges from the ground to connect the gas supply to your gas meter. Since the early 2000s gas risers have been made from non-corrodible plastic materials. Prior to that most were metal, as seen in this example from a home built in the mid-1990s.

Over time, metal in the ground corrodes and develops thin spots that can develop holes where gas leaks out. In most cases, the gas company is responsible for maintaining the meter and all the gas pipe coming from the street to the meter.

Homeowners are responsible for the gas system that runs from the meters into and throughout their homes. Gas meters usually are located at the rear or on the side of a single-family home, within inches of the outer wall. In multi-family housing gas meters may be inside.

2.Gas pressure regulator– Leaks also develop in and around gas pressure regulators (the disc-like object on the left side of the image shown). Leaks develop at joints of all types due to people or tools bumping the pipes, or perhaps faulty installation. Sometimes a diaphragm in the pressure regulator can leak because it is defective or foreign matter may have gotten in the gas line to foul it. That said, it is not unusual to smell gas around the regulator because it will vent gas at times to regulate the pressure.

Try a bubble test. Mix three tablespoons of dishwashing detergent in a quart of water and spray the mixture around the joints. If you see bubbles, it becomes a job for a licensed plumber or the gas company. If the leak is on the house side of the meter or the side where the gas supply enters the meter, it is your responsibility as the homeowner. If between the meter and the street, it is a job for the gas company.

Swimming pool heaters may have gas pressure regulators, too. In most cases, homeowners are responsible for maintenance and repairs to them, as the gas travels through the gas meter for the property before it gets to the pool heater.

3. Fireplace valve – The valves that control gas flow to gas fireplaces frequently develop leaks. Valves, like any mechanical device, can wear out with use. The difficulty of repair usually depends on where the fireplace gas valve is located. If it’s in the floor of a home with a basement or crawl space it can be reached easily.

4.Pilot Lights– Gas appliances require a way to ignite the gas to produce a flame when you want to cook, heat your home or get hot water. Newer standing pilot lights have a thermocouple safety device that will shut off the gas supply to the pilot light if the flame goes out.

Some older gas appliances do not have this safety feature: if the pilot light gets blown out the gas can build up in the room and pose the danger of explosion from the smallest spark.

Pilot lights have mostly been replaced by electronic igniters that shoot a spark directly into the gas at the burner or directs the gas over a glow rod that ignites it. This system is more efficient because gas flows only when someone turns it on. There is no pilot light to go out and cause a possibly dangerous situation.

5. Joints and fittings – Any joint in a gas line not sufficiently tightened or sealed can develop a gas leak. Gas furnaces, ovens, range tops, driers water heaters, and other gas appliances usually are connected wit

Plumbers wrap thread seal tape on the threads on the male connector. When tightened, the tape is squeezed to fill in any gaps. If the tape was not properly applied or was not applied at installation, a gas leak is a near certainty.

As with any suspected gas leak, this is not a DIY job. Get a licensed plumber. The best way to be sure you don’t have a gas leak is to a plumber to an annual inspection of your home’s gas system.

If you smell natural gas or have any reason to think you may have a gas leak in or around your home start investigating immediately. If the smell is strong, leave the area immediately. If the gas smell is faint, you may wish to try to locate the source by smell and a bubble test. Do not attempt a repair.

If you have been searching for a safety release valve that you can use to reduce short-term pressure surges successfully and diminish the effects of gas leaks, this is the product for ...

... regulators have safety valves which will slam shut in the event of emergencies, such as the gas reaching too high a pressure level. The valve works to protect any fittings ...

This product has hydraulically actuated class A gas safety valves to EN 161 used for automatic shut-off. It shuts off when unstimulated for gas and air, ...

The S 104 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

The S50 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

The S100 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

... Pressure Safety Valve + Rupture Disk is protected and may be utilized autonomously as essential security gadgets or in conjunction. There are 3 possible combinations. The first combinations ...

It"s a Safety valve in according with Directives ATEX 20K/34/EU. Technical Norm Fire Prevention 41/256 31/10/2019. d.P.R. 10/520 19/03/1955 and subsequent amendments.

This range of spring loaded conventional and balanced safety relief valves is specifically designed for overpressure protection of unfired pressure vessel (ASME Section VIII application). ...

130 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function, ...

V651 Series safety relief valves are produced as safety and relief type. Safety valves are pressure relief elements used to evacuate excessive pressure ...

PVS type slam shut valves are pilot-operated relief valves in which the opening and the closing of the main plug is controlled by a pilot device which is very ...

The EMERSON BM7 SERIES is a disk slam-shut valve characterized as automatic isolating elements, which are suitable for installation as safety devices in regulating stations. This device has a high operation ...

... control and regulate the gas, air flow to burners and other combustion devices. HMV is a unique safety valve that can be supplied for the requiremen of handling higher ...

Type 50 is a safety valve for universal use. It can be used for nearly any industrial application, e.g. in shipping and pipeline construction, the chemical and petrochemical industries, ...

The RIEGER Safety valve Type SH prevents excessive pressure in steam and gaseous media in plant components and tanks. The set pressure is generally higher than the operating pressure of the system.

... sewage, gas, glycol, diathermic oil, industrial water, steam and other natural and aggressive media, depending on theresistance of materials usedfor the construction ofthe valve.

8613371530291

8613371530291