gas oven safety valve repair factory

Safety valve maintenance and repair ensures your industrial system will not only remain operational, but also safe for your personnel and the environment. In the event of a failure, a safety valve helps contain the challenge to a specific location or releases pressure to stop it, which also means these devices are subject to extreme duress in industrial environments.

Millennium Power Services offers expert insight into our customer’s needs, supporting the evaluation of specific concerns or mechanical issues with your safety valves. Whether you are performing preventive maintenance or reacting to a malfunction, our team of experts can spring into action and facilitate shop or on-site repairs and testing along with new safety valves.

Documentation and pictures are provided for your records upon completion of repairs as well as progress pictures and reports so you will know before the work is completed what repairs are required. All this and more are provided to you as an alternative to the high pricing and long delivery times you are presently encountering. Make us your one-stop shop for hydraulic actuator and valve repairs.

Gas Safety ValvesThese valves automatically control main gas flow. Our automatic pilot valves shut off both the main and pilot gases. Pilot gas is tapped from the main line within the control. Gas will flow only to the pilot burner when the reset button is depressed. The manual pilot valve stop can be adjusted for maximum pilot flow.

Kunkle Relief Valve OverviewWhen it comes to industrial and commercial safety and relief valve products, Kunkle’s valve’s catalog is second to none in steam, air, gas, and liquid applications.

Kunkle relief valves range in size from ¼” NPT to 6” flange and are suitable in cryogenic and high temperatures up to 800°F environments at vacuum to 7,500 psig pressure. Kunkle Valve’s code certifications meet several global and national board standards, including ASME Section I, Section IV, and Section VIII, PED, CRN, TU and Chinese, as well as non-code requirements.

Relief Valves for Steam ServiceSteam supplies heat for industrial and chemical processes and also is used to heat buildings, supply mechanical energy, and drive mechanical equipment. Steam moves from the boiler to the end point, then heats by direct heating or indirect heating through a heat exchanger. Kunkle steam relief valves are critical to protecting equipment such as boilers, steam lines, and pressure valves, from being over-pressurized.

Relief Valves for Air ServiceKunkle designs valves for air service, for example for air compressors in mechanical shops and small factories where either low-pressure or high-pressure air is required. NASVI stocks Kunkle relief valves for air service in iron, steel and bronze for a variety of uses.

Relief Valves for Liquid ServiceKunkle also makes valves for liquid service, which provide bypass relief in a variety of applications and liquid types.

More About KunkleKunkle Valve is a renowned pressure relief valve manufacturer. Erastus B. Kunkle invented the safety valve to prevent overpressure in locomotive engines. Kunkle patented it in 1875. Since that time, Kunkle has earned its reputation for high-quality valves, and other equipment manufacturers ship their products with Kunkle’s valves pre-installed.

NASVI has stocked Kunkle safety relief valves since we opened in 1975, so we are confident when we call ourselves Kunkle safety valve experts. Every day we fulfill orders for our customers looking for Kunkle relief valves for steam, air, gas, and liquid applications.

VSI is your premier source for control valves, pressure relief valves, and safety relief valves. Our factory-certified experts are on-call 24/7 for repairs, testing, sizing & selection, replacement, and installation.

As your trusted source for factory-certified service solutions and consistent value and quality, VSI offers excellent customer service and world-class products and services. VSI has been focused on a legacy of quality and service since its inception in 1975 in Oklahoma City by founder Bill Campbell. Over the years, VSI has expanded its footprint to include four locations, offering service, repair, installation, and custom solutions across the United States. We offer excellent customer service, best-in-class products, and a wide variety of solutions for the process industry. VSI is the premier source for safety valves, pressure relief valves, control valves, and actuation products and services. Contact us to find out how we can help you.

Adapt almost any rotary actuator to a linear valve. Converting pneumatic actuation to electric helps increase operational efficiency and lower emissions.

VSI is a Consolidated™ Green Tag Center™ offering factory-certified repairs, installation, maintenance, and the full range of Consolidated pressure and safety relief valves. We have in-house certified technicians and product experts, and a large inventory to ensure fast delivery.

Our factory-certified and safety-trained, field service technicians are ready to be dispatched to your site. Capabilities include optimization, repair, and maintenance on pressure relief valves, safety valves, control valves, line valves, and actuation.

VSI has been helpful in many ways, from greasing valves, valve repair, valve replacement, and training our guys as well. We can’t say enough about quotes, labor support, material delivery time, and billing. Aaron has helped us out of several jams over the years and we appreciate it.

VSI has rebuilt our pressure relief valves here at [our processing plant] for several years now and I have always been very pleased with their service and quality of work. The work is always completed on time and we have had no reliability issues with the valves they’ve worked on. It’s always a pleasure working with VSI and I look forward to continuing the relationship.

Valve Sales Inc. provides outstanding service and support for all of our valve needs. Their dedication to quality and consistency allows our equipment to run more reliably and improves overall performance of our facility. Our goal is to provide consistent high performing products to our customers and VSI allows us to achieve this goal.

The entire team at VSI has always been able to meet my needs and always exceeds my expectations. I have a great relationship with both the sales and service teams they are always ready to answer technical questions and provide excellent advice on ways to solve problems in the field and are always ready with solutions no matter how obscure or unusual the problem. VSI is more than ready and able to meet all my valve needs at any given moment.

TULSA, OK – August 31, 2022 - Valve Sales Inc. (VSI), and Baker Hughes have partnered to distribute, service, and repair the complete line of Consolidated™ pressure relief valves. VSI’s service and… Read More

If you turn on your gas oven and it doesn"t heat up, there are several possible causes, and you may be able to remedy the problem yourself, without calling a repair service.

Unplug the appliance and turn off the breaker that is dedicated to the appliance before attempting repairs. Appliance repair experts are worth looking into and are typically affordable.

If you are lucky, the problem may simply be that the electrical circuit supplying power to the oven has tripped a circuit breaker. Even though the oven heats with gas, it requires electrical power to operate the timer and other components, and if the circuit breaker has tripped, the oven will refuse to heat.

Since this is a gas oven, it will be connected to a circuit with a standard 15- or 20-amp breaker, not a large double-pole (usually 50-amp) breaker such as those used by electric ovens. Your oven may have its own breaker, or it may be tied into one of the small appliance or kitchen receptacle (outlet) circuits with a common breaker. If the breaker serving the oven has not tripped, the next thing to check is the gas supply and igniter.

Although rare, it is possible that your supply of natural gas or liquid propane gas has been interrupted for some reason. This usually happens when the main gas valve has been shut off to make some repair or replacement in the system and hasn"t been turned on again. Check the main gas valve, as well as any valves located on branch lines, to make sure they are in the ON position. If your oven has just been repaired or replaced, it"s also possible that the gas valve on the supply pipe hasn"t been turned back on. If the gas supply checks out to be fine, then turn to the gas igniter on the oven itself.

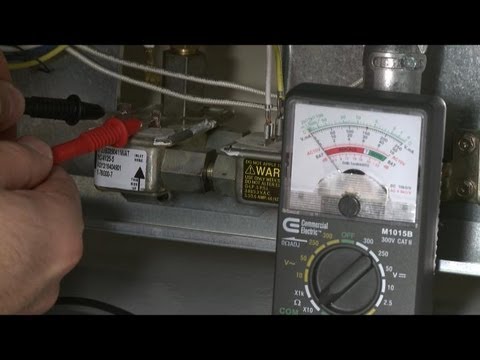

The problem could be that your oven igniter has simply gone bad. In normal operation, when the oven control is turned to bake, the igniter turns on and starts to glow bright orange. After the igniter gets hot, the gas valve opens and sends gas through the burner. The igniter lights the gas coming from the burner and the oven begins to heat.

If, however, the igniter doesn"t glow hot enough, the oven will not light, and you"ll likely smell a little gas. Don"t worry though; the gas valve is equipped with a safety mechanism that shuts off the gas if the igniter isn"t working properly.

To check the igniter, turn off the circuit breaker to the oven, then confirm the power is off by making sure the oven light, clock, and any other electrical functions are not working.

Remove the oven racks and the large metal plate (there may be more than one) at the bottom of the oven. This should expose the gas burner and igniter.

If the igniter looks okay, you can turn the power back, set the oven to heat, and observe the igniter at the beginning of the heating cycle. It should glow a bright orange within a few seconds. If it does not, and the gas does not ignite quickly, turn off the oven to stop the ignition function. The igniter has failed the test and will need to be replaced.

Before you can replace the igniter, you"ll have to order a replacement for the defective one. Not all igniters are the same. In fact, they are pretty much all different and have different electrical connections. The only way to get the right replacement part is to start with the oven"s model number and serial number. This may be on the back of the unit, inside the door or drawer, or even on a card or tab that slides out from behind the control panel of the oven. With your model and serial numbers in hand, you can search online for a replacement part, or call or visit a local appliance parts supplier. You can also contact the oven manufacturer online or by phone.

Shut off the power before doing any work on the oven, and be careful not to touch the igniter coil. Sometimes, these are black-colored spring-like coils; other times they are flat prong-like loops extending from the base of the igniter. The coil is very fragile, and oil from your hands getting on it can shorten the lifespan of the igniter.

Remove and replace the gas igniter, following the instructions included with the new igniter. It is an easy job, requiring only screwdrivers, a circuit tester, and a replacement igniter.

8613371530291

8613371530291