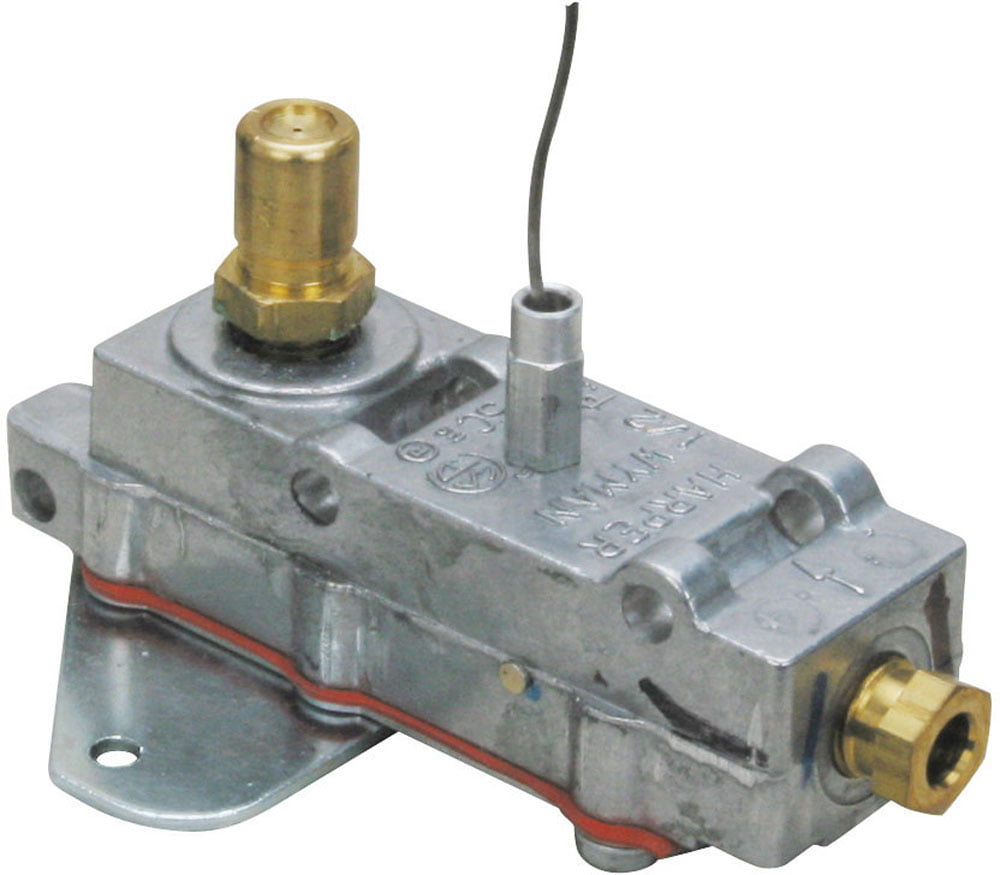

harper wyman safety valve free sample

The present invention relates to an improved control system and valve structure for gas ovens, and more particulaly to a system and valve structure for preventing unsafe conditions due to opening of the oven door or absence of a standing pilot flame.

For reasons of safety is it desirable to prevent operation of a gas oven when the oven door is open. For one example, in mobile homes and other recreational vehicles gas ovens may be designed to use outside air for combustion. In this situation, operation of the oven with the door open can defeat this arrangement and cause dangerous oxygen depletion within the vehicle. Moreover, operation of any oven with the door open produces other safety problems such as the danger of fire.

Important objects of the present invention are to provide an improved system and an improved valve structure for controlling pilot gas flow in an oven so that the oven cannot be operated when the oven door is open or when no standing pilot flame is present; to provide an improved pilot control valve structure; and to provide a novel arrangement for controlling gas flow to the oven in dependence upon the position of the oven door and in dependence upon the presence or absence of a standing pilot flame.

Briefly, the above and other objects and advantages of the invention are achieved by the provision of an improved system and valve structure for a gas oven including an oven door movable between closed and opened positions and a main over burner disposed within the oven. A pilot burner located adjacent the main burner produces a standby pilot flame and a control pilot flame in response to the supply of a pilot flame gas flow and a control flame gas flow. A safety valve admits gas to the main burner in response to presence of the control pilot flame. An oven control provides the standing pilot gas flow and the control pilot gas flow by way of a novel pilot valve structure.

In accordance with one feature of the invention, the pilot valve structure includes a valve serving to interrupt the control pilot gas flow whenever the oven door is moved from its closed position. Consequently, no control pilot flame is present when the oven door is opened, and as a result of operation of the safety valve, no gas is admitted to the main burner. However, during opening of the oven door, the standby pilot flame continues to exist.

The pilot valve structure includes a single outlet for supplying both standing and control pilot gas flows to the dual rate pilot. The valve structure includes a first inlet for receiving control pilot flow and a second inlet for receiving standing pilot flow. A first valve member interrupts all flow to the dual rate pilot in its normally closed position and is movable to an open position by manual operation in order to light the standing pilot flame and thereafter is held in open position by means of a flame sensor disposed adjacent the standing pilot flame. The door responsive control pilot flow valve is disposed in the housing of the pilot valve structure, and serves to control flow through the control pilot flow inlet in response to position of the oven door.

FIG. 1 is a largely schematic and diagrammatic simplified view of a gas oven including an oven control system and valve structure embodying the principles of the present invention;

Having reference now to FIG. 1 of the drawing, there is illustrated an oven control system designated as a whole by the reference numeral 10 and constructed in accordance with the principles of the present invention. The oven control system 10 is associated with an oven 12, illustrated only in part, and includes a novel pilot control valve structure generally designated as 14 constructed in accordance with features of the present invention. The system 10 and valve structure 14 may be incorporated into any desired type of oven installation, and for purposes of example the illustrated oven 12 is associated with a free standing range including a door 16 hingedly mounted upon an oven front wall 18 for movement between open and closed positions. In accordance with important features of the invention, the system 10 and valve structure 14 prevent operation of the oven when the oven door is opened, and prevent admission of gas to the oven when no standing pilot flame is present.

Fuel is supplied to the main burner 20 from a gas supply manifold 26 by way of an oven control 28, a conduit 30, a safety valve 32 and a conduit 34. Although the oven control system 10 of the present invention may be adapted for many different types of oven installations and may make use of many different types of oven controls, the control 28 of the illustrated arrangement is of the type disclosed and claimed in U. S. Pat. No. 3,563,457 -- Bergquist et al. This control includes an operating knob 36 for controlling the operation of the oven 12.

Operating knob 36 is movable from the "off" position to a variety of operating positions wherein desired oven cooking temperatures are thermostatically maintained. In such positions the oven temperature is maintained at the temperature selected through setting of the knob 36 by the admission of fuel from the manifold 26 through the control 28 to a control pilot supply conduit 40 and to the conduit 30 and safety valve 32 as well as to the standing pilot supply conduit 38. Reference may be had to said U.S. Pat. No. 3,563,457 for a further description of the structure and operation of the oven control 28 beyond that necessary for an understanding of the present invention.

Admission of fuel from the control 28 and conduit 40 to the pilot 24, under the control of the valve structure 14 as described below, results in admission of fuel to the oven burner 20. More specifically, fuel flowing from the valve structure 14 to the pilot 24 through a conduit 42 enters through an inlet fitting 44 (FIGS. 2, 3 and 4) to a tubular pilot body 46 and is mixed with primary air entrained through an aeration aperture 48. The outlet end of tube 46 includes an upper outlet 50 and a lower outlet 52, and a deflector 54 is spaced from the end of the tubular body 46.

The standing and control pilot flames produced by pilot 24 are illustrated in FIGS. 3 and 4. When standing pilot fuel flow provided to the pilot 24 from control 28 through conduit 38, valve structure 14 and conduit 42 is ignited, a standing pilot flame designated by reference numeral 56 and indicated by broken lines in FIGS. 3 and 4 is produced. This standing pilot flame impinges upon a flame sensing device comprising a fluid charged blub 58 communicating by way of a conduit 60 with the valve structure 14.

When flow to the pilot 24 is augmented by the control pilot gas flow from the control 28, conduit 40, valve structure 14 and conduit 42, the flame at the pilot 24 extends into the deflector 54, and is partly deflected downward to produce the control pilot flame 62 shown in broken lines in FIG. 4. Standing pilot flame 56 continues to exist at upper pilot outlet 50 while the control pilot flame is produced at the lower outlet 52. The control pilot flame impinges upon a flame sensing device comprising a fluid charged bulb 64 communicating with safety valve 32 by way of a conduit 66.

Having reference now to the safety valve 32, this type of valve is well known to those skilled in the art, and any commercially available valve could be used in the system 10. One example of such a safety valve may be found in U.S. Pat. No. 3,469,781 -- Sekera, Jr. Valve 32 includes an inlet 68 connected to the control 28 by conduit 30 and an outlet 70 communicating with the burner 20 by way of conduit 34. The function of the safety valve 32 is to permit the flow of gas into the main burner 20 only during such time as a control pilot flame 62 is sensed at the pilot burner 24 by bulb 64. Heating of bulb 64 causes the valve 32 to be operated from its closed condition to its open condition in response to the establishment of a control pilot flame 62, and cooling of bulb 64 in the absence of a control pilot flame 62 results in closing of the valve 32. Reference may be had to said U.S. Pat. No. 3,469,781 for a further description of the structure and operation of the safety valve 32.

In accordance with important features of the present invention, the pilot control valve structure 14 is provided in the oven control system 10 in order to prevent unsafe operation of the oven 12 when no standing pilot flame 56 is present and/or when the oven door 16 is moved from its closed to its open position. In general, the valve structure 14 includes a housing 76 closed by a cover plate 78 and having an inlet 80 communicating with the standing pilot supply conduit 38, an inlet 82 communicating with the control pilot supply conduit 40, and an outlet 84 communicating by way of the conduit 42 with the pilot burner 24.

Unsafe operation of the oven when the oven door is open is prevented by means of a valve generally designated as 86 incorporated in the valve structure 14. The valve 86 is controlled by a door responsive operating linkage 88 to open communication between the control pilot supply conduit 40 and the pilot 24 only when the oven door 16 is in its closed position, and to prevent the flow of gas to the pilot 24 when the oven door 16 is in its open position.

Undesirable admission of fuel to the oven 12 when no standing pilot flame 56 has been established is prevented by means of a valve generally designated as 90 controlling flow through the outlet 84 of the valve structure 14 to the pilot 24. Valve 90 is normally closed and can be moved to its open position by means of a manual operating linkage 92, and can be maintained in its open position by a standing pilot flame responsive operating linkage 94.

Referring more specifically now to the valve structure 14, the two valves generally designated as 86 and 90 are of similar construction. Each includes a movable valve member including a reciprocating slider element 96 movable in a bore in the housing wall and provided with grooves 98 for flow of gas through the valve when in its open position. A washer 100 is press fitted onto each slider element 96 to retain an O-ring seal 102 in position between the washer 100 and the housing. Normally a spring 104 held in compression between the washer 100 and a spring retainer and fitting element 106 forces the O-ring seal 102 into sealing relation between the washer 100 and the housing 76 in order to maintain the respective valve 86 or 90 in its normally closed position. Each slider element 96 is provided with an operating pin 108 extending into the interior of the housing 76 for moving the slider element 96 against force of the spring 104 in order to open the respective valve 86 or 90.

In accordance with a feature of the invention, the valve 86 permits gas to flow to the pilot 24 to produce the control pilot flame 62 only when the oven door 16 is moved to its closed position. When oven door 16 is open, the valve 86 is in its closed position as illustrated in FIG. 2 of the drawings and no fuel flows from the conduit 40 to the pilot 24 through the valve 86. As a result, no control pilot flame 62 is established and the valve 32 does not open to admit fuel to the oven burner 20.

In order to operate the valve 86 between positions, the cover plate 78 of the valve structure 14 carries a boss 110 slidably supporting a push pin 112 carrying a push plate 114. A spring 116 held in compression between the boss 110 and the plate 114 holds the pin 112 in its normal position illustrated in FIG. 2 when the oven door is open. When the oven door is closed, the door responsive operating linkage 88 (FIG. 1) which may include any suitable force transmitting structure indicated by broken lines 117 coupled between a door guide 118 and a push rod 120 or other pushing device engages the push plate 114 and forces the push pin 112 into the housing 76 by overcoming the force of the spring 116. The end of the pin 112 engages and depresses the operating pin 108 of the slider element 96 thus opening the valve 86 and permitting fuel to flow from the inlet 82 through the housing 76 and from the outlet 80 through the conduit 42 to the pilot 24.

In accordance with another feature of the invention, the structure 14 includes the valve 90 for preventing the admission of any fuel to the oven 12 until such time as a standing pilot flame 56 is established. When no standing pilot flame is present, the valve 90 is in its normally closed position as illustrated in FIG. 2 of the drawing. In order to condition the oven for operation, a standing pilot flame 56 is established. In order to permit gas to flow to the pilot 24 in order to ignite a standing flame, the operator of the oven first operates the manual linkage 92 in order to open the valve 90. With reference to FIG. 1, it can be seen that in the illustrated arrangement the manual linkage 92 includes a push button 122 movable within a housing 124 supported in the front wall 18 of the oven. When the push button is depressed against the force of a push button spring 126 a suitable force transmitting arrangement designated by a broken line 128 moves a push rod 130 in order to open the valve 90.

The valve 90 is manually controlled in response to movement of the push rod 130 by means of a push pin 132 (FIGS. 2-4) reciprocally supported by a boss 134 in the cover plate 78 and normally held in the position illustrated in FIG. 2 by means of a spring 136 held in compression between the boss 134 and a push plate 138. When the push rod 130 moves against the push plate 138, the pin 132 moves into housing 76 to depress the operating pin 108 of the slider element 96 thereby to open the valve 90.

Once the valve 90 has been opened by operation of the manual linkage 92 and fuel is flowing to the pilot 24, the standing pilot flame 56 is ignited by a match or other suitable ignition means. When the standing pilot flame 56 is established as illustrated in FIG 3 of the drawings, the flame heats the standing pilot flame sensing bulb 58 causing expansion of the fluid held therein. This expansion is accommodated by an expansible diaphragm 140 disposed within the housing 76 and communicating with the bulb 58 through conduit 60. Expansion of diaphragm 14 causes a power element 142 to pivot an operating lever 144 of the flame responsive operating linkage 96 around a pivot member 146. The lever depresses the operating pin 108 of the valve 90 to hold the valve 90 open so long as the standing pilot flame 56 continues.

The operation of the oven control system 10 and of the pilot control valve structure 14 will be apparent to those skilled in the art in view of the preceding detailed description. Briefly, the structure 14 is shown in FIGS. 1 and 2 in a non-operating or fully shut down condition wherein the oven door 16 is open and wherein no flame exists at the pilot 24. In this condition, the valves 86 and 90 of the valve structure 14 are both closed and no gas is admitted to the pilot burner 24. In addition, the valve 32 is closed in the absence of a control pilot flame 62 and no gas is admitted to the main oven burner 20.

In order to prepare the oven 12 for operation, the operating knob 36 of the oven control 28 is moved from the "pilot off" to the "off" position so that communication is established to the standing pilot flow conduit 38 leading to the inlet 80 of the valve structure 14. The push button 122 is depressed and to open the valve 90 and establish communication between the conduit 38 and the conduit 42 and pilot 24. The gas flowing from the pilot 24 is ignited and, as illustrated in FIG. 3, the standing pilot flame is produced. The standing pilot flame 56 heats the bulb 58 and the diaphragm 140 expands and lever 144 holds the valve 90 in its open position. At this time the push button 122 may be released by the operator of the oven 12 and the valve 90 will nevertheless be maintained in its open position by the continuing standing pilot flame 56.

The standing pilot flame 56 continues to burn to maintain a continuing source of ignition in the oven 12. In order to carry out a cooking operation with the oven 12, the oven door 16 is closed. When this occurs, the valve 86 is opened to permit the flow of fuel from the control pilot flow conduit 40 through the valve structure 14 and conduit 42 to the pilot 24. When the operating knob 36 of the control 28 is moved to an operating position, gas flows through conduits 40 and 42 to the pilot burner 24, and as illustrated in FIG. 4 a control pilot flame 62 is established. Simultaneously, the control 28 admits gas to the conduit 30 and inlet 68 of the valve 32. When the control pilot flame 62 heats the bulb 64, the valve 32 is operated to its open condition and fuel flows through the valve 32 and conduit 34 to the main burner 20 where it is ignited by flame at the pilot burner 24.

If at any time during operation of the oven the oven door 16 is moved from its closed position, flame at the main burner 20 is discontinued and the control pilot flame 62 at the pilot burner 24 is also discontinued while the standing flame is permitted to continue for reignition when the door is closed. More specifically, when the door 16 is open, the door responsive operating linkage 88 causes the valve 86 to close to prevent flow from the control pilot flow conduit 40 through the inlet 82 into the valve structure 14. As a result the control pilot flame 62 is discontinued and the bulb 64 cools. The safety valve 32 then closes to discontinue flow into the main burner 20 until such time as the oven door 16 is reclosed.

F16K35/027—Means to prevent accidental or unauthorised actuation to be locked or disconnected by means of a pushing or pulling action the locking mechanism being actuated by pushing or pulling the valve actuator, the valve actuator being rotated subsequently to bring the valve closure element in the desired position

The invention relates to a valve or tap for fluids, comprising a body, a revolving shutter in said body between a closing position and opening position, and control means for rotating said shutter, wherein said control means can be moved axially between a raised position in which they are locked angularly to the body of the valve and a lowered position in which they are free to rotate, said means being normally held in a raised position by an elastic part.

The present invention relates to a valve or tap for fluids with a ball shutter set in the fluid passage duct revolving between an opening and closing position of said duct. [0001] BACKGROUND OF THE INVENTION

In the known embodiments, the ball shutter is constrained to a control rod with a throttle or grip lever fixed at the free end for opening/closing the valve. In practice, it is enough to rotate the throttle or grip lever even just a little to alter the position of the ball shutter and therefore the section of the passage of the fluid. It has been noticed that in some cases, such rotations of the throttle can occur accidentally, for example during plant maintenance, after strong vibrations or by unauthorised people, for example children. [0002] SUMMARY OF THE INVENTION

The object of the present invention is to resolve this type of problem by proposing a valve or tap for fluids of the type with ball shutter with a mechanical stop device to reduce the risk of accidental or unwanted rotations of the throttle or grip lever controlling the ball shutter. [0003]

Such object is achieved with a valve or tap for fluids comprising a body, a shutter revolving in said body between an opening and closing position, and control means for rotating said shutter, where said control means can be moved axially between a raised position in which they are locked angularly to the body of the valve and a lowered position in which they are free to rotate. [0004]

In practice, then, in order to be able to rotate the throttle or grip lever, and therefore also the ball shutter with the control means, it is first necessary to unlock these means by moving them axially. In other words, two consecutive, separate manoeuvres rather than just one are needed to operate the valve. [0006]

It is therefore clear that the control devices of the valve or tap can only be rotated intentionally and by authorised personnel, who know how to work the throttle or grip lever. [0007]

FIG. 7 represents a view from above of the valve control means in an unlocked open position.[0015] DESCRIPTION OF A PREFERRED EMBODIMENT OF THE INVENTION

The valve or tap for fluids comprises a body [0016] 10 in which a duct 11 is made, in a known manner, for the passage of the fluid. A ball shutter 12 is set in the body 10 revolving between an open and closed position of the duct 11. Control means 13, 14 are connected to the ball shutter 12 by means of which the shutter can be rotated 90° between said two open and closed positions. A throttle or grip lever 15 is connected to the control means for this rotation.

According to the invention, the control means comprise a first pin [0017] 13 joined to the ball shutter 12 and a second pin 14 placed in prosecution of the first and constrained angularly to this, for example by means of geometric coupling. The throttle or grip lever 15 is screwed to the top of said second pin 14. The latter can also be moved axially in relation to the first pin 13 between a raised locked position, in which it is constrained angularly to the valve body, and cannot therefore be rotated, and a lowered unlocking position, in which the throttle or grip lever 15, the two pins 13, 14 and the ball shutter 12 can be rotated. The run of the second pin 14 in relation to the first 13 is indicated by X in the drawings.

The second pin [0018] 14 presents a cylindrical hollow base 16 for coupling with and sliding on the free end of the first pin 13. A stem 21 reaches up from the base 16, with a basically rectangular transversal section, with rounded sides of a smaller width, bearing a threaded hole 27 for screwing a screw 28 to fasten the throttle or grip lever 15. The cylindrical base 16 is guided externally into a round slot 17 made in the body 10 of the valve.

For this to be locked angularly to the body [0023] 10 of the valve, the washer 19 has at least one radial tooth 25, which is inserted into a corresponding notch 25′ provided in said body 10. The washer 19 and the two pins 13, 14 are finally held in the relative slots in the body of the valve by an elastic ring 26 that is set and locked above the washer 19.

From the above, it will be appreciated that, before rotating the throttle or grip lever [0024] 15 from the locking position, pressure must be applied in an axial direction on said throttle, so that the second pin 14 moves towards the first releasing itself from the slits of the washer 19 only then can the control parts be rotated 90° to open the valve. Once these control parts have been brought back into the angular starting position, they will automatically return to the locking position thanks to the upward thrust of the spring 24.

It shall be noted that in the example of embodiment represented in the drawings, when the control means [0025] 13,14 and 15 are rotated in the valve opening position—FIGS. 5,6 and 7—the steps 22 of the second pin 14 stay below the washer 19 making the second pin 14 remain in a lowered unlocking position. This allows the control means to be rotated in the valve closure position without needing to apply any prior axial movement.

Should it also be necessary to lock the control means in the valve opening position, it would be enough to make two more slits in the washer [0026] 19 in a diametrically opposite position in relation to those connected with the valve closure position to allow the second pin 14 to be raised and angularly locked to the washer 19.

1. Valve or tap for fluids comprising a body (10), a revolving shutter (12) in said body, and control means (13, 14, 15) for the rotation of said shutter, wherein said control means comprise locking means in an angular direction to the body (10), said locking means being movable in an axial direction between a raised position for locking to said body (10) and a lowered position for unlocking from said body, said lowered position being suitable for allowing said control means to rotate.

3. Valve or tap according to claim 1 or 2, wherein the control means comprise a first pin (13) joined to the shutter (12) and a second pin (14) constrained in an angular direction to the first pin, said second pin being movable in an axial direction in relation to the first pin between a raised position for locking to the body (10) and a lowered position for unlocking from said body, the means for locking to the body (10) being connected to said second pin (14).

4. Valve or tap according to claim 3, wherein a washer (19) is provided around the second pin, said washer being locked into a slot (18) made in the body (10) of the valve, said second pin (14) and said washer being shaped to be constrained in an angular direction when the second pin (14) is in a raised position and released when the second pin is in a lowered position.

5. Valve or tap according to claim 4, wherein the washer (19) presents at least one radial slit (20), and wherein the second pin (14) presents a stem (21) designed to engage normally in said slit, said stem having a radial extension that decreases towards the top so that to be released from said slit when the second pin is moved in a lowered position.

6. Valve or tap according to claim 5, wherein the washer (19) presents two opposite radial slits (20), and in which the stem (21) of the second pin (14) presents a basically rectangular section, a step (22) being made in each of the sides of a smaller width of said stem, said step being designed to engage in a correspondent radial slit of the washer.

7. Valve or tap according to claim 6, wherein the radial slits (20) of the washer (19) are connected by opposite circumference arcs (23), and wherein the second pin (14) is rotatable along said arcs (23) when it is in a lowered locking position.

8. Valve or tap according to any one of the claims from 3 to 7, wherein the second pin (14) presents a hollow cylindrical base (16) guided externally into a round slot (17) made in the body (10) of the valve and shaped internally to join to and slide on the first pin (13).

9. Valve or tap according to claim 8, wherein a slot is made in the first pin (13) for an elastic element acting on the cylindrical base (16) of the second pin (14) to keep the latter in a raised locking position.

11. Valve or tap according to any one of the claims from 4 to 10, wherein the washer (19) presents at least one radial tooth (25) designed to be inserted into a corresponding notch (25′) made in the body (10) of the valve for its angular locking to this.

12. Valve or tap according to any one of the claims from 8 to 11, wherein the washer (19) is partially overlapping the base (16) of the second pin (14), and wherein an elastic ring (26) set and locked above the washer holds this and the pins in the relative slots in the body (10) of the valve.

13. Valve or tap according to any one of the claims from 4 to 12, wherein a throttle or grip lever (15) is fixed to the top of the second pin (14) for operating the valve.

Gas pipe shutoff valve fitting has a ring section with an inner collar with structured cut-outs and recesses to be operated by the handgrip in a low cost assembly for fitting into the housing without modification

Charles 0.1 Lamar, "Chicago, 111.; assig"norto Har"per-Wyman Company, Chicago, Ill., a co"rporation of Illinois Applicationjluly so, 1948, Serial No." 11,6ss

such as a stove or range burner, to a continuously burning pilot flame located a short distance from the burner through a tube called a flash tube. The"gas is so conducted when a control valve is opened to supply gas to the burner and, when ignited by the pilot flame, the flash of ignition travels or flashes back through the tube and ignites gas escaping from the burner ports. This type of ignition is quite commonly used and many difierent types of apparatus have been devised to effect it.

The burners Ill may be of conventional construction. As illustrated, they include burner bases 20 and burner caps 22 having a seriesof burner ports 24 near their outer peripheries. Gas is supplied to the burners under the control of conventional valves, not shown, and when gas is supplied to the burners the gas escapes through the burner ports 24 and is ignited by al -flame flashed from the pilot burner [2 through aflash tube and escapes near the main burner end to ignite gas escaping through the lighter and burner ports.

In accordance with one of the primary features of the present invent on, the arrangement of the pilot burner housing structure and flash tubes is such that the flash tubes are supportable solely by the housing and the method of support is such that the tube cannot be rotated nor can it be moved angularly or tipped relative to the"pilot burner housing to any substantial extent. The arrangement thus facilitates fabrication and as-- sembly of the ignition apparatus and it also serves to locate the main burner end of the flash tube quite closely in desired position relative to the lighter jetfrom which the outer end of the tube may be suspended, if desired, by a connector 50 of a type disclosed and claimed in the copending application of Philip S. Harper, Serial No. 673,849,

G01N2001/205—Devices for withdrawing samples in the liquid or fluent state for flowing or falling materials by deviating part of a fluid stream, e.g. by drawing-off or tapping using a valve

8613371530291

8613371530291