herose safety valve made in china

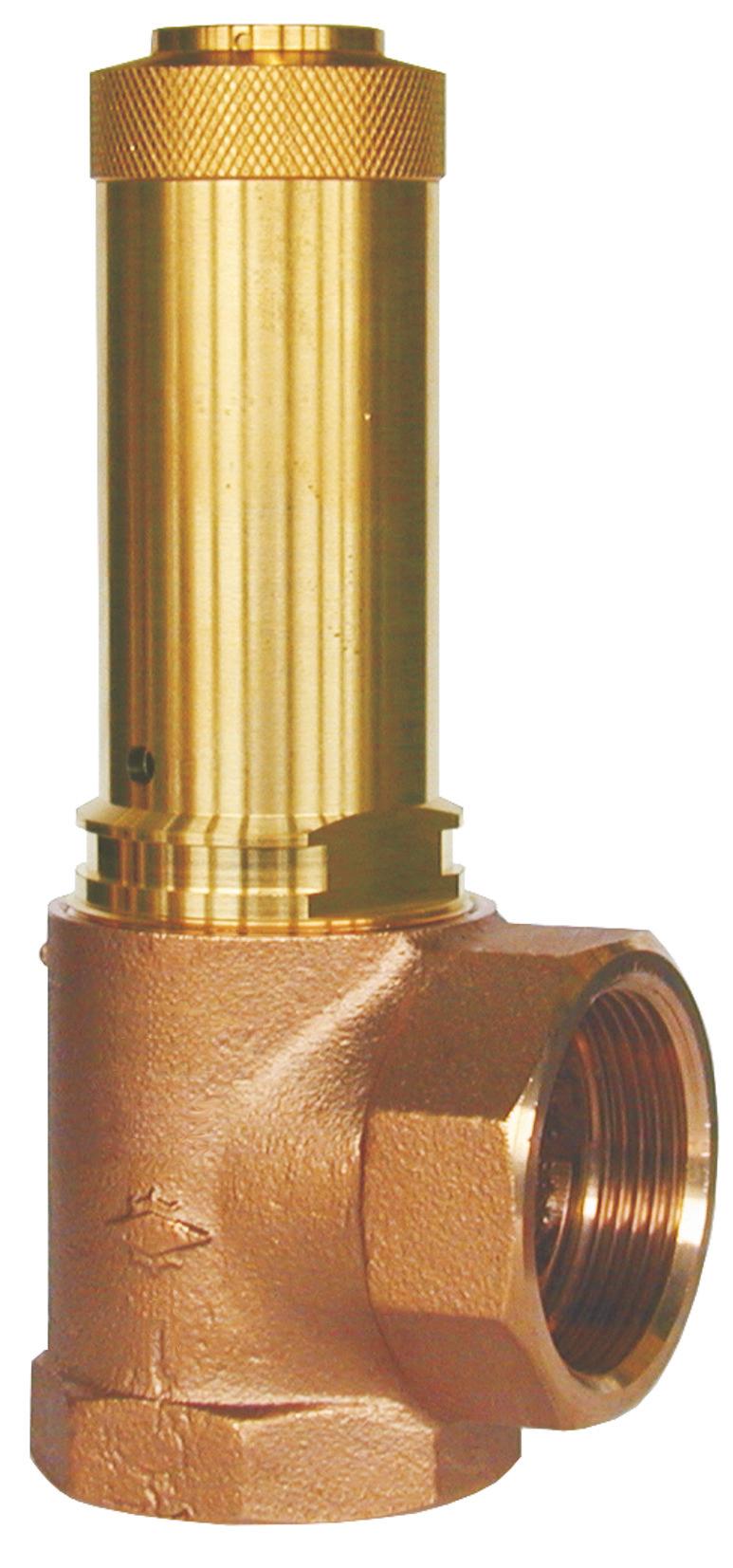

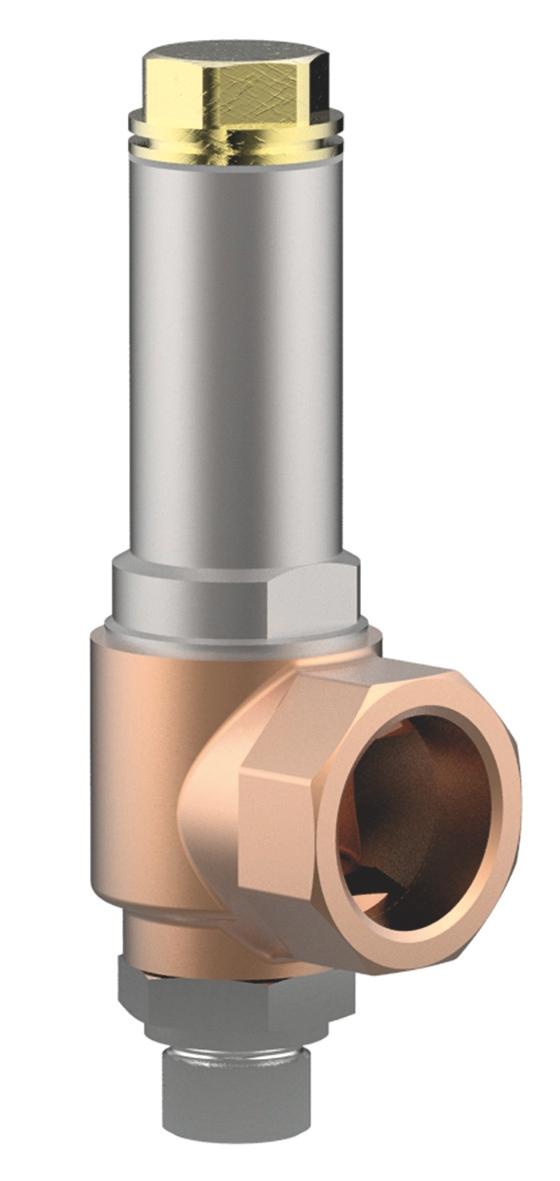

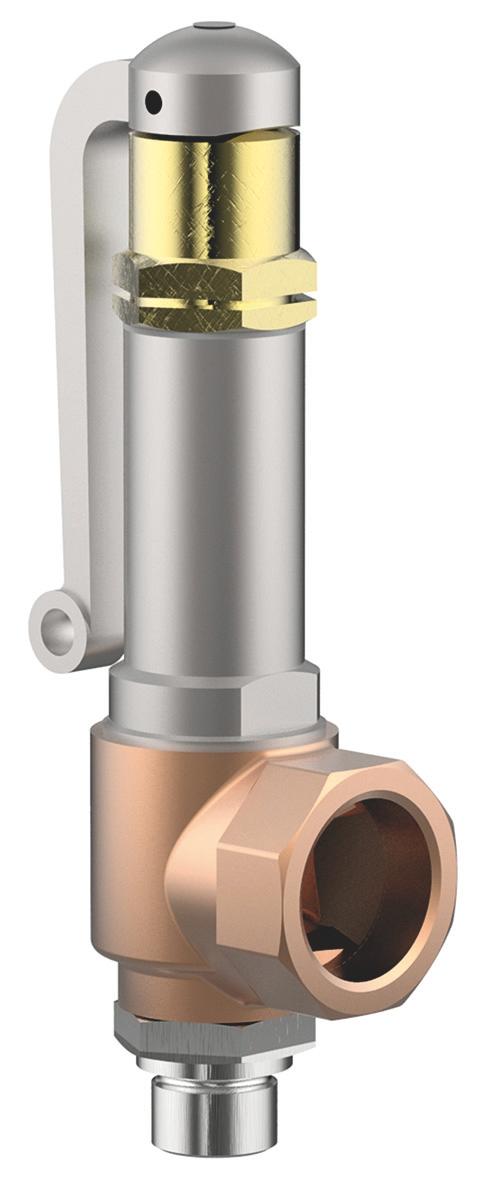

Valves for industrial applicationsIn order to prevent the uncontrolled rise in pressure in pressure vessels or pressurized pipelines, a safety valve is inserted. The safety valve is designed so that it opens at a given maximum pressure, thereby relieving the line or the container. Safety valves find their use in almost all areas of the pressure vessel and pipeline construction. In cryogenics as a spring-loaded safety valve for example.

HEROSE cryogenic safety valves are certified to global certifications for CN, TR CU and ASME. Thus they can be used worldwide, regardless of where the system is installed later. Cryogenic safety valves are available in sizes from DN6 to DN50 and secure pressures up to 550 bar, at operating temperatures of -270°C to +400°C. The safety valves are manufactured primarily in stainless steel but also in bronze and brass.

Please find the cryogenic safety valves in the product choice below. You can combine different product characteristicsto find your cryogenic safety valve better.

Safety with superiorityHEROSE provides safety around the world for the handling of technical gases, steams and liquids. With 140 years experience in the development, manufacture and sale of valves with a high level of innovation and modern production with certified quality management, our company is one of the world"s leading manufacturers and suppliers of

We specialise in developing and manufacturing individual solutions required by the market right up to the production stage. We have developed, e.g. an innovative valve generation for use in extreme temperatures between -270° C and +400° C, special valves for air separation and valves for the liquefaction of natural gas (LNG).

Foundry master Theodor Rose set up the valve factory Th. Rose KG in Altona. He started production of valves for ship construction and building technology

Construction of the new production facilities in Bad Oldesloe covering 3500 square meters. Continuing more than 130 years of tradition, quality valves are still manufactured here

Nickel plating provides a high resistance to acids and alkalis and can be recognised by a slightly "yellowish" appearance compared with chrome plated versions. Chrome plating also provides additional protection due to its greater hardness and can be visually recognised by its clear mirror-finish. However, the surface gloss can only be controlled within certain limits (surface gloss vs. durability) and it always depends on the existing surface structure of the substrate material. Essentially, the surface gloss depends on the degree of gloss of the underlying nickel plating. Normally, the external components of HEROSE valves are treated. However, this does not mean that the internal components can be treated if required.

Electroplating refers to processed for the electrochemical deposit of metallic coatings onto metallic or non-metallic substrates. Electro-crystallisation is carried out in an aqueous solution of metal salts, either by the external application of direct current (method I), or without the use of current by means of the reaction of the metal ions with a reducing agent (method II). The components of HEROSE safety valves are given a high-gloss nickel plating by means of method I. Although methods which do not use current, e.g. chemical nickel, plate all surfaces which are wetted by the electrolyte, they do not provide the required degree of gloss.

After triggering by a pressure increase of within 5%, full-stroke safety valves open suddenly to the constructive limit of their stroke. The proportion of the stroke up to sudden opening must not exceed 20% of the total stroke. (See also DIN ISO 4126-1:2004, AD 2000 data sheet A2, ASME Code Sec. VIII Div I; UG-125 (c) )

According to AD 2000 data sheet A2 and DIN ISO 4126-1:2004, safety valves must close within a pressure reduction below the triggering pressure of 10% for compressible media and 20% for incompressible media.

It is not possible to make a general statement regarding the degree of sealing for helium. If a helium leak test is required, the customer must state his specifications. HEROSE will then attempt to achieve the customer"s specifications by alternating leak tests and reworking.

The tightness of a safety valves is examined at HEROSE according to the following procedure (see API 527): The outlet shall be locked with an adapter, to which a hose is plugged. On the other site this hose is connected with a tube, which plunges in a glass full of water. The tube shall have an outside diameter of 7.9mm, an inside diameter of 6.12mm and an immersion depth of 12.7mm. The amount of bubbles per minute gives evidence about the level of leakage. Permitted values are ruled in the API 527. Higher requirements for the tightness need a separate individual handling of the valve. Other than metal sealing valves, soft-seal valves have to be bubble-tight up to 90% of the set pressure.

After that, the disc of the safety valve begins already to float on the seat until the safety valve starts to open audibly. Because of external factors (vibrations, temperature increase), which could have an effect on this, the safety valve could start to open earlier. Therefore HEROSE recommends limiting the max. operating pressure up to 85% of the set pressure of the safety valve. Therefore the tightness is guaranteed in any case.

HEROSE is the leading manufacturer worldwide of valves for cryogenic applications and services. Based on 140 years of experience in the development and manufacture of valves, we strive to provide customers with technical solutions over and above industry standards.

Our cryogenic safety valves are installed for protection against overpressure in tank containers and pipelines used for the storage, distribution and transport of liquefied gases — such as oxygen, nitrogen, argon, carbon dioxide, helium, hydrogen, etc. — at temperatures as low as -270°C (-454°F). A bellow-sealed option is available.

A major global gas company successfully subjected our cryogenic safety valves to an endurance test of 144,000 opening and closing cycles, and have subsequently been using our valves with trouble-free operation in over 35,000 installations for almost ten years.

Our diverter valves have been tested by a well-known cryogenic bulk vessel manufacturer. These tests reported a valve life expectancy of over 150 years.

HEROSE’s product range of LNG valves included bronze valves which are TUV-certified according to EN 12567, as well as stainless-steel valves which are additionally fire-safe approved according to EN ISO 10497.

This approval ensures that our fire-safe LNG valves remain tightly shut off, protecting plant and personnel when fires occur. HEROSE’s fire-safe LNG valves have been installed in critical applications worldwide.

Our product range of industrial safety valves covers the fields of gases, vapours, fluids and refrigerants. A special development is the industrial safety valve for pneumatically drained silo vehicles. Like other valves in the HEROSE range, this industrial safety valve is resistant to extreme vibration and environmental conditions.

As an environmentally aware company, we strive to ensure excellent sealing characteristics in all our industrial safety valves, minimising emissions to the atmosphere.

HEROSE offers the full package of cryogenic globe valves, control valves, check valves and emergency-closure valves, as well as diverter ball valves and change-over valves. All types are available in bronze or stainless steel, either for manual operation or as an actuated design.

More recently, we have introduced a complete range of stainless-steel gate valves, which takes HEROSE’s quality and design capabilities into new applications, such as cryogenic road tankers.

HEROSE is extending its range of products for cryogenic technology with ball valves. Especially for CO2 tanks and ISO containers for offshore use, or any other application where a rapid opening and closing of the valve is required, these cryogenic ball valves are an optimum supplement to the HEROSE product range.

HEROSE offers a range of pneumatic actuated cryogenic control valves. These valves are working with a linear or equal percentage control characteristic and are approved for air gases, vapours and cryogenic liquefied gases including LNG.

HEROSE’s success is ensured by our highly qualified staff. Our engineers are committed to the ongoing development of our valves to find tailor-made solutions for our customer base when existing products fail to meet their application requirements.

Our customers benefit from our TÜV approved quality systems according to the latest editions of DIN EN ISO 9001, PED 97 / 23 / EG, AD 2000 and TPED 99 / 36 / EG. The high-quality design of the HEROSE range is verified by the fact product complaints have only been made against less than 0.03% of the total valves we have manufactured. The company’s primary target is customer satisfaction.

Herose is the leading manufacturer worldwide of valves for cryogenics and pressure containers. Herose has been engaged with our customers for more than 130 years, to maintain safe handling of air, steam, technical gases, and cryogenic liquids. Herose understand our customer"s challenges. With products made according to the highest known standards and an above-average investment in intensive research and development with a quality management that stresses the highest possible control and continuous improvement we meet their requirements everywhere and at all times.

Delta’s Agencies are all manufacturers, long respected as innovative suppliers of quality products in the field of industrial valve technology. Click on Logo’s below, which are linked to the websites of some of our major suppliers:

Founded by a group of TUV ISO 9001 certified manufacturers with CRN Registration, API 607 Fire-safe Approval, 94/9/EC Atex Certification, Germanischer Lloyd, TRD 100 & PED 97/23/EC accredited Anson foundries, is dedicated to providing a complete line of ball valves for your processing needs. Delta keep a wide range of standard stainless steel ball valves in stock and carbon steel ball valves are available upon request. Anson Flow specialise in valves for duties in the oil, gas, petrochemical and other processing industries.

DeZURIK is a leading manufacturer and provider of valve solutions for the water and waste water industry with over 250 years of combined history, DeZURIK is recognized worldwide for high-quality products, superior performance and innovation. From the introduction of the Eccentric Plug Valve in 1928 to the newest innovations in Knife Gate Valves, AWWA Butterfly Valves, V-Port Ball Valves, Check Valves and High Performance Butterfly Valves, they remain at the forefront of technology and provide effective solutions for industry.

Herose (Germany) are the market leader in the supply of Gate, Globe, ball and check valves for the worlds Cryogenic gas industry. Delta stock in Auckland, a full range of Cryogenic Ball valves and spares to support OEM.

EMME TECHNOLOGY S.r.l., founded in 1996, manufacture rack and pinion pneumatic actuators, solenoid valves, limit switches, and related automation accessories and hardware.

PETER SMITH VALVE COMPANY Specialise in the manufacture of small to medium size valves for the control of fluids and gases in most pipe conveying systems including parallel slide valves for steam applications. Peter Smith Valve Company manufacture in Cast Iron, Cast Steel and Gunmetal for use by major industries, steam, water authorities and marine applications.

Jiangsu SUNE Valve Co., Ltd. (SUNE) is a professional valve manufacturer, a sister company of Yancheng H&M Pressure Valve Co. Ltd .The company has very strong experience on ANSI/ASME/DIN standard valves, which include Gate Valve, Globe Valve, Swing Check Valve, Ball Valve, and strainers etc.SUNE Division is known for its strong ball valve manufacturing capability and are a partner with several world-wide brands including Newco and Cameron as well as their own.

Severn Glocon specialise in Critical Duty Control Valves, focusing on applications that no other manufacturers can resolve using their unique anti cavitation trims and bespoke Valve designs. Solutions available for Compressor Anti surge Recycling, Production Chokes, Level Control Valve separators, Main oil line pump recycling and water injection pump re Cycling Valves.

Sofis is a premium supplier of industrial valve safety products such as valve interlocks, valve position indicators, partial stroke testing devices and portable valve actuators. Our greatest strength is in providing simple and reliable custom-made products

Tosaca specialise in the design and manufacture of Safety Relief Valves and air/vacuum valves, all in accordance with DIN, EN, ANSI, API and other standards, with rigorous quality controls according ISO 9001:2000.

YDF are manufacturers of Petrochemical Valves, with three production facilities and their own foundry based in Yancheng City China. YDF have Exon approval and world wide acceptance they are a quality supplier of Gate, Globe, check and Ball valves.

Zavero is a leading Company in industrial valves production for Oil&Gas application all over the world. Zavero"s high quality valves are customized and designed to meet Customer’s requirements, technical goals appositely engineered job by job to ensure the best adherence and a longer working life, both for manual and automated operations.

8613371530291

8613371530291