high pressure safety valve manufacturers brands

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

Emergency situations are not the only times relief valves are active; once installed they continuously regulate the flow of substance. They can also be pre-set to open when the pressure or temperature gets to a certain point that may be dangerous. Generally valves are placed on or near the pump head of the hose, pipe or tube. A wide variety of relief valve designs exist, although most resemble ball-check valves, swing check valves or diaphragm valves.

This last is particularly useful when controlling a flow of fluids that contains suspended solids. Most relief valves are spring operated, as are the majority of check valves. One specialized type of relief valve is known as a vacuum relief valve. As opposed to a normal relief valve, which relieves high pressure, a vacuum relief valve is used to relieve dangerously low pressures, or vacuums, by inserting air or an inert gas.

Like every other type of check valve, relief valves may be constructed from a variety of materials, including PVC, brass, ductile iron, copper, polyethylene, polypropylene, aluminum, steel, stainless steel and rubber. Which raw substance is used to produce each relief valve depends on the environment said relief valve will be in. The wrong product could result in erosion or contamination of the process stream. However, as long as research is done, finding the appropriate type of relief valve is possible. Every plumbing or fluid transfer application in the industrial, commercial and domestic arenas employ or will employ check valves. In fact, check valves of all kinds are an essential part of every day life. Because they need not be supervised to function and prevent product malfunction, check valves are not only desirable but often required by law to ensure the safety of water, gas and pressure applications.

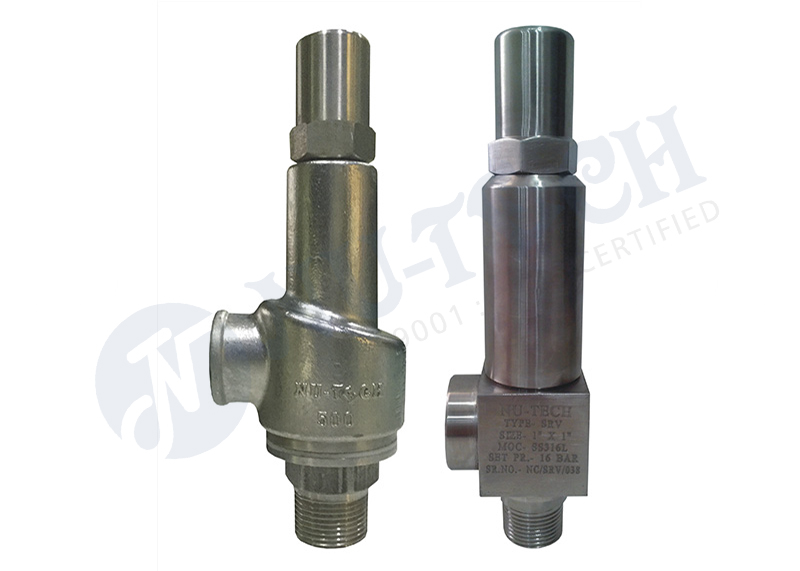

Distributor of safety relief valves. Features O-ring seats for leak-proof properties, wide hex valve nozzle for wrenching service, dual control rings for adjustability, ball bearing pivot between disc and spring for misalignment correction, and grooved piston model disc for sliding area reduction. Available in stock pressure settings of 125 to 200 psig, sizes from 1/4 to 6 in., and 5 to 6500 psi pressure range. Applicable to air gas, cryogenics, liquids, acids, caustic chemicals, ammonia and other corrosive liquids, and hydraulic system relief. Brass, bronze, iron, steel, and stainless steel body constructions are offered.

... -start valve with Series MX2 air treatment units without the need for additional connection interfaces. The soft-start valve is positioned upstream of the safety valves, ...

Two hands safety valve, which allows a safety use of two hands pneumatic controls (for example two push-button 3/2 N.C. to a certain distance) excluding false signals in case of push-button ...

The SI2 safety valve prevents the allowed operating pressure from being exceeded by more than 10%. If, after opening, the adjusted response pressure falls ...

... stainless steel full-lift clean service safety valve designed to AD Merkblatt A2 and TRD 421 standards and suitable for pure steam, vapour and inert gases.

Insert style flow control valves are comprised of a precision orifice in parallel with a check valve, combined into a single component. Each is designed for easy installation into metal housings using ...

Press-in style flow control valves are comprised of a precision flow orifice in parallel with a check valve, combined into a single component. Each part is designed for easy installation into plastic ...

If you have been searching for a safety release valve that you can use to reduce short-term pressure surges successfully and diminish the effects of gas leaks, this is the product for you. With a pe of ...

... have been type tested as well. These pressure regulators have safety valves which will slam shut in the event of emergencies, such as the gas reaching too high a pressure level. The valve ...

This product has hydraulically actuated class A gas safety valves to EN 161 used for automatic shut-off. It shuts off when unstimulated for gas and air, or even biologically produced methane. It has AISi ...

The S 104 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

The S50 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

The S100 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

... Pressure Safety Valve + Rupture Disk is protected and may be utilized autonomously as essential security gadgets or in conjunction. There are 3 possible combinations. The first combinations ...

Excavator pipe-rupture valves prevent uncontrolled cylinder movement in the event that a pipe or hose bursts. The ESV valve fulfills all of the requirements of the ISO 8643 and EN 474-5 standards for ...

Material: Body- CF8M; Valve Seat- CF8M Métal Seat, PTFE Soft Seat available Orifice Size: fc"(15mm), 3/4M(20mm), l"(25mm), l1/4,’(32mm)I ltë”(40mm), ...

The Safety valves from ATOS are designed to guarantee protection for application on various devices, especially those that monitor spool position. They are also recommended for hydraulic ...

The S50 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high ...

The S100 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high ...

139 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function, ...

Also known as pressure relief valves (PRV), pressure safety valves (PSV), and safety valves, these systems act as a safety measure. They relieve excess pressure from equipment failure, process upset, or fire by opening an auxiliary passage to divert the fluid (liquid, gas, steam or air) away from the pressure vessel. Once the pressure in the vessel is released and the danger is over the relief valve closes itself. Emergency situations are not the only times relief valves are active; once installed they continuously regulate the flow of substance. They can also be pre-set to open when the pressure or temperature gets to a certain point that may be dangerous.

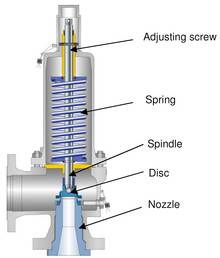

Generally valves are placed on or near the pump head of the hose, pipe, or tube. A wide variety of relief valve designs exist, although most resemble ball-check valves, swing check valves or diaphragm valves. This last is particularly useful when controlling a flow of fluids that contains suspended solids. Most relief valves are spring operated, as are the majority of check valves. One specialized type of relief valve is known as a vacuum relief valve. As opposed to a normal relief valve, which relieves high pressure, a vacuum relief valve is used to relieve dangerously low pressures, or vacuums, by inserting air or an inert gas.

Which raw substance is used to produce each relief valve depends on the environment said relief valve will be in. The wrong product could result in erosion or contamination of the process stream. However, as long as research is done, finding the appropriate type of relief valve is possible. Every plumbing or fluid transfer application in the industrial, commercial, and domestic arenas employ or will employ check valves. In fact, check valves of all kinds are an essential part of every day life. Because they need not be supervised to function and prevent product malfunction, check valves are not only desirable but often required by law to ensure the safety of water, gas, and pressure applications.

The RV10 safety relief valve is well-suited for overpressure protection of production equipment, including compressors, scrubbers, separators, pipelines or anywhere overpressure protection may be required.

Taylor Valve Technology® is a manufacturer leader in high-quality industrial valves. We deliver safety relief, high-pressure relief, and back pressure relief valves. Our wide array of choke and control valves and pilot-operated valve products are second to none. Products are designed for demanding industrial needs, meeting quality API and ASME Code requirements. High-demand oil & gas industry, chemical plants, power generators, and the processing industry depend on our valves for consistency and durability. Get effective flow control of liquid, steam, and gas. Valves ship from the Taylor Valve Technology, Inc. United States facility. Delivering worldwide, you can depend on quick turnaround times.

Curtiss-Wright"s selection of Pressure Relief Valves comes from its outstanding product brands Farris and Target Rock. We endeavor to support the whole life cycle of a facility and continuously provide custom products and technologies. Boasting a reputation for producing high quality, durable products, our collection of Pressure Relief Valves is guaranteed to provide effective and reliable pressure relief.

While some basic components and activations in relieving pressure may differ between the specific types of relief valves, each aims to be 100% effective in keeping your equipment running safely. Our current range includes numerous valve types, from flanged to spring-loaded, threaded to wireless, pilot operated, and much more.

A pressure relief valve is a type of safety valve designed to control the pressure in a vessel. It protects the system and keeps the people operating the device safely in an overpressure event or equipment failure.

A pressure relief valve is designed to withstand a maximum allowable working pressure (MAWP). Once an overpressure event occurs in the system, the pressure relief valve detects pressure beyond its design"s specified capability. The pressure relief valve would then discharge the pressurized fluid or gas to flow from an auxiliary passage out of the system.

Below is an example of one of our pilot operated pressure relief valves in action; the cutaway demonstrates when high pressure is released from the system.

Air pressure relief valves can be applied to a variety of environments and equipment. Pressure relief valves are a safety valve used to keep equipment and the operators safe too. They"re instrumental in applications where proper pressure levels are vital for correct and safe operation. Such as oil and gas, power generation like central heating systems, and multi-phase applications in refining and chemical processing.

At Curtiss-Wright, we provide a range of different pressure relief valves based on two primary operations – spring-loaded and pilot operated. Spring-loaded valves can either be conventional spring-loaded or balanced spring-loaded.

Spring-loaded valves are programmed to open and close via a spring mechanism. They open when the pressure reaches an unacceptable level to release the material inside the vessel. It closes automatically when the pressure is released, and it returns to an average operating level. Spring-loaded safety valves rely on the closing force applied by a spring onto the main seating area. They can also be controlled in numerous ways, such as a remote, control panel, and computer program.

Pilot-operated relief valves operate by combining the primary relieving device (main valve) with self-actuated auxiliary pressure relief valves, also known as the pilot control. This pilot control dictates the opening and closing of the main valve and responds to system pressure. System pressure is fed from the inlet into and through the pilot control and ultimately into the main valve"s dome. In normal operating conditions, system pressure will prevent the main valve from opening.

The valves allow media to flow from an auxiliary passage and out of the system once absolute pressure is reached, whether it is a maximum or minimum level.

When the pressure is below the maximum amount, the pressure differential is slightly positive on the piston"s dome size, which keeps the main valve in the closed position. When system pressure rises and reaches the set point, the pilot will cut off flow to the dome, causing depressurization in the piston"s dome side. The pressure differential has reversed, and the piston will rise, opening the main valve, relieving pressure.

When the process pressure decreases to a specific pressure, the pilot closes, the dome is repressurized, and the main valve closes. The main difference between spring-loaded PRVs and pilot-operated is that a pilot-operated safety valve uses pressure to keep the valve closed.

Pilot-operated relief valves are controlled by hand and are typically opened often through a wheel or similar component. The user opens the valve when the gauge signifies that the system pressure is at an unsafe level; once the valve has opened and the pressure has been released, the operator can shut it by hand again.

Increasing pressure helps to maintain the pilot"s seal. Once the setpoint has been reached, the valve opens. This reduces leakage and fugitive emissions.

At set pressure the valve snaps to full lift. This can be quite violent on large pipes with significant pressure. The pressure has to drop below the set pressure in order for the piston to reseat.

The pilot is designed to open gradually, so that less of the system fluid is lost during each relief event. The piston lifts in proportion to the overpressure.

At Curtiss-Wright we also provide solutions for pressure relief valve monitoring. Historically, pressure relief valves have been difficult or impossible to monitor. Our SmartPRV features a 2600 Series pressure relief valve accessorized with a wireless position monitor that alerts plant operators during an overpressure event, including the time and duration.

There are many causes of overpressure, but the most common ones are typically blocked discharge in the system, gas blowby, and fire. Even proper inspection and maintenance will not eliminate the occurrence of leakages. An air pressure relief valve is the only way to ensure a safe environment for the device, its surroundings, and operators.

A PRV and PSV are interchangeable, but there is a difference between the two valves. A pressure release valve gradually opens when experiencing pressure, whereas a pressure safety valve opens suddenly when the pressure hits a certain level of over pressurization. Safety valves can be used manually and are typically used for a permanent shutdown. Air pressure relief valves are used for operational requirements, and they gently release the pressure before it hits the maximum high-pressure point and circulates it back into the system.

Pressure relief valves should be subject to an annual test, one per year. The operator is responsible for carrying out the test, which should be done using an air compressor. It’s imperative to ensure pressure relief valves maintain their effectiveness over time and are checked for signs of corrosion and loss of functionality. Air pressure relief valves should also be checked before their installation, after each fire event, and regularly as decided by the operators.

Direct-acting solenoid valves have a direct connection with the opening and closing armature, whereas pilot-operated valves use of the process fluid to assist in piloting the operation of the valve.

A control valve works by varying the rate of fluid passing through the valve itself. As the valve stem moves, it alters the size of the passage and increases, decreases or holds steady the flow. The opening and closing of the valve is altered whenever the controlled process parameter does not reach the set point.

Control valves are usually at floor level or easily accessible via platforms. They are also located on the same equipment or pipeline as the measurement and downstream or flow measurements.

An industrial relief valve is designed to control or limit surges of pressure in a system, most often in fluid or compressed air system valves. It does so as a form of protection for the system and defending against instrument or equipment failure. They are usually present in clean water industries.

A PRV is often referred to as a pressure relief valve, which is also known as a PSV or pressure safety valve. They are used interchangeably throughout the industry depending on company standards.

The world is rapidly changing. As the industries we serve face increasing pressure to reduce their carbon footprint, digitally transform processes and optimize operations, the Valves team at Baker Hughes is ready to help our customers meet those challenges. Our culture of innovation and legacy of quality make us uniquely positioned to recognize and adapt to changing industry trends. From staying abreast of new manufacturing processes and materials sciences development, to converting our facilities and processes to reduce our own carbon footprint, we are creating solutions to help customers achieve their goals.

Consolidated boasts 140+ years of dedicated Pressure Relief Valve (PRV) Engineering and Manufacturing expertise. We know overpressure protection! With more than 10 major first-to-market products and features, Consolidated continues to deliver innovative technical solutions to the world"s most challenging overpressure protection applications. When combined with the expertise and full-scale service of the Green Tag Center (GTC) Network, Consolidated is able to provide a comprehensive approach to Valve Lifecycle Management (VLM) that is second to none.

Comprehensive Valve Lifecycle Management (VLM) enabled by state-of-the-art tools and delivered by the unparalleled Consolidated Green Tag Center (GTC) Network, Consolidated supports our product throughout the entire lifecycle.

With more than 1,050 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME XIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Nine subsidiaries and offices in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

Hyper Valve is trusted name in Indian valve industry. With our in depth industry experience, We manufacture, supply and export our superior quality Industrial Valves to our clients in all over the India and many other countries with the brand name Hyper Valve. We mainly manufacture Thermal Relief Valve, Safety Relief Valve & Pressure Relief Valve, Automatic Control Valve, Pressure Reducing Valve & Pressure Safety Valve, Pressure Regulators & Back Pressure Regulators.

Hyper Valve is a one of the famous brand of industrial valve on which people trust with closed eye because it is not only a brand but also commitment to reliability, quality, good performance and service. Our all products go through the strict sequence of the quality check from the raw material to the final manufactured product to ensure the finest quality of the valve. That’s why our clients believe in Hyper Valve’s product and use our products without any worries.

Our all products are manufactured using high quality materials in our advanced manufacture processing unit. Our organization is supported by a team of experts who are highly qualified and experienced. This staff take good care in offering the unique range of products to our clients from industries like Chemical & Petrochemical Industries, Process Industries, Nuclear Power Plant, Textile & Rayon Industries, Oil & Gas Refineries, Pulp & Paper Industries, Water Treatment Plants, Fertilizer Plants, Thermal and Nuclear Plants, Steel Plants, Pharmaceutical Plants etc.

Hyper Valve is one of the leading industrial valves manufacturer located at Ahmedabad, Gujarat, India. Our company is involved in manufacturing, design, supply and export of industrial valves. The company established the predefined structure and find out all resources to meet the growing industry demands and technical compliance. Hyper Valve is having the quality management certificate ISO 9001: 2015. We strictly follow various standards like ASME B 16.11, API 598 / BS 5146, API 602 / BS 5352, ASME B 16.34, API 598, ASME B 1.20.1, ASME B 16.25 and many other engineering standards.

Strong Valves is known as one of the biggest Safety Valves come in various sizes, shapes, and dimensions and can be modified to match our customers" specific requirements. Strong Valves sells and distributes Safety Valves that have been thoroughly tested. Safety Valves at Strong Valves are subjected to many toughness and hardness tests before being distributed to our customers. Our Safety Valves and their various variants are manufactured in India under international standards.

Safety Valves Manufacturers, Safety Valves Suppliers, Safety Valves Stockists, Back-Flow Safety Valve Manufacturer, High-Temperature Safety Valve Supplier in India

Our high-quality Safety Valves are specifically intended for the petrochemical sector, chemical industries, steel factories, fire prevention systems, and shipping industries, among other applications. Safety Valves, and their various varieties, are created and developed to meet international quality standards. —Precision-crafted Stainless Steel Safety Valves made from the highest quality raw materials.We can also customize Back-Flow Safety Valve and other varieties to meet the needs of our customers. In India, we are also the top supplier of Diaphragm Valves

Product Description: When the front pump pressure exceeds the specified amount, a Back-Flow Safety Valves is installed on the liquidoid refluence pipeline of the pan pump"s output at the liquefied petroleum gas station.

Product Description: Take, for example, Flange connection dimensions that conform with JB/T2769-94 standard series one and two for additional pressure protection devices. These Safety Valves are used for steam-related equipment and pipelines when the operating temperature with the C type is less than 425 degrees Celsius.

Product Description: These Safety Valves are used for steam-related equipment and pipelines where the operating temperature of the C type is less than 425 degrees Celsius and the I type is less than 500 degrees Celsius.

Product Description: This safety valve is utilized in steam, air, and other medium equipment and pipelines where the working temperature is less than 350 oC. Take, for example, supplementary pressure-relieving gadgets.

Product Description: This safety valve is utilised in steam, water, and other pipeline equipment and pipelines. Take, for example, additional pressure-relieving gadgets. The dimensions of the flange connecting flanges are in accordance with JB/T 2769-94 standard series one.

It"s part of a group of pressure safety valves (PSV) or Safety Valves (PRV) that also includes relief valves, safety relief valves, pilot-operated relief valves, low-pressure safety valves, and vacuum safety valves. When cold rinse water is utilized during hot CIP (clean-in-place) or SIP (sterilization-in-place) operations, vacuum safety valves (or combination pressure/vacuum safety valves) are used to prevent a tank from collapsing while it is being emptied.

Strong Valves is one of the only few largest Safety Valves suppliers in India. Strong Valves is one of India"s leading suppliers and manufacturers of Safety Valves. Each month we tend to supply/export Safety Valves, Back-Flow Safety Valves to Indian ports around forty containers to completely different customers.

Due to giving a prime quality of Safety Valves at lower costs with the accessible services, we have our sales representatives at most of the important cities of India that are:

Our high-quality Safety Valves and in-house processing capabilities have helped us establish ourselves as one of India"s most promising and leading exporters ofSafety Valves. We have frequent shipments to various nations for our freshly acquired clientele. Our ready supply of Safety Valves enables us to transport and meet the demands and wishes of our customers.

An auxiliary passage, which is where the relief valve sends the extra liquid or gas to relive the pressure in a mechanism, is usually just an extra pipe that leads to a chamber where most likely the fluid is burned and the gas left over is released into the atmosphere. This is a particular necessity in the chemical and petrochemical manufacturing industry, as well as in petroleum refining plants, natural gas processing and power generation industries.

If the pressure in a hydraulic pump exceeds its designed pressure limit, internal leakage or damage to the pump components can occur. Depending on what the liquid is, such leaks could also cause serious damage to individuals in the vicinity and the environment.

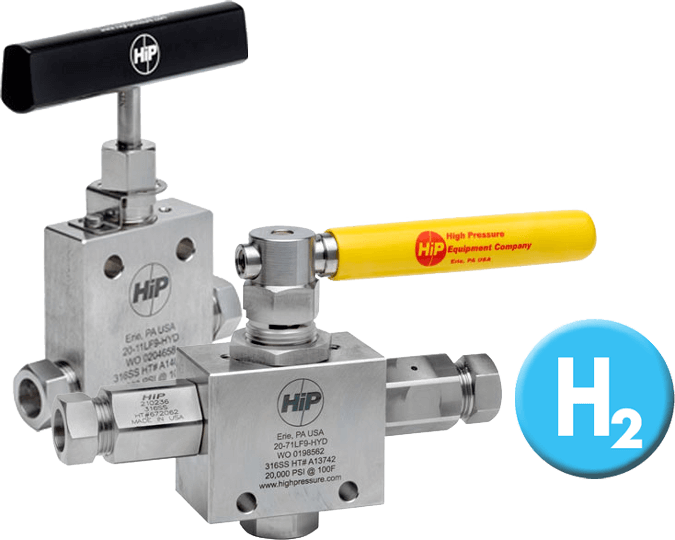

In hydraulic control systems, the relief valve acts as a check valve, with a ball and an adjustable spring. When a relief valve opens to divert fluid into an auxiliary passage, the pressure inside the hydraulic cylinder drops and allows the valve to close. A hydraulic system will often employ several types of valves, although the hydraulic relief valve is usually the first encountered in the circuit.

Hydraulic relief valves can be found in almost any mechanism that runs on hydraulic power, such as automobile transmissions, brakes, power steering, aviation and in industrial and construction machinery. Relief valves are built from the same basic materials that most hydraulic valves are made from. The strong and corrosion resistant metals that are most common are stainless steel, aluminum, iron, brass and copper.

Aluminum and stainless steel are thin, light weight and flexible, while still retaining the strength necessary to control the flow of liquid. Usually when a heavy metal like iron is used for the body of a valve, one of those two lighter metals is still used for the disc or plunger.

Plastic is also used, particularly thermoplastics that are developed specifically to be used as valve material. Although they are not as resistant to corrosion as metal, they are cheaper. It"s all about options.

8613371530291

8613371530291