hisec safety valve pricelist

Hisec simple steel bar 10 bar "1" is a model of safety valve (relief valve) made by Hisec company in Taiwan with a maximum working pressure of 10 bar, which is used to maintain safety in home installations such as motorhomes.

In general, safety valves are one of the most important and vital equipment in installation systems such as motorhomes and industrial sites, which open in case of a sudden increase of pressure to prevent the system from exploding and by discharging a volume of fluid (gas, air, steam or water) to Outside the system, they stabilize the pressure.

Hisec safety valves in two types of simple and simple in sizes of 1 inch, with a maximum working pressure of 10 or 20 bar made of brass or steel, are among the highest quality and at the same time the cheapest safety valves on the market for industrial applications. , Commercial or home-produced and supplied.

In the reference site and Damatajhiz store, all kinds of Hisec Asl safety valves have been provided for you, dear customers, in order to create a good feeling of optimal and smart purchase of safety valves.

Hisec simple steel bar 20 bar "1/2" is a model of safety valve (relief valve) made by Hisec company in Taiwan with a maximum working pressure of 20 bar, which is used to maintain safety in home installations such as motorhomes.

In general, safety valves are one of the most important and vital equipment in installation systems such as motorhomes and industrial sites, which open in case of a sudden increase of pressure to prevent the system from exploding and by discharging a volume of fluid (gas, air, steam or water) to Outside the system, they stabilize the pressure.

Hisec safety valves in two types of simple and lever in sizes of 1/2 to 2 inches, with a maximum working pressure of 10 or 20 bar made of brass or steel, are among the highest quality and at the same bar the cheapest safety valves on the market for industrial applications. , Commercial or home-produced and supplied.

In the reference site and Damatajhiz store, all kinds of Hisec Asl safety valves have been provided for you, dear customers, in order to create a good feeling of optimal and smart purchase

Safety valves English safety valve is an industrial valve product, whose main function is to protect the pipeline from pressure surge beyond the rated value. During work, it is always in the closed state. When the inlet pressure exceeds the rated value, the valve opens to allow some liquid to flow through and recirculate to the container. The safety valve operates on the Bernoulli principle.

Safety valve and pressure relief valve are two types of valves with completely different features, but some people still confuse these two types of valves, so to compare the differences between them, people can follow the table below. down here.

Valve shaft: Connected to the valve disc, is a straight shaft made from high-strength materials, the main function of which is to support the opening and closing of the valve disc.

Valve body: Has a structure of an inlet and an outlet port connected to the main pipe, which is a pressure reducing pipe and an exhaust pipe to let the fluid flow to the tank. Valve body is usually made from materials such as stainless steel, copper, cast iron, steel ...

Spring: Using the elastic force of the spring to adjust the valve to open and close for pressure relief, the spring can change the compression through an adjustment screw.

Valve cover: Connected to the valve body by bolts, making the valve tight and easy to maintain, this cover is usually made of the same material as the valve body.

Adjustment screw: The adjusting screw is a part used to adjust the set pressure for the safety valve, it will directly adjust the compression of the spring.

When the pressure passing through the pipe exceeds the rated pressure to which this safety valve is preset, the pressure level of this flow exceeds the compression force of the spring. The piston will be pushed up, the safety valve is opened to discharge the fluid, excess pressure to the outside or be connected to the pipe connecting the tank to discharge to the tank. This helps to reduce the pressure.

When the pressure level in the pipeline returns to normal, the piston is pushed back to the original position, the safety valve will close completely.

Valve body: The valve body is usually made up of materials such as cast iron, copper, stainless steel, steel, etc. This valve body also has two installation ports, the inlet and outlet ports.

Auxiliary valve spring: The spring of the auxiliary valve is designed with great rigidity, which is the main part of this safety valve to adjust the set pressure of the safety valve.

Main valve spring: The spring of the main valve has a design with less stiffness than the spring of the auxiliary valve. The spring of the main valve is connected together with the piston.

Piston: A detail that closes and opens the valve"s outlet, through this part, the fluid can be discharged when overpressure or blocked when the pressure returns to normal pressure.

When the pressure in the system is below the set rating. Both the auxiliary valve and the main valve of the safety valve will be in the closed state. The higher the pressure, the greater the pressure in the upper chamber of the piston, the tighter the piston is closed (under pressure conditions below rated pressure).

When the pressure is above the rated pressure, the auxiliary valve opens, releasing the pressure in the chamber above the piston. At this time, the pressure under the piston is greater than the pressure above the piston, so the piston is pushed up, releasing the pressure in the system through the exhaust port.

When the pressure in the system returns to the pressure level below the rated pressure, the auxiliary valve closes and the main valve closes, the cycle repeats the same.

These safety valve products are mainly because of their compact, simpler design, which helps to reduce structural materials, so the cost will also be lower than indirect-acting safety valve products.

Designed with an extra valve to adjust the valve, these safety valves have a more moderate pressure release, are easier to adjust, have multiple pressure settings, and can set the rated pressure to a high level. than.

These full valves often have a more complicated structure, more details and more parts, which often makes it more difficult to maintain, service and repair the valve if the valve fails.

These indirect-acting safety valves are more suitable for clean, treated fluid applications, their auxiliary valves are often quite sensitive to dirt and are prone to clogging.

Designed with threaded connection. This type of valve is usually produced with a smaller size, with the characteristics of being compact and simple. For quick and convenient installation.

Designed with a recoil arm, which is directly linked to the valve shaft. This product will help to release pressure directly manually in case of emergency.

In the field of oil and gas, oil and gas industry, valves are used with the main purpose to discharge toxic substances to help prevent fire and explosion.

Currently, safety valves have a very diverse design, so choosing the right product for certain applications is not difficult. So, here are some tips to keep in mind:

Next, it is necessary to consider what type of system the application is (steam, gas or liquid systems). Because these fluids will have their own characteristics and valves will also have separate designs.

For example: In compressed air applications where the gas can be discharged directly to the environment, a valve with an open bonnet can be selected. For applications where liquid is discharged to the tank, or gaseous fluids are not allowed to be discharged into the environment, it is necessary to use a valve with a tight bonnet.

The structure of the valve is a factor to consider in the selection process. Valves with different structures have different characteristics and applications.

Performance is a factor to consider, valve performance requirements will vary from application to application which is why it is important to choose the right valve.

Standard requirements, safety valve standards are often concerned, because it is related to structure and performance. This standard is generally approved by independent bodies.

After determining the set pressure of the valve, we proceed to set the set pressure through the adjustment part which is the adjusting screw on the valve body.

It is necessary to flush the pipeline before installation, to avoid the accumulation of impurities and dirt that are the factors that cause damage to the details in the valve.

These valves need to be installed according to their installation standards, with different connection types the installation standards of these types will be different.

Leaks are often caused by a number of reasons such as: incorrect installation, faulty gaskets in the valve, making the valve unable to close properly. The condition of impurities and dirt mixed in the fluid can cause blockage, causing the valve to not close properly.

Failure to close or open error. The reason is that valves have discs stuck in the open position, unable to close, which causes fluid loss. Valves that do not open are discs stuck in the closed position, causing the valve to not work, which prevents the system from releasing excess pressure and endangers the system.

To prolong the life of the valve, the best way is to maintain and maintain the valve regularly and properly. Recommended maintenance period is at least once every 12 months.

Handless stainless steel safety valve is a type of hydraulic device widely used in pipeline systems or in tanks, tanks containing gas or liquid. Valves are made entirely of stainless steel and are responsible for regulating pressure in pipeline systems or in tanks.

With the nature of being made of stainless steel, it has high pressure resistance and corrosion resistance. Valves have a full range of sizes so that users can choose and install suitable for piping systems.

With its outstanding advantages, the sleeveless stainless steel safety valve is quite popularly used in a number of factories and in a number of fields such as:

With stainless steel material, the valve can operate in many different environments, even in highly corrosive environments such as chemicals or solutions. All operating components are located inside the valve body so that no functional parts can be blocked from the outside, this allows for adequate cleaning of the external components.

The valve switches to automatic without additional auxiliary power as soon as the pressure exceeds the previously adjusted level and closes quickly and safely.

Currently, our company Viva is a unit specializing in providing customers with all kinds of industrial valves as well as sleeveless stainless steel safety valves with the best price today. Our products are quality assured and are imported from the leading countries in the industry and are trusted by many people.

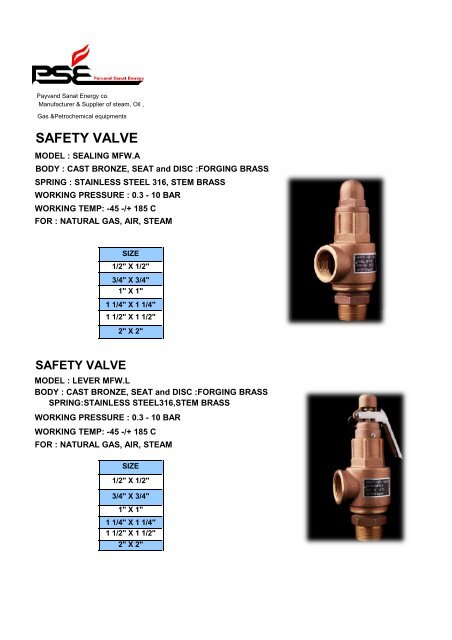

SAFETY VALVEMODEL : SEALING MFW.ABODY : CAST BRONZE, SEAT and DISC :FORGING BRASSSPRING : STAINLESS STEEL 316, STEM BRASSWORKING PRESSURE : 0.3 - 10 BARWORKING TEMP: -45 -/+ 185 CFOR : NATURAL GAS, AIR, STEAM

SAFETY VALVEMODEL : LEVER MFW.LBODY : CAST BRONZE, SEAT and DISC :FORGING BRASS SPRING:STAINLESS STEEL316,STEM BRASSWORKING PRESSURE : 0.3 - 10 BARWORKING TEMP: -45 -/+ 185 CFOR : NATURAL GAS, AIR, STEAM

SAFETY VALVE HISEC MODEL : SEALING MFW.ABODY : CAST BRONZE, SEAT and DISC :FORGING BRASS SPRING : STAINLESS STEEL 316, STEM BRASS WORKING PRESSURE : 0.3 - 10 BAR WORKING TEMP: -45 -/+ 185 C FOR : NATURAL GAS, AIR, STEAM

SAFETY VALVE MODEL : LEVER MFW.L BODY : CAST BRONZE, SEAT and DISC :FORGING BRASS SPRING:STAINLESS STEEL316,STEM BRASS WORKING PRESSURE : 0.3 - 10 BAR WORKING TEMP: -45 -/+ 185 C FOR : NATURAL GAS, AIR, STEAM

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale safety valve price list on Alibaba.com. When you search for safety valve price list and related items, you will be able to find many types of safety valve price list varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of safety valve price list that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

Relief and safety Valves are used in high pressure systems to control the pressure and keep balance of the system. The different between safety valves and relief valves is that the safety valves fully open or close under a certain pressure while the relief valves can open in proportion to the pressure in front of them. The safety and pressure relief valves are used automatically. They both operate under similar conditions. When the pressure builds up in a system, it has to be managed by releasing the material to flow through. These valves have a threshold pressure at which they open. The consolidated safety and safety relief valves comprise of a bonnet vent and bellow with springs.

The springs are set up for the threshold pressure and when the pressure exceeds the threshold, the spring is pushed into the bonnet vent and the bellow opens the valve. The Safety Relief Valves can be open and shut valves. They either open or shut off at any given pressure. This is mostly for the safety of an application not to explode under high pressure. The Pressure Relief Valve on the other hand releases the material after the threshold pressure, but not fully. If the pressure is slightly higher the threshold, then the valve opens slightly. If the pressure is very high above the threshold, it opens wider. It also functions in the same manner when the pressure drops down. The valve closes in proportion to the pressure. The safety valve shuts down at once only when the pressure is below the threshold.

Ready Stock of ASTM A351 CF8M Spring Loaded Safety Valve in wide range of Sizes, Stainless Steel Air Compressor Pressure Relief Valve Manufacturers In India

Relief Valves are designed to control pressure in a system While Safety Valves are used for controlling the pressure in a system they release pressure immediately in the event of an emergency or system failure

The Setpoint of relief valve is usually set at 10 Percent above working pressure limit while safety valve is usually set at 3% above working pressure limit.

If you are operating systems that can only be off for short periods of time, it is sensible to keep a spare valve to swap over and then the removed valve can be inspected and recertified.

8613371530291

8613371530291