how does a safety valve work in stock

As soon as mankind was able to boil water to create steam, the necessity of the safety device became evident. As long as 2000 years ago, the Chinese were using cauldrons with hinged lids to allow (relatively) safer production of steam. At the beginning of the 14th century, chemists used conical plugs and later, compressed springs to act as safety devices on pressurised vessels.

Early in the 19th century, boiler explosions on ships and locomotives frequently resulted from faulty safety devices, which led to the development of the first safety relief valves.

In 1848, Charles Retchie invented the accumulation chamber, which increases the compression surface within the safety valve allowing it to open rapidly within a narrow overpressure margin.

Today, most steam users are compelled by local health and safety regulations to ensure that their plant and processes incorporate safety devices and precautions, which ensure that dangerous conditions are prevented.

The principle type of device used to prevent overpressure in plant is the safety or safety relief valve. The safety valve operates by releasing a volume of fluid from within the plant when a predetermined maximum pressure is reached, thereby reducing the excess pressure in a safe manner. As the safety valve may be the only remaining device to prevent catastrophic failure under overpressure conditions, it is important that any such device is capable of operating at all times and under all possible conditions.

Safety valves should be installed wherever the maximum allowable working pressure (MAWP) of a system or pressure-containing vessel is likely to be exceeded. In steam systems, safety valves are typically used for boiler overpressure protection and other applications such as downstream of pressure reducing controls. Although their primary role is for safety, safety valves are also used in process operations to prevent product damage due to excess pressure. Pressure excess can be generated in a number of different situations, including:

The terms ‘safety valve’ and ‘safety relief valve’ are generic terms to describe many varieties of pressure relief devices that are designed to prevent excessive internal fluid pressure build-up. A wide range of different valves is available for many different applications and performance criteria.

In most national standards, specific definitions are given for the terms associated with safety and safety relief valves. There are several notable differences between the terminology used in the USA and Europe. One of the most important differences is that a valve referred to as a ‘safety valve’ in Europe is referred to as a ‘safety relief valve’ or ‘pressure relief valve’ in the USA. In addition, the term ‘safety valve’ in the USA generally refers specifically to the full-lift type of safety valve used in Europe.

Pressure relief valve- A spring-loaded pressure relief valve which is designed to open to relieve excess pressure and to reclose and prevent the further flow of fluid after normal conditions have been restored. It is characterised by a rapid-opening ‘pop’ action or by opening in a manner generally proportional to the increase in pressure over the opening pressure. It may be used for either compressible or incompressible fluids, depending on design, adjustment, or application.

Safety valves are primarily used with compressible gases and in particular for steam and air services. However, they can also be used for process type applications where they may be needed to protect the plant or to prevent spoilage of the product being processed.

Relief valve - A pressure relief device actuated by inlet static pressure having a gradual lift generally proportional to the increase in pressure over opening pressure.

Relief valves are commonly used in liquid systems, especially for lower capacities and thermal expansion duty. They can also be used on pumped systems as pressure overspill devices.

Safety relief valve - A pressure relief valve characterised by rapid opening or pop action, or by opening in proportion to the increase in pressure over the opening pressure, depending on the application, and which may be used either for liquid or compressible fluid.

In general, the safety relief valve will perform as a safety valve when used in a compressible gas system, but it will open in proportion to the overpressure when used in liquid systems, as would a relief valve.

Safety valve- A valve which automatically, without the assistance of any energy other than that of the fluid concerned, discharges a quantity of the fluid so as to prevent a predetermined safe pressure being exceeded, and which is designed to re-close and prevent further flow of fluid after normal pressure conditions of service have been restored.

Years ago, it was not uncommon to read news about tragic boiler explosions, sometimes resulting in mass destruction. Today, boilers are equipped with important safety devises to help protect against these types of catastrophes. Let’s take a look at the most critical of these devices: the safety valve.

The safety valve is one of the most important safety devices in a steam system. Safety valves provide a measure of security for plant operators and equipment from over pressure conditions. The main function of a safety valve is to relieve pressure. It is located on the boiler steam drum, and will automatically open when the pressure of the inlet side of the valve increases past the preset pressure. All boilers are required by ASME code to have at least one safety valve, dependent upon the maximum flow capacity (MFC) of the boiler. The total capacity of the safety valve at the set point must exceed the steam control valve’s MFC if the steam valve were to fail to open. In most cases, two safety valves per boiler are required, and a third may be needed if they do not exceed the MFC.

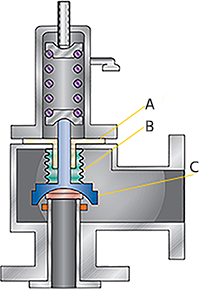

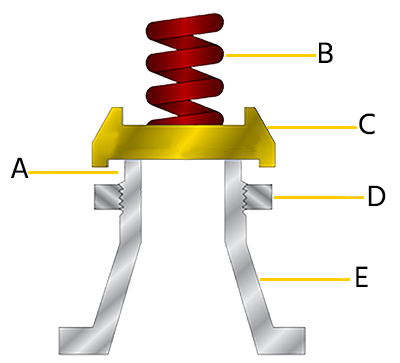

There are three main parts to the safety valve: nozzle, disc, and spring. Pressurized steam enters the valve through the nozzle and is then threaded to the boiler. The disc is the lid to the nozzle, which opens or closes depending on the pressure coming from the boiler. The spring is the pressure controller.

As a boiler starts to over pressure, the nozzle will start to receive a higher pressure coming from the inlet side of the valve, and will start to sound like it is simmering. When the pressure becomes higher than the predetermined pressure of the spring, the disc will start to lift and release the steam, creating a “pop” sound. After it has released and the steam and pressure drops below the set pressure of the valve, the spring will close the disc. Once the safety valve has popped, it is important to check the valve to make sure it is not damaged and is working properly.

A safety valve is usually referred to as the last line of safety defense. Without safety valves, the boiler can exceed it’s maximum allowable working pressure (MAWP) and not only damage equipment, but also injure or kill plant operators that are close by. Many variables can cause a safety valve on a boiler to lift, such as a compressed air or electrical power failure to control instrumentation, or an imbalance of feedwater rate caused by an inadvertently shut or open isolation valve.

Once a safety valve has lifted, it is important to do a complete boiler inspection and confirm that there are no other boiler servicing issues. A safety valve should only do its job once; safety valves should not lift continuously. Lastly, it is important to have the safety valves fully repaired, cleaned and recertified with a National Board valve repair (VR) stamp as required by local code or jurisdiction. Safety valves are a critical component in a steam system, and must be maintained.

All of Nationwide Boiler’s rental boilers include on to two safety valves depending on the size; one set at design pressure and the other set slightly higher than design. By request, we can reset the safeties to a lower pressure if the application requires it. In addition, the valves are thoroughly checked after every rental and before going out to a new customer, and they are replaced and re-certified as needed.

%20Cross-Section.png)

Thus, its operation is automatic; it will open only to release the pressure and not exceed the liquid force; therefore, its use is more common with fluids (although, they can also be used with vapours or moderate gases). In terms of capacity, they can withstand low pressures and their processes are continuous.

Safety valves is a product designed to protect the system from overvoltage. Safety valves act to reduce pressure by releasing excess pressure from the system.

The safety valves are in the normal state, ie in the normal pressure level, the valve disc will always be in the closed state. When the pressure exceeds the set pressure, the safety valve disc will be raised to open the outlet, the safety valve will be opened to release the pressure. When pressure returns to normal, the safety valve closes.

When the pressure of the system increases, overpressure occurs, the inlet pressure of the safety valve increases beyond the set pressure of the safety valve, at this time, the valve disc will be lifted out of position. its position by the pressure of the flow.

However, the higher the valve disc is raised, the greater the compression force of the spring on the disc, the higher the reset pressure will be. This means that the pressure must continue to increase in order for the flow to continue to flow through the valve.

The pressure level that rises above the set pressure set at the safety valve is called overpressure. This overpressure must be within the allowable range of the safety valve. It is specified in current standards and for different applications it will be specified differently. Example: For compressible liquids the acceptable overpressure is 3% - 10%, for normal liquids it is 10% - 25%.

The safety valves are designed with different opening angles, i.e. the height of the raised valve disc will be different. Classification based on the opening ratio of the safety valve, there are 3 main types of safety valves: full proportional open safety valve, small proportional open safety valve, medium proportional open safety valve.

Fully open safety valve: With this type of safety valve, the valve disc will be fully opened, the valve disc is raised enough so that the curtain area does not affect the discharge area. With safety valves of this type, the discharge capacity of the safety valve will be determined by the area of the borehole.

The safety valve opens in small proportion: The safety valve opens in a small proportion which means that the valve disc will not open completely, the lifting ratio of the common valve disc is ¼ - 1/20 of the diaphragm diameter.

Medium-proportionally open safety valve: In this medium-proportional open safety valve, the valve disc will open in the ratio between the fully-proportioned safety valve and the small-proportional open safety valve.

The set pressure or lifting force of the disc will be affected by many other factors, other external influences, including the effect of back pressure, which is the back pressure level from the valve outlet.

When the pressure in the system returns to normal the safety valves are required to close, however the safety valves are not closed because the area of the disc is still in contact with the liquid. Therefore, in order for the safety valves to close, the pressure in the system must drop below the set pressure.

The set pressure and reset pressure will have certain differences and are specified in percentages. Depending on the type of safety valve and depending on the application, the difference of set pressure and reset pressure will be different. For pressurized fluids, the difference between set pressure and reset pressure is usually less than 10%, for liquids the difference between set pressure and reset pressure can be as high as 20 %.

Back Pressure: Back pressure has a discharge back pressure level and an additional back pressure level, i.e. a back pressure level generated at the discharge port of the valve at the closed valve position and the open valve position. The back pressure will affect the valve opening pressure.

Our repair service center is designed to keep your customer’s safety and relief valves at peak operating efficiency. And put extra profits in your pocket.

North American’s Service Center is equipped to handle any safety valve repair. NASVI has the specifications for nearly every safety valve ever made—allowing technicians to make repairs to exact specifications. The center has six lathes on site, so technicians can restore tolerances on existing parts in quick order. If a part cannot be restored, it can generally be replaced from our extensive parts inventory.

Once repairs are complete, valves are tested and then set at one of six, fully equipped test stations. The boiler is on every day for testing steam valves. It’s always ready, allowing us to set and ship your valves fast.

Over the years, our Service Center has proven popular with maintenance managers. It allows the plant to have their valves repaired, serviced and set quickly, which minimizes downtime. They also like the service because it saves them money.

Our repair service also includes updating the valve to the latest design standard when necessary. All valves serviced in our repair facility carry a one-year standard warranty. North American holds ASME’s V and UV stamps and National Board’s NB and VR stamps. The next time your customer has questions about repairing or upgrading their safety or relief valves, give one of our application engineers a call.

With North American’s Service Center, you can maximize your customer’s uptime while saving both time and money. Make our Service Center your service center. Just one call will provide quick solutions to all your repair needs. An application engineer will work directly with you to customize a program to meet your customer’s needs.

You don’t have to be an expert in the field of safety and relief valves to sell them. We are here to help. Our goal is to make it easy for you to profit from the sales of safety and relief valves. Our expertise comes from taking care of our customers for over 42 years. And our large inventory allows us to offer same day shipment from stock on every valve Kunkle makes.

The sole responsibility of our dedicated applications engineers is to take care of your requirements. We will help you with sales planning, product selection and after sale service when needed. We will even provide you with catalogs that have no reference to NASVI. Our valuable advice is free and as close as your phone. So the next time your customer calls and needs a safety or relief valve, call a NASVI Applications Engineer.

They’ll have a quick answer on price, availability and shipment. When it comes to selling safety valves, you don’t have to stock anything. Simply call 1-800-800-8882 or visit us on the web at www.nasvi.com. We’ll make it easy for you!

Our two-truck unit responds to customer requests anywhere, offering on-site repair and resetting of safety valves during scheduled maintenance shutdowns.

Step into the mobile repair unit and you’ll find all the equipment necessary to perform highest-caliber repairs: sand blaster, compressor, lathe, mill/drill press, lapping machine–-it’s all inside. There’s also a Consolidated® seat-resurfacing machine with all adapters for every orifice in the Maxi-Flow® boiler line. Completed valve work will carry the VR stamp.

The Field Service Unit also includes a state of-the-art computerized lift-assist testing unit that allows for testing set pressures and resetting high-pressure safety valves in the field. The testing unit makes testing valves that are welded in-line or stationary possible without removing the valves. Your customers won’t be required to pressure down or increase pressure to test for set pressure. The lift assist testing unit also allows for resetting valves after repairs have been made while the valves are on-line.

If you have prospects or customers that bought their replacement valves elsewhere because you haven’t been able to provide on-site service, you will want to get back with them and talk about this service. If you have questions about pricing and scheduling of our Field Service Unit, give us a call at (800) 800-8882.

With our partner specifications archives, six on-site lathes, technical know-how and 35,000 in-stock valves, we’ve got your valve repairs covered. Valves are quickly repaired and set following exact specifications, and if they’re irreparable, chances are we’ve got a replacement in stock.

A “safety valve” is an exception to mandatory minimum sentencing laws. A safety valve allows a judge to sentence a person below the mandatory minimum term if certain conditions are met. Safety valves can be broad or narrow, applying to many or few crimes (e.g., drug crimes only) or types of offenders (e.g., nonviolent offenders). They do not repeal or eliminate mandatory minimum sentences. However, safety valves save taxpayers money because they allow courts to give shorter, more appropriate prison sentences to offenders who pose less of a public safety threat. This saves our scarce taxpayer dollars and prison beds for those who are most deserving of the mandatory minimum term and present the biggest danger to society.

The Problem:Under current federal law, there is only one safety valve, and it applies only to first-time, nonviolent drug offenders whose cases did not involve guns. FAMM was instrumental in the passage of this safety valve, in 1994. Since then, more than 95,000 nonviolent drug offenders have received fairer sentences because of it, saving taxpayers billions. But it is a very narrow exception: in FY 2015, only 13 percent of all drug offenders qualified for the exception.

Mere presence of even a lawfully purchased and registered gun in a person’s home or car is enough to disqualify a nonviolent drug offender from the safety valve,

Even very minor prior infractions (e.g., careless driving) that resulted in no prison time can disqualify an otherwise worthy low-level drug offender from the safety valve, and

Other federal mandatory minimum sentences for other types of crimes – notably, gun possession offenses – are often excessive and apply to low-level offenders who could serve less time in prison, at lower costs to taxpayers, without endangering the public.

The Solution:Create a broader safety valve that applies to all mandatory minimum sentences, and expand the existing drug safety valve to cover more low-level offenders.

During the forecast period, the global safety valve market size is estimated to reach USD 13.2 Billion by 2030 and is expected to exhibit a significant growth rate of 9.20% CAGR.

Safety Valves are precautionary valves that automatically actuate when the preset safety valve pressure and temperature are exceeded. These safety valves can be used to protect the critical equipment from damage by controlling excess pressure without any electrical support. For protecting equipment from unsafe pressure these mainly operate at a predetermined pressure. Additionally, these valves protect the employees around the plants and the environment around them. Safety valves are used in various applications like pharmaceutical, construction, oil & gas industries which foster the growth of the market.

During the lockdown, the global safety valve market is negatively impacted. Not only the safety valve market but the whole world was also affected drastically by this pandemic. To control the prevalence of the coronavirus, the government has imposed stringent regulations like lockdowns, maintaining social distance, covering the face with masks, manufacturing industries shut down, and transportation bans.

Even though at the primary stage of the pandemic, the safety valve market has fallen. Developing the innovations in the safety valve system and growing awareness regarding the benefits of the safety valve market by the key players are increasing the growth of this market.

Growing demand for safety valves in the oil & gas industry, the rise in nuclear energy generation, the growing importance of safety valves in industrial processes are the major driving factors of this market. The continuous need for safety valve replacement and the use of 3D printers in manufacturing lines are boosting the growth of the market. The safety valve market is highly dependent on investments in manufacturing facilities.

Some of the numerous factors that drive the safety valve market are rising demand for water & power, pollution control regulations, and rapid growth of process industries are supposed to escalate the growth of the safety valve industry during the assessment period. Growth in the construction of nuclear power plants is fueling the growth of the market. The increase of accidental incidences and soaring demand for safety valves in several industrial sectors are increasing the growth of the global market.

The constant growth of oil & gas exploration in few parts across the globe is restraining the market. The fabrication of safety valves are very expensive which is hindering the market growth

To increase the growth of the safety valve market industry integration of safety valves into the Internet of Things (IoT) environment is creating the opportunity. The innovations in the safety valve systems are anticipated to increase the strong growth of the market.

To provide a strategic profile of the prominent key players in the market, analyze their core competencies, forecast statistics, and draw a global safety valve market growth landscape.

The global safety valve market based on material is sub-segmented into steel, alloy, cast iron, cryogenic, and others. As the steel safety valves are durable and don’t leak in hot or cold temperatures, the steel segment is expected to dominate the global market.

It is segmented into less than 1”, 1” to 10”, and 11” to 20”, and 20” & above. Among these, during the review period, the 1” to 10” segment is projected to grow at the significant CAGR for the safety valves market for the benefits behind this size range like controlling the flow and pressure of liquids, gases, and slurries within different end-use industries.

The global safety valve market industry is divided into oil & gas, energy & power, food & beverage, chemicals, water & wastewater treatment, and others. In the global safety market, the oil & gas segment is expected to hold the largest share, because the oil & gas industries are the most significant revenue-generating industries which need almost all types of valves like gate, globe, ball, check and butterfly. Some of the products include a safety valve air compressor, safety valve boiler, and safety valve heater.

Asia-Pacific, Europe, North America, the Middle East & Africa, and South America are the main geographies included in this market. Due to the rapid urbanization and growing industrialization Asia-Pacific holds the largest safety valve market share.

The global safety valve market region-wise is divided into Asia-Pacific, Europe, North America, and the Middle East & Africa. Out of these regions, Asia-Pacific holds the largest market share for its growing infrastructural developments, rise of investments in various industries like oil & gas, construction industry, and drastic urbanization. Growing demand from mining, chemical, and municipal industries is expected to propel market growth in this region.

Safety valves are used in the application of the construction industry to control liquid flow in firefighting systems, water supply systems, and piping systems. The rising construction industry propels the market growth in this region. North America is accounting as the second-largest market for its growing investments in the construction industry.

As per the report of BP Statistical Review of World Energy 2018, the refinery output in 2017 in North America is registered as 2.13% and is predicted to grow during the forecast period.

Naples, Italy, Baker Hughes launched a new steam test facility in November 2018, ASME Section I safety valves that serve better to the European aftermarket with a rapid response for steam applications. The future development of the current aftermarket is launched as the new aftermarket plant which is expanded by the product scope and capacity of the plant. To fulfill the range of Masoneilan control valves and consolidated safety valves ranging up to 2000 psi test pressure.

In October 2018, Emerson Electric Co. to help the LNG marine transportation consumers developed low-pressure pilot operated pressure relief valves (POPRVs) by reducing their size which helps to reduce the investments by 25% and protects the end-users from overpressure by offering them extra profit margin.

In May 2019, the Mexican government announced that it is going to construct a new refinery set in the Tobasco coast, Mexico in June 2019. Hence safety valves are used in refineries to control the pressure of liquids and gases in plants.

This global safety valve market research includes the Market Overview, COVID-19 analysis, Market Dynamics, Study Objectives, Segment Overview, Regional Analysis, Competitive Landscape, Recent developments, Segmentation Table, and FAQs. The market scenario includes the safety valve market drivers, restraints, challenges, and opportunities. The safety valve forecast segments are material, size, end-use, and region.

RM2BHFJN7–Coryton, Stanford-le-Hope, Essex, UK. 25th Apr, 2020. A build up of pressure caused a safety valve to release at a power station (initially thought to be the oil refinery nearby) in Coryton, close to DP World port cranes on the Thames Estuary, creating steam and noise in the area leading people to believe that there had been an explosion. Local fire brigade and emergency services attended

RMT94YD7–Papin holding a diagram of a steam engine, lithograph, 1689. Denis Papin (August 22, 1647 - 1712) was a French physicist, mathematician and inventor. He worked with Robert Boyle from 1676-79, publishing an account of his work in Continuation of New Experiments (1680). During this period, Papin invented the steam digester, a type of pressure cooker with a safety valve.

RMGE4JB3–(September 6, 1963) Vent flowing cryogenic fuel and T/C Rake mounted on a 1/10 scale model Centaur in the l0 x l0 Foot Supersonic Wind Tunnel. The fuel being used is liquid hydrogen. The point of the test is to determine how far to expel venting fuel from the rocket body to prevent explosion at the base of the vehicle. This vent is used as a safety valve for the fumes created when loading the fuel tanks during launch preparation. Liquid hydrogen has to be kept at a very low temperature. As it heats, it turns to gas and increases pressure in the tank. It therefore has to be vented overboard whi

RMMR3WYE–Illustration depicting Papin"s steam engine (1707) for pumping water from mines. It was the first engine to use the safety valve he had invented twenty-seven years earlier for his "digester". (1647-1713) a French physicist, mathematician and inventor, best known for his pioneering invention of the steam digester, the forerunner of the pressure cooker and of the steam engine. Dated 19th century

RM2BHFJR5–Coryton, Stanford-le-Hope, Essex, UK. 25th Apr, 2020. A build up of pressure caused a safety valve to release at a power station (initially thought to be the oil refinery nearby) in Coryton, close to DP World port cranes on the Thames Estuary, creating steam and noise in the area leading people to believe that there had been an explosion. Local fire brigade and emergency services attended

RME14RJF–Apr. 18, 2012 - The main road through the area is always busy: The gaunt, Barren Hills are a constant reminder of the wilderness of the territory afar. The safety valve with its ever-burning flame at the top is behind the wire pending on the night.

RMCYXCAB–A well engineered brass and ferrous metal model gas fired horizontal stationary steam set, The brass boiler with metal cladding and normal fittings, weight and lever safety valve, main stop and lagged steam line to single horizontal cylinder¦ mill engine with overmounted valve chest and brass bound cylinder, barrelled connecting rod, counterbalanced crankshaft, spoked flywheel and multi rope pulley. Other details include feed water heater and hand feed pump ,the whole finished in maroon, black and polished brightwork and mounted on a brick and tiled plinth with, Additional-Rights-Clearences-NA

RMT965J2–Color enhanced lithograph of Papin holding a diagram of a steam engine, 1689. Denis Papin (August 22, 1647 - 1712) was a French physicist, mathematician and inventor. He worked with Robert Boyle from 1676-79, publishing an account of his work in Continuation of New Experiments (1680). During this period, Papin invented the steam digester, a type of pressure cooker with a safety valve.

RMW56XWK–Model of a Hydraulic Press, Model of a simple hydraulic press on a wooden floorboard. On the one hand is a manually operated pump, equipped with a pump arm, regulator, overflow and safety valve. The pump arm can be set in two positions. The regulator is a screw valve. The safety valve is adjusted with a weight. A tube for the liquid runs from the pump to the bottom of the press, where an oval press platform is pushed upwards., Joseph Bramah (possibly), United Kingdom, 1820, iron (metal), copper (metal), wood (plant material), model: h 41 cm × w 56 cm × d 27 cm packaging capsule: h 45.5 cm × w

RMMR3X05–Illustration depicting Papin"s steam engine (1707) for pumping water from mines. It was the first engine to use the safety valve he had invented twenty-seven years earlier for his "digester". (1647-1713) a French physicist, mathematician and inventor, best known for his pioneering invention of the steam digester, the forerunner of the pressure cooker and of the steam engine. Dated 19th century

RM2JM8GB6–Alain Sauthier, Director of Nant de Drance poses in front of a safety valve of the penstock in the newly operational Nant de Drance pumped storage electricity power plant in Finhaut, Switzerland, August 4, 2022. REUTERS/Denis Balibouse

RMCYXC6B–A well engineered brass and ferrous metal model gas fired horizontal stationary steam set, The brass boiler with metal cladding and normal fittings, weight and lever safety valve, main stop and lagged steam line to single horizontal cylinder¦ mill engine with overmounted valve chest and brass bound cylinder, barrelled connecting rod, counterbalanced crankshaft, spoked flywheel and multi rope pulley. Other details include feed water heater and hand feed pump ,the whole finished in maroon, black and polished brightwork and mounted on a brick and tiled plinth with, Additional-Rights-Clearences-NA

RF2JHG6MN–An industrial pressure safety valve, abbreviated as "psv" a well-known concept in the industry. Specially made to prevent dangerous high pressures in

RMP3880C–. Grand Geyser Cone and safety valve, Yellowstone National Park. Coverage: 1881-1889. Source Imprint: Fargo, D.T. : F. Jay Haynes, 1881-1889.. Digital item published 1-25-2006; updated 2-12-2009. 129 Grand Geyser Cone and safety valve, Yellowstone National Park, by Haynes, F. Jay (Frank Jay), 1853-1921

RM2JM8G81–Alain Sauthier, Director of Nant de Drance talks to a journalist in front of a safety valve of the penstock in the newly operational Nant de Drance pumped storage electricity power plant in Finhaut, Switzerland, August 4, 2022. REUTERS/Denis Balibouse

RF2JHG6N4–An industrial pressure safety valve, abbreviated as "psv" a well-known concept in the industry. Specially made to prevent dangerous high pressures in

RMP38806–. Grand Geyser Cone and safety valve, Yellowstone National Park. Coverage: 1881-1889. Source Imprint: Fargo, D.T. : F. Jay Haynes, 1881-1889.. Digital item published 1-25-2006; updated 2-12-2009. 129 Grand Geyser Cone and safety valve, Yellowstone National Park, by Haynes, F. Jay (Frank Jay), 1853-1921 2

RM2D3PPTK–Iraqi looters wave to the passing convoy of U.S. Marines as they ride a stolen small construction vehicle in the suburbs of Iraqi capital Baghdad April 7, 2003. British Air Marshal Brian Burridge said during his briefing at Central Command on Monday looting was almost "an inevitability". "There is a release of pent up annoyance and hatred against the Ba"ath Party and the Ba"ath regime but once that safety valve is blown...the business of protecting property becomes easier," he said. REUTERS/Oleg Popov OP/AA

RMTWH30F–Relief and safety valve of turbine unit no. 1, located in the subway below the Generator Room; looking south. The safety valve was manufactured by the Chapman Valve Company of Springfield, Massachusetts. It is identical to the adjacent safety valve for turbine unit no. 2. Photo by Jet Lowe, HAER, 1989. - Puget Sound Power and Light Company, White River Hydroelectric Project, 600 North River Avenue, Dieringer, Pierce County, WA; Shuffletin, Samuel L; Stine, Charles; Webster, Edwin; Baker, Charles H

RMD6K57N–A technician walks away from the safety valve of the drill on the drilling platform of German-Canadian oil company Firma CEP (Central European Petroleum GmbH) near Pudagla on the island of Usedom, Germany, 02 April 2012. After suspedning the controversial search for oil on Usedom in the fall of 2011, work on the the platform now starts up again. Photo: STEFAN SAUER

RM2CF74YH–Vent flowing cryogenic fuel and T/C Rake mounted on a 1/10 scale model Centaur in the l0 x l0 Foot Supersonic Wind Tunnel. The fuel being used is liquid hydrogen. The point of the test is to determine how far to expel venting fuel from the rocket body to prevent explosion at the base of the vehicle. This vent is used as a safety valve for the fumes created when loading the fuel tanks during launch preparation. Liquid hydrogen has to be kept at a very low temperature. As it heats, it turns to gas and increases pressure in the tank. It therefore has to be vented overboard while the rocket sits o

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291