how to calculate cdtp in safety valve quotation

Further for Convetional Valve API-521 paragraph 4.2.3.3 A convetional PRV Operating with a constant superimposed back pressure normally required a correction factor to compensate for the back pressure. In this case the required set pressure minus superimposed back pressure is equal to CDTP. This change account for the addtional closing force exerted on the valve disk by back pressure.

Now, we have to add this pressure for back pressure consideration or valve is tested based on CDTP, But if we tested based on CDTP than this is less that the set pressure as CDTP is Set Pressure - Superimposed back pressure.

(100Mbs) Over 2000 Questions and Answers. Full API document, codes, questions on each applicable Code/Section (1-2 months) prior to participate in Prometric examination. Full Training presentations for self learning. Bonus: API 510, 571 Flash Cards, PSV notes – excel files.

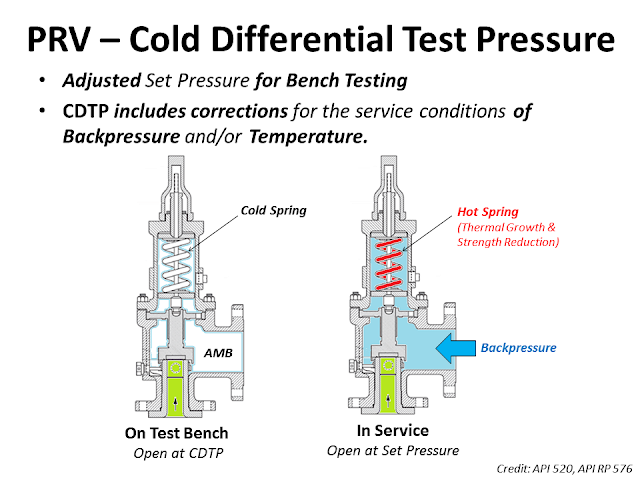

The Cold Differential Test Pressure (CDTP)of thePressure Relief Valve (PRV) is a set pressure that is adjusted to be used for the PRV (Bench Testing). Because in actual use conditions, the PRV may be affected by the Backpressure. And the operating temperature. Therefore, when testing at room temperature and without backpressure, it is necessary to adjust the set pressure to compensate for these factors. In other words, the shop test pressure = CDTP.

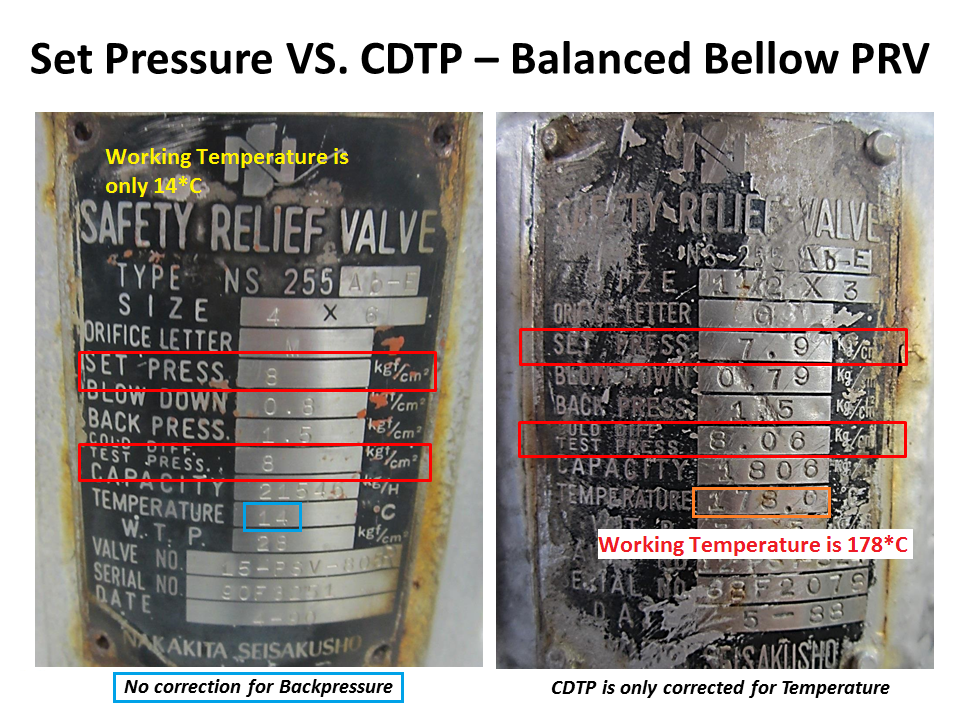

An example of aCold Differential Test Pressure (CDTP)with abackpressure (superimposed)effect. In this case, CDTP is equal to Set Pressure minus Backpressure.

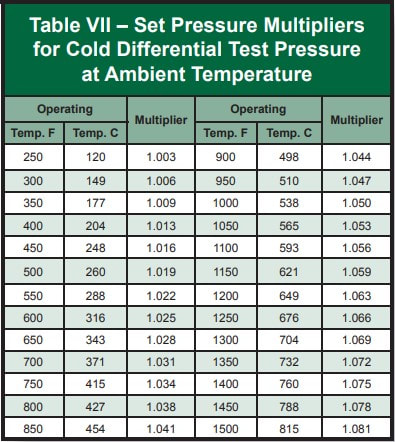

An example of aCold Differential Test Pressure (CDTP)with different temperature compensations for use and testing. And an example ofCDTP that has been adjusted to compensate for both Backpressure (Superimposed) and temperatureeffects.

Test Stand or Test Bench is a set of equipment used for Pressure Relief Valve (PRV) in Pop Test (Set Pressure Test), Blowdown and Seat Tightness Test (Leakage Test)

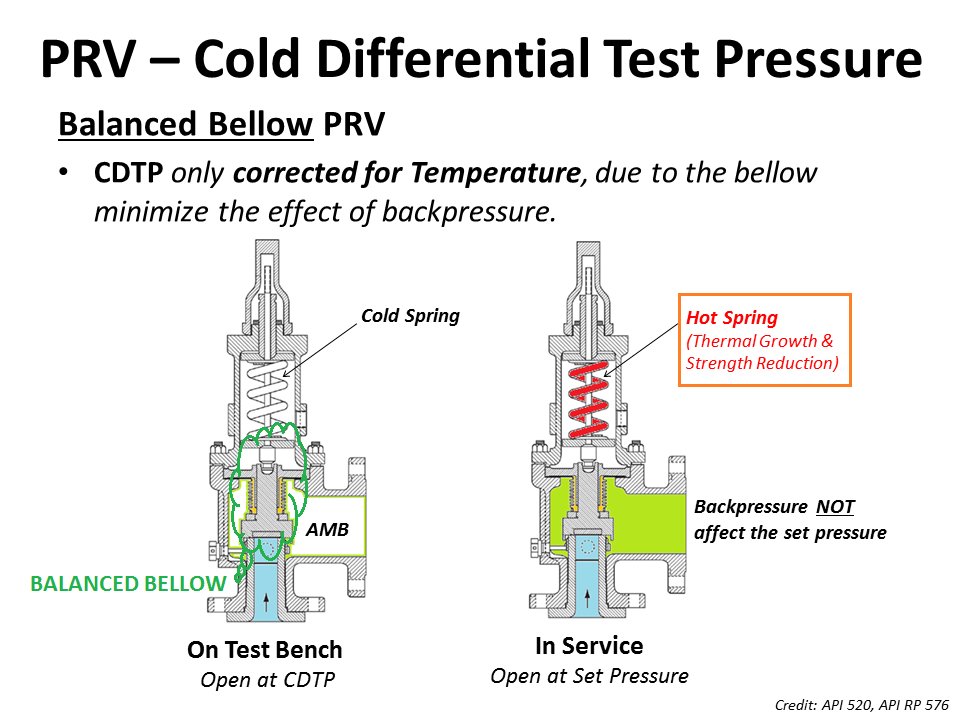

As for theBalanced Bellow Pressure Relief Valve, which has a bellowfor reducing the impact of theBackpressure, the Cold Differential Test Pressure (CDTP) of the Balanced Bellow Type PRV will compensate only for the impact of different temperatures between the Shop Test and In-service.

Built-up back pressure is the backpressure generated due to pressure losses at the outlet of an open relief valve when it is discharging. This pressure depends on the pressure of the vent header downstream to the relief valve and the relieving flowrate which is being discharged. The built-up backpressure is the pressure in the vent header plus pressure drop in the line from relief valve to vent header, when the valve is discharging at full capacity.

For certain relief valve designs, the backpressure on the valve acts as a closing force and can affect the opening pressure for the valve. ‘Conventional’ valves are highly susceptible to this effect and hence not used in applications where high backpressure is expected. ‘Balanced Bellows’ and ‘Pilot Operated’ relief valves relatively shielded from effects of high backpressure.

For some relief valves (especially conventional type relief valves), the opening of the valve is affected by backpressure seen by the valve. If the backpressure seen by such relief valves is higher than atmospheric, then it has to be designed to open at a lower differential pressure value than the relief valve set pressure minus atmospheric pressure. However when the relief valve is tested before installation, it only sees atmospheric pressure as backpressure. Hence to open this relief valve at same differential pressure value, the set point pressure for opening the valve has to be lower than original design set point pressure. This set point value is known as cold differential test pressure (CDTP).

For pilot operated and balanced bellows type relief valves, effect of backpressure on valve opening characteristics is very low and hence CDTP is the same as the original design set point pressure value.

The primary purpose of a pressure relief device is protecting a vessel against overpressure only; they do not protect against structural failure when the vessel is exposed to extremely high temperatures such as during a fire.

A pressure relief valve is a pressure relief device designed to open and relieve excess pressure and to reclose and prevent further flow of fluid after normal conditions have been restored. A pressure relief valve opens when its upstream pressure reaches the set pressure. It then allows fluid to flow until its upstream pressure falls to the closing pressure (The value of the closing pressure is less than that of the set pressure and will be reached after the blow down phase is completed). It then closes, preventing further flow.

Examples of specific types of pressure relief valves include; safety valve, relief valve, conventional safety relief valve, balanced safety relief valve and pilot-operated pressure relief valve.

Curtain area: The area of the cylindrical or conical discharge opening between the seating surfaces above the nozzle scat created by the lift of the disc.

Effective discharge area: A nominal or computed area used with an effective discharge coefficient to calculate the minimum required relieving capacity for a pressure relief valve per the preliminary sizing equations contained in this practice. API Standard 526 provides effective discharge areas for a range of sizes in terms of letter designations, ‘”U” through “T”.

Huddling chamber: An annular chamber located downstream of the seat of a pressure relief valve for the purpose of assisting the valve to achieve lift.

Coefficient of discharge:The ratio of the mass flow rate in a valve to that of an ideal nozzle. It is used for calculating flow through a pressure relief device.

The effective coefficient of discharge is a nominal value used with an effective discharge area to calculate the minimum required relieving capacity of a pressure relief valve This capacity is determined in accordance with the applicable per the preliminary sizing equations given in this Recommended Practice.

The rated coefficient of discharge is determined in accordance with the applicable code or regulation and is used with the actual discharge area to calculate the rated flow capacity of a pressure relief valve.

The maximum allowable working pressure (MAWP)is the maximum gauge pressure permissible at the top of a completed vessel in its normal operating position at the designated coincident temperature specified for that pressure.

The pressure is the least of the values for the internal or external pressure as determined by the vessel design rules for each element of the vessel using actual nominal thickness, exclusive of additional metal thickness allowed for corrosion and loadings other than pressure. The maximum allowable working pressure is the basis for the pressure setting of the pressure relief devices that protect the vessel. The MAWP is normally greater than the design pressure but must be equal to the design pressure when the design rules are used only to calculate the minimum thickness for each element and calculations are not made to determine the value of the MAWP.

The design pressure of the vessel along with the design temperature is used to determine the minimum permissible thickness or physical characteristic of each vessel component as determined by the vessel design rules. The design pressure is selected by the user to provide a suitable margin above the most severe pressure expected during normal operation at a coincident temperature. It is the pressure specified on the purchase order. This pressure may be used in place of the maximum allowable working pressure in all cases where the

Accumulationis the pressure increase over the maximum allowable working pressure of the vessel allowed during discharge through the pressure relief device, expressed in pressure units or as a percentage of MAWP or design pressure. Maximum allowable accumulations are established by applicable codes for emergency operating and fire contingencies.

Overpressure is the pressure increase over the set pressure of the relieving device allowed to achieve rated flow. Overpressure is expressed in pressure units or as a percentage of set pressure. It is the same as accumulation only when the relieving device is set to open at the maximum allowable working pressure of the vessel.

Blowdown: the difference between actual popping pressure of a pressure relief valve and actual reseating pressure expressed as a percentage of set pressure or in pressure units.

Blowdown pressure: the value of decreasing inlet static pressure at which no further discharge is detected at the outlet of a pressure relief valve after the valve has been subjected to a pressure equal to or above the popping pressure.

The cold differential test pressure (CDTP) is the pressure at which a pressure relief valve is adjusted to open on the test stand. The cold differential test pressure includes corrections for the service conditions of back pressure or temperature or both.

Opening pressure is the value of increasing inlet static pressure at which there is a measurable lift of the disc or at which discharge of the fluid becomes continuous, as determined by seeing, feeling or hearing.

Closing Pressure is the value of decreasing inlet static pressure at which the valve disc reestablishes contact with the seat or at which lift becomes zero as determined by seeing, feeling or hearing.

Simmer is the audible or visible escape of compressible fluid between the seat and disc which may occur at an inlet static pressure below the set pressure prior to opening.

Built-up back pressure: pressure existing at the outlet of a pressure relief device caused by the flow through that particular device into a discharge system.

Superimposed back pressure: the static pressure existing at the outlet of a pressure relief device at the time the device is required to operate. It is the result of pressure in the discharge system from other sources. This back pressure can be constant if the valve outlet is connected to a process vessel or system which is held at a constant pressure. In most cases, however, the superimposed back pressure will be variable as a result of changing conditions existing in the discharge system.

Before you begin pressure-relief system design, watch out for these common mistakes in identifying overpressure scenarios, performing sizing calculations, and installing the system in the field.

Errors in the design and installation of pressure-relieving devices (PRDs) and their respective pressure-relief systems (PRSs) create risk. For example, incomplete documentation is confusing, creates nuisance rework, and can put a facility at risk of citation. Improper equipment selection and installation can also present real safety hazards.

Inexperienced as well as experienced engineers are bound to make or discover mistakes at some point in their careers. If an error is made in PRS design, we must learn from that mistake and communicate that knowledge. This article will help you recognize common rationale, sizing, and installation pitfalls, and eliminate unnecessary risk at the earliest opportunity.

▲Figure 1. It is easier to control cost, process safety, and other factors at the beginning of the design process than during the end stages of a project.

The saying, “The most effective and efficient mitigation or elimination of risk is achieved at the earliest juncture and at the most fundamental level,”can be applied to practically any discipline and any situation, including process safety and pressure-relief system design. In any project, there is the least amount of risk (e.g.,financial, safety, etc.) and the greatest amount of control over change at the onset; the opposite becomes true at the end of a project (Figure 1).

To detect and eliminate design and installation deficiencies, you must understand the physical components within the PRS, as well as the system’s implementation. In other words, understand the big picture. This article first describes the potential pitfalls found at the early stages of the big picture, where we have the most influence over the outcome of a design. It then covers pitfalls found in the later stages of design and post-installation.

Despite notions to the contrary, organizations do not ask engineers to design PRSs to pass the time; the work is purposeful and important to the safe operation of facilities. Just as using a dull knife to cut meat increases risk, asking an unintelligent engineer to design a PRS escalates risk. Stay sharp! Engineers who lack awareness or believe that designing a PRS is busy work will develop risk-prone systems. Engineers and supervisors should ask themselves key questions to identify potential pitfalls and to sharpen their minds if dullness is detected.

The engineer. For the sake of this article, let us assume that the engineer is any individual contributor who performs tasks related to PRS or PRD design. Regardless of whether the engineer is responsible for a single design task or an entire cradle-to-grave design, he or she should ask the following questions before starting work: What is the scope of work? The scope of work provides specificity and boundary conditions.

Why does this facility need this PRS or this PRD? Convincing yourself intellectually of the necessity of the PRS will drive you to be more conscientious while you work.

Do I know how to do this work? Prior experience is not always a prerequisite, but you must be able to figure out the steps required to complete a task.

Who should I go to when I have questions? Even the most experienced engineers need someone else with whom they can discuss ideas and ask questions. Do not be afraid to ask questions — it is how you learn.

What work aid documents are relevant? Be familiar with the codes, standards, practices, and rules used by your facility or organization to ensure consistent, compliant designs — for example, the ASME pressure vessel code ASME VIII (1) and the American Petroleum Institute standard on depressurizing systems, API 521 (2).

The supervisor. The supervisor is responsible for the management of engineers and their work, but may also act as an individual contributor, performing tasks like those done by the engineer.

In addition to asking the previous questions, the supervisor should also ask these questions before starting work: Am I available to answer questions? An overburdened supervisor prevents the free exchange of information within the group; supervisors should delegate responsibilities to preempt bottlenecks.

Are the right people doing the right tasks? While it’s obvious that a junior engineer should not perform a complex task like a tower reflux failure scenario on the first day, it’s less obvious that your senior process engineer should not be focused on junior-level engineering tasks, such as filling out specification sheets for liquid thermal relief valves.

The organization.It is my experience that some organizations perform PRS design, installation, or maintenance better than others. Some of the better performers share several important characteristics: OSHA Voluntary Protection Program (VPP) status(3). A facility obtains VPP status when it goes above and beyond the U.S. Occupational Safety and Health Administration’s (OSHA) minimum requirements. This designation indicates that the facility has a collective interest in safe, compliant operation from upper management down to individual contributors.

dedicated PRS staff. Having staff dedicated to PRS design, installation, and maintenance helps ensure that institutional knowledge is maintained and that the PRS design and installation are carried out in a consistent manner. An organization where employees are focused on unit operations only, or where employees are not familiar with industry standards like API 521, will not be as effective at maintaining their pressure-relief systems.

strong interdisciplinary teamwork. PRS construction and maintenance necessitate the teamwork of multiple disciplines and crafts, including process engineers, piping designers, pipefitters, inspectors, and other specialists. Many organizations have all of these types of individuals, but if there is not an established communication or teamwork protocol to support cross-functional efforts, it will be difficult to construct or maintain PRSs effectively.

Some facilities that fall outside the scope of OSHA’s process safety management (PSM) regulation (4) should, nevertheless, have an internal equivalent for PSM compliance. Otherwise, they may not have a system in place to show why or where PRSs exist, nor an internal impetus to pay attention to their PRSs.

The first step in PRS design is identifying overpressure scenarios and qualifying each scenario with a rationalization. For example: Scenario A applies because a fire will boil the liquid contents of this vessel; Scenario B does not apply because there is no upstream source of pressure that can exceed the design pressure of the protected system.

If you assume that a scenario is applicable when it really is not, your PRD will be designed for a contingency that will never occur. On the other hand, overlooking an applicable scenario can cause risk because the PRD sizing requirements are not realized. The rest of this section covers the latter case and reviews some often-overlooked scenarios.

Blocked outlet and overfilling.A check valve can get stuck shut and not permit flow. Or it might have been installed backwards and open in the wrong direction. Either of these situations can lead to overfilling and overpressure.

Centrifugal pump deadhead pressure should be calculated based on maximum possible suction pressure, not normal upstream pressure. Never calculate deadhead pressure based solely on the pump total dynamic head at zero flow — the suction pressure must be added to the total dynamic head to ensure the relief device is sized correctly.

Centrifugal pumps in hot service may perform much differently during a cold startup — when outlets are more likely to become blocked — than they do under normal operating conditions. Look for pumps that operate at very high temperatures (e.g., 400–700°F), and compare the fluid’s specific gravity (SG) at the operating temperature to its SG at ambient temperature.

The pressure exerted by a pump is directly proportional to the specific gravity of a fluid. For example, let us assume that a pump has a maximum suction pressure of 100 psig under all circumstances, and a maximum total dynamic head of 425 ft. Let us also assume that it pumps fluid that has a hot, operating SG of 0.6 and a cold, ambient SG of 0.8. We can calculate the pump deadhead pressure for the hot and cold conditions:

For a system that should not exceed 225 psig, the blocked outlet scenario would not apply under hot operating conditions, but it would apply under cold startup conditions.

Do not mistake a positive-displacement pump or compressor for a dynamic machine like a centrifugal pump or axial compressor. Whereas a blocked dynamic machine may continue running without causing overpressure, blocked outlet scenarios will almost always be applicable to positive-displacement machines, which work by moving a fixed volume of fluid at a given rate. Positive-displacement machines pull fluid into a fixed volume and then push the fluid out without allowing simultaneous ingress or backflow. In a blocked outlet condition, compressible fluids (gases and vapors) will continue to accumulate in the fixed volume of the discharge until so much fluid has accumulated that the pressure eventually exceeds the mechanical limitations of the machine. Incompressible fluids (liquids) are much less forgiving, since there is practically no further compression that the fluid can undergo.

Heat and material imbalance (cooling, reflux failures, etc.).Consider the enthalpy (heat) of streams entering and leaving your protected column system, not just heating and cooling duties. For example, say that some overhead exchangers stop working but have residual cooling duty of 20 MMBtu/hr, and the reboiler has a continuous but reduced duty of 19 MMBtu/hr. You might assume that no relief is necessary because the cooling duty exceeds the heating duty. However, the feed stream may be packed with enthalpy, tipping the scale toward a viable overpressure scenario.

Consider a protected column system located downstream of another column system (e.g., a debutanizer downstream of a depropanizer). In the event of upstream heating failure, lighter upstream components can travel downstream to a lower-pressure system, which may cause accumulation of noncondensables, a blocked vapor outlet, and other upsets. You should explore all of these overpressure scenarios when designing the PRS.

Failure of automatic controls.A control valve may fail in any position. Never assume that a control valve will only fail in the position indicated on a piping and instrumentation diagram (P&ID). Murphy’s Law — anything that can go wrong will go wrong — applies to control valves.

Many flow, pressure, and temperature control valves are globe valves, which provide significantly greater resistance to flow than gate, butterfly, and ball valves. However, not all control valves are globe valves. Because control valve symbols are sometimes ambiguous on P&IDs, engineers might mistake one valve type for another, which might cause them to underestimate scenario severity or miss the scenario applicability altogether.

A gas blowby scenario (i.e., vapor blow-through) generally occurs when an upstream liquid level control valve system fails and a liquid level is lost, allowing high-pressure gas or vapor to flow through the liquid line into a lower-pressure downstream system.

Each of this scenario’s stages should be evaluated: First, check upstream and downstream liquid inventories. Second, size for the liquid overfill that would occur if the upstream liquid inventory were to exceed the empty volume downstream. Next, size for the liquid displacement that would occur if high-pressure gas or vapor were to enter the liquid-packed downstream system (pushing liquid out at the volumetric rate that gas or vapor enters). Then, size for the eventual gas blowby that would occur if all of the liquid were to be displaced. Note that gas blowby would not be prevented if the downstream system is first overfilled with upstream liquid through the faulty level controller — indeed, this would create a liquid relief first, followed by liquid displacement, before finally becoming gas blowby.

Inadvertent valve opening (including reverse flow).Control valve bypasses are typically gate valves. This might not affect the applicability of a particular scenario, but it will affect the scenario’s severity, because gate valves are generally much less restrictive than control valves. Bypass gate valves can allow significantly more high-pressure fluid to pass into a lower-pressure system than its control valve counterpart. In addition to inadvertent opening of the bypass, many designers consider the simultaneous, 100% opening of control valves and their bypasses in the control valve failure scenario, which highlights how severe a bypass failure is compared to the failure of a control valve.

Because checking for an inadvertent valve opening in manifolds or tank farms is a tedious task, an engineer can easily miss a scenario simply because of mental fatigue. Consider approaching these scenarios by identifying sources of overpressure first, not valves that can be opened.

Check valves are often overlooked as sources of reverse flow because many engineers assume that they do not fail open (i.e., get stuck open) or leak when they are in the closed position. However, both of these situations do occur, and API Standard 521 (2)encourages engineers to consider this scenario. Check valve failure can go unnoticed during normal operation, which is also known as latent failure.

Chemical reaction.When identifying overpressure scenarios, consider all possible chemical reactions. If you or your supervisor does not have the experience or resources required to perform reactive system relief sizing, seek outside help. Never ignore reactive chemistry.

Fire.Consider the potential for a nearby fire to cause an overpressure in the vessel or tank of interest. Check the distance to possible sources of fire and determine the thermal radiation the fire could produce.

Fluids with high vapor pressures may vaporize rapidly at atmospheric pressure instead of pooling on the ground. If these fluids leak through broken fittings, flanges, or holes, they can create jet fires. There is a common belief that relief valves cannot protect against jet fires because jet fires are very narrowly focused and cause only localized heating with rapid vessel wall failure. However, this is a worst-case scenario; jet fires may dissipate heat across a large surface area, which can cause an overpressure scenario in the impinged vessel. Guidance and formulas in API 521 (2) can help you calculate the heat input for such a scenario.

Heat exchanger failure. Always check the maximum allowable working pressure (MAWP) of other equipment and piping connected to a heat exchanger. In the event of a tube leak or rupture in a heat exchanger, the high-pressure side may not cause overpressure of the low-pressure side of the exchanger. However, the piping and equipment connected to the low-pressure side of the exchanger may be susceptible to overpressure.

Once you identify a possible overpressure scenario, you must choose an appropriately sized PRD. Whereas the common pitfalls in overpressure scenario identification are conceptual and easy to overlook, it is easier to prevent and identify mistakes in PRD sizing due to its quantitative nature.

API vs. ASME sizing.Generally, pressure-relief valves are sized using the equations provided in API 520 Part 1 (5), which take slightly different forms depending on the fluid phase being relieved.

where A is relief area, W is flowrate, C is a function of the ratio of ideal gas specific heats (Cpand Cv), Kd is the API effective coefficient of discharge, P1is the upstream relieving pressure, Kb is the capacity correction factor for backpressure, Kc is the combination correction factor for installations with a rupture disk upstream of a pressure-relief valve (PRV), T is the relieving temperature of the vapor or gas, Z is the compressibility factor for the vapor or gas, and M is the molecular weight of the vapor or gas.

where Q is the volumetric flowrate, Kw is the capacity correction factor for backpressure, Kv is the viscosity correction factor, G1 is the liquid specific gravity at the relieving temperature, and P2 is the total backpressure.

Preliminary sizing can utilize API-designated effective orifice areas and effective discharge coefficient (Kd). But, API 520 Part 1 encourages final sizing and selection using actual area and rated discharge coefficient, which can often be obtained from Ref. 6 (known as the ASME Redbook NB-18).

When sizing a relief valve, never mix ASME values with API values. Mixing these values in calculations can cause you to overestimate the capacity of the PRD, which could lead to vessel rupture during an overpressure event (Table 1). Table 1. Mixing API and ASME values can overestimate the capacity of a pressure-relief device. These values are for a 2 ″×J×3″ pressure-safety valve. Effective AAPI = 1.287 in2 (per API Standard 526 (7))

Assume a pressure-safety valve (PSV) has a 2-in. inlet connection, an API J orifice, and a 3-in. outlet connection; this is referred to as a 2″×J×3″ PSV. Many PSVs use this designation to convey relative size (e.g., 3″×K×4″, 8″×T×10″). Table 1 shows that the highest risk occurs when the actual orifice area (AASME) is used with the API gas discharge coefficient (Kd), because the capacity of the PRD would be overstated — i.e.,the PRD would be undersized. An undersized PRD will not relieve as much as it should, which can permit overpressure beyond the equipment’s allowable accumulated pressure and lead to a loss of containment.

These types of mix-ups occur more frequently when a PSV is not a standard valve; for example, a full-bore valve or other non-API-letter-designated valve. Avoid the temptation to use the actual area reported by the manufacturer with the Kdvalue specified in API 520 during preliminary sizing.

Mix-ups in liquid sizing may present less risk because liquid KASME values tend to be higher than API liquid Kd, but mix-ups should, nonetheless, be avoided.

Prior to the 1980s, there was no differentiation between liquid-trim and vapor-trim valves used in relief service — most valves were designed for vapor. Liquid scenarios typically could not drive a vapor-trim valve fully open until approximately 25% overpressure was reached. After 1986, liquid-trim valves were certified to fully open at 10% overpressure.

There is a common misconception that conventional or bellows valves are trimmed to handle both vapor and liquid (i.e., dual-trim). Do not assume that a vapor-trim valve can relieve liquid just as well as a liquid-trim equivalent. Only some valves have this dual-trim characteristic; the most widely used is the modulating pilot relief valve. Conventional and balanced bellows valves with dual-trim are exceedingly rare.

If a valve has a vapor trim (i.e., is not certified for liquid), its capacity for liquid scenarios must be de-rated using the Kp factor, which is 0.6 for 10% overpressure scenarios. Otherwise, the capacity can be overestimated by 66% or more!

Liquid-trim valves have geometry that allows them to open properly for liquid overpressure scenarios. Although liquid-trim valves will also open for vapor scenarios, the gas coefficient of discharge for a liquid-trim valve will not be identical to that of a similar vapor-trim valve. There is no published consensus for a gas coefficient of discharge corrected for liquid-trim valves, but there is ongoing discussion within AIChE’s Design Institute for Emergency Relief Systems (DIERS), as well as in the API Subcommittee on Pressure-Relieving Systems (SCPRS).

It is widely believed and accepted that conventional or bellows valves with liquid trim will have the same gas coefficient of discharge as a similar vapor-trim valve, but that is not necessarily true. The gas coefficient of discharge in a liquid-trim valve will be de-rated from its vapor-trim equivalent (i.e., the Kd would be less than 0.975 for vapor flowing through a liquid-trim valve).

Keep an eye out for liquid-trimmed valves at or near their capacity for vapor scenarios and recognize that capacity may be overestimated in these situations.

PRDs for fluids with a compressibility factor (Z) outside of the range of 0.8–1.1 should be sized using the direct integration approach described in Annex B of API 520 Part 1 (5), because the standard method of vapor sizing for critical flow is not always appropriate at these conditions. Whereas the standard vapor sizing equations consider compressibility at the PRD inlet pressure only, the direct integration approach follows the fluid behavior (i.e., density) along an isentropic expansion path as it depressurizes through the PRD nozzle from the inlet pressure to the downstream pressure. The latter approach can provide a more accurate prediction of fluid behavior, and thus the flow, through the PRD.

Most contemporary software will guide users to the applicable equations if fluid compressibility is outside the prescribed range. Older installations may have been sized using the incorrect method or formulas. Often, the incorrect sizing formulas are applied when designers use simpler sizing tools such as back-of-napkin calculations and Excel spreadsheets.

This pitfall is not as common for installations sized or revalidated within the past ten years. Be aware that smaller or older facilities with many high-pressure gas and vapor services are more likely to have used traditional vapor sizing rather than direct integration, so overestimation of valve capacity is likely only a problem where installed devices are at or near their capacities.

Choosing a fluid’s correct initial relief temperature is important because it can significantly influence subsequent flashing. A process fluid may be subcooled at the inlet of the relief device and then begin flashing as it depressurizes through the PRD and into the disposal system (or atmosphere).

For example, assume that a pressurized vessel contains saturated water normally at 300°F (52 psig operating pressure) and has a PRD discharging to atmosphere set at 100 psig. However, the same vessel may operate as high as 326°F (83 psig). If liquid overfilling is a valid overpressure scenario, the engineer might be tempted to size the PRD using the normal operating temperature (300°F). As the liquid water exits the PRD and enters the atmosphere, it will flash because the boiling point at atmospheric pressure is approximately 212°F. The amount of flashing, though, is influenced by the initial temperature. In fact, the amount of flashing (the volume of liquid that expands into a vapor) will be greater if the initial relief temperature is 326°F. Since the volumetric flow and PRD sizing requirements are larger when there is more flashing, it is wise to choose the higher, albeit abnormal, temperature.

The step between sizing and installing a PRD is the detailed design phase, during which the rest of the PRS design is developed. Engineers are not typically responsible for the detailed design of new PRS installations. For example, an engineer may specify that the PRD outlet needs to be 6-in. Sch. 40 piping, but may not determine the precise geometry of the disposal system.

Two pitfalls commonly prevent engineers (and organizations) from successfully bridging the gap between PRD sizing and proper installation — pockets and unintended pipe dimensions.

Pockets.A pocket is a low point in a piping system (Figure 2), which can limit relief capacity, block flow, incite damaging slug flow, and allow liquids to accumulate.

Process engineers often scribble “DO NOT POCKET” on P&IDs that they send to pipe designers for detailed design, but sometimes the installation ends up with pockets nonetheless. There are many convenient excuses for putting pockets in PRD outlet piping (e.g.,running piping to go around existing structures), but the real culprit is often a lack of communication. Engineers must be sure to communicate and work with pipe designers to avoid pockets. Pipe designers will do their best to follow guidance from engineers on design P&IDs, but they may not know where to turn if something is in the way of the engineer’s pocketless vision.

Unintended pipe dimensions and tie-ins.Shorter pipe lengths with larger diameters are often desirable in relief device installations because they have smaller pressure drops than longer, smaller-diameter piping. The engineers designing PRDs often do not work in the facility where the PRD will be installed and may not know where platforms, catwalks, or other piping and valves are located. Thus, the routing for new PRS piping is often determined only after someone walks through the facility to identify the physical locations and limitations. Although the engineer may have envisioned a PRS with 5-ft inlet and 40-ft outlet piping, in reality the detailed design may need to be much longer with many more fittings, which adversely affects the pressure drop and desired tie-in location. If this occurs, the engineer must adjust the sizing calculations to account for the longer piping, because the pressure drop might increase and the relief capacity decrease.

The key to preventing this pitfall, too, is to communicate with the pipe designers! The importance of dialogue during detailed design is often overlooked, but can be critical if pressure drop becomes too high.

Once equipment is designed, purchased, and installed, it becomes as-built. The term as-built simply refers to how equipment exists in the field and how its installation is depicted in engineering drawings. Sometimes, designs that seem good on paper are installed poorly in the field.

Expanders in PSV inlet piping. A PRD’s inlet should be smaller than or the same size as the connection on the equipment that the PRD protects (Figure 3). This is an ASME VIII code requirement, and violation of it carries the risk of an OSHA citation. Expanders in the PRD’s inlet piping can limit PRD capacity and cause increased inlet pressure drop.

Relief device set pressure higher than protected equipment set pressure.With a few specific exceptions, the PRD set pressure must always be specified at or below the equipment’s MAWP. If the PRD set pressure is higher than the MAWP on a P&ID, it is typically a typographical error. But if this is the as-built condition, it represents a higher risk of loss of containment, since PRDs are designed to protect at 10%, 16%, or 21% pressure accumulation as per ASME VIII guidelines (1). This concern is more likely to occur when the MAWP of a piece of equipment is de-rated or an MOC system does not actively engage PRS personnel.

Relief device installed on the bottom of a liquid system.Ideally, PSVs should be installed in the vapor space of equipment. PRDs installed in the liquid space are much more susceptible to liquid displacement or two-phase flow, which may have been overlooked in the evaluation of vapor scenarios (e.g., fire). This installation concern carries the physical risk of inadequate sizing to handle liquid displacement or two-phase flow conditions.

Check valves in the relief device outlet piping. Check valves cannot be guaranteed to remain open, nor can they be controlled open by administrative means. The potential blockage of a check valve carries the physical risk of the relief device failing to handle overpressure. For this reason, check valves should not be located in the relief path.

For any installation concern that can be spotted on a P&ID, subsequent visual confirmation in the field is warranted. In addition to the pitfalls you can find on P&IDs, visual verification can also reveal:

Lengthy inlet piping.Lengthy or tortuous inlet or outlet piping may incur significant pressure drop. Although a relief design basis that does not reflect the as-built piping situation may pose a citation risk, inordinate pressure drop may cause relief device instability and backpressure-limited capacity, which pose physical risks. These concerns are most pronounced in large relief devices (e.g., 4″×P×6″, 6″×Q×8″, 6″×R×8″, 8″×T×10″).

▲Figure 4. (a) Bellows vents must not be blocked or closed. (b) A closed bellows vent will have little to no relief capacity when backpressure exceeds overpressure.

Plugged bellows vent.Some PSVs are balanced against the effect of back-pressure by a bellows, which is vented from the PSV to atmosphere. Bellows vents are often labeled DO NOT BLOCK, but mistakes happen (Figure 4). Blocking the bellows vent turns the balanced PSV into a conventional, unbalanced PSV, which presents the physical risk of having little to no relief capacity when back-pressure exceeds overpressure.

Intervening gate valves installed with stems pointing up. Gate valves allow for isolation of relief devices for maintenance purposes and are sealed open during normal operation. Long-term corrosion or vibration can break or shake gates loose from their stems, which may go unnoticed; if a gate valve in horizontal piping is installed with its stem pointed up, a dislodged gate could block the relief path entirely. Therefore, it’s crucial that these valves are installed on their sides.

Sideways relief valves. PSVs should be installed in the vertical upright position. Sideways valves may not operate as intended — either opening unexpectedly or leaking.

Atmospheric outlet piping within arm’s reach.Relief devices discharging to atmosphere should vent to a safe location. If you can look into the end of a PRD tailpipe, DON’T. This PRD and discharge piping has been installed incorrectly.

Literature Cited American Society of Mechanical Engineers, “Rules for Construction of Pressure Vessels,” BPVC Section VIII Div. 1, New York, NY (2015).

U.S. Occupational Safety & Health Administration, “Voluntary Protection Programs,” Directorate of Cooperative and State Programs, OSHA, U.S. Dept. of Labor, Washington, DC, www.osha.gov/dcsp/vpp/index.html (accessed Feb. 2016).

U.S. Occupational Safety & Health Administration, “Process Safety Management of Highly Hazardous Chemicals,” 29 CFR 1910.119, U.S. Dept. of Labor, Washington, DC, www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=9760 (accessed Feb. 2016).

American Petroleum Institute, “Sizing, Selection, and Installation of Pressure-Relieving Devices, Part I — Sizing and Selection,” Standard 520, Part I, 9th ed., API, Washington, DC (July 2014).

National Board of Pressure Vessel Inspectors, “National Board Pressure Relief Device Certifications,” NB-18, Columbus, OH, www.nationalboard.org/Index.aspx?pageID=64 (accessed Feb. 2016).

This article is based on the AIChE webinar, “Whoops! I Made a Mistake Sizing My Relief Device and Then I Installed It Incorrectly!” To watch this webinar, as well as other webinars presented by Justin Phillips, P.E., visit www.aiche.org/academy.

were easily tampered with or accidentally released. In 1856 John Ramsbottom invented a tamperproof spring loaded safety valve which became universal on railways and later on stationary

Controlled safety valves consist of the main valve and a control device. They also include directacting safety valves with supplementary loading in which, until the response pressure is reached, an

A rupture disk designed and manufactured to be installed upstream of other piping components. Nonfragmenting rupture disks do not impair the function of pressure relief valves when the disk ruptures.

A definite time interval between inspections or tests should be established for every pressurerelieving device on operating equipment. Depending on operating experiences, this interval may vary

serves to detect leakages due to a potentially defect bellows. This recommendation follows API 5202, the only standard providing a statement concerning the vent hole.

the restriction while relieving. In some cases, critical flow can occur not only in the pressurerelief valve nozzle but also at the discharge-pipe outlet to atmosphere. In this case, the noise

safety valve. This paragraph presents a short introduction on the topic of phase change and twophase flows and is helpful to understand the sizing algorithms presented e.g. by API RP 520 (see

in temperature but to condensation of some vapor: in any Point X the medium is present as a twophase mixtures. The condensation goes on until the condition of saturated steam (Point C) is

For multi-component systems, whose nominal boiling range is greater than 150°F or for singlecomponent systems close to the thermodynamic critical point or supercritical fluids in condensing

For multi-component systems, whose nominal boiling range is greater than 150°F or for singlecomponent systems close to the thermodynamic critical point s is given by Eq. 7.4.7.3-2.

7.4.7.5 Omega Method API 520-1 (2020) Chapter C2.3 Sizing for Subcooled Liquid at the Pressurerelief Valve Inlet Using the Omega Method considering SI-Units

LESER recommends the installation of the pressure relieving valve on the cold side of a shell-andtube heat exchanger. The reason is to prevent thermal expansion or even vaporizing of the cold

Wang, B.H.; Adcock, J.L.; Mathur, S.B.; Van Hook, W.A., Vapor pressures, liquid molar volumes, vapor nonidealities, and critical properties of some fluorinated ethers: CF3OCF2OCF3, CF3OCF2CF2H, c-CF2CF2

Shi, L.; Zhu, M.; Han, L.; Duan, Y.; Sun, L.; Fu, Y.-D., Thermophysical Properties of Difluoromethane (HFC32), Science in China, Ser. E, 1998, 41, 435-42.

- SA-105 - Specification for carbon steel forgings for piping applications - SA 182 - Specification for forged and rolled alloy and stainless steel pipe flanges, forged

fittings, and valves and parts for high-temperature service - SA-193 - Specification for alloy-steel and stainless steel bolting materials for high-temperature

service - SA-194 - Specification for carbon and alloy steel nuts for bolts for high-pressure or hightemperature service, or both - SA-216 - Specification for steel castings, carbon, suitable for fusion welding for hightemperature service - SA-217 - Specification for steel castings, martensitic stainless and alloy, for pressurecontaining parts, suitable for high-temperature service - SA-351 - Specification for casting, austenitic, austenitic-ferritic (duplex), for pressure –

thickness of a flange. If a chart has such a limit it is noted under the chart. See EN 1092-1 annex G for p/t ratings of flanges with a larger value of vR and F.2.4 for further information on vR.

Height of full raised portion is equal to the depth of groove dimension E, but is not subjected to the tolerances for E. Former fullface contour may be used.

DIN EN ISO 4288, Geometrical Product Specifications (GPS) - Surface texture: Profile method Rules and procedures for the assessment of surface texture

An additional stainless steel tag can be used for further information, e.g. customer specific tagnumber. The customer defines the input. Depending on the amount of letters it is chosen

In practice the user may encounter various problems with the operation of a safety valve. If an unacceptable problem is found, it needs to be determined if it is a potential safety issue which requires

The purpose of this chapter is to give an overview of common safety issues and operational problems, their possible symptoms and causes along with the immediate actions and preventive

measures recommended by LESER. This overview does not claim to be complete. For detailed information do not hesitate to contact LESER or an authorized LESER service partner. You will find

The following table shows how the information in this chapter is organised. Using the table as a starting point, try first to identify the observable symptom in the list below and then go to the page indicated on the right. This page contains details about possible causes, immediate actions and preventive

For your convenience, the symptoms have been grouped into Problem Areas (e.g. “Leakage”, “Opening/Closing”) and can be looked up in a Problem Area Chart using their symptom number and description.

The following charts show detailed information on individual symptoms, including background information, if required („Note”), possible causes, immediate actions and preventive measures. The symptoms are grouped into problem areas.

520 1.2.3.3 o). LESER defines simmering at an inlet static pressure >90% of the set pressure. Permanent simmering is undesirable as it will lead to wear of the seat/disc and permanent loss of medium. Simmering is a typical part of the operating characteristic for safety valves with a set a set pressure defined as pop.

disc where the disc contacts the pressure relief valve seat during cycling… Flutter is similar to chatter except that the disc does not come into contact with the seat during cycling.

frequent opening means that the safety valve goes through a complete operating cycle and discharges enough medium to lower the pressure in the protected equipment below the reseating

moving parts are affected. Limited corrosion might be acceptable, provided it does not affect the operability of the safety valve or the pressure containing properties of body or bonnet.

are affected. Limited corrosion might be acceptable, provided it does not affect the operability of the safety valve or the pressure containing properties of body or bonnet. Likewise,

pressure. It is a damageable part because it is thin-walled. Failure reasons can be: corrosion, too high temperatures or an exceed of the allowable cycles in case the safety valve is

8613371530291

8613371530291