how to fix pressure cooker safety valve factory

Pressure cooking is a wonderful way to prepare food that cooks thoroughly and quickly at a high temperature. Some are worried about the dangers of using a pressure cooker, so it is helpful to find out how to check your pressure cooker safety valve for safe operation.

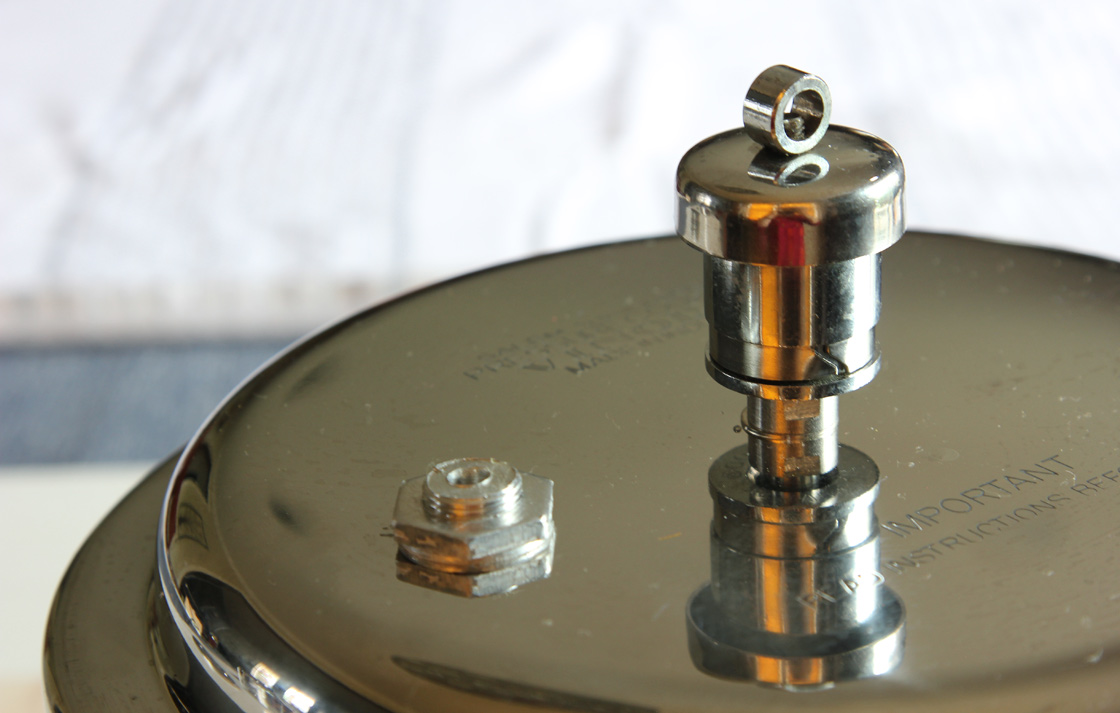

For those worried that a pressure cooker might explode, the safety valve is the design feature that prevents this from happening. If the cooker has a safety valve, you can see it installed on the cooker’s lid.

A pressure cooker is designed to trap the steam inside to increase the pressure. However, too much pressure is not safe. The valve must release pressure if it gets too high.

The blog of pressure cooking today has many recipes that are delicious. There are 25 recipes for pasta so you can try a new one every day for nearly a month.

There is a weight inside many of the safety valves that is lifted by the internal steam pressure when it reaches a certain amount. When the pressure lifts the weight inside the valve, this allows some steam to escape.

Jeffrey Eisner who says “he is a nice Jewish boy from Long Island.” He started with pressure cooking by making a simple mac and cheese dish with a recipe that he shared on YouTube. The video was an immediate success and led to his making new recipes for pressure cooking.

In a sealed cooker, as the pressure builds up, the boiling point of water rises. This phenomenon is the cause of the increased heat that cooks the food more thoroughly and faster.

The science that explains this is fascinating. The normal boiling point of water under standard atmospheric pressure of 15 pounds per square inch (psi) is 212°F (100°C). In a pressure cooker, the atmospheric pressure doubles from 15 psi to 30 psi. This added pressure raises the boiling point of water from 212°F (100°C) to 250°F (121°C).

If you see steam escaping from the safely valve do not worry. The steam escaping from the safety valve is its normal function, which means the valve is working properly.

If the internal pressure within the cooker gets high enough, this lifts a weight in the safety valve that allows steam to escape. The escaping vapor lowers the pressure. You can hear the steam escaping, making a whistling sound, or rattling the valve.

The first pressure cooking devices were used in the 17th century. They were useful to remove fat and collagen from bones so that the bones could then be ground down to make a pure bone meal.

The inventor of the device, Denis Papin, called it a “steam digester” or “bone digester.” His invention was the precursor to both pressure cookers and the steam engine. Surprisingly, the early designs did not have any safety features, and this caused some of the first ones to explode while being used.

The legacy of those early pressure-cooking devices may be why some still fear this problem even today. Papin, to his credit, came up with a design improvement that is what we call a safety valve to avoid the dangers of these explosions.

By the 1930s, the modern pressure cooker design became useful in a home kitchen. The Flex-Seal Speed Cooker, invented by Alfred Vischer, came out in 1938.

These home cookers became even more popular in 1939 with the release of the design by the National Pressure Cooker Company (now called National Presto Industries), which is still manufacturing these cookers today.

The first-generation cookers had a safety valve that worked with a weight. When the internal pressure rises high enough to lift the weight, some steam escapes, and the valve makes a distinctive rattling sound.

Second-generation cookers use a spring-loaded valve that makes less noise and is adjustable for pressure sensitivity by using a dial, which is on the cooker.

Third-generation models are the most recent versions. They use an electric heating source that is regulated by the internal pressure. These devices do not need a safety valve because the heat source automatically shuts off before the pressure gets too high.

Suppose you are thinking about getting a new cooker. In that case, there is another device that you might consider called a food dehydrator, which I describe in the article entitled, “How Much Electricity Does a Dehydrator Use?” here.

For the styles of cookers with a safety valve, it may not be obvious when the valve is not working if it is blocked. You may notice the lack of steam while the cooker is heated. The valve could rarely be blocked, but if not cleaned properly, it is possible.

Alternatively, the valve may be broken, missing, or the pot may not seal properly. These problems might allow too much steam to escape. This leakage may cause the cooker not to heat up properly and not allow the internal pressure to build up to the proper level.

One of the signs of a problem with a lack of pressure is that the food takes much longer to cook than you normally expect when using a cooker of this type.

One tip in the video is not to open the cooker after finishing cooking and take the lid to run it under cold water. This sudden temperature change can make the safety valve work less well and may cause the need to change the valve more frequently.

If you use a cooker that needs a valve to work properly and the valve is broken or missing, you can replace it with a new valve. Be sure to get the manufacturer’s specifications to ensure you use the correct replacement part.

Some of these problems include the ventilation knob being open or not enough liquid is in the cooker (requires at least one cup). Another cause is the sealing ring is missing, damaged, covered with food particles, or not in the proper position.

The video narrator shows how she cleans her float valve for her instant pot that she uses as a cooker. If you use too little liquid or too much, the cooker may not pressurize.

For the type with screws, hold the valve from the bottom of the lid with the pliers and use the screwdriver to remove the screws from the top to remove the broken part. Replace it with the new one and tighten the screws that hold it in place by holding it with the pliers from the bottom of the lid again and tightening the screws from the top.

For the type with a nut, use the wrench to loosen it for removal and perhaps a socket when you put on the new valve to tighten it with enough torque to hold it securely in the proper position.

Modern pressure cookers that are in good repair are quite safe. The one caution to remember is not to overfill the cooker so that the food might block the safety valve. This overfilling with food would be very difficult to do and not something to worry about for normal use.

Be careful where you keep your cooker on the countertop because it is important to know how hot a stovetop can get. Even when turned off, a stovetop may still be very hot, which I discuss in this article.

Now you know everything you need to know about a pressure cooker safety valve. You know what they do, how they work, and how to replace one if it needs repair. Enjoy your pressure-cooking recipes without worrying about the safety valve.

If having a safety valve on your cooker still bothers you, consider buying an electric cooker without a valve that instead has a built-in safety feature that automatically shuts off power if the pressure gets too high.

Pressure cookers are not an innovative cooking technology, but seemingly slightly forgotten. They are known for a long time, even before ceramic hobs, modern ovens, bakeries and various facilitating small appliances that save a lot of manual work. The fact is, however, that their application is back - regardless of whether old antiques will be removed or a new purchase will be made.

The new kitchen stoves are almost identical in appearance to those of the past. The difference is that nowadays, fear of exploitation is eliminated little by little, because there is enough information available for proper operating instructions, possible malfunctions, implementation of advanced safety mechanisms and more. Experts recommend a new investment for a new type of dimension in cooking.

Closing mechanism - this is about the auto-lock function. For those models that do not have one, the problem may be with the locking mechanism or incorrect locking. This results in the inability to reach the correct pressure

Valve - The pressure valve may not be correctly installed. This is a common cause of under-pressure. Remember to clean the pan frequently, especially the valve. For this purpose, there is a certain technique that must be followed

Old Seals and Valve - Depreciation is a normal process that requires replacement. For these and other silicone and rubber components, it is recommended to replace it at about 18 months

Thick liquids and other thickeners - delicious dishes become cooked in a pressure cooker - fast and easy, but some products impede the process of reaching the required pressure. These are thick liquids and flour, which usually plays the role of thickener. It is recommended that they be eliminated or added thereafter

Handle - Used frequently and can loosen over time. May be the cause of shortage of high pressure. Check the goodness of the handle before setting the pan to cook your meal

Liquids - they are allowed, but must be maintained within certain limits. Otherwise, it will take a long time to reach the required pressure. Follow the instructions for the maximum that can be set so you have no problems

Food - The maximum capacity according to different recipes must be respected here. Usually, food is placed in the space, and for others up to half. Consider the instructions carefully to allow the permitted amount of ingredients, spices and liquids

Frozen foods - Cooking frozen foods in a pan is allowed, but the process is prolonged. In them, the pressure builds up more slowly. Keep in mind that any frozen food extends its preparation by about 30 minutes

Valve Problems - The valve is a basic element that serves to maintain the desired pressure. It must be properly secured and replaced for at least a year and a half, as wear may be a major problem in this regard.

Depreciated seals- Worn pot seals need to be replaced again as they wear out over time. The cookware may also contain other rubber or silicone parts that may need more frequent replacement

Outside temperature - this problem is actually related to improper operation - the heat can be very reduced. Look for the manual of your pot model to find out the right time for this action

Food that is cooked - If you put flour or some thick liquid in the pressure cooker, it can cause food to be thrown out. The spraying process occurs when the pressure is released

The valve is not well adjusted - steam is released through the valve, and it may not be properly adjusted. This is normal at first, but keep in mind that at this point you need to adjust yourself to eliminate excessive steam

The pan is too hot - the heat used must be adapted to the cooker. You may find it harder at first, but you will get used to it later. This may be a clear indication of the subsequent evaporation of steam, so take care of less pressure to reduce heat

Food is not prepared properlyThis is a common occurrence for anyone who starts using the appliance. Do not try the pressure cooker for the first time when you have guests. Foods that are slightly raw or overcooked may be due to an incorrect recipe or to:

Heat during pressure cooking - do not leave heat to a maximum so as not to remove dried, boiled or charcoal food. Adjust the heat level according to the needs of the different foods

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Pressure cookers are both simple and complicated at the same time. From the user’s perspective, they seem quite simple – to operate. But a lot of time has been invested in creating these cookers as we know them today – with all of their safety features and automated functions. Every little part of the cooker plays an important role in keeping the user safe, cooking delicious food and ensuring the quality of the product.

What’s the use of a pressure cooker’s safety valve? It’s, as the name suggests, a safety mechanism. If the pressure cooker fails to release excess pressure, the inner pressure will rise above controllable levels. When that happens, the safety valve will burst and let out the excess pressure to prevent an explosion. The safety valve is commonly found on the cooker’s lid.

Pressure cookers are designed to trap the steam that is produced by the boiling liquids inside the cooker to increase the pressure inside the vessel. The cooker must, however, release some pressure when it exceeds certain limits to prevent an explosion.

This is done through a release valve, which holds a weight. When the pressure inside the cooker is high enough to lift the weight, the excess steam escapes – creating a whistling sound.

If the release valve fails to let out steam for some reason, the pressure inside the container will rise to unbearable levels and eventually cause an explosion.

You can find safety valves on any equipment that is used to accumulate high pressure-levels (chemical plants, gas storage tanks, pressure cookers, etc). This is a safety mechanism that keeps the object from reaching levels of pressure that it cannot contain. If it wasn’t for the safety valve, reaching said levels would otherwise result in an explosion.

This isn’t exactly the way every safety valve is designed but the main principle seems to be the same. When it comes to pressure vessels, the safety valve is known as the final safety device. It will not engage unless all other measures fail to release pressure.

Of course, while the safety valve is a fine feature to have, us users must do our best to prevent our cookers from reaching high levels of pressure. This is done by following the manufacturer’s guidelines when cooking, taking good care of our cookers, and never leave our cooker unattended.

Here’s a list of things that can cause the pressure cooker to reach maximum levels of pressure (electric pressure cookers max out at 12.5psi~ and regular stovetop pressure cookers at 15psi~).

Overfilling the cooker: Some foods will swell when cooked, and take up more space than they initially did. The cooker should, therefore, never be loaded more than two-thirds full. The expanding ingredients may block or clog the release valve which, in turn, results in unbearable pressure levels.

Cooking ingredients that froth: Ingredients such as pasta, beans, rice, and oatmeal froth easily when cooked. The boiled-up foam may prevent the release valve from transporting the excessive pressure out of the cooker.

The pressure cooker is damaged: If your pressure cooker is damaged and fails to regulate pressure levels, the pressure inside the cooker can rise far beyond the cooker’s limits. This will cause the safety valve to burst and let out the excessive pressure. Safety valves and venting valves should be checked on a regular basis to ensure that they are working properly.

There wasn’t enough liquid in the cooker: If the user hasn’t added sufficient amounts of liquid in the cooker prior to starting the cycle, the liquids inside the cooker will eventually evaporate and the cooker will start boiling dry. This can cause the temperature and pressure inside the cooker to rise above safe levels. This may cause the safety valve to fuse.

Adjustments weren’t made when needed: Traditional stovetop pressure cookers demand the user to make manual adjustments throughout the process to regulate pressure and temperature. Electric pressure cookers handle this automatically. On a traditional pressure cooker, the user must keep track of the pressure gauge and lower the temperature when full operating pressure is reached. Continuing cooking on full operating pressure can cause pressure levels to reach unsafe levels. This, in turn, causes the fuse to blow.

The cooker is used on large flames: If the cooker is placed on large flames, the flames will extend to the side of the cooker, this may overheat the pressure cooker and blow the fuse. Large cookers require large flames but small cookers don’t – adjust the flames according to the size of the cooker.

Yes, you can replace a safety valve on a pressure cooker, and if your safety valve is damaged or out-of-function, I strongly recommend that you do so.

There are two ways of replacing the safety valve on a pressure cooker. The first method approaches the safety valve from inside the lid and the second method from the outside.

The first method, which approaches the safety valve from the outside, is done by inserting a blunt knife or turning the screw in the hole from the outside while you hold the screw on the inside. Turn the knife to turn the screw. It should loosen up eventually.

Some models may require you to remove the handle in order to get to the actual safety valve. The methods used to replace the safety valve will, of course, vary depending on the model.

Both yes and no. But I highly advise against it. Safety valves are designed and installed for a reason. Without the safety of the valve, cooking in a pressure cooker could, potentially, have devastating consequences. It’s easily avoidable by replacing or repairing your unit. Saving a couple of dollars is nothing compared to your health and well-being.

No, it’s not possible to cook in a pressure cooker with a missing safety valve. Without the valve, the pressure cooker will not be able to reach and maintain enough pressure to cook a meal. The absence of the valve opens up an escape route for steam, which would otherwise be trapped in the cooker.

Yes, it’s possible to cook in a pressure cooker with a flawed, damaged or defective safety valve as long as the valve is still shut and intact. I can’t stress enough how bad of an idea this is. If the valve is damaged and the cooker reaches pressure levels above predetermined limits, the valve may not be able to release the excess pressure – which will cause the cooker to explode. Superheated steam will fly from the exploded cooker and burn anything in its path.

The best thing you can do is to get in contact with customer support if you suspect that your cooker isn’t working properly. It’s worth mentioning that the pot (without the lid) can be used as a regular pot too.

If the safety valve is damaged or broken, it should be replaced by a completely new valve. The easiest way to get a hold of a valve that suits your cooker is by contacting the company that manufactured the pressure cooker. Because these relief valves play such a vital role, it’s very important that you use the right kind of valve for your pressure cooker.

When a safety valve fails to lift when predetermined pressure levels are reached, the blowout plug will self-destruct to prevent an explosion. This blowout plug, created to burst when needed, is made of hardened rubber, more specifically; either hardened neoprene or viton.

I regularly use my Hawkins pressure cooker for meals. After two years of use (and to my dismay) the safety valve burst. Luckily the rice was already cooked by then!

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is applicable). Packaging should be the same as what is found in a retail store, unless the item is handmade or was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller"s listing for full details.See all condition definitionsopens in a new window or tab

We offer Pressure Cooker Valves which are renowned for its precise functionality and quality. We have hired pool of adroit professional who employ latest tools and advanced technologies in order to manufacture these pressure cooker valves. These valves are easy to use and widely used in the pressure cookers to ensure that theyread more...

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Pressure relief valves (safety relief valves) are designed to open at a preset pressure and discharge fluid until pressure drops to acceptable levels. The development of the safety relief valve has an interesting history.

Denis Papin is credited by many sources as the originator of the first pressure relief valve (circa 1679) to prevent overpressure of his steam powered “digester”. His pressure relief design consisted of a weight suspended on a lever arm. When the force of the steam pressure acting on the valve exceeded the force of the weight acting through the lever arm the valve opened. Designs requiring a higher relief pressure setting required a longer lever arm and/or larger weights. This simple system worked however more space was needed and it coud be easily tampered with leading to a possible overpressure and explosion. Another disadvantage was premature opening of the valve if the device was subjected to bouncing movement.

Direct-acting deadweight pressure relief valves: Later to avoid the disadvantages of the lever arrangement, direct-acting deadweight pressure relief valves were installed on early steam locomotives. In this design, weights were applied directly to the top of the valve mechanism. To keep the size of the weights in a reasonable range, the valve size was often undersized resulting in a smaller vent opening than required. Often an explosion would occur as the steam pressure rose faster than the vent could release excess pressure. Bouncing movements also prematurely released pressure.

Direct acting spring valves: Timothy Hackworth is believed to be the first to use direct acting spring valves (circa 1828) on his locomotive engine called the Royal George. Timothy utilized an accordion arrangement of leaf springs, which would later be replaced with coil springs, to apply force to the valve. The spring force could be fine tuned by adjusting the nuts retaining the leaf springs.

Refinements to the direct acting spring relief valve design continued in subsequent years in response to the widespread use of steam boilers to provide heat and to power locomotives, river boats, and pumps. Steam boilers are less common today but the safety relief valve continues to be a critical component, in systems with pressure vessels, to protect against damage or catastrophic failure.

Each application has its own unique requirements but before we get into the selection process, let’s have a look at the operating principles of a typical direct acting pressure relief valve.

In operation, the pressure relief valve remains normally closed until pressures upstream reaches the desired set pressure. The valve will crack open when the set pressure is reached, and continue to open further, allowing more flow as over pressure increases. When upstream pressure falls a few psi below the set pressure, the valve will close again.

Most commonly, pressure relief valves employ a spring loaded “poppet” valve as a valve element. The poppet includes an elastomeric seal or, in some high pressure designs a thermoplastic seal, which is configured to make a seal on a valve seat. In operation, the spring and upstream pressure apply opposing forces on the valve. When the force of the upstream pressure exerts a greater force than the spring force, then the poppet moves away from the valve seat which allows fluid to pass through the outlet port. As the upstream pressure drops below the set point the valve then closes.

Piston style designs are often used when higher relief pressures are required, when ruggedness is a concern or when the relief pressure does not have to be held to a tight tolerance. Piston designs tend to be more sluggish, compared to diaphragm designs due to friction from the piston seal. In low pressure applications, or when high accuracy is required, the diaphragm style is preferred. Diaphragm relief valves employ a thin disc shaped element which is used to sense pressure changes. They are usually made of an elastomer, however, thin convoluted metal is used in special applications. Diaphragms essentially eliminate the friction inherent with piston style designs. Additionally, for a particular relief valve size, it is often possible to provide a greater sensing area with a diaphragm design than would be feasible with a piston style design.

The reference force element is usually a mechanical spring. This spring exerts a force on the sensing element and acts to close the valve. Many pressure relief valves are designed with an adjustment which allows the user to adjust the relief pressure set-point by changing the force exerted by the reference spring.

What is the maximum flow rate that the application requires? How much does the flow rate vary? Porting configuration and effective orifices are also important considerations.

The chemical properties of the fluid should be considered before determining the best materials for your application. Each fluid will have its own unique characteristics so care must be taken to select the appropriate body and seal materials that will come in contact with the fluid. The parts of the pressure relief valve in contact with the fluid are known as the “wetted” components. If the fluid is flammable or hazardous in nature the pressure relief valve must be capable of discharging it safely.

In many high technology applications space is limited and weight is a factor. Some manufactures specialize in miniature components and should be consulted. Material selection, particularly the relief valve body components, will impact weight. Also carefully consider the port (thread) sizes, adjustment styles, and mounting options as these will influence size and weight.

In many high technology applications space is limited and weight is a factor. Some manufactures specialize in miniature components and should be consulted. Material selection, particularly the relief valve body components, will impact weight. Also carefully consider the port (thread) sizes, adjustment styles, and mounting options as these will influence size and weight.

A wide range of materials are available to handle various fluids and operating environments. Common pressure relief valve component materials include brass, plastic, and aluminum. Various grades of stainless steel (such as 303, 304, and 316) are available too. Springs used inside the relief valve are typically made of music wire (carbon steel) or stainless steel.

Brass is suited to most common applications and is usually economical. Aluminum is often specified when weight is a consideration. Plastic is considered when low cost is of primarily concern or a throw away item is required. Stainless Steels are often chosen for use with corrosive fluids, when cleanliness of the fluid is a consideration or when the operating temperatures will be high.

Equally important is the compatibility of the seal material with the fluid and with the operating temperature range. Buna-N is a typical seal material. Optional seals are offered by some manufacturers and these include: Fluorocarbon, EPDM, Silicone, and Perfluoroelastomer.

The materials selected for the pressure relief valve not only need to be compatible with the fluid but also must be able to function properly at the expected operating temperature. The primary concern is whether or not the elastomer chosen will function properly throughout the expected temperature range. Additionally, the operating temperature may affect flow capacity and/or the spring rate in extreme applications.

Beswick Engineering manufactures four styles of pressure relief valves to best suit your application. The RVD and RVD8 are diaphragm based pressure relief valves which are suited to lower relief pressures. The RV2 and BPR valves are piston based designs.

8613371530291

8613371530291