how to reset propane tank safety valve quotation

The safety relief valve is one of the most important and vital valves on any LP Gas container. All propane tanks and cylinders are required by law to be fitted with pressure relief devices designed to relieve excess pressure. The function of a safety relief valve is to keep a propane tank from rupturing in the unlikely event of excessive pressure buildup. Propane tank relief valves are also known as pop off valves, pressure venting valves or relief valves.

Relief valves are held in the closed position by the force of a powerful spring. As long as the pressure inside the tank is less than that of the spring, the valve will remain closed. If tank pressure rises to that of the spring, the valve will open resulting in a hissing sound outside the tank. If the pressure in the tank rises significantly higher than that of the spring, the valve will fully open. When the valve fully opens, it initially makes a loud pop followed by a blast of released propane gas. Once the pressure is released and the tank pressure falls below that of the spring, the valve closes.

Most propane tanks in residential and commercial service have internal safety relief valves. The reason for an internal valve as opposed to an external pressure relief valve is it presents less of an obstruction when moving the tank. Internal relief valves are generally placed near the end of the propane tank on above ground containers.

Found primarily on older tanks, external relief valves operate in the same manner as an internal relief valve with the spring mechanism being outside the propane tank itself. Relief valves on multvalves are always fitted with external safety relief valves. Older tanks with an external relief valve installed on the container are generally replaced with internal pressure relief valves, provided they are connected to a dedicated tank opening specifically designed for the placement of the relief valve.

Because the safety relief valve performs such a vital role in the protection of the propane tank, it should be maintained and repaired by licensed propane professionals only. Do not ever look into a relief valve or stand over it.

A protective cover should be placed over the relief valve to ensure proper operation. If the valve has debris in the upper mechanism of the relief valve and it opens, the debris may cause the valve to remain open resulting in a potentially dangerous situation and/or excessive loss of propane. A simple protective relief valve cover can be made from a plastic bag fastened around the external portion of the valve with a rubber band.

If a you encounter a relief valve that seems to be "hissing" (opened to relieve pressure) do not tap it or mess with it. If the tank has been recently filled in hot weather and the face gauge reads over 80 or 85%, spray some water from a hose on the tank. This may cool it down and reduce the expansion of the liquid in the tank. Call your propane company immediately and inform them of the situation.

Pictured here is a relief valve that was apparently leaking. Instead of calling the propane company to replace the valve, the customer decided to fix the problem himself. Using a soldering iron, he soldered the leak until it stopped leaking. In the process of "repairing" the leak, the customer completely sealed the relief valve in a closed position placing himself and his family in a very dangerous situation.

In this type of situation, a relief valve that is sealed shut will not allow the tank to vent excess pressure if it is overfilled or the pressure inside the tank exceeds the working pressure of the container. In a case where the tank is unable to vent to the outside, the tank is subject to rupturing causing more harm and damage than money saved by trying to fix it yourself. Let the propane company or LPG professional handle any problems with thesafety relief valve.

Check that the hose attachment is properly connected to the propane tank, and double-check that the screw-on valve is tightened. Some propane tanks have safety features that won’t allow gas to escape from the canister unless the hose connection is tightly secured with the gas release mechanism.

Take a look at your connector. If it’s less than an inch long, it won’t be long enough to depress the check valve inside the valve. In this case, you’ll need a new connector that’s over an inch long.

If your valve is turned all the way on, the tank may not release propane. This is a safety feature. Start over, turning the valve only once, then igniting the grill.

If none of these actions work, it’s possible that you have a faulty regulator, which stops the flow of propane. In this case, it’s best to get a new hose with a regulator, and try again.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Every once in a while I get frustrated-frantic with a tank. I shut it off, get a full one and put it on my big Weber grill. Open it slowly, always works. Then like a dummy I take the partial in for a fill but only when I have one or two more empties. I like to make it worth the trip.

Just got my winter supply at the house. It cost $.99 per gallon so the price they charge to fill a 20 lb tank (about 4.5 gallons) costs .89 a pound. A well to do guy in my home town was filling his own 20 lb tanks off of the 500 gallon house tank with some creative plumbing he had assembled. Had a slight accident and though he did not get burned, he did burn up his garage and half of a very nice house.

It’s summertime, folks, and that means it’s the grilling season. Sure, we all love grilling year round but there’s nothing quite like a summer barbecue. Before you fire up that grill I allow me to engage you in a quick discussion about our ‘propane bottles.’

Grilling cylinders are technically known as 20 lb. DOT cylinders because they are built to DOT specifications. DOT specifications include rules that deal with metal thickness, pressure capabilities, and longevity of the tank. These cylinders can only legally contain 20 lbs. of propane. Propane weighs 4.24 lbs. per gallon. That means there is approximately 4.7 gallons of propane in your grilling cylinder when it’s full.

Grilling cylinders can be refilled or exchanged at a cylinder exchange cage. Refilling stations must refill the cylinder by weight. That’s why when you get your grilling cylinder refilled, the attendant will place it on a set of scales before they start the pump. Sometimes the attendant even uses a screwdriver and opens a small hole in the valve. You’ll hear a hissing noise as the bottle fills. When the grilling cylinder reaches 80% capacity, a white mist will shoot out of the small hole indicating that the cylinder is full. ‘Full’ in the propane industry, when regarding tanks and cylinders, is actually 80% of the water capacity of the tank or cylinder being filled. Propane is very susceptible to temperature changes and will expand or contract greatly with changes in the outside temperatures. To compensate for this possible dangerous expansion, we never completely fill up a tank or cylinder. We always stop at the 80% level.

Grilling cylinders are equipped with all kinds of safety features. One such feature is the OPD valve. The OPD valve ensures that your grilling cylinder isn’t over filled. All cylinders that hold less than 100 lbs. of propane are required by law to have this type of valve installed. OPD stands for Overfill Protection Device and that is exactly what it is designed to do. As the cylinder is being filled and the liquid level rises, it also raises a small float attached to the bottom of the valve. As this float rises to approximately 809% of the volume of the tank, the valve will shut and stop propane from being allowed into the cylinder. Despite the OPD being required by law to be on your grilling cylinder, the law also says it must still be filled by weight. The OPD is a safety backup.

Your grilling cylinder is rated to be used for a period of 12 years from the date of manufacture. On the cylinder collar you will ding the date of manufacture in a month-year format, stamped into the metal. Each time that your cylinder is filled it must be visually inspected and looking at the date of manufacture is usually one of the first items that the refilling agent will look for. A cylinder may be re-qualified by doing a visual inspection by a properly trained agent and will require a new date followed by the letter E stamped into the collar. This will allow the cylinder to be filled for another 5 years. Some companies do this re-qualification for their customers but most do not.

Many customers find that the cylinder exchange cages are the way that they prefer to get a full cylinder of propane for their grill. The customer brings an empty cylinder to the cage location, leaves the empty, and gets a full cylinder. The price for exchange is generally higher than having your cylinder refilled yourself but the exchange cage locations are generally open when a cylinder filing station may be closed. When using the exchange cages, the customer is assured that the cylinder has benen inspected and filled by a professional. Another drawback of the exchange process is that some companies will, by policy, not put a full 20 lbs. of propane in the exchange cylinder. Be sure to check the cage before purchasing to ensure that you are getting a full 20 lb. cylinder.

Another safety measure installed in grilling cylinders is an excess flow valve. The excess flow will engage and stop the full flow of propane through the valve if it sense that the gas line may have been broken or installed incorrectly. Over the years, I have seen customers open the valve swiftly, allowing gas to fill unpressurized gas hose so quickly that the excess flow ‘thinks’ that there is a problem and will shut the gas. It will release a small amount of gas to pressurize the hose on the downstream side of the valve in order to reset itself. For an unknowing customer, this small amount of gas being released is just enough to light a very small flame in their grill. This usually lends to the assumption that there’s something wrong with the grill. If this happens to you, simply turn off the burners on the grill and turn the cylinders valve to the off position and the excess flow will reset itself. You may even hear a small click when the reset occurs. After being reset, open the valve slowly (very slowly). Once the hose is pressurized, full gas flow will occur.

One last thing to be aware of when handling your grilling cylinder is a hissing sound coming from the back side of the valve. This is the pressure relief valve. It is designed to relive excess pressure that may build up inside of the cylinder. If you discover the valve is hissing or leaking, move the cylinder away from people and buildings in a cool place and away from any source of ignition. Call the person that filled the cylinder and follow their directions.

My understanding is the safety is in the regulator, if there is to large of a flow of gas it trips and restricts it. That is why you need to turn the tank on with the burners off. If you can"t get the appliance to work shut the tank off while the burners are on then turn them off and the regulator should reset.

I thought that is why they went to the outside threads, because the old tanks with the internal threads you could turn on and gas would flow. I was always taught to open it and close it fast to make sure any dirt got blown out. when they went to the external thread the tank won"t flow unless it is hooked up. I never investigated what is in there that the new hook up triggers to allow the gas to flow.

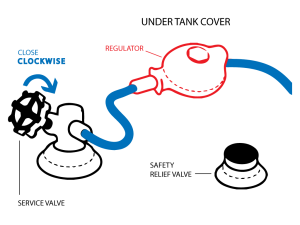

Houses or buildings utilizing gas energy require a gas piping system to power heaters, ovens, and other heating appliances. One of the most important elements of a gas piping system is the propane service valve, which controls propane gas flow in and out of a building. While there may be many other valves within gas plumbing, this valve functions as an on/off switch and serves as the main point of control for cutting off or allowing for the flow of gas into a piping system.

Propane valves are simply used to turn gas on or off. Similar to that of a water faucet, propane valves consist of a handwheel that controls propane gas flow when turned. When the wheel is turned, a stem and seat mechanism located within the valve opens or closes to prevent or allow gas flow from the tank.

Using propane gas requires an LP gas regulator, which decreases the amount of pressure released into the gas line, keeping it at an acceptable and safe level while still meeting the needs of the application.

There are multiple different valves in any propane system, each of which has a particular job. At IPS Equipment, we provide some of the most common types of valves for propane systems, including:

A pressure or safety relief valve is a safety mechanism that every propane system needs. It allows excess pressure in the tank to be slowly and safely released. Without this valve, pressure can build up and cause the tank to crack or rupture.

The relief valve has a pressurized spring. If the pressure levels within the tank grow too high, the spring forces the valve open just enough to return the pressure levels to acceptable levels. Once the pressure decreases, the spring relaxes, and the valve automatically closes.

This valve is where gas delivery personnel add new gas to a propane tank. Propane delivery trucks have hoses that can be attached to the filler valve so propane can be pumped into the tank. This valve is also pressure-activated, and it opens automatically in response to the pressure in the hose.

Filler valves have gaskets that operators can push the hose end against to avoid propane leaks. They also only allow for unidirectional fluid movement, meaning that once the tank is full, there is no risk of propane escaping when the hose is withdrawn.

This shut-off valve prevents gas from entering the building and any attached appliances. You can use this central point of control like an on/off switch to completely halt the path of gas in the system.

This valve is also called a vapor return valve or vapor eliminator valve. It ensures that propane is delivered at the proper pressure levels from the propane delivery truck to a personal tank and returns any excess propane back to the delivery truck. This is similar to a safety valve, except the vapor equalizing valve ensures the propane is delivered at proper pressures for optimum use, not safety. This is especially crucial during hot weather or in warm environments, as that can increase the pressure.

This specialized valve is meant for use by propane companies only. It allows operators with the proper tools to drain liquid propane from the tank. Propane tanks must be drained to <5% capacity levels before they can legally be moved.

IPS Equipment specializes in supplying propane marketers with reliable valves, fittings, regulators, and more for propane systems. Contact us today to learn more about our comprehensive products or services, or browse through our catalog to start your order.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291