hydrogen safety valve quotation

Double block and bleed needle hydrogen valve with full bore is used for hydrogen application up to pressure of 1550 bar Compact and easy to use High reliability High safety

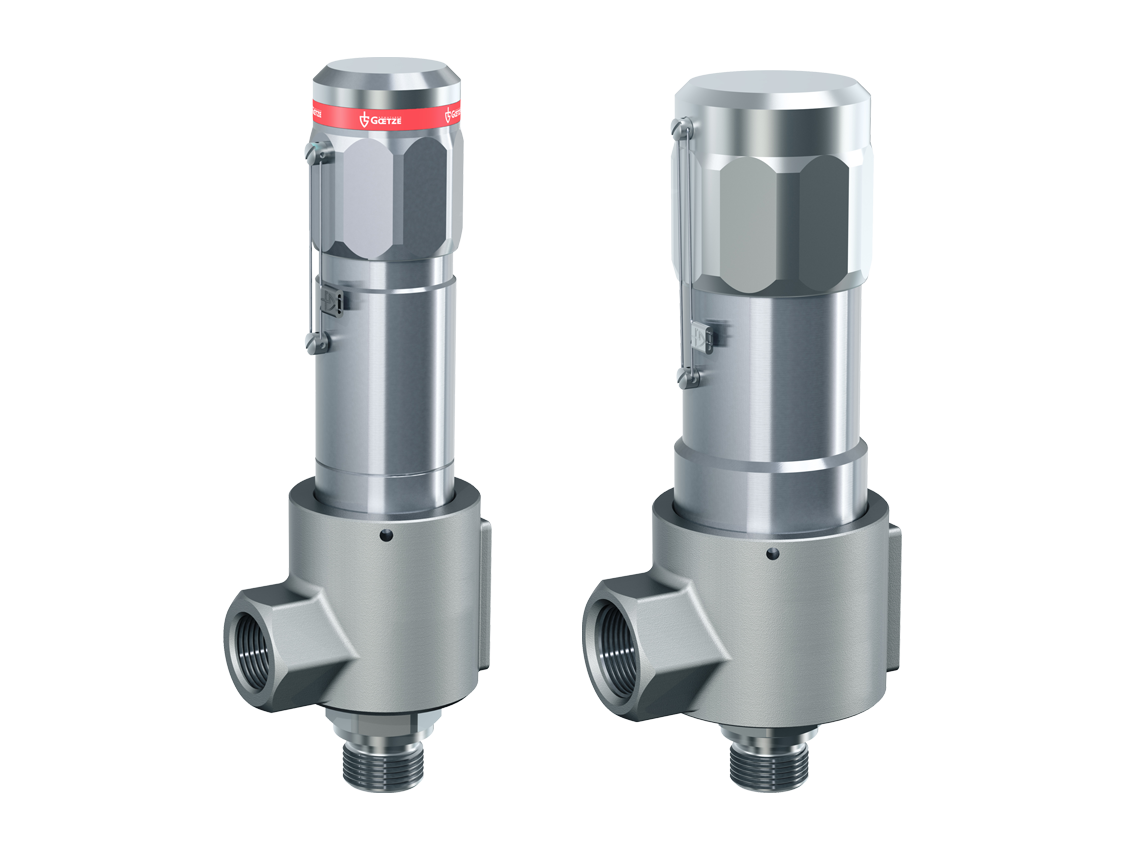

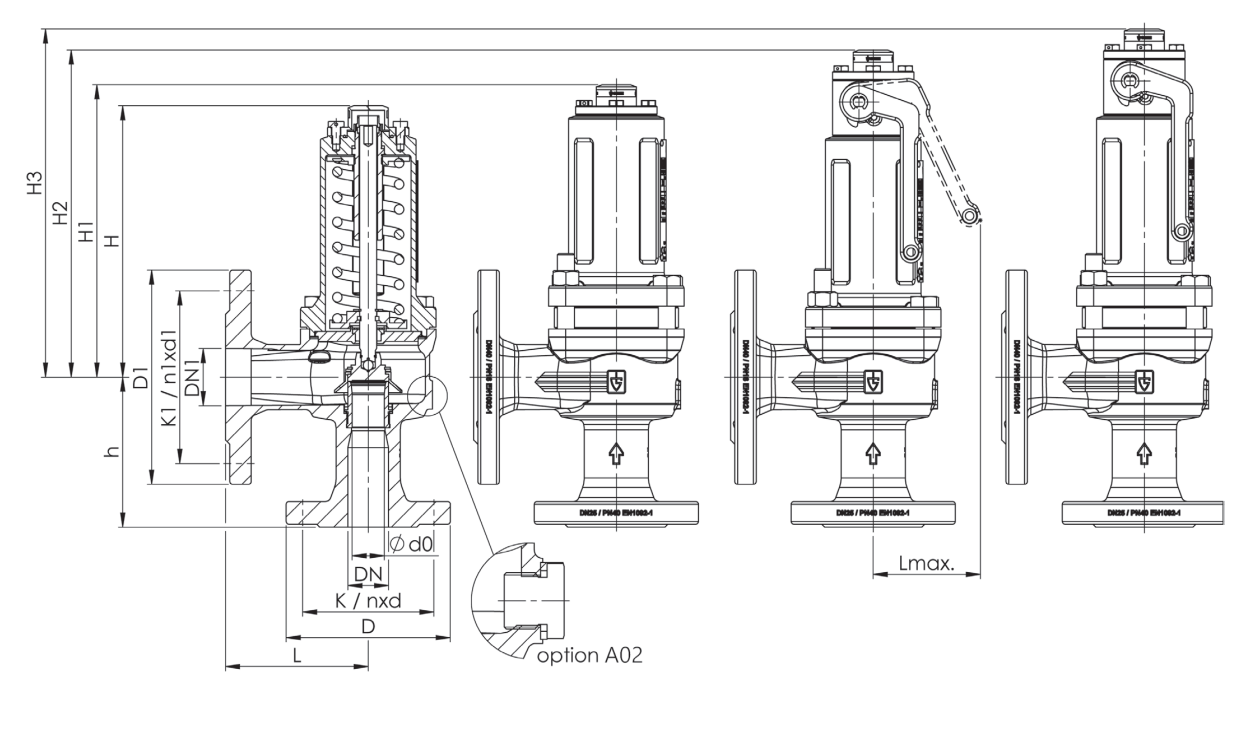

Hydrogen pressure relief valve – series 451Our safety valves is used to prevent excess pressure of the vessels in different applications and prevent the further release of gases after normal conditions have been restored.

In addition to the basic version the numerous sealing possibilities and materials, back-pressure compensating metal bellows and / or a gastight cap offer the necessary optional extras required to fulfill the highest safety requirements.

Double block and bleed needle hydrogen valve with full bore is used for hydrogen application up to pressure of 1550 bar Compact and easy to use High reliability High safety

Hydrogen pressure valve for home use are suitable for home use. They are safe and easy to use as a hydrogen water maker, safe for both use and home use.

Hydrogen pressure valve for home use can also improve blood circulation. There is also a need for hydrogen therapy at home, such as a hydrogen pressure device for skin.

Hydgen pressure valves offer a stable and stable hydrogen pressure. They do not contain any hydrogen at all at the same time, as they are not applied to water or other metals.

Hefei Sinopower Technologies Co., Ltd. develops and distributes various products in the hydrogen energy industry chain, including but not limited to hydrogen production, hydrogen storage, hydrogen supply, stacks and BOP parts, fuel cell system assemblies, fuel cell vehicles, etc.

We have an experienced professional technical research and development team, which can provide professional services from product selection and matching, system design, product customization development and technical support. We provide hydrogen fuel cell design and R&D services and finished hydrogen fuel cell products for mainstream forklift companies in China. We have experience in stack integration and packaging services and are well received by customers at home and abroad.

BRASS CYLINDER VALVE MADE BY SHERWOOD VALVE IN USA. THIS VALVE HAS A 1/2"-14 NGT INLET AND A CGA 350 OUTLET FOR CARBON MONOXIDE AND HYDROGEN SERVICE NO PRD .THE HANDWHEEL IS ALLOY. THIS VALVE IS PRIMARILY USED ON MANIFOLD SYSTEMS FOR INDUSTRIAL APPLICATIONS. PLEASE DOWNLOAD OUR TECH SHEET FOR DETAILS REGARDING MATERIALS, REPLACEMENT PARTS, ETC.

WITT is a manufacturer of Pressure relief valvesor Safety relief valves for technical gases. They are designed to protect against overpressure by discharging pressurized gases and vapors from pipelines, pressure vessels and plant components. Safety relief valves (SRV) are often the last line of defense against explosion – and such an explosion could be fatal. Other common names for safety relief valves are pressure relief valve (PRV), safety valve, pressure safety valve, overpressure valve, relief valve or blow-off valve.

WITT safety valves are very precise. They are individually preset to open at a predetermined pressure within the range 0.07 to 652 Psi. Their small size and orientation-independent installation allow a wide range of connection options. WITT relief valves also stand out due to their high blow-off flow rates of up to 970m³/h. They can be used within a temperature range of -76° F to +518°F and even with very low pressures.

For maximum safety, WITT undertakes 100 % testing of each safety relief valve before it is delivered. In addition, WITT offers individual testing of eachsafety valveby the TÜV, with their certificate as proof of the correct set pressure.

WITTsafety relief valvesare direct-acting, spring-loaded valves. When the preset opening pressure is reached, a spring-loaded element in the valve gives way and opens, and the pressure is relieved. Once the pressures are equalized, the valve closes automatically and can be reactivated any time the pressure rises again. Depending on the application and the nature of the gas, the safety relief valvescan either discharge to atmosphere, or via a connected blow-off line. The opening pressure of the safety valves is preset by WITT at the factory according to the customer’s requirements.

Safety relief valvesare used in numerous industries and industrial applications where, for example, gases pass through pipelines or where special process vessels have to be filled with gas at a certain pressure.

These include, among other things:Pipeline, plant and container constructionIndustrial furnace constructionInsulators and reactors (e.g. “glovebox” systems)hydrogen-powered vehiclesAdditive manufacturing (3D printer)

For most industrial applications using technical gases, brass is usually the standard material of construction of thesafety relief valvebody/housing. For the use of pressure relief valves with aggressive and corrosive gases, the housings are made of high-quality stainless steel (1.4541/AISI 321, 1.4404/AISI 316L, 1.4305/AISI 303 or 1.4571/AISI 316Ti). The use of aluminium as a housing material is also possible.

Depending on the type of gas used and individual customer requirements, various sealing materials and elastomers are available to ensure the safety of your systems under even the most difficult conditions.

WITT pressure relief valves are available with different connections. In addition to the standard versions with the usual internal or external threads, special versions with KF or CF flanges, VCR or UNF threads can also be ordered. Special adapters for connecting the safety relief valve to a blow-off line are also available.

HiP has been in the forefront of providing high pressure valves, fittings and tubing to support our customers as they incorporate hydrogen in their zero-carbon energy strategies. The ongoing build-out of the hydrogen refueling infrastructure necessary to support the fuel cell powered trucks, buses, cars, forklifts and other equipment depends on products designed and built to meet the unique challenges of hydrogen. HiP is a worldwide leader in delivering safe and reliable products to handle the high pressures and extreme temperatures associated with handling hydrogen.

Over the last ten years, HiP has produced tens of thousands of valves and fittings for hydrogen applications. As demand has continued to increase, we have committed the resources to develop a complete line of standard products for use with hydrogen, all either in stock or available with short lead-times. We have engineered our high pressure valve stems, packing and associated soft goods to meet the unique requirements of hydrogen. The standard material for all HiP valve bodies and fittings is 316 stainless steel, which is hydrogen compatible. In addition, we offer a range of special materials such as hastelloy and monel.

They are also available with limit switches and solenoid valves. The single-acting actuators utilize a fail-safe feature: The Air-to-Open actuator closes the valve on loss of operating pressure, while the Air-to-Close actuator opens the valve on loss of operating pressure. These safety features are necessary in critical systems.Check Valves

Provide maximum filtration surface area for removal of contaminating particles from the fluid system. May be used in systems requiring high flow rates with minimum pressure drop. Available in nominal ratings of: 5, 10, 20, 40 and 100 micron.Regulating Valves

These Regulating Relief valves use a differential area poppet design with a high ratio between the seal and seat area for smooth control, repeatability and low deadband between crack and reseat pressure. The design also makes the control settings virtually unaffected by downstream outlet pressure.Hand Tools

Our high-pressure valves, fittings, and tubing are designed and constructed for durability and longevity. They offer excellent performance in demanding environments, such as those found in hydrogen applications.

Hydrogen is extremely small and highly reactive. As such, it is essential to use the right types of valves, fittings, and tubing in hydrogen systems. Otherwise, there is a risk of explosion. Our line of hydrogen products is up to challenge!

In hydrogen piping systems, any weak points may enable the pressurized gas to create small cracks or leaks that can lead to an explosion. That’s why it is essential to use properly designed and constructed pipes, valves, and fittings. Components for hydrogen applications feature high-pressure coned and threaded connections that are engineered to accommodate high pressures, high temperatures, and other extreme conditions without risk of leaking.

In response to the growing popularity of hydrogen fuel cell systems, many standards, regulations, and codes have been established and adopted to address the safety concerns inherent to the technology. One such standard is ISO 19880, which specifies the safety performance requirements and proof of design test methods for components in gaseous hydrogen fueling stations. The third section of the standard outlines the requirements and restrictions for valves.

In pressurized systems, high-pressure valves provide protection against overpressurization and bursting. They are vital safety elements in hydrogen systems since they control the flow of gaseous hydrogen and enable the system to be shut down in the event of an emergency. However, they are also potential weak points at which hydrogen may be released unintentionally through leaks or cracks.

High-pressure valves are built to handle extreme conditions in critical applications. Ones used in hydrogen piping systems are constructed from durable and reliable materials that are compatible with the process fluid, the process conditions, and the application environment.

Many types of valves are used for hydrogen service, all of which have excellent closure capabilities. Those designed and manufactured for use in gaseous hydrogen stations include:

The standard material recommendation for fittings and tubes used in hydrogen service applications is 316 stainless steel. The material is hydrogen compatible, meaning it will not degrade when exposed to hydrogen over an extended period.

High-pressure tubing for hydrogen systems should have a seamless design to eliminate any potential weak points where cracks or leaks may occur. It should also be hard, not annealed, since hard tubing offers about 40% higher tensile strength than annealed tubing.

Looking for high-pressure valves, fittings, and tubing you can trust in your most critical applications and operations? Turn to the experts at MAXPRO!

Maximator is an ISO 9001:2015 certified company committed to providing quality products to customers. All of the valves, fittings, and tubing we distribute from them are designed and manufactured in accordance with American Society of Mechanical Engineers (ASME) standards and European Pressure Equipment Directive 97/23/EC. They are also TUV certified and CE Mark compliant. If you want high-quality products engineered for reliability and safety, we are here to help.

Hydrogen will likely be a key technology in the coming years. However, quality valves, fittings, and pipes are needed to support hydrogen infrastructure and equipment. Given the unique properties of the material, carefully designed and constructed components are vital to ensure safe operation.

For more information on the high-pressure valves, fittings, and tubing available at MAXPRO and how they benefit hydrogen piping systems,contact usorrequest a quotetoday.

8613371530291

8613371530291