laser safety valve manufacturer

Well-known companies worldwide rely on LESER safety valves. With its sole focus on overpressure protection, the safety valve specialist LESER is one of the international market leaders.

With more than 1,050 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

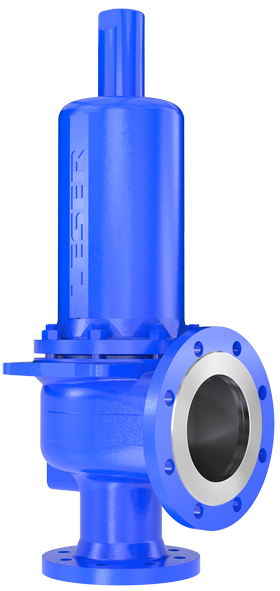

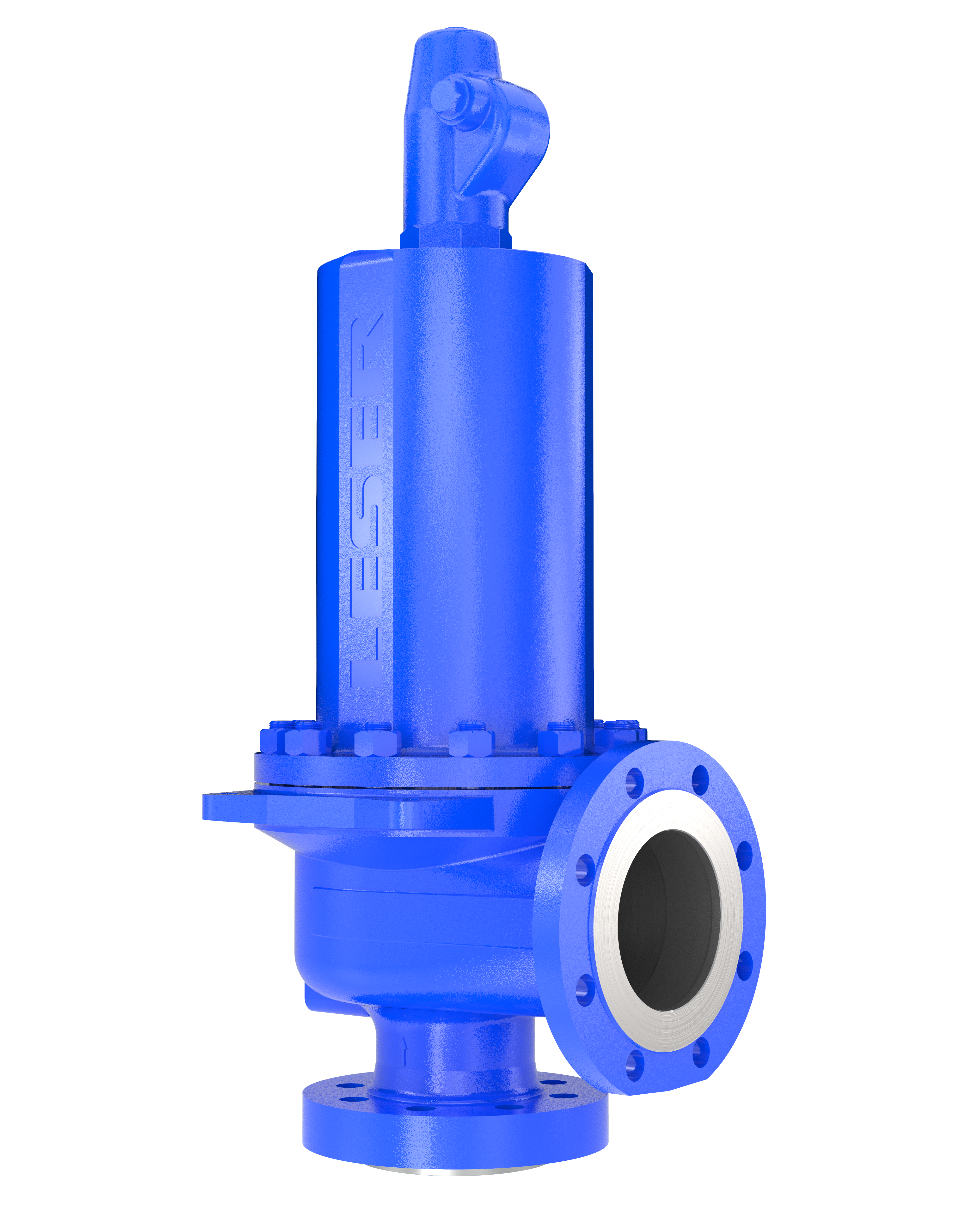

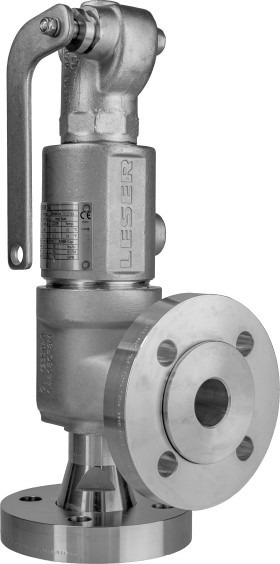

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME XIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Nine subsidiaries and offices in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

In 1885 the company developed its first safety valve for the protection of steam boilers. Even at that early date, LESER products were working for the safety of man and the environment. Since the 1970"s LESER has specialized only in safety valves.

LESER safety valves are used by leading petrochemical, industrial gas, machine building, oil and gas production, chemical, food and pharmaceutical companies. LESER offers spring-loaded and pilot-operated safety valves for all industrial applications according to PED and ASME VIII as well as application-based solutions for special requirements. The LESER product range offers the right product for almost every application.

LESER safety valves are developed and manufactured in Germany. The LESER product range offers the right product for almost every application. Multiple options and special materials complete the range as a well as client-specific solutions.

Attractive Pricing - As the largest safety relief valve manufacturer in Europe (and #3 worldwide), LESER has the ability to produce high-quality products in a cost-efficient manner through large batch sizes and full automation of production; this allows LESER to pass on cost savings to the customer.

LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide, backed by more than 200 years of tradition. LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the API, PED and ASME VIII. Major companies in the oil and gas, petrochemical, chemical, energy, technical gases, LNG/LPG etc use LESER safety valves. LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany.

Established in the year 2016, we “A R Enterprise” are a notable and prominent Sole Proprietorship firm that is engaged in manufacturing a wide range of Ball Valve, Butterfly Valve, Gate Valve, Globe Valve, etc. Located inVadodara (Gujarat, India), we are supported by a well functional infrastructural unit that assists us in the manufacturing of a wide range of products as per the set industry norms. Under the headship of "Mr. Altaf" (Proprietor), we have gained a remarkable and strong position in the market.

LESER uses modern technologies to manufacture safety valves precisely and in high quality. Their safety valves are produced at the Hohenwestedt plant, which is, with a capacity of 130,000 valves per year, the largest production site for safety valves in Europe. In addition, LESER manufactures in Paithan/India and Tianjin/China for the respective local markets.

Since the 1980"s LESER has been the number one supplier for safety valves in the world and strengthens this position each year. LESER currently has 7 different locations worldwide and continiues to expand its international presence in an effort to supports its growing customer base.

High performance relief valves, compact relief valves, high efficiency relief valves, modulate action relief valves, clean service relief valves, critical service relief valves.

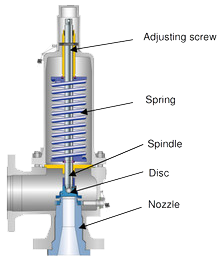

A safety valve is an important part of any engineering system or industrial installation working with media under high pressure, it is the safety of the operating personnel, the exclusion of equipment destruction and emergency situations.

Conveniently, the safety valve supplier can service, adjust or reset the pressure, and can repair and replace parts if necessary. LESER safety valves are known all over the world and are widely used in industry and heating. To provide customers with more options for service safety valves, OPEKS Energosystems, the official distributor of LESER, uses a proprietary set of LESER equipment and tools to set up and maintain valves at its own production facilities.

Setting the required response pressure of the safety valve consists of the following main steps:Fastening the safety valve using a standard mount in a tuning stand. Preparing to set up.

Valve assembly. Checking the tightness of the valve in the closed position, at a pressure less than the design one to prevent leakage of the working medium. Valve seat polishing, other work if necessary.

Setting up safety valves at the OPEKS production facility allows us to provide a shorter delivery time, shorten the period of service work, provide more opportunities and better service to our customers. Also, the company"s warehouse regularly maintains new valves for water, gases of different diameters with a response pressure, which is most often found in inquiries.

Cooperation with OPEKS Energosystems, which supplies and maintains LESER safety valves, as well as manufactures heat exchange equipment, modular units, steam condensate systems and other heat and power equipment, favorably stands out for its great opportunities for our Clients.

W&O, a global supplier to the marine and upstream oil and gas markets for pipe, valves and fittings, valve automation, and engineered solutions, has partnered with LESER in an exclusive distribution agreement to bring its safety relief valves to the United States maritime industry. This marks W&O’s first exclusive distribution agreement with a direct original equipment manufacturer of safety relief valves in the company’s 40-year history.

“W&O is excited to announce this partnership with LESER, and to do so at one of the industry’s marquee events, the International WorkBoat Show”, said Michael Hume, president and CEO of W&O. “The LESER safety relief valves are German-engineered and manufactured, and will be an excellent addition to the tank venting solutions we currently bring to our customers. This partnership is a natural fit for W&O, as LESER is equally committed to meeting customer needs, providing the highest quality product and engineering solutions to fit specific applications.”

The W&O and LESER partnership will prove very beneficial to customers for numerous reasons, including: short delivery times due to high stock of raw material and finished goods at the Charlotte, North Carolina, LESER facility, a variety of solutions from eight product groups and 40 safety relief valve types, and customer support offered by both companies.

The Leser Flanged Safety Relied Valve Series in accordance to API 526 are designed to meet all applications which require API. These valves open rapidly with an overpressure of max. 10% to full design lift and have a maximum blowdown of 7% for steam/gas service and 20% for liquid service. Service for protection of processes and equipment.

LESER India is one of the leading manufacturing companies for safety valves in India. The state of the art manufacturing facility is located in Paithan, Aurangabad. The sales and marketing organization headquartered in Mumbai offers powerful and competent service.

The company was established in 1987 as a joint venture between Fainger Engineering, India, and LESER GmbH & Co. KG, Germany to manufacture safety valves with a proven design and technology. Since 2010, the company is a 100% subsidiary of LESER with now more than 120 employees.

Our modern manufacturing and testing facilities ensure high quality safety valves and a large central stock guarantees short delivery times for valves and spare parts. To date, the more than 150,000 LESER India safety valves installed underline the trust the customers have in LESER India.

Our safety valves are being used by customers across all major industries like oil & gas, petrochemicals, chemicals, pharmaceuticals, and Original Equipment Manufacturers (OEMs).

With more than 800 employees LESER is the No. 1 manufacturer of safety valves in Europe as well as a leading player in its industry worldwide. LESER safety valves are developed in Hamburg for the international market and produced in the modern plant in Hohenwestedt. Leading companies in industries like chemical, petrochemical, industrial gas, oil and gas production, mechanical engineering as well as food and pharmaceutical industry rely on LESER safety valves.

Heaton Valves Africa, as the sole agency holder for LESER in Africa, has at its disposal the latest LESER product range, safety valve sizing and system design technology.

Stockholding comprises a complete range of safety relief valves from 15mm through 300mm. Materials include cast iron, cast steel, chrome and stainless steel. Connections cover NPT and BSP screwed, DIN and ANSI flange standards. Both DIN and API specification safety relief valves are available set and tagged, complete with all necessary certification, within hours of order placement. A replica of the standard safety valve test rig as used at LESER’s test facility in Hohenwestedt, Germany, is situated in HVA’s workshop at HVA’s Head Office. This ensures the quality standards demanded by LESER are maintained.

8613371530291

8613371530291