leser pilot operated safety valve brands

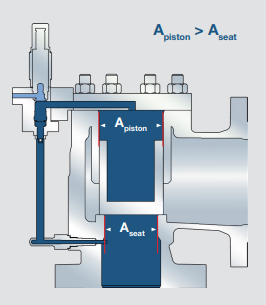

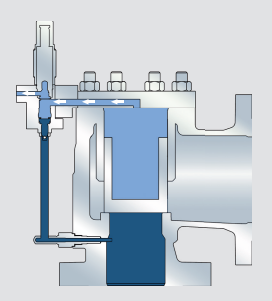

Pilot operated safety valves are controlled by the process medium in which they operate. To achieve this, system pressure is fed to the pilot valve (= control component for the main valve) via the pressure tapping line which uses the space in the dome above the main valve piston to open and close the main valve.

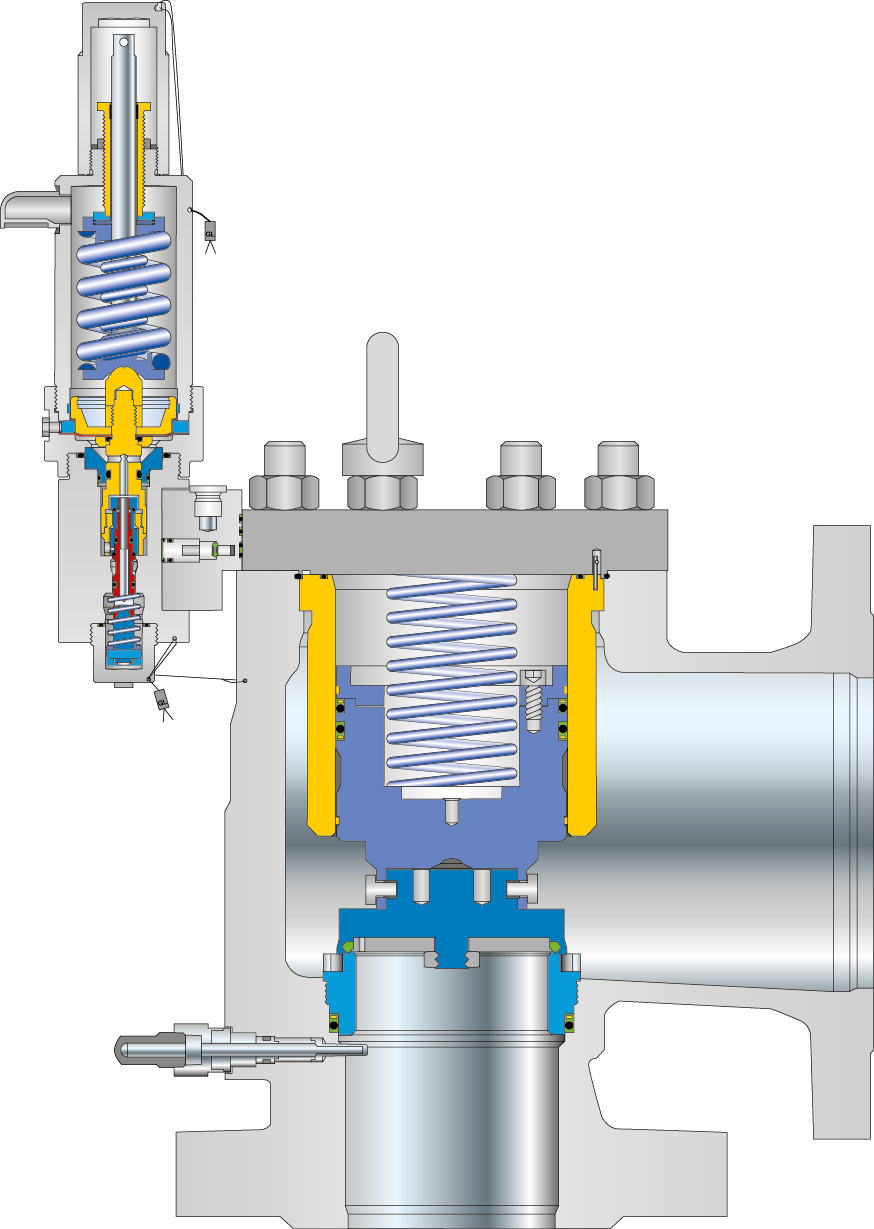

The pilot valve, also called the “pilot”, is the control unit of the pilot-operated safety valve. It controls the function and behavior of the main valve.

The liquefaction process must be designed efficiently so that the LNG can be offered economically. The necessary cryogenic media temperatures of -161 to -164 °C represent a challenge for the technical design of the individual components in the plant. This also applies in particular to the safety valves, which must function reliably as the final protection in the event of overpressure, even at the cryogenic process and Russian ambient temperatures.

LESER valves meet all requirements for use in natural gas liquefaction plants and offer a complete product range. The valves are designed in the low-maintenance “Durable Design” and can be adapted to the plants by various options.

The tightness of the safety valves has been proven under real conditions at media temperatures below -146 °C on LESER’s own cryogenic test bench. The precise helium leak test is based on the DIN EN 13648-1 standard.

The plant efficiency was supported by the use of pilot-operated safety valves (POSV) in the relevant areas. In contrast to spring-loaded safety valves, they are tight until they respond and thus meet the requirement of a higher operating pressure in relation to the response pressure of the plant. Six POSVs now support the efficiency of LIMUM® technology the liquefaction plant.

The LESER POSV for LNG is based on the proven design for LPG applications - Liquefied Petroleum Gas, which has been in use for many years as a standardized solution.

For the LNG low temperature range, LESER has further developed the design modularly so that it can be adapted to the respective project requirements. In the plant in Russia, for example, an evaporator was used and the pilot was thermally decoupled from the main valve to ensure a gaseous media state in the pilot. A temperature-resistant PTFE compound for piston sealing in the main valve enables the spring-loaded lip seal to be used at operating temperatures as low as -162 °C. The main valve is equipped with a PTFE compound for the sealing of the piston. The special seat bushing design does not require a soft seal in the wetted inlet area. The controlling pilot valve is available with a low-temperature resistant soft seal in Pop Action and Modulate Action versions for various requirements.

LESER’s project department supported Linde from the first FEED phase to the commissioning of the project. The production segment “Project Assembly” is specially designed for the requirements of projects and offers optimal conditions for customer acceptance.

Why did the customer choose LESER products?Linde relies on LESER’s know-how in the cryogenic market, for example in projects with temperatures down to -269 °C for liquid helium applications. The company has been working with LESER in the field of technical gases for many years and knows their services very well. The joint experience in the project management of air separation plants and the complete LNG product range, in particular the modular Cryo-POSV in the Pop Action version, were important for Linde.

With more than 1,050 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME XIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Nine subsidiaries and offices in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

Pilot action type: Pop Action | Open: 1% opening pressure tolerance | Closed: 3 - 7% (adjustable also beyond API standard from 3 up to 15%) closing pressure tolerance | Application: Gas

LESER Safety Valves for every industrial application Product Range Compact Performance High Performance API Clean Service H2SO4 HNO3 NH3 HCL Critical Service Modulate Action Best Availability High Efficiency Series 810 – Pop Action Type 811 Series 820 – Modulate Action Type 821

Product Range TYPE 811 TYPE 821 LESER Type 811 Pop Action pilot-operated safety valves are non-flowing, which minimizes the flow of media through the pilot for decreased emissions and extended valve life. Set pressure is not affected by back pressure. Features: • Set pressures: 36 – 1480 psig, 2.5 – 63 barg • Sizes: 1" x 2" up to 8" x 10" (DN 25 – DN 200) with API Standard Orifices and Extra (full-bore) Orifices • Adjustable blowdown of 3 – 7% • Complete stainless steel construction of pilot valve • Certified for air / gas service (ASME Section VIII, DIN EN ISO 4126, AD 2000-Merkblatt) Soft...

How to Find the Right Product Group Valve Finder No No No No No No Critical Service Clean Service Best Availability Mediumcontrolled Changeover valve Bursting disc Spring loaded Safety Valves High operating to set pressure ratio, high backpressure or low total height? Clean Service application? Critical Service / highly corrosive application? API specified application? Additional components beyond safety valves Steam, gas and liquid application with low capacity in relation to valve size? High Performance API Compact Performance Modulate Action High Efficiency Orifice F Yes Yes Yes Yes Yes...

LWN 487.71-E 00/02 Contents Chapter/Page General Valve Finder 00/01 Chapter/Page Sizing & Selection How to Construct the Article Number 02/01 How to Construct the Remaining Order Code 02/02 Reference: Identifying the Flange Pressure Rating (ASME) 02/03 Reference: Identifying the Article Number, Series 810 02/05 Reference: Identifying the Article Number, Series 820 02/07 Reference: Application range Soft seal disc / Metal disc 02/09 Reference: • Option Codes for Connections acc. to DIN EN 1092 • Option Codes for Connections acc. to JIS B2220 02/11 02/12 Reference: Option Codes for Flange...

01/01 LWN 487.71-E Series 810 and 820 Overview LESER Pilot Operated Safety Valve (POSV) LESER Pilot Operated Safety Valves (POSVs) are designed according to the API 526 standard. The full range of sizes from 1" x 2" up to 8" x 10" (DN 25 – DN 200) with all orifices from D – T is available for pressure ratings up to pressure class 600 x 150. Beyond API 526, LESER offers so-called Extra Orifices (also known als Full Port or Full Bore nozzles, see page 01/09). The Extra Orifices provide maximum capacity in relation to valve size. In addition, LESER POSVs come in two different functional...

Product Description Series 810 and 820 Specifications and Approvals The LESER Pilot Operated Safety Valve (POSV) comprises the POSV main valve and a pilot valve based on either the Pop Action (Series 810) or the Modulate Action (Series 820) designs. The table below shows their common and their specific features. Specification at a glance Product Description 1) The possible flange pressure ratings depend on the size of the valve. Refer to page 02/11 to verify the correct option codes and availability of DIN EN and JIS flange ratings. LESER Pilot Operated Safety Valve (Main Valve and Pilot...

01/03 LWN 487.71-E Product Description Good Reasons for the LESER Pilot Operated Safety Valve Pilot operated safety valves have been a proven technology for many decades especially in ASME oriented regions. However, some of the older designs show potential for improvement in areas like external tubing, capacity and delivery times. Based on customer feed back and extended research and using Computational Fluid Dynamics (CFD), Rapid Prototyping and one of the most modern factories for safety valves, LESER has developed the latest POSV on the market. The new LESER POSV offers unique benefits...

LWN 487.71-E 01/04 Product Description Feature Benefit for user Benefit for assembler / maintenance High capacity / small size EXTRA ORIFICE Higher capacity for same valve size with Extra Orifice types. For details see page 01/09 Smaller valve sizes possible Small footprint in system -20% Others LESER POSV 20% less space requirement than typical competitive designs Space-saving system designs possible Small footprint in system Modular system Pop Action and Modulate Action pilot valves can be exchanged without tubing modification Easy later upgrade Less spare parts stock required. Easy...

Applications – Functional Areas Across applications, there are four main functional requirements covered by the LESER Pilot Operated Safety Valve (POSV). High Back Pressure Applications • LESER POSVs can be operated in applications with a back pressure ratio (i.e. a ratio of back pressure / set pressure) of up to 70%. Spring loaded safety valves can be typically used up to 50% of back pressure. • The absolute maximum back pressure is determined by the pressure class of the main valve outlet. Typically, LESER POSVs can be used for much higher back pressures than spring loaded safety valves....

Product Description LWN 487.71-E 01/06 Applications – Examples Compressors in Gas Main Systems Pressure relief devices in these applications must allow for high operating pressures in relation to set pressure, which are required for efficient gas transport. Additionally, compressor vibrations put through requirements on the tightness of the safety valve. LESER Series 810 and 820 POSVs offer an ideal solution for these conditions because: • they enable highest possible operating pressure to set pressure ratios facilitating maximum energy density of transport medium • they are not susceptible...

Product Description 01/07 LWN 487.71-E Sour Gas Applications (NACE) LESER Pilot Operated Safety Valves (POSVs) are available for sour gas (H2S) service. Regulatory Requirements The material requirements for hydrogen sulfide (H2S) service (sour gas service) are specified in the NACE standards, MR0175/ISO 15156 (Upstream processes), and MR0103 (Downstream processes). Since the body of the pilot valve is manufactured from stainless steel, only the spring in the pilot valve of the Series 810 Pop Action POSV and the dome spring in the main valve need to be replaced for compliance with these NACE...

LESER safety valves are used by leading petrochemical, industrial gas, machine building, oil and gas production, chemical, food and pharmaceutical companies. LESER offers spring-loaded and pilot-operated safety valves for all industrial applications according to PED and ASME VIII as well as application-based solutions for special requirements. The LESER product range offers the right product for almost every application.

LESER safety valves are developed and manufactured in Germany. The LESER product range offers the right product for almost every application. Multiple options and special materials complete the range as a well as client-specific solutions.

Attractive Pricing - As the largest safety relief valve manufacturer in Europe (and #3 worldwide), LESER has the ability to produce high-quality products in a cost-efficient manner through large batch sizes and full automation of production; this allows LESER to pass on cost savings to the customer.

LESER Authorized Repair Centre (LARC) Network - More than 30 LARCs in North America provide the end-user with access to authorized, reliable, and convenient local support for the repair of their installed base.

LESER safety valves are used by leading companies in industries such as chemical, petrochemical, industrial gases, oil and gas production, and machine building, as well as the food and pharmaceutical industry. LESER offers spring-loaded and pilot-operated safety valves for all industrial applications according to PED and ASME VIII as well as application-based solutions for special requirements.

With almost 200 years of history, LESER has manufactured its safety valves to reflect state-of-the-art design and developed a product range to provide solutions for all sectors of industry. Customer satisfaction is the impetus behind LESER’s progress. LESER defines its products based on 7 pillars of achievement; rapid availability, product range, global network, quality, reliability, price and sustainability.

Curtiss-Wright"s selection of Pressure Relief Valves comes from its outstanding product brands Farris and Target Rock. We endeavor to support the whole life cycle of a facility and continuously provide custom products and technologies. Boasting a reputation for producing high quality, durable products, our collection of Pressure Relief Valves is guaranteed to provide effective and reliable pressure relief.

While some basic components and activations in relieving pressure may differ between the specific types of relief valves, each aims to be 100% effective in keeping your equipment running safely. Our current range includes numerous valve types, from flanged to spring-loaded, threaded to wireless, pilot operated, and much more.

A pressure relief valve is a type of safety valve designed to control the pressure in a vessel. It protects the system and keeps the people operating the device safely in an overpressure event or equipment failure.

A pressure relief valve is designed to withstand a maximum allowable working pressure (MAWP). Once an overpressure event occurs in the system, the pressure relief valve detects pressure beyond its design"s specified capability. The pressure relief valve would then discharge the pressurized fluid or gas to flow from an auxiliary passage out of the system.

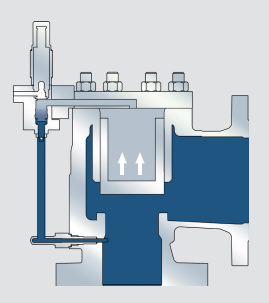

Below is an example of one of our pilot operated pressure relief valves in action; the cutaway demonstrates when high pressure is released from the system.

Air pressure relief valves can be applied to a variety of environments and equipment. Pressure relief valves are a safety valve used to keep equipment and the operators safe too. They"re instrumental in applications where proper pressure levels are vital for correct and safe operation. Such as oil and gas, power generation like central heating systems, and multi-phase applications in refining and chemical processing.

At Curtiss-Wright, we provide a range of different pressure relief valves based on two primary operations – spring-loaded and pilot operated. Spring-loaded valves can either be conventional spring-loaded or balanced spring-loaded.

Spring-loaded valves are programmed to open and close via a spring mechanism. They open when the pressure reaches an unacceptable level to release the material inside the vessel. It closes automatically when the pressure is released, and it returns to an average operating level. Spring-loaded safety valves rely on the closing force applied by a spring onto the main seating area. They can also be controlled in numerous ways, such as a remote, control panel, and computer program.

Pilot-operated relief valves operate by combining the primary relieving device (main valve) with self-actuated auxiliary pressure relief valves, also known as the pilot control. This pilot control dictates the opening and closing of the main valve and responds to system pressure. System pressure is fed from the inlet into and through the pilot control and ultimately into the main valve"s dome. In normal operating conditions, system pressure will prevent the main valve from opening.

The valves allow media to flow from an auxiliary passage and out of the system once absolute pressure is reached, whether it is a maximum or minimum level.

When the pressure is below the maximum amount, the pressure differential is slightly positive on the piston"s dome size, which keeps the main valve in the closed position. When system pressure rises and reaches the set point, the pilot will cut off flow to the dome, causing depressurization in the piston"s dome side. The pressure differential has reversed, and the piston will rise, opening the main valve, relieving pressure.

When the process pressure decreases to a specific pressure, the pilot closes, the dome is repressurized, and the main valve closes. The main difference between spring-loaded PRVs and pilot-operated is that a pilot-operated safety valve uses pressure to keep the valve closed.

Pilot-operated relief valves are controlled by hand and are typically opened often through a wheel or similar component. The user opens the valve when the gauge signifies that the system pressure is at an unsafe level; once the valve has opened and the pressure has been released, the operator can shut it by hand again.

Increasing pressure helps to maintain the pilot"s seal. Once the setpoint has been reached, the valve opens. This reduces leakage and fugitive emissions.

At set pressure the valve snaps to full lift. This can be quite violent on large pipes with significant pressure. The pressure has to drop below the set pressure in order for the piston to reseat.

The pilot is designed to open gradually, so that less of the system fluid is lost during each relief event. The piston lifts in proportion to the overpressure.

At Curtiss-Wright we also provide solutions for pressure relief valve monitoring. Historically, pressure relief valves have been difficult or impossible to monitor. Our SmartPRV features a 2600 Series pressure relief valve accessorized with a wireless position monitor that alerts plant operators during an overpressure event, including the time and duration.

There are many causes of overpressure, but the most common ones are typically blocked discharge in the system, gas blowby, and fire. Even proper inspection and maintenance will not eliminate the occurrence of leakages. An air pressure relief valve is the only way to ensure a safe environment for the device, its surroundings, and operators.

A PRV and PSV are interchangeable, but there is a difference between the two valves. A pressure release valve gradually opens when experiencing pressure, whereas a pressure safety valve opens suddenly when the pressure hits a certain level of over pressurization. Safety valves can be used manually and are typically used for a permanent shutdown. Air pressure relief valves are used for operational requirements, and they gently release the pressure before it hits the maximum high-pressure point and circulates it back into the system.

Pressure relief valves should be subject to an annual test, one per year. The operator is responsible for carrying out the test, which should be done using an air compressor. It’s imperative to ensure pressure relief valves maintain their effectiveness over time and are checked for signs of corrosion and loss of functionality. Air pressure relief valves should also be checked before their installation, after each fire event, and regularly as decided by the operators.

Direct-acting solenoid valves have a direct connection with the opening and closing armature, whereas pilot-operated valves use of the process fluid to assist in piloting the operation of the valve.

A control valve works by varying the rate of fluid passing through the valve itself. As the valve stem moves, it alters the size of the passage and increases, decreases or holds steady the flow. The opening and closing of the valve is altered whenever the controlled process parameter does not reach the set point.

Control valves are usually at floor level or easily accessible via platforms. They are also located on the same equipment or pipeline as the measurement and downstream or flow measurements.

An industrial relief valve is designed to control or limit surges of pressure in a system, most often in fluid or compressed air system valves. It does so as a form of protection for the system and defending against instrument or equipment failure. They are usually present in clean water industries.

A PRV is often referred to as a pressure relief valve, which is also known as a PSV or pressure safety valve. They are used interchangeably throughout the industry depending on company standards.

Steam Safety Valve is designed to meet the rigorous process conditions which are essential for steam boilers. This spring loaded safety valve is used in superheater and reheater applications and is specially engineered to provide fast response to overpressure and blowdown requirements. The Starsteam safety valves are designed to provide high integrity performance and repeatability particularly at high pressure and high temperatures in power plants as well as oil and gas applications. This safety valve features a Stardisc design which guarantees perfect tightness at high temperatures as well as repeated and accurate positioning on the nozzzle.

LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide, backed by more than 200 years of tradition. LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the API, PED and ASME VIII. Major companies in the oil and gas, petrochemical, chemical, energy, technical gases, LNG/LPG etc use LESER safety valves. LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany.

Pilot Operated Safety Valves from the High Efficiency product group are especially suitable for applications with high pressure and offer optimal tightness right up to set pressure. They meet all the requirements of API 526 and therewith offer 100% compatibility. LESER offers pilot operated safety valves with rapid or proportional opening characteristics.

The POSV consists of a main and a pilot valve. The pilot valve has two designs: The pop action-design ensures a rapid opening of the main valve. This version is important for applications where the discharge capacity needs to be reached quickly e.g. for gas applications. The modulate action-design has a gradual opening. The aim is, to minimize the media...

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME VIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

8613371530291

8613371530291