leser pilot operated safety valve for sale

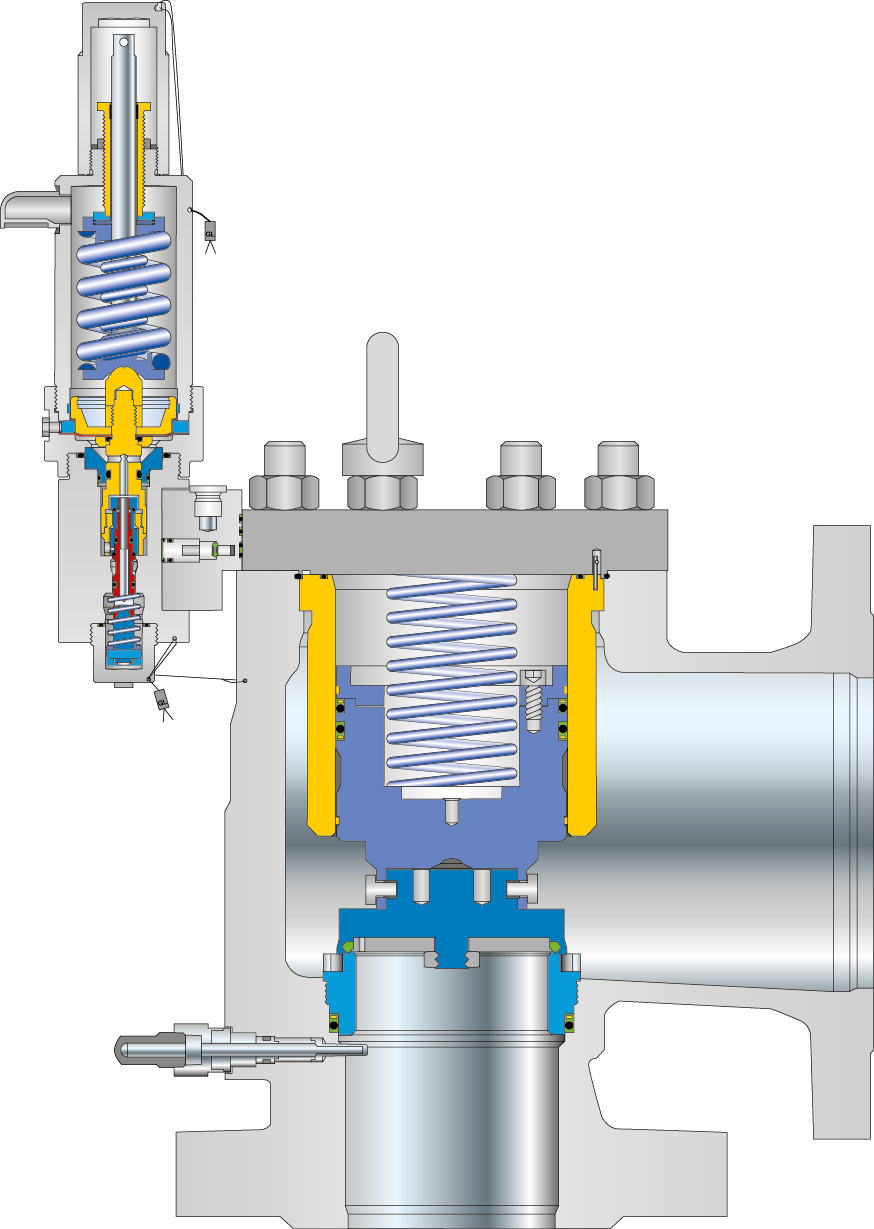

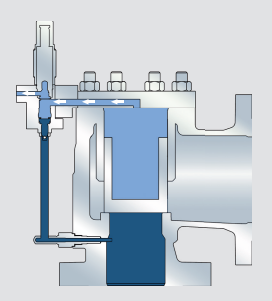

Pilot operated safety valves are controlled by the process medium in which they operate. To achieve this, system pressure is fed to the pilot valve (= control component for the main valve) via the pressure tapping line which uses the space in the dome above the main valve piston to open and close the main valve.

The pilot valve, also called the “pilot”, is the control unit of the pilot-operated safety valve. It controls the function and behavior of the main valve.

The primary purpose of a pressure relief valve is to protect life, property and the environment. Pressure relief valves are designed to open and release excess pressure from vessels or equipment and then close again.

The function of pressure relief valves differs depending on the main type or loading principle of the valve. The main types of pressure relief valves are spring-loaded, weight-loaded and controlled pressure relief valves.

Regardless of the type or load, pressure relief valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

With more than 1,050 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

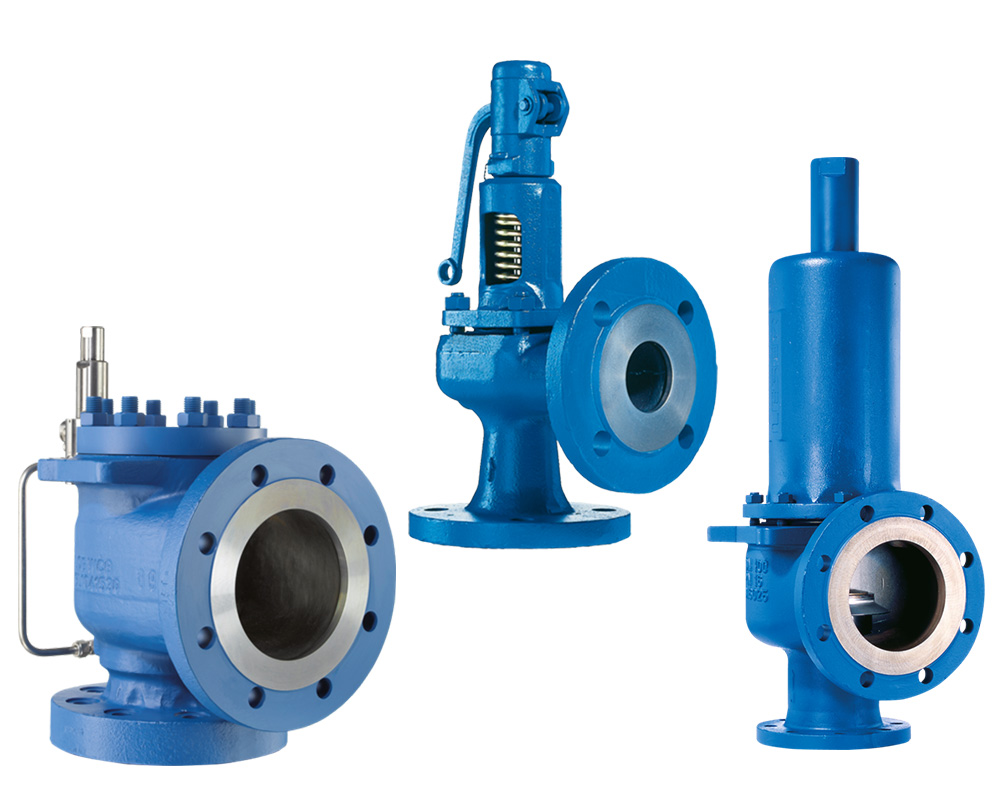

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME VIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Twelve subsidiaries and offices in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

Pilot action type: Pop Action | Open: 1% opening pressure tolerance | Closed: 3 - 7% (adjustable also beyond API standard from 3 up to 15%) closing pressure tolerance | Application: Gas

The liquefaction process must be designed efficiently so that the LNG can be offered economically. The necessary cryogenic media temperatures of -161 to -164 °C represent a challenge for the technical design of the individual components in the plant. This also applies in particular to the safety valves, which must function reliably as the final protection in the event of overpressure, even at the cryogenic process and Russian ambient temperatures.

LESER valves meet all requirements for use in natural gas liquefaction plants and offer a complete product range. The valves are designed in the low-maintenance “Durable Design” and can be adapted to the plants by various options.

The tightness of the safety valves has been proven under real conditions at media temperatures below -146 °C on LESER’s own cryogenic test bench. The precise helium leak test is based on the DIN EN 13648-1 standard.

The plant efficiency was supported by the use of pilot-operated safety valves (POSV) in the relevant areas. In contrast to spring-loaded safety valves, they are tight until they respond and thus meet the requirement of a higher operating pressure in relation to the response pressure of the plant. Six POSVs now support the efficiency of LIMUM® technology the liquefaction plant.

The LESER POSV for LNG is based on the proven design for LPG applications - Liquefied Petroleum Gas, which has been in use for many years as a standardized solution.

For the LNG low temperature range, LESER has further developed the design modularly so that it can be adapted to the respective project requirements. In the plant in Russia, for example, an evaporator was used and the pilot was thermally decoupled from the main valve to ensure a gaseous media state in the pilot. A temperature-resistant PTFE compound for piston sealing in the main valve enables the spring-loaded lip seal to be used at operating temperatures as low as -162 °C. The main valve is equipped with a PTFE compound for the sealing of the piston. The special seat bushing design does not require a soft seal in the wetted inlet area. The controlling pilot valve is available with a low-temperature resistant soft seal in Pop Action and Modulate Action versions for various requirements.

LESER’s project department supported Linde from the first FEED phase to the commissioning of the project. The production segment “Project Assembly” is specially designed for the requirements of projects and offers optimal conditions for customer acceptance.

Why did the customer choose LESER products?Linde relies on LESER’s know-how in the cryogenic market, for example in projects with temperatures down to -269 °C for liquid helium applications. The company has been working with LESER in the field of technical gases for many years and knows their services very well. The joint experience in the project management of air separation plants and the complete LNG product range, in particular the modular Cryo-POSV in the Pop Action version, were important for Linde.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

LESER POSVs can be operated in applications with a back pressure ratio (i.e. a ratio of back pressure/set pressure) of up to 70%. Spring loaded safety valves can be typically used up to 50% of back pressure.

The absolute maximum back pressure is determined by the pressure class of the main valve outlet. Typically, LESER POSVs can be used for much higher back pressures than spring loaded safety valves.

The LESER POSVs open and operate independently of back pressure (within back pressure operating limits, see previous). The set pressure of the POSV is not affected by back pressure of any kind, i.e. superimposed, constant or variable.

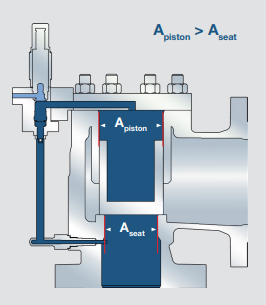

Since closing forces increase when approaching set pressure, LESER POSVs are particularly suitable for applications with high tightness requirements. Tightness is ensured up to 97% of set pressure because the closing forces increase approaching set pressure. Together with the defined blowdown, this allows operating the sytem close to the set pressure of the valve.

In a POSV, the system pressure acts on the main valve piston trying to push it open. It is, however, opposed by the same pressure because system pressure is also re-directed to the dome area above the piston.

Since the area of the piston exposed to pressure is larger in the dome than on the system side, this creates a greater net closing force on the main valve disc/nozzle. Approaching set pressure, closing forces increase

The Leser safety valve is a product safety valve. This safety valve product line is manufactured by the manufacturer Leser, a very famous safety valve manufacturer in Germany. The manufacturer of Leser, specializes in only one product, which is a safety valve.

German Leser safety valves are widely used in a variety of industries. This Leser safety valve product is applied to a number of industries such as: in the petroleum, chemical, pharmaceutical, energy, food production, shipbuilding, heating industries...

Leser full valves are produced in a variety of lines and models, with each type, each line will have separate applications. Each line, model will have a different design and structure, and different materials.

Safety valve company Leser is a German manufacturer of safety valves Leser. Safety valve company Leser is the largest safety valve manufacturer in Germany, the largest in Europe, in addition to being one of the world"s leading safety valve manufacturers.

Leser products are manufactured according to different standards, depending on the local supply, Leser"s products will be produced according to different standards. , China for these two markets.

First of all, let"s find out what is a safety valve? Safety valve is a safety device used as a safety device for the working system. The safety valve is not responsible for regulating pressure, it only has the function of releasing pressure in an overpressure situation.

Safety valves are used to ensure the safety of the system, people and the environment. The safety valve is designed to release excess pressure from the system until the pressure returns to normal and in the normal state the safety valve is closed.

Why is there a safety valve symbol? When installing a system, it is necessary to first create a drawing to build up the overall diagram of the system. In the system will install many different equipment, machines, valves. Therefore, each device will be designated with a unique symbol to identify the correct equipment and installation. So what is the symbol of the safety valve, you can observe through the image

The Leser API safety valve product has the ability to work in extreme temperature and pressure conditions, the ability to work in high and low temperatures is very good, the temperature range of this product line it is -268 degrees Celsius to 538 degrees Celsius and the working pressure of the valve can be up to 0,12 bar to 413bar.

This product line is a series of pilot valve operated safety valves. This series of products are used with high capacity applications, this safety valve has the highest discharge capacity in its class.

This valve is as its name suggests, highest discharge capacity, operating pressure up to 96% of set pressure, back pressure up to 90% of set pressure.

Designed with sizes from DN25 to DN200, made from alloy steel materials, WCB, CF8M, SA 352 LCB, etc. The working conditions of this pressure relief valve line are from -48 degrees Celsius to -200 degrees Celsius. 2,5 degrees Celsius, pressure from 426bar to XNUMXbar.

This safety valve product line features a compact design, this safety valve product is often applied to compact applications, with sizes from DN15 to DN40 and a variety of connections, flanges and threads.

Low pressure safety valve products are applied to low pressure dynamic applications, the working pressure level of this product line can only work to the highest pressure of 160bar.

Microbiological safety valve is a pressure reducing valve product line that is applied from the microbiological stainless steel material line with a smooth surface to ensure food safety and hygiene, this safety valve product is often applied to various applications. food, beverages and pharmaceuticals.

Microbiological safety valve products have the following types: 481, 483, 484, 485, 488. Different types with different designs, sizes and capacities, so the application with each type will be different.

This safety valve is manufactured with PTFE liner, PTFE liner design, as known PTFE material has good high temperature working ability, plus good corrosion resistance, thus helping to produce This safety valve product can perfectly be installed in the system with corrosive nature.

LESER offer spring loaded and pilot operated safety valves for all industrial applications according to the European Pressure Equipment Directive 2014/68/EU (CE-mark) and ASME VIII Division 1 (UV-Stamp).

Major global companies in chemicals, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding as well as heating and air conditioning industries use LESER safety valves.

![]()

Safety valve maintenance and repair ensures your industrial system will not only remain operational, but also safe for your personnel and the environment. In the event of a failure, a safety valve helps contain the challenge to a specific location or releases pressure to stop it, which also means these devices are subject to extreme duress in industrial environments.

Millennium Power Services offers expert insight into our customer’s needs, supporting the evaluation of specific concerns or mechanical issues with your safety valves. Whether you are performing preventive maintenance or reacting to a malfunction, our team of experts can spring into action and facilitate shop or on-site repairs and testing along with new safety valves.

We are currently seeking self motivated, talented individuals with a minimum of 5 years experience in valve applications. If you meet this brief we would be interested to hear from you. Send your CV to sales@valvedistributors.com.au

8613371530291

8613371530291