leser safety valve manual pdf price

LESER Safety Valves for every industrial application Product Range Compact Performance High Performance API Clean Service H2SO4 HNO3 NH3 HCL Critical Service Modulate Action Best Availability High Efficiency Series 810 – Pop Action Type 811 Series 820 – Modulate Action Type 821

Product Range TYPE 811 TYPE 821 LESER Type 811 Pop Action pilot-operated safety valves are non-flowing, which minimizes the flow of media through the pilot for decreased emissions and extended valve life. Set pressure is not affected by back pressure. Features: • Set pressures: 36 – 1480 psig, 2.5 – 63 barg • Sizes: 1" x 2" up to 8" x 10" (DN 25 – DN 200) with API Standard Orifices and Extra (full-bore) Orifices • Adjustable blowdown of 3 – 7% • Complete stainless steel construction of pilot valve • Certified for air / gas service (ASME Section VIII, DIN EN ISO 4126, AD 2000-Merkblatt) Soft...

How to Find the Right Product Group Valve Finder No No No No No No Critical Service Clean Service Best Availability Mediumcontrolled Changeover valve Bursting disc Spring loaded Safety Valves High operating to set pressure ratio, high backpressure or low total height? Clean Service application? Critical Service / highly corrosive application? API specified application? Additional components beyond safety valves Steam, gas and liquid application with low capacity in relation to valve size? High Performance API Compact Performance Modulate Action High Efficiency Orifice F Yes Yes Yes Yes Yes...

LWN 487.71-E 00/02 Contents Chapter/Page General Valve Finder 00/01 Chapter/Page Sizing & Selection How to Construct the Article Number 02/01 How to Construct the Remaining Order Code 02/02 Reference: Identifying the Flange Pressure Rating (ASME) 02/03 Reference: Identifying the Article Number, Series 810 02/05 Reference: Identifying the Article Number, Series 820 02/07 Reference: Application range Soft seal disc / Metal disc 02/09 Reference: • Option Codes for Connections acc. to DIN EN 1092 • Option Codes for Connections acc. to JIS B2220 02/11 02/12 Reference: Option Codes for Flange...

01/01 LWN 487.71-E Series 810 and 820 Overview LESER Pilot Operated Safety Valve (POSV) LESER Pilot Operated Safety Valves (POSVs) are designed according to the API 526 standard. The full range of sizes from 1" x 2" up to 8" x 10" (DN 25 – DN 200) with all orifices from D – T is available for pressure ratings up to pressure class 600 x 150. Beyond API 526, LESER offers so-called Extra Orifices (also known als Full Port or Full Bore nozzles, see page 01/09). The Extra Orifices provide maximum capacity in relation to valve size. In addition, LESER POSVs come in two different functional...

Product Description Series 810 and 820 Specifications and Approvals The LESER Pilot Operated Safety Valve (POSV) comprises the POSV main valve and a pilot valve based on either the Pop Action (Series 810) or the Modulate Action (Series 820) designs. The table below shows their common and their specific features. Specification at a glance Product Description 1) The possible flange pressure ratings depend on the size of the valve. Refer to page 02/11 to verify the correct option codes and availability of DIN EN and JIS flange ratings. LESER Pilot Operated Safety Valve (Main Valve and Pilot...

01/03 LWN 487.71-E Product Description Good Reasons for the LESER Pilot Operated Safety Valve Pilot operated safety valves have been a proven technology for many decades especially in ASME oriented regions. However, some of the older designs show potential for improvement in areas like external tubing, capacity and delivery times. Based on customer feed back and extended research and using Computational Fluid Dynamics (CFD), Rapid Prototyping and one of the most modern factories for safety valves, LESER has developed the latest POSV on the market. The new LESER POSV offers unique benefits...

LWN 487.71-E 01/04 Product Description Feature Benefit for user Benefit for assembler / maintenance High capacity / small size EXTRA ORIFICE Higher capacity for same valve size with Extra Orifice types. For details see page 01/09 Smaller valve sizes possible Small footprint in system -20% Others LESER POSV 20% less space requirement than typical competitive designs Space-saving system designs possible Small footprint in system Modular system Pop Action and Modulate Action pilot valves can be exchanged without tubing modification Easy later upgrade Less spare parts stock required. Easy...

Applications – Functional Areas Across applications, there are four main functional requirements covered by the LESER Pilot Operated Safety Valve (POSV). High Back Pressure Applications • LESER POSVs can be operated in applications with a back pressure ratio (i.e. a ratio of back pressure / set pressure) of up to 70%. Spring loaded safety valves can be typically used up to 50% of back pressure. • The absolute maximum back pressure is determined by the pressure class of the main valve outlet. Typically, LESER POSVs can be used for much higher back pressures than spring loaded safety valves....

Product Description LWN 487.71-E 01/06 Applications – Examples Compressors in Gas Main Systems Pressure relief devices in these applications must allow for high operating pressures in relation to set pressure, which are required for efficient gas transport. Additionally, compressor vibrations put through requirements on the tightness of the safety valve. LESER Series 810 and 820 POSVs offer an ideal solution for these conditions because: • they enable highest possible operating pressure to set pressure ratios facilitating maximum energy density of transport medium • they are not susceptible...

Product Description 01/07 LWN 487.71-E Sour Gas Applications (NACE) LESER Pilot Operated Safety Valves (POSVs) are available for sour gas (H2S) service. Regulatory Requirements The material requirements for hydrogen sulfide (H2S) service (sour gas service) are specified in the NACE standards, MR0175/ISO 15156 (Upstream processes), and MR0103 (Downstream processes). Since the body of the pilot valve is manufactured from stainless steel, only the spring in the pilot valve of the Series 810 Pop Action POSV and the dome spring in the main valve need to be replaced for compliance with these NACE...

André Ramseyer AG Flamatt, Switzerland info@ramseyer.ch LESER UK Bristol, Great Britain sales@leser.co.uk High Performance 1 LESER worldwide Hong Kong LESER Shenzen, China sales@leserchina.com High Performance Flanged Safety Relief Valves Series 441 Series XXL Series 444 LESER Polska Poznan, Poland leser@leser.pl LESER S.A.R.L. Toulouse, France contact@leser.fr LESER LLC Charlotte (NC), USA salesus@leser.com LESER LTDA. Rio de Janeiro, Brazil leser.vendas@leser.com.br LESER representatives LESER LLP Singapore sales@leser.com.sg LESER Office Middle East Bahrain gopal.n@leser.com FAINGER LESER Valves Mumbai, India info@fainger.com LESER stock and local assembly CATALOG 1 High Performance Catalog 1 Edition May 2012 / 2.000 0777.5465 The-Safety-Valve.com LESER GmbH & Co. KG 20537 Hamburg, Wendenstr. 133-135 20506 Hamburg, P.O. Box 26 16 51 Fon +49 (40) 251 65-100 Fax +49 (40) 251 65-500 E-Mail: sales@leser.com www.leser.com The-Safety-Valve.com E

Product Range LESER Safety Valves for every industrial application High Performance Compact Performance Series 441 Type 441, 442 DIN Type 441, 442 ANSI API Series XXL Type 441, 442 XXL High Efficiency Clean Service H 2 SO 4 HNO 3 NH 3 HCL Critical Service Series 444 Type 444 DIN Type 444 ANSI Series 441 Full nozzle Type 441, 442 Full nozzle DIN Modulate Action Type 441, 442 Full nozzle ANSI Series 458 Best Availability Type 455, 456 Type 457, 458 to refer lease ormance P Perf High atalog 2 C

General Type 441, 442 DIN DN 20, 40, 50 Set pressure 0.1 – 40 bar, 1.5 – 580 psig Flanges according to DIN EN 1092 Frontview 441 ANSI H4 4c Type 441, 442 ANSI Valve size 1" – 4" Set pressure 0.1 – 51 bar, 1.5 – 740 psig Flanges according to ASME B16.5 FV 441 FN H2 4c Type 441, 442 XXL DN 200 – 400, 8" – 16" Set pressure 0.2 – 25 bar, 3 – 360 psig Flanges according to DIN EN 1092 and ASME B16.5 Frontview 441 XXL H4 4c Type 444 DIN DN 25 – 80 Set pressure 0.1 – 16 bar, 1.5 – 232 psig Flanges according to DIN EN 1092 Type 444 ANSI Valve size 1" – 3" Set pressure 0.1 – 16 bar, 1.5 – 232 psig...

Contents Overview Chapter/Page General 00/05 How to use: Signs and symbols, Flange drillings and facings 00/07 How to use: Determination of coefficient of discharge Kdr / w Pressure temperature ratings • Metric Units • US Units Flange drillings and facings Order information – Spare parts Available options Approvals Capacities • Steam [Metric Units + US Units] • Air [Metric Units + US Units] • Water [Metric Units + US Units] 00/09 LESER Effective Orifice LEOS/G 00/11 LESER Effective Orifice LEOL 00/12 Sour gas service 02/10 02/11 00/08 How to use: Capacity sheets 02/06 02/08 Dimensions and...

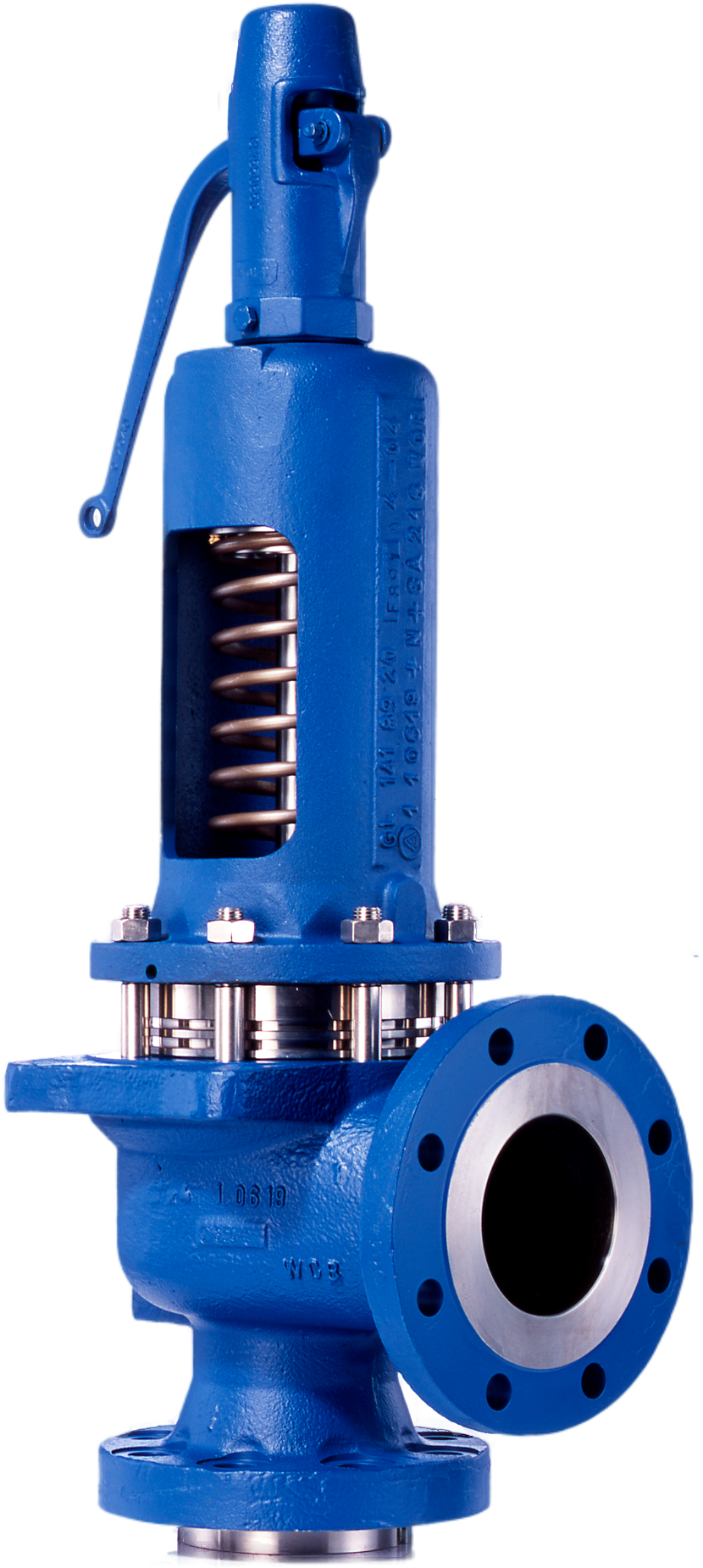

General General Information LESER – High Performance Safety Valves The High Performance product group represents 3 High capacity related to the safety valve size 3 High adaptability 3 Excellent price / performance ratio LESERs High Performance Safety Valves Are designed to meet all industrial applications. Open rapidly with an overpressure of 5 % to the full design lift. • re used particularly for vapours and gases where A the maximum mass flow has to be discharged rapidly. • ave a maximum blowdown of minus 10 % for steam/ H gas service and minus 20 % for liquid service. • re one of the...

General General Information Applications General Design Features LESER – High Performance Safety Valves LESERs High Performance Safety Valves Are the ultimate solution for all industrial applications for steam, gas and liquid. Offer a large variety of types, materials and options to suit any application: Typical applications for LESER High Performance Safety Valves are: valve sizes from DN 20 to DN 400 – 3/4" to 16" provide a high connectivity to the application • nlet pressure ratings PN 16 to PN 400 / class 150 to I class 2500 to fit all required design pressures • Orifice sizes from E to...

How to find the right Product Group Yes High Efficiency Yes Clean Service Yes Critical Service Medium controlled High operating to set pressure ratio, high backpressure or low total height? No Clean Service application? No Critical Service / highly corrosive application? Yes API No Steam, gas and liquid application with low capacity in relation to the valve size? Yes Modulate Action Spring loaded API specified application? Safety Valves No No Orifice ≥ F High Performance Required Orifice letter? Additional components beyond safety valves 00/03 Yes Best Availability Bursting disc Orifice ≤...

General Valve finder How to find the right Safety Valve DIN EN 1092 ASME B16.5 Flange standard? No Full nozzle-design required? Type 441 DIN Type 442 DIN Type 441 ANSI Type 442 ANSI DIN EN 1092 ASME B16.5 Yes Type 441 Full nozzle DIN Type 442 Full nozzle DIN Type 441 Full nozzle ANSI Type 442 Full nozzle ANSI ≤ PN40 / CL300 ≥ PN63 / ≥ CL600 Flange rating? Semi nozzle up to 100 bar / 1450 psig Full nozzle up to 400 bar / 5800 psig ≤ DN 150 / 6" ≥ DN 200 / 8" Valve size, inlet? Serie 458 Type 455 Type 456 Type 457 Type 458 Type 441 XXL Type 442 XXL General industry Stainless steel...

General Valve selection Temperature range Type acc. to DIN EN 441, 442 DIN 441, 442 ANSI 441, 442 XXL 444 DIN 444 ANSI 441, 442 441, 442 Full nozzle Full nozzle DIN ANSI 455, 456 457, 458 -270 -270 -270 -196 -45 -45 -270 -270 -85 450 450 550 200 200 450 450 550 550 min. [°F] -454 -454 -321 -49 -49 -454 -454 -121 -454 max. [°F] acc. to ASME min. [°C] max. [°C] 842 842 1022 392 392 842 842 1022 1022 -268 min. [°C] -268 -268 -184 -45 -45 -268 -268 -129 max. [°C] 538 538 427 200 200 538 538 538 538 min. [°F] -450 -450 -300 -49 -49 -450 -450 -20 -450 max. [°F] 1000 1000 800 392 392 1000 1000...

8613371530291

8613371530291