mercer safety valve free sample

Use the following forms to provide us with the specifics of your application and we’ll take it from there. Just save the filled out form on your computer and then email it to insidesalesgroup@mercervalve.net.

Mercer Valve Co., Inc® is committed to safely providing the highest quality pressure relief valve featuring our patented “Auto Seat Technology”® at a competitive price, delivered on time, and serviced by our trained professionals.We continue to improve our products and services, while meeting industry standards to satisfy our customer’s expectations.

Mercer Valve Company provides a Made in the USA manufactured high-quality safety relief valve. Our patented “Auto Seat Technology”® has a proven extended seat life that will allow your valve to open, close, seat and seal over and over again.

In 2023, the sales of Pressure Relief Valve in Global Market is expected to reach US$ 4,509.8 Mn. and is projected to expand steadily at a CAGR of 4.6% to reach a market valuation of close to US$ 7,070.9 Mn by 2033.

In recent past valve costs have increased globally, which can be attributed to growing tariffs from the North American region, particularly the US. Leading players from the European and American regions have facilities in both high- and low-income nations. In contrast, labor-intensive production processes like the creation of rough castings for valves and valve components take occur in low-cost manufacturing nations like China. These processes include design, research and development, and testing. Due to low prices and quality maintenance, OEMs are able to do so. However, growing US government tariffs on steel and aluminum imports from China have had a substantial negative influence on pressure relief valve profit margins and costs.

However, the rapid growing industrialization and increasing safety precaution are the factors that are expected to fuel the market growth of Pressure relief valves across the globe during the assessment period, the Pressure relief valve market is expected to experience demand growth with CAGR of 4.6% during the forecasted period.

From 2017 to 2022, the Global Pressure Relief Valve Market expanded at a CAGR of around 2.4%. The advancement in product technology to connect the valves digitally enables end users to monitor pressure in various applications digitally which has generated significant demand from the various industry sector during the forecasted period.

Numerous applications where pressure levels are crucial for continuous and efficient machinery performance demand for the utilization of pressure relief valves. These include the various sectors operating with steam, air, gas, or liquid such as oil and gas, power generation and the petrochemicals industry. Multiphase applications and chemical processing systems both have high installation rate of pressure relief valves. With rapid development industrial sector & expansion of oil & Gas pipelines across the developing as well as developed economies the demand for PRV is also expected to expand, Persistence Market Research expects the market to expand at a 4.6% CAGR through 2033.

Both emerging and advanced regions have seen a surge in oil and gas consumption. In order to meet the rising demand and supply for oil and gas, industries are concentrating on expanding their production facilities through onshore and offshore exploration. Since the oil and gas sector is one of the key end uses for the global pressure relief valves market thus expanding oil & gas Sector is generating lucrative opportunity for the demand growth of PRVs in upcoming period.

Furthermore, growing regulation for use of pressure relief valves in power generation sector is further set to create opportunities for the market. For instance, there are currently about 50 nuclear reactors under development. By safeguarding turbines, super heaters, and boilers to enable the stations to operate at prescribed pressures, pressure relief valves play a crucial part in the successful and safe operations of nuclear facilities.

Manufacturing businesses will be significantly and directly impacted by the Asia Pacific region"s volatile and uncertain markets. The operational costs of the manufacturing processes, which are the main concern of manufacturers, will be directly impacted by rising tariffs and raw material costs used to manufacture valves. Rising raw material costs immediately impact the integrity of the supply chain and the selling price of a product. Manufacturers in the Asia Pacific region are becoming increasingly concerned about the steady growth in cost of the raw materials used to make pressure relief valves. This is expected to, restrain the market"s expansion for pressure relief valves.

With an absolute dollar opportunity of around US$ 600.0 Mn, North America is expected to be the most lucrative market for pressure relief valves suppliers. U.S is leading the North American market, and is expected to witness a 1.5X growth during 2023-2033. The market for pressure relief valves has recently experienced considerable growth in sales as a result of growing industrialisation and advancements in urban waste water management systems. Apart from that U.S. is also second largest importer & Exporter of Pressure relief valves, which makes it a targeting region for the manufacturers & Suppliers.

In 2023, the German Pressure Relief Valve market is likely to hold around 25% of the market by value share in Europe. Germany"s extensive remanufacturing capabilities are likely to play a crucial part in development of industrial growth. Sales growth for pressure relief valves is anticipated to be boosted in the upcoming years as manufacturers are planning to invest more in safety & developments of industrial Sites.

With a CAGR of 5.9%, India is expected to lead the South Asian market throughout the assessment period and experience significant expansion. Pressure relief valve demand is anticipated to increase as a result of India"s low production and labour costs, as well as less regulations & certifications required for PRVs, which are encouraging various industry players, including oil & gas, pharmaceutical, chemical, and textile manufacturers, to expand their manufacturing facilities in India.

By the end of the assessment period, spring-loaded pressure relief valves will hold a value share of over 40% of the market for pressure relief valves worldwide. Due to its broad range of applications and other technological advantages over other valves, this valve is widely utilized. The design and use of pressure relief valves is covered by a number of international codes and standards, the most popular of which being the ASME (American organization for mechanical engineers) Boiler and Pressure Vessel Code, also known as ASME code. Despite the fact that this code varies by region.

In 2023, the demand for pressure relief valves is primarily driven by the Medium Pressure segment in Set Pressure segment of the market. By the end of the forecast period, it is projected that pressure relief valves with a medium pressure range will still be widely utilized in a variety of end use sectors. The market for medium pressure relief valves is expected to continue expanding due to rising end-use sectors including oil and gas, chemical, and others.

Mercer Stendal will leverage data from these intelligent valve controllers for predictive maintenance and condition monitoring. With the upgrade, the company aims to further minimize unplanned downtime and improve plant availability.

“The aim of the valve modernization project is to save compressed air, improve the reliability of energy supplies and increase plant availability. Cooperation between Mercer Stendal and Valmet’s flow control team is very good. Planning and implementation have been trouble-free. Small challenges in the early stages of implementation were quickly detected with the support of Valmet’s valve technology center, then resolved and eliminated. Since then, these bugs have no longer existed, and the positioners have run to our satisfaction,” says Frank Wegener, Energy Manager at Mercer Stendal.

“We are proud to continue our cooperation with Mercer Stendal and provide them with our industry proven valve solutions that enable even more reliable and sustainable operations. Thanks to their air-saving technology, our intelligent NDX valve controllers help reduce the plant"s CO2 emissions,” says Raimar Hellwig, Head of Sales and Services, DACH region, Flow Control, Valmet.

The delivery includes 800 intelligent Neles™ NDX valve controllers of the latest generation and 500 Neles™ B1 pneumatic actuators which will replace older actuators. The agreement also includes on-site support for installation and configuration of the NDX valve controllers within Valmet’s DNA Field Device Manager.

Valmet’s Neles™ NDX intelligent valve controller is the next generation positioner, designed to operate on all type of control valves and in all types of industrial applications. It guarantees end product quality in any range of operating conditions with unparalleled performance, best-in-class diagnostics and years of reliable service. It offers several operational cost benefits such as savings on supply air, inventory management and valve maintenance.

Valmet’s Neles™ B1-series quarter-turn actuators are designed for use both in control and on-off service. This actuator offers extremely long cycle life and is well suited for almost any type of rotary valve. It’s designed to be wear and corrosion resistant and enables safe and easy maintenance.

Mercer Stendal is a subsidiary of the North American group Mercer International Inc. Mercer operates production sites in Germany, Canada and Australia. Mercer Stendal produces softwood pulp, bioenergy and various biochemicals from about 3.5 million solid cubic metres annually. The company employs around 455 people, including 30 trainees. Today, after several large optimization projects, including the current Stendal 740 project, the mill has 740,000 tonnes of NBSK capacity, 148 MW of green electricity, and a modern turpentine and tall oil extraction plant. Like all Mercer pulp facilities, Stendal produces enough green energy to meet their internal needs as well as to provide green energy to the electricity grid.

Johannes-Falco Kreienbaum, Sales Manager Valve Controls & Actuators, Germany, Austria & Switzerland, Valmet, tel. + 49 172 44 72 908, email: johannes-falco.kreienbaum@valmet.com

9609 NW 4TH ST., OKLA. CITY, OK 73127 (P): (405) 495-6533 (F): (405) 495-8728 Toll Free 1-800-833-6402 sales@mercervalve.net

Houston Branch Office Bridgeport Branch Office 6218 LONG DR., HOUSTON, TX 77087 6218 LONG DR., HOUSTON, TX 77087 (P): (713) 242-6960 (F): (713) 242-6963 (P): (940) 683-9002 (F): (940) 683-9004 Toll Free 1-866-833-6402 Toll Free 1-866-683-9002 houston@mercervalve.net bridgeport@mercervalve.net

Calgary Branch Office Chicago Branch Office #203, 2835 23RD ST. NE, CALGARY, AB T2E 7A4 Customer Relations Department (P): (403) 250-5557 (F): (403) 250-5661 PO BOX 597, LIBERTYVILLE, IL 60049 canada@mercervalve.net Toll Free 1-866-855-5460 chicago@mercervalve.net

9500 Series Pilot Operated Safety Relief Valve Sizing Program POINT MOUSE ON RED ARROW TO VIEW DISCLAIMER To use the Mercer Valve sizing program, the information on "DATA ENTRY" sheet must be comp changing the "DATA ENTRY" sheet, notice the red arrows thoughout the sheet. Point on these more infomation about the program. This information may help entering correct data into the Enter data into the shaded boxes and use the pull down menu boxes to choice different option information is entered and correct, the program will solve for required area and choose a valve given conditions. The pull down menus at the bottom of the screen will allow you to select the accessories. After your selection process is complete the data entry sheet can be printed. In ad the "Printout" a data sheet for the Pilot Operated Valve can be viewed and printed. . This info important for the proper selection, quoting, and ordering of the valve. Thank you for using Me Company, Inc.

RY" sheet must be completed. While he sheet. Point on these arrows forring correct data into the program. o choice different options. When allarea and choose a valve size to meet ll allow you to select the appropriateheet can be printed. In addition usingd and printed. . This information is. Thank you for using Mercer Valvev5.1-CUST as of 10-DEC-2008 12/08/2021SAK 9500 SERIES PILOT OPERATED RELIEF VALVE SIZING

Main Valve Options Main Body Material: Carbon Steel Inlet Flange Type: RF x RF Inlet Size: 1x2 Flange Ratings: 150 lb x 150 lb Pilot Valve Options Pilot Type: Snap Pilot Body Material: Carbon Steel Options Options: (0) No Options Sour Gas Service: No

Note: This sizing program does not take material compatibility or pressure and temperature limitations into account for choosing materials. Please verify all material choices with Mercer Valve Company, Inc.v5.1-CUST as of 10-DEC-2008 12/08/2021SAK Pilot Operated Valve Data Sheet Oklahoma City Home Office December 8, 2021 9609 NW 4TH ST., OKLA. CITY, OK 73127 (P): (405) 495-6533 (F): (405) 495-8728 Toll Free 1-800-833-6402 sales@mercervalve.net

Houston Branch Office 6218 LONG DR., HOUSTON, TX 77087 (P): (713) 242-6960 (F): (713) 242-6963 Toll Free 1-866-833-6402 Customer Name: houston@mercervalve.net Company: Location: Bridgeport Branch Office Phone: 6218 LONG DR., HOUSTON, TX 77087 Fax: (P): (940) 683-9002 (F): (940) 683-9004 Email: Toll Free 1-866-683-9002 Reference #: bridgeport@mercervalve.net Valve Tag Number System Information System Type Non-Compressor Application Fluid Fluid State Natural Gas Gas Molecular Weight Specific Gravity 17.400 0.600 Fluid Data Ratio of Specific Heats Gas Constant 1.268 344 Compressibility Factor 1.000 Required Capacity 100.000 SCFM Superimposed Const BP Superimposed Variable 0.000 psig 0.00 psig Built-up Back Pressure Total Back Pressure 0.000 psig 0.00 psig Operating Temperature Relieving Temperature 60.000 °F 100.000 °F Sizing Information Operating Pressure Atmospheric Pressure 70.00 psig 14.70 psia Set Pressure Flowing Pressure 100.00 psig 124.7 psia Allowable Over Pressure 10% 10.00 psig Sizing Method ASME, Section VIII Required Area 0.042 in² Selected Orifice Flow Coefficient "D" Orifice 0.870 Sizing Results Selected Orifice Area 0.151 in2 Maximum Valve Capacity 361.165 SCFM Main Valve Seat Material Teflon Main Valve Body Material Carbon Steel Pilot Valve Upper Seat/Lower Seat Materials Viton/Viton Materials Pilot Valve Body Material Carbon Steel Valve Internals Stainless Steel Spring Material 17-7 Stainless Steel O-Rings Viton O-Rings and Buna-N Back-Up O-Rings Backflow Preventer NO Pressure Snubber NO Additional Inlet Supply Filter NO Test Gag NO Options Pulsation Test Port NO Field Test Connnection NONE System Blowdown NONE-STANDARD Pressure Sensing DIRECT Sour Gas Service NO Valve Type Snap Action

Valve Information Inlet Size Outlet Size 1 in. 2 in.

Mercer County residency required. Non-residents will be required to establish residency within one (1) year of employment. Candidates are required to undergo a background check, drug screen and physical.

Candidate would be subject to all Civil Service regulations. Send application, resume and cover letter to: Raissa Walker, Personnel Director, Mercer County Administration Building, 640 South Broad Street, PO Box 8068, Trenton, NJ 08650-0068 or via e-mail to personnel@mercercounty.org.

The Mercer County, Department of Buildings & Grounds is seeking to hire an Assistant Sewage Plant Operator to work at the Mercer County Correction Center Sewer Plant. Under the direction of an experienced operator, candidate will receive on-the-job training in the operation of a sewage plant, performs duties designed to acquaint and increase the knowledge of the candidate with the various procedures involved in controlling the flow and processing of sewage, which will lead to the development skills necessary to advance to the journeymen level; does other related duties.

Candidate will be subject to all Civil Service regulations and processes. Send Resume, application, and cover letter to: Raissa L. Walker, Personnel Director, Mercer County Administration Building, 640 South Broad Street, PO Box 8068, Trenton, NJ 08650-0068 or via e-mail topersonnel@mercercounty.org.

Under the supervision on the Mercer Stables Director/Supervisor performs daily tasks associated with direct care for the horses, programs, and facility.

Ensures the highest quality of care and attention are given to the horses. Ensures the safety of the horses and the facility kept at all times. Handles difficult horses properly then this arises.

Has knowledge of, and is able to implement the use of, firefighting equipment, safety precautions, and disaster safety evacuation plan. Must be able to meet the physical demands as outlined below. Persons with mental or physical disabilities are eligible as long as they can perform the essential functions of the job after reasonable accommodation is made to their known limitations. If the accommodation cannot be made because it would cause the employer undue hardship, such persons may not be eligible.

Mercer County is an EOE/AA/ADA Employer. The Park Commission is actively seeking to create a diverse workforce that closely matches the diversity of our County. We strongly encourage people from underrepresented groups to apply.

The Mercer County Office of Education (Office of the Executive County Superintendent) seeks an exceptional individual to support the office"s goals of assisting school districts. This person will perform secretarial and clerical duties in an efficient and effective manner that helps the professional staff in performing responsibilities, such as providing technical support and guidance to school district staff. The person should be able to function calmly and effectively in a fast-paced environment and interact with the public respectfully. Demonstrated experience in dealing with confidential and sensitive information is necessary. General Responsibilities and qualifications include:

Candidate would be subject to all Civil Service regulations. Send application, resume and cover letter to: Raissa L. Walker, Personnel Director, Mercer County Administration Building, 640 South Broad Street, PO Box 8068, Trenton, NJ 08650-0068 or via e-mail to personnel@mercercounty.org.

Requirements – B.S. in Social Sciences preferred. Candidate must possess excellent written communication skills, organizational skills and detail-oriented. Candidate is expected to be proficient in Microsoft applications. Must be a Mercer County resident at time of hire or within six months of hire.

The Mercer County Park Commission seeks an enthusiastic and experienced individual to manage Capital City Farm (CCF), a 2-acre urban farm in Trenton, New Jersey. Mercer County manages Capital City Farm with the dual goals to 1) provide fresh local produce to those in need in the Trenton area, and 2) provide agricultural jobs, internships and learning opportunities for Mercer County residents and students.

Please email cover letter and resume to Anthony Cucchi at acucchi@mercercounty.org. Mercer County is an EOE/AA/ADA Employer. The Park Commission is actively seeking to create a diverse workforce that closely matches the diversity of our County. We strongly encourage people from underrepresented groups to apply.

Mercer County (NJ) Planning Department serves 12 diverse municipalities within urban, suburban and rural settings in Central New Jersey. Mercer County has had an aggressive land preservation program for over 30 years. The Mercer County Planning Department is seeking an individual with 5 plus years of experience in the preservation of open space and farmland. This position is a supervisory level position overseeing entry level staff and working with senior staff on implementing and supporting all aspects of the County’s open space program.

The Mercer County Correction Center is seeking custody staff to provide direct supervision of our inmate population. This is a full-time position. Prospective employees must be available work shifts in a 24 hour facility. Overtime is mandatory. Qualified candidates will:

Send application, resume and cover letter to: Raissa Walker, Personnel Director, Mercer County Administration Building, 640 South Broad Street, PO Box 8068, Trenton, NJ 08650-0068 or via e-mail to personnel@mercercounty.org.

The Mercer County Emergency Services Department has openings for a demanding and rewarding career that involves meeting the public safety needs of answering 9-1-1 and dispatching Fire and EMS Resources via two-way radio systems. We provide a comprehensive training program and one-on-one training. No prior dispatching experience necessary.

Required to successfully complete training and obtain certification by the NJ Office of Emergency Telecommunications Services (OETS) for NJ Basic Public Safety Telecommunicator and NJ Emergency Medical Dispatcher, as a condition of continued employment. (Classes will be provided)

Appointees who successfully complete the 12-month training period will be eligible for advancement under Civil Service Commission procedure to the title of Public Safety Telecommunicator 1.

Send application, resume and application with cover letter to: Raissa L. Walker, Personnel Director, Mercer County Administration Building, 640 South Broad Street, PO Box 8068, Trenton, NJ 08650-0068.

Youth Services - Candidate will be responsible for monitoring programs funded by Mercer County Division of Youth Services. This includes reviewing grant proposals, onsite monitoring to collect factual data and ascertain accurate reporting to provide guidance on improving programmatic effectiveness. Staffs commissions and committees under the purview of the division.

Position available for the County of Mercer, Department of Human Services, Community Services. Responsibilities include receiving food from the caterer and reheating precooked meals for serving to a large group of participants for the Nutrition Program for the Elderly of Mercer County. Assisting with the clean-up and storage of kitchen utensils and equipment. Previous food handling experience a plus.

Candidate would be subject to all Civil Service regulations. Send application, resume and cover letter to: Raissa Walker, Personnel Director, Mercer County Administration Building, 640 South Broad Street, PO Box 8068, Trenton, NJ 08650-0068 or via e-mail to personnel@mercercounty.org. .

Position available for the County of Mercer, Department of Human Services. Candidate will be responsible for overseeing the Office of Youth Detention and Adult Re-entry Services which requires the supervision of two (2) staff. This includes effectively communicating with various juvenile and adult system partners – multiple County Youth Detention Centers, the Mercer County Correction Center and Mercer County Family Court-NJ Judiciary.

Candidate would be subject to all Civil Service regulations. Send application, resume and cover letter to: Raissa Walker, Personnel Director, Mercer County Administration Building, 640 South Broad Street, PO Box 8068, Trenton, NJ 08650-0068 or via e-mail to personnel@mercercounty.org. .

Safety valves and pressure relief valves are crucial for one main reason: safety. This means safety for the plant and equipment as well as safety for plant personnel and the surrounding environment.

Safety valves and pressure relief valves protect vessels, piping systems, and equipment from overpressure, which, if unchecked, can not only damage a system but potentially cause an explosion. Because these valves play such an important role, it’s absolutely essential that the right valve is used every time.

The valve size must correspond to the size of the inlet and discharge piping. The National Board specifies that the both the inlet piping and the discharge piping connected to the valve must be at least as large as the inlet/discharge opening on the valve itself.

The connection types are also important. For example, is the connection male or female? Flanged? All of these factors help determine which valve to use.

The set pressure of the valve must not exceed the maximum allowable working pressure (MAWP) of the boiler or other vessel. What this means is that the valve must open at or below the MAWP of the equipment. In turn, the MAWP of the equipment should be at least 10% greater than the highest expected operating pressure under normal circumstances.

Temperature affects the volume and viscosity of the gas or liquid flowing through the system. Temperature also helps determine the ideal material of construction for the valve. For example, steel valves can handle higher operating temperatures than valves made of either bronze or iron. Both the operating and the relieving temperature must be taken into account.

Back pressure, which may be constant or variable, is pressure on the outlet side of the pressure relief valve as a result of the pressure in the discharge system. It can affect the set pressure of the upstream valve and cause it to pop open repeatedly, which can damage the valve.

For installations with variable back pressure, valves should be selected so that the back pressure doesn’t exceed 10% of the valve set pressure. For installations with high levels of constant back pressure, a bellows-sealed valve or pilot-operated valve may be required.

Different types of service (steam, air, gas, etc.) require different valves. In addition, the valve material of construction needs to be appropriate for the service. For example, valves made of stainless steel are preferable for corrosive media.

Safety valves and relief valves must be able to relieve pressure at a certain capacity. The required capacity is determined by several factors including the geometry of the valve, the temperature of the media, and the relief discharge area.

These are just the basic factors that must be considered when selecting and sizing safety valves and relief valves. You must also consider the physical dimensions of the equipment and the plant, as well as other factors related to the environment in which the valve will operate.

The Spring Loaded Pressure Relief Valves market reports provide a detailed analysis of area market expansion, competitiveness, global and regional market size and growth analysis. It also offers recent developments such as market share, opportunity analysis, product launch and sales analysis, segmentation growth, market innovation and value chain optimization and SWOT analysis. The latest reports on the market cover the current impact of COVID-19 on the market. This has brought about some changes in market conditions. Early and future assessments of rapidly changing Spring Loaded Pressure Relief Valves market scenarios and impacts are covered in the report.

A spring loaded safety valve is a safety device used to protect a pressurized system or vessel from overpressure. The basic design of a spring-loaded safety valve consists of a nozzle or valve inlet mounted on a pressurized system, a disc secured to the valve inlet to restrain flow under standard operating conditions, a spring to keep the disc closed, and a bonnet element for closing operation. This device is generally used in pneumatic, hydraulic and electronic systems to control working pressure.

The Spring Loaded Pressure Relief Valves market was valued at approximately USD 4.2 billion in 2017 and is projected to grow at a CAGR of 3.5% during 2022-2030

Emerson Electric Co., Parker Hannifin Corp., Watts, Baker Hughes, Rexnord Corporation, Curtiss-Wright Corporation, The Weir Group plc, ALFA Laval AB, CIRCOR International, Inc., IMI plc, Mercer Valve Co., Inc..

In November 2019: Emerson introduces the Daniel™ V707 backpressure control valve. This product has an adjustable spring and is specially designed for the crude oil industry, especially for LACT (Lease Automated Custody Transfer) skids.

North America is expected to be the most profitable market for pressure relief valve suppliers. The U.S. leads the North American market and is expected to witness 1.5-fold growth during 2023-2033. The pressure reducing valve market has recently experienced considerable sales growth owing to increasing industrialization and advancements in urban wastewater management systems. Apart from this, the United States is also the second largest importer and exporter of Pressure Relief Valves, which makes it a target region for manufacturers and suppliers.

– A broad and precise understanding of Spring Loaded Pressure Relief Valves Industry is offered in the segmented form based on product types, applications, and regions.

– Understanding Spring Loaded Pressure Relief Valves Industry business plans, policies, technological advancements, and company profiles of top players.

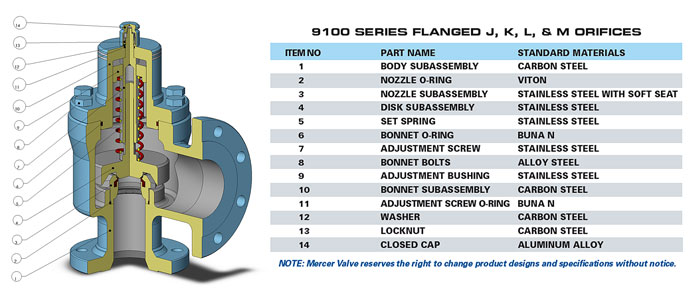

2 Mercer Valve Company 1980s Mercer valve was founded by Wesley Taylor with his Auto Seat Technology patent for pressure relief valves. Mercer s first valve line was the 8100 Series introduced in Auto Seat Technology is incorporated in the valve design, allowing it to pop and reseat time and time again. Unlike the competition, the valve has a soft seat design with a fully guided disk and spring to help the valve have a longer life. With the introduction of our 8100 Series, Mercer Valve started a VR Certified Valve Repair Division. The repair division repairs all relief valve manufacturers and also has mobile units for on-site repair and testing. In addition to the VR shop, we have added an ANSI shop, repairing ball valves, orbit valves, gate valves, as well as many other kind of valves. The 8700 Series was Mercer Valve s next endeavor. This valve has the same guiding system as the 8100 Series, but incorporates a hard seat. The guiding system increases the repeatability of the valve opening and closing. 1990s Mercer s 9100 Series, the industrial pressure relief valve, was introduced in The 9100 Series was developed to handle industrial gases and liquids, while continuing to use the proven design of Auto Seat Technology. The 9100 Series also provides more options for the customer including different soft seat and seal materials, threaded and flanged connections, and sizes ranging from 1/2 x 1 to 4 x 6. In 1995, Mercer Valve added the 9100 Series Model 20 to their product line. This valve line is used for high pressure service up to 8700 psig set pressure. Mercer Valve entered the pilot operated relief valve market with the 9500 Series. The 9500 Series includes API Orifice Sizes from D through T and Full Bore Orifices up to 8 inches. Mercer s 9500 Series includes both a snap action pilot and a modulating action pilot. The modulating pilot is unlike any in the industry, having full modulation throughout the over pressure range. Continuing in the Mercer tradition, the 9500 Series has a long life due to the usage of Auto Seat Technology. With the growth and success of our valve lines, Mercer Valve moved in a new building. This houses the home office, repair division, and manufacturing department. The facilities also include an expanded fully functioning flow lab. Mercer Valve has always strived to be safe minded and engineer driven. The expanded flow lab has increased testing and enabled further research and development. 2000s In 2000, Mercer opened a Houston Branch to help service our Houston customers more efficiently. The Houston Branch assembles valves keeping lead times at a minimum. The Houston Branch is also a VR Certified repair shop. A few years later, Mercer opened a location in Calgary, AB, Canada to support our Canadian customers. Mercer Valve also opened a new repair center in Oklahoma City to accommodate the increasing repair business. The new repair center offers a larger area for the repair of other oilfield equipment including glycol pumps, chemical pumps, ball valves, gate valves, orbit valves, etc

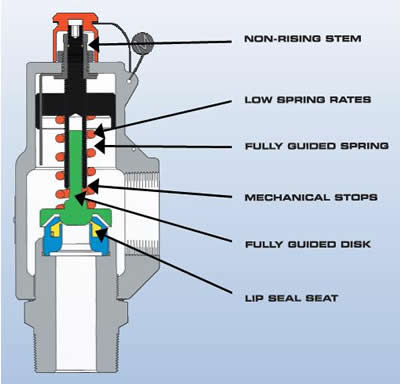

3 MERCER VALVE COMPANY, INC. is Mercer Valve s patented soft seat relief valve design. increases seat life, reduces repairs, and gives the valve a consistent set pressure. is a non-rising stem design that uses low rated springs to achieve a consistent set pressure. A fully guided disk and spring give the valve accurate set pressures and help with reseating after each pop. The lip seal seat creates a tighter seal up to set pressure allowing for less leakage. Mechanical stops allow the disk to open to the same point every pop, allowing for the same flow rate and limiting spring stress. reduces the need for repair while giving an accurate set pressure and tight seal. NON-RISING STEM LOW SPRING RATES FULLY GUIDED SPRING MECHANICAL STOPS FULLY GUIDED DISK LIP SEAL SEAT

4 NON-RISING STEM The adjustment screw in the Mercer Valve is a non-rising stem, meaning that when adjusting the set pressure the adjustment screw does not move up or down. When the adjustment screw is turned, it moves the adjustment bushing straight up and down increasing and decreasing the tension in the spring. The adjustment bushing never turns. Because the adjustment bushing never turns, it does not transmit a torque into the disk and seat when adjusting the set pressure. This helps extend the seat life of the valve. MECHANICAL STOPS Due to Mercer Valve having a non-rising stem design the adjustment screw never moves up and down. Because the adjustment screw is always in the same place it can be used as a mechanical stop for the disk. This allows the disk to open the same amount each time the valve opens. This gives the valve the same capacity every pop. The mechanical stop is positioned so that the disk is always held up by the flow of the valve until the pressure drops low enough to reclose the valve. The mechanical stop also does not allow the spring to be over compressed, reducing stress on the spring. FULLY GUIDED SPRING The spring in the Mercer Valve is guided from top to bottom. With a fully guided spring the spring is only compressed vertically so the spring keeps consistent tension from one pop to the next

5 FULLY GUIDED DISK The disk is aligned on the top through the adjustment screw and at the bottom of the disk by the radius on the disk. When a relief valve begins to vent, the flow of the valve pulls everything toward the outlet. Guiding the disk allows the disk to only move up and down and not to the sides. This keeps the disk from being pulled toward the outlet. With the disk only rising up and down the disk has a consistent opening and reseating. The radius on the bottom of the disk also helps insure that the valve reseats after each pop. If the disk is not centered on the nozzle at reclose, the radius on the bottom of the disk helps to realign the disk. The spring force will push the disk down and the radius will allow the disk to roll back into place. LOW SPRING RATES A spring rate is the amount of force the spring exerts for how much it is compressed. Mercer Valve uses low rated springs to help keep stresses out of the spring. The more force that the spring is exerting, the higher the stresses in the spring. When a spring is over stressed the properties of the spring are changed, affecting the set pressure of the valve. LIP SEAL SEAT Mercer uses a lip seal soft seat. On reclose the seat flexes, allowing the brute impact of the disk reclosing to be taken by the hard nozzle, while still providing the soft seat seal. Also before the valve reaches set pressure, the pressure is applied underneath the lip seal, pushing the seat against the disk. This gives a tight seal up to the set pressure and extends the seat life

6 General Terms Set Pressure is the point at which the pressure relief valve is set to open. Over Pressure is the amount of pressure above the set pressure that is allowed for the valve to go to full lift and achieve full flow. For most applications this is typically 10% or 3psi, which ever is greater. Conventional Pressure Relief Valve is a direct spring operated valve. The spring tension controls the opening and closing of the valve. The set pressure is affected by back pressure on this type of valve. Pilot Operated Pressure Relief Valve is a valve where the opening and closing of the main valve is controlled by an auxiliary pressure relief valve called a pilot. The main valve is the primary relief device. Back Pressure is pressure on the outlet side of the valve. There are 2 types of back pressure, superimposed and built-up. Some types of back pressure can affect the flow rate and/or the set pressure. Built-up Back Pressure is pressure in the outlet of the valve caused by the flow of the valve after the valve opens. This type of back pressure does not affect the set pressure. Superimposed Back Pressure is the pressure on the outlet of the valve at the time the valve opens. This back pressure is caused by other sources and will affect the set pressure of a conventional pressure relief valve. Superimposed back pressure can be variable or constant. Blowdown is the difference between when a valve opens (set pressure) and when the valve closes. Typically blowdown is expressed as a percentage of the set pressure. Auto Seat Technology is Mercer Valve s patented soft seat relief valve design. Auto Seat Technology increases seat life, reduces repairs, and gives the valve a consistent set pressure. Common Codes and Standards American Society of Mechanical Engineers Boiler and Pressure Vessel Code, Section VIII, Division 1 UG , Appendix II, Appendix M American Petroleum Institute Recommended Practices 520 part I, 520 part II, and 521 & Standards 526, 527, and 2000 US Department of Transportation CFR Title 49, Chapter 1 Compressed Gas Association S-1.1, S-1.2, and S

7 Sizing Overview There are multiple ways of sizing a pressure relief valve depending on the type of system the valve is installed. In some cases multiple scenarios may be present and all cases should be considered. Pressure relief valves are sized to relieve a specified flow at the particular conditions of the system the valve is installed. The flow rate used in sizing the pressure relief valves is based on the amount needed to be relieved to prevent further overpressure of the system. The result of the pressure relief sizing gives a minimum required area to produce the required flow rate. The minimum required area is then used to select the proper orifice area for the valve. Different standards and organizations have developed sizing methods and calculations. Two of the most common methods for blocked flow sizing are from American Society of Mechanical Engineers (ASME) and The American Petroleum Institute (API). The calculations are similar for both methods. The main difference between the methods is the discharge coefficient and orifice areas used. API uses generic values for both the discharge coefficient and orifice areas, while ASME uses the actual orifice area for the particular valve series and the measured discharge coefficient

11 Discharge Coefficients Valve Series ASME Gas/Vapor Discharge Coefficient ASME Liquid Discharge Coefficient ASME Gas/Vapor Slope ASME Liquid Flow Factor API Gas/Vapor Discharge Coefficient API Liquid Discharge Coefficient 8100 Series 1/2 Diameter.800*.639* Orifice 8100 Series 3/4 Diameter.830*.711* Orifice 9100 Series Series Model Series.854* Series API Orifice Letters 9500 Series Full Bores * = 8100 Series and 8700 Series are certified under the slope method. The discharge coefficients for these orifices have been calculated from the slopes and Flow Factors

8613371530291

8613371530291