niezgodka safety valve free sample

Niezgodka was founded 1967 in Hamburg Germany. Niezgodka’s core product areas are Safety Relief valves, Pressure reducing Valves, Vacuum and Pressure Relief Valves, and specialist Foodtec and Pharmacy Valves. Flowstar is the exclusive stockist distributor for Niezgodka in the UK, Ireland, Singapore, Malaysia and Indonesia.

Niezgodka Type 10.2 Safety Valves are suitable for pressure safety in processes with steam, gases and liquids. The pressure can be adjusted to your needs.

The Niezgodka Type 10.2 Safety Valve body and spring bonnet are made from 316Ti stainless steel and can handle a temperature range from -60°C to 280°C. These pressure safety valves are installed in a vertical position and can be adjusted to the needed pressure for your process.

AST S.P.A. is committed in 1951 to being a premier leader for innovative products and services according to customer needs and requirements. It is the mission of AST S.p.A. an ISO 9001 certified company to provide responsive, innovative and cost effective products and services according to customer specific needs and requirements and to serve the wide energy market by effectively communicating with customers for safety and environment while maintaining outstanding quality of the products compliance to EC directives 97/23/CE (PED), 94/9/CE (ATEX), EN 4126-1, EN 12516, ASME B16.34, API 520, API 526

BESA Ing. Santangelo S.p.A. designs and produces safety valves since 1946 to discharge gases and liquids. Main activity fields are heaters and boilers manufacturing, shipyards, power generation plants as well as pharmaceutical, chemical and petrochemical industry. Design & construction according to European directives.97/23/CE (PED), 94/9/CE (ATEX), EN 4126-1, EN 12516, ASME B16.34, API 520, API 526 and certified/approved by I.S.P.E.S.L. and pascal (PED directive), ICIM (ATEX directive), RINA

FNC is a well-known manufacturer of a wide range of products for low-pressure storage tanks such as flame and detonation arresters, breather valves, emergency vents a gauge hatches. Sales and application engineers of ERIKS flow control and FNC are actively involved in helping customers develop new products. FNC possesses in-house facilities for adapting all of its products to the wishes of customers.

Level And Flow Control Engineers as the most dedicated Manufacturer and Exporter of Pressure Relief Valve, Industrial Strainers, Level Gauge, Flow Indicators and much more. Our experienced professionals manufacture these products using the most excellent grade raw material in our state of the art infrastructure.

Welcome to airpower Europe! We are proud to present you the new actuator twin torque, a new concept in the field of actuators. Now is the best time to profit from 25 years of experience in the field of actuating technology and periphery accessories as well as automation & process engineering. Gains to made with airpower: Technically mature product know-how, constructed and produced according to international standards, guarantee absolute safety. The most important advantages and benefits in the deployment of twin-torque actuators have been put together and listen on the next pages. We also assume that it is right that you always have access to our extensive know-how and experience in valve control technology when and where you need it.

RITAG products are designed for chemical plants, pharma-ceutical plants, power stations, refineries, shipbuilding, off- and on-shore facilities, building services engineering and for general plant engineering. They are, of course, available in all customary nominal dimensions and pressure ratings. All RITAG wafer type check valves are manufactured and labelled according to the Pressure Equipment Directive 97/23/EC.

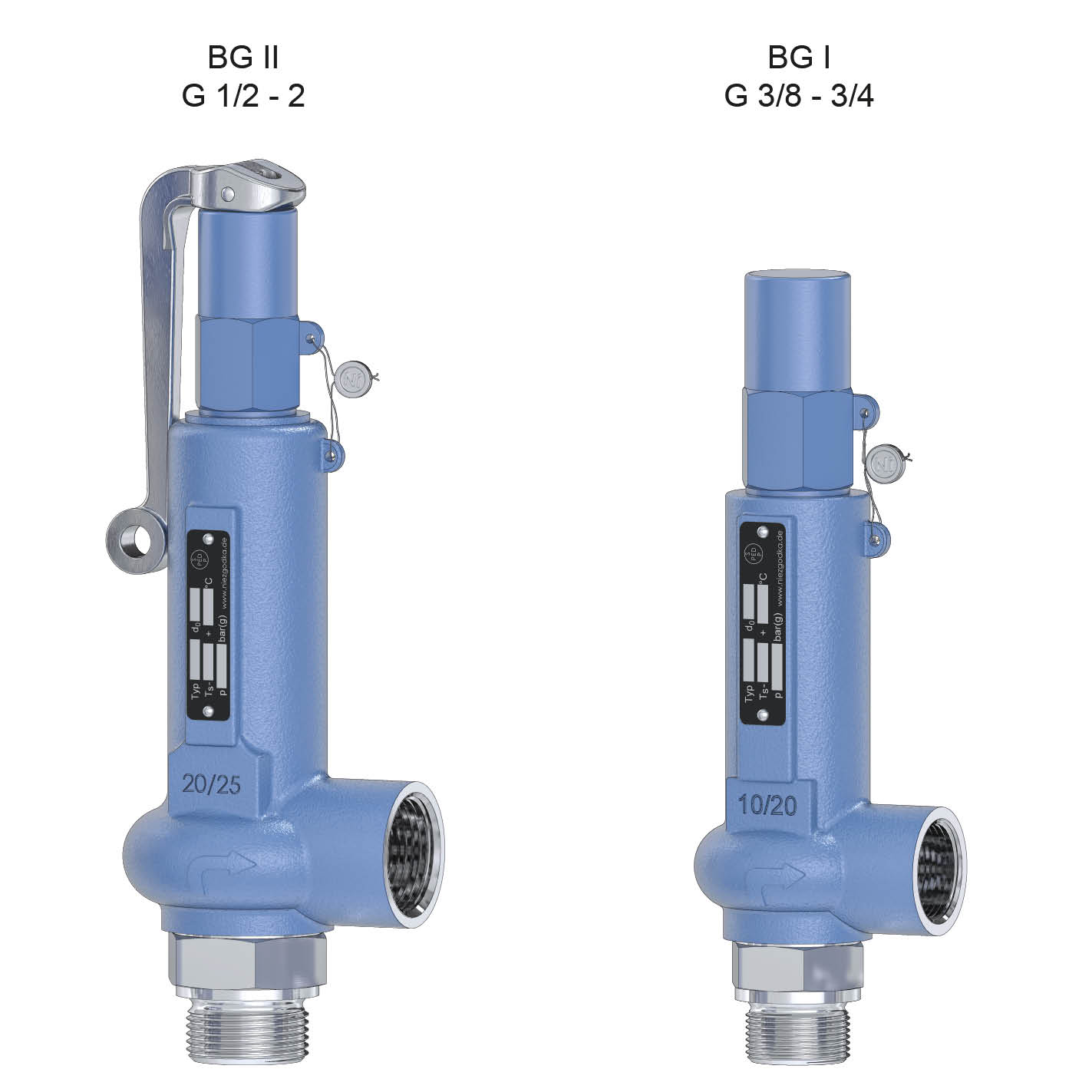

As manufacturers of fittings made of rust- and acidresistant materials Niezgodka GmbH is in contact with well-renowned consumers and dealers not only in the European area.

Highly sensitive fields of application in industrial and commercial plants. This is where our valves are to be found. Even where plastic would be permissible, we use solid metal. For boilers and compressors, for pumps and pipelines, marine engines, solar plants and bulk transport vehicles. Our comprehensive range of high-quality, innovative and reliable valves covers all industrial applications.

A safety valve must always be sized and able to vent any source of steam so that the pressure within the protected apparatus cannot exceed the maximum allowable accumulated pressure (MAAP). This not only means that the valve has to be positioned correctly, but that it is also correctly set. The safety valve must then also be sized correctly, enabling it to pass the required amount of steam at the required pressure under all possible fault conditions.

Once the type of safety valve has been established, along with its set pressure and its position in the system, it is necessary to calculate the required discharge capacity of the valve. Once this is known, the required orifice area and nominal size can be determined using the manufacturer’s specifications.

In order to establish the maximum capacity required, the potential flow through all the relevant branches, upstream of the valve, need to be considered.

In applications where there is more than one possible flow path, the sizing of the safety valve becomes more complicated, as there may be a number of alternative methods of determining its size. Where more than one potential flow path exists, the following alternatives should be considered:

This choice is determined by the risk of two or more devices failing simultaneously. If there is the slightest chance that this may occur, the valve must be sized to allow the combined flows of the failed devices to be discharged. However, where the risk is negligible, cost advantages may dictate that the valve should only be sized on the highest fault flow. The choice of method ultimately lies with the company responsible for insuring the plant.

For example, consider the pressure vessel and automatic pump-trap (APT) system as shown in Figure 9.4.1. The unlikely situation is that both the APT and pressure reducing valve (PRV ‘A’) could fail simultaneously. The discharge capacity of safety valve ‘A’ would either be the fault load of the largest PRV, or alternatively, the combined fault load of both the APT and PRV ‘A’.

This document recommends that where multiple flow paths exist, any relevant safety valve should, at all times, be sized on the possibility that relevant upstream pressure control valves may fail simultaneously.

The supply pressure of this system (Figure 9.4.2) is limited by an upstream safety valve with a set pressure of 11.6 bar g. The fault flow through the PRV can be determined using the steam mass flow equation (Equation 3.21.2):

Once the fault load has been determined, it is usually sufficient to size the safety valve using the manufacturer’s capacity charts. A typical example of a capacity chart is shown in Figure 9.4.3. By knowing the required set pressure and discharge capacity, it is possible to select a suitable nominal size. In this example, the set pressure is 4 bar g and the fault flow is 953 kg/h. A DN32/50 safety valve is required with a capacity of 1 284 kg/h.

Coefficients of discharge are specific to any particular safety valve range and will be approved by the manufacturer. If the valve is independently approved, it is given a ‘certified coefficient of discharge’.

This figure is often derated by further multiplying it by a safety factor 0.9, to give a derated coefficient of discharge. Derated coefficient of discharge is termed Kdr= Kd x 0.9

Critical and sub-critical flow - the flow of gas or vapour through an orifice, such as the flow area of a safety valve, increases as the downstream pressure is decreased. This holds true until the critical pressure is reached, and critical flow is achieved. At this point, any further decrease in the downstream pressure will not result in any further increase in flow.

A relationship (called the critical pressure ratio) exists between the critical pressure and the actual relieving pressure, and, for gases flowing through safety valves, is shown by Equation 9.4.2.

Overpressure - Before sizing, the design overpressure of the valve must be established. It is not permitted to calculate the capacity of the valve at a lower overpressure than that at which the coefficient of discharge was established. It is however, permitted to use a higher overpressure (see Table 9.2.1, Module 9.2, for typical overpressure values). For DIN type full lift (Vollhub) valves, the design lift must be achieved at 5% overpressure, but for sizing purposes, an overpressure value of 10% may be used.

For liquid applications, the overpressure is 10% according to AD-Merkblatt A2, DIN 3320, TRD 421 and ASME, but for non-certified ASME valves, it is quite common for a figure of 25% to be used.

Two-phase flow - When sizing safety valves for boiling liquids (e.g. hot water) consideration must be given to vaporisation (flashing) during discharge. It is assumed that the medium is in liquid state when the safety valve is closed and that, when the safety valve opens, part of the liquid vaporises due to the drop in pressure through the safety valve. The resulting flow is referred to as two-phase flow.

The required flow area has to be calculated for the liquid and vapour components of the discharged fluid. The sum of these two areas is then used to select the appropriate orifice size from the chosen valve range. (see Example 9.4.3)

Rotork has installed over 150 RC200 pneumatic actuators to perform critical safety functions on a railway line in Turkey. Actuators operating fire dampers on an extension of the Kadıköy Kartal Tavşantepe metro line to the Sabiha Gökçen airport in Tukey has ensured the safety of passengers. The Sabiha Gökçen ai...

40 years ago, CALDER began manufacturing Valve Testers because founder, John Emmitte, realized that companies were not testing valves properly. Even today, many pressure relief valve testers are homemade or fabricated in a manner that does not provide the valve with enough volume and...

Engineered for heavy-duty, reduced-maintenance performance and manufactured in a variety of body and seal materials, the D Series WKM* valves are commonly selected for many specialized applications such as gas distribution, gas transmission, oilfield production, and industrial applications.

DRAFT prEN ISO 4126-6:2013 Safety devices for protection against excessive pressure � Part 6: Application, selection and installation of bursting disc safety devices (ISO/DIS 4126- 6:2013).

Following an accidental fire at the IOCL Jaipur Terminal, an extensive review of safety measures recommended by the MB Lal Committee has resulted in the introduction of failsafe actuators for critical tank farm applications.

Flowstar Ltd, the Hull based stockist of safety, relief and reducing valves, has increased its stock of the Broady 3500 API / ASME Safety Valve in Carbon Steel and Stainless Steel in both standard and fully UK made variants.

Solar power technology uses the energy of the sun to produce superheated steam for power turbines. The Dewrance range of extraction check valves have been specifically designed for installation i...

Steam and fluid systems can be upgraded quickly and easily to safer and more cost-effective maintenance procedures with the new space-saving Spirax SafeBloc� Double Block and Bleed (DBB3) Valve. The design of new plant layouts is also simplified.

Reliability has always been the overriding priority for Rotork valve actuator design, and now Rotork IQPro intelligent electric valve actuators are available with a Safety Integrity Level (SIL) option for applications...

Safety valves are used to protect processes, personnel and the environment against process disruption. Such valves are operated only in trip situations, but when they are required to operate, it is essential that they ensure that the valve is switched to the safety position. However, because these shutdown valves are rarely cycled, there is always ...

Reliability has always been the overriding priority for Rotork valve actuator design, and now Rotork IQPro intelligent electric valve actuators are available with a Safety Integrity Level (SIL) option for application...

How do you size the safety valve for a supercritical steam boiler? Steam boilers are increasingly being designed to operate under supercritical conditions i.e. pressures above 220 bar and temperatures above 374�C. Sizing equations for safety valves on steamboilers are often given in codes and standards for saturated and superheated steam assuming �...

Mike joined SFC in 2002 as Sales and Marketing Manager and has been instrumental in driving the company�s strong sales performance, particularly in China and USA. Mike is also responsible for promoting SFC�s latest valve operating products into new markets. Mike has over 26 years� experience within the interlock industry and within the Halma group ...

Following a highly successful 2008, which has continued into 2009, Safety Systems UK Ltd is now looking to develop its growing Asian market. Key agents from Asia were invited to the company�s headquarters in Worsley for their first Asian Agents Conference, commencing on the 15th June and concluding on 17th June.

In today�s demanding oil and gas applications where the operating pressures and temperatures are increasing, the need for safety and the need for assured valve shut off providing absolute and verifiable isolation are regularly becoming the standard for critical applications.

Iron technology leader Saint-Gobain PAM UK, part of leading international materials company Saint-Gobain, has scooped an award for �Partnership Initiative of the Year� at Safety and Health Practitioner�s Institution of Occupational Safety and Health Awards 2011. Held at the Hilton Hotel in Park Lane, London, the winning entry was for highlighting a...

Rotork Fluid Systems has supplied the specialised hydraulic actuator package for a second sub-sea safety isolation valve (SSIV) installation on the same offshore gas gathering project off the coast of Egypt.

Safety Systems UK Ltd has been named among the country�s top performers in the first ever EEF Future Manufacturing Awards, by winning one of the five North West UK region company awards at a presentation in Manchester�s Imperial War Museum on Thursday 19th November 2009.

Emerson�s new FIELDVUE� DVC6200 SIS digital valve controller responds to safety demands, and features partial stroke and position monitoring capabilities for the final control element in a safety instrumented system (SIS). Intelligent automatic partial stroke valve testing provides improved safety and reliability versus traditional pneumatic and ja...

Helsinki-2012 was a banner year at the Metso Flow Laboratory, where a corporate initiative to increase the numbers of valves certified to the most stringent environmental emissions standards continues. In 2012, numerous Neles� metal-seated and Jamesbury� soft-seated valve products were certified to meet the requirements of the global ISO15848-1 sta...

The company is renowned for innovative solutions to common problems and their valve products have been used globally in the oil and gas industry for years. Products include various safety relief valve...

For many years BVAA has been �banging the drum� when it comes to the correct selection and application of Safety and Relief Valves. But that is only half the story� To understand these critical function valves properly you do need a good knowledge of the design basics and a thorough understanding of the definitions and terminology, which unfortunat...

Whether onshore or offshore, maintenance procedures to Safety Relief Systems on live plants is a cause for concern, particularly as an open path to relief must be maintained during all times of the work exercise. Smith Flow Control�s PSV system ensures maintenance procedures on safety relief systems operate in a safe sequence.

Mr Ed Haynes, CEN Consultant on PED, has made an assessment on the following draft standards and has made comments with regard to the relationship between them and ISO 4126-7 �Safety devices for protection against excessive pressure -- Part 7: Common data� (which is already publi...

Behind each and every successful product lie thousands of hours and probably millions of pounds in research and development. Not surprising then that there is often a queue of unscrupulous businesses waiting to capitalise by producing cheap copies. Within any valve each component has been carefully designed and selected to work together to achieve ...

Attention is drawn to the implications that hydrostatic pressure testing may be waived for certain types of safety valves. This might result in manufacturers using this standard failing to meet the essential safety requirements in the Pressure Equipment Regulations 1999 (as amended). This matter was raised with the Commission Working Group �Pressur...

Health and safety has always been an integral part of Kent Introl�s philosophy, and the company�s robust approach has recently been independently recognised, via the attainment of both OHSAS 18001 and the RoSPA silver award.

In the process industry, mechanical interlocks guarantee strict adherence to procedures and help avoid human error. They are particularly useful for highly dangerous operations such as pigging and valve changeover procedures.

The Health and Safety Executive (HSE) has contacted two of our customers in the past week, requesting evidence of their site�s preventative maintenance and management of ageing plant plans.

Flowstar Ltd, the Hull based stockists of safety, relief and reducing valves, has added new Niezgodka product to its extensive range from the German manufacturer.

Industrial valve specialist Orseal, who provide flow control solutions for all fluids and gases, have built up over the years considerable specialist experience of providing valves for highly demanding applications.

The Seetru LGS� Safety Relief Valve range represents state-of-the-art design with dual guided spindle as well as the Seetru Rock-Seal� seal technology for repeatable high performance sealing.

The Seetru LGS� safety relief valve is a high quality valve of modular design and construction incorporating the Seetru proprietary compact design technolo...

Automated safety systems are increasingly being integrated around the world and across diverse industries � including process, household and commercial products, medical, nuclear, automotive, railway, and avionics

Designed with safety in mind, the product boasts an ATEX approved aluminium body (for use in hazardous environments) and, unusually for this type of product, an integral single coil solenoid valve.

The APL7 can offer a cost-effective solution when compared to a standard switchbox with a separate solenoid valve as only one cable & one cable glan...

In the process industry, mechanical interlocks guarantee strict adherence to procedures and help avoid human error. They are particularly useful for highly dangerous operations such as pigging and valve changeover procedures.

Functional safety, a key current topic in the process automation industry, will be addressed on 29 April 2015 at a workshop hosted by AUMA Riester GmbH & Co. KG at the company�s Muellheim headquarters in Germany

If solenoid valves do not operate correctly when required, the consequences can be catastrophic. Thierry Filley, vice president of engineering, ASCO fluid control products at Emerson, explains the valve design considerations for maximising operational reliability and process safety

Emerson has expanded its range of angle seat valves with the new ASCO™ Series 290D, available now in Europe and globally by late 2022. After 25 years of proven use in the field, Emerson identified key opportunities to opt...

Flowstar Ltd, the Hull based stockist of safety, relief and reducing valves, has increased its stock of the Besa Steam Safety Valves. Besa valves are fully manufactured within Europe.

Albion Valves (UK) Ltd, an increasingly popular UK valves supplier, is advising distributors to ensure they check for type test approvals and certification of the EU"s Pressure Equipment Directive (PED) conformity, when specifying safety valves, as opposed to relief valves in a pressurized system.

Smith Flow Control provided a solution by developing a custombuilt operating panel that enhances safety and increases efficiency. It does this by moving the control and operation of Eni Norge�s large n...

Emerson Process Management has introduced the Enardo 850/950 series of wirelessly-monitored pressure vacuum relief valves (PVRVs) that provide safety and emissions control by managing the pressure in storage tan...

NABIC has long been recognised as the industry standard for commercial and industrial hot water applications. In fact, NABIC valves, available in gunmetal and stainless steel, are also suitable for use with a wide variety of fluids and gases including steam, hot water and air.

This European Directive specifies the essential Health and Safety Requirements applicable to machinery. The BVAA Guidelines supported by CEIR takes the view that most actuated valves are excluded from the definition of machinery and therefore the Machinery Directive does not apply. As a result of concerns expressed by VDMA of Germany t...

Jim Breeze, Product Manager, Instrumentation Connections and Process Valves at Parker Hannifin Corporation, the global leader in motion and control technologies, looks at the importance of pressure monitoring for offshore environments.

COI TECH Safety valves are fully European and can manufacture in AISI 316L, Carbon Steel, Brass, Aluminium Bronze, Monel, Duplex, Super Duplex, Inconel, Hastelloy, Titanium, PVC, PTFE, PP, PCTFE PVDF as standard.COI TECHNOLOGY has been trading for over 40 years in the field of pressurised systems and specialises in the design, development and distr...

The Health and Safety Laboratory (HSL) is one of the world"s leading providers of health and safety solutions to industry, government and professional bodies.The main focus of HSL�s work is on understanding and reducing health and safety risks and offers health and safety research, expert advice, consultancy, specialist training and products. The H...

ValvTechnologies Europe, the leading service provider for control, safety relief, parallel slide gate and manual valves across Europe, Africa and the Middle East, announced today that the company reached five years without a lost-time injury.

Bulk materials and powders in sectors such as the chemical, pharmaceutical and food industries and others can be very dangerous. One spark � and the dust explodes. It is no surprise, then, that the topic of safety when handling bulk materials is at the top of the list of many companies. Festo has a wide product range and the necessary expertise for...

Facilities with safety instrumented systems can now take advantage of the new SIL 2/3 functional safety certification of Emerson�s Rosemount� 8800 Vortex flow meters, per IEC 61508, which can help mitigate risk, enhance plant safety, and protect personnel.

Industry professionals from the BVAA membership came together at CSA Group UK (near Chester) for a seminar on conformity assessment for the valve and actuator industry.

Presentations and discussions were held around the need and importance of conformity assessment for industry, and the best way to combine multiple approvals (Functional Safety an...

The TEG is a group of experts having a background of Safety Valve manufacturing, service and repair. It will meet to initially discuss the issues currently being faced by manufacturers and end users of achieving a regulated system of safety valve service, maintenance testing and repair. If there is support for the idea, and subject ...

IEC 61508:2010 does not state that certification of products is necessary to claim compliance with the requirements of the standard. However, certification of products can be used to support its integrity, availability and reliability, once it is implemented within a safety instrumented system (SIS).

Les Littlewood, Sales Director of Albion Valves UK Ltd discusses how valve technology is taking a lead in industrial workplace safety, and explains how getting the basics right can help safeguard Britain�s workforce.

Periodic maintenance and testing of safety relief valves is a necessary aspect of plant safety and should not be seen as a box ticking exercise to ensure compliance with a relevant standard or legislation. The downtime, co-ordination of services and cost implications of a relief valve campaign can be complex and demanding and if the job is not done...

Rotork Fluid Systems customised linear hydraulic spring-return valve actuators meet the critical safetyrelated specifications for an offshore gas field in the Middle East.

These actuators operate 220mm (9�) gate valves on skids requiring a High Integrity Pressure Protection System (HIPPS) certification manufactured for the Hasbah Offshore Facili...

Specialising in equipment for steam, heat transfer and energy management, ARI-Armaturen offers an extensive range of valves, steam traps and engineered systems for numerous applications and industries.

Due to the significant interest and subsequent sales volume of QK chain wheels Quickits have taken the decision to supply FREE safety cable kits with all chain wheels supplied

New guidelines introduced by the Safety Assessment Federation (SAFed) have once again brought the issue of health and safety in industrial environment to the fore, shining a light specifically on the dangers associated with industrial processes operated by high pressured systems

It continuously monitors upstream and downstream pipeline pressure dynamics to provide early detection of pipeline breaks and initiate automatic valve actuator movement to a pre-selected emergency position.

It�s a technological disrupter with exciting potential applications in oil and gas exploration and production. For example, Festo has used digital pneumatics to control and monitor latch opening on the fingerboard of an oil exploration platform. The benefits include cost and time savings in installation, a reduced safety risk for employees, lower e...

This standard will define procedures and methods with which all relevant components of automated industrial valve packages can be evaluated according to the rules of IEC 61508-1, -2 and -4 to -7 in order to integrate them into a safety instrumented system (SIS). It will provide a method to determine all relevant factors, associated ...

Albion Valves Ltd, a leading UK valve supplier has added a range of WRAS approved double check valves to their portfolio to ensure distributors are specifying superior, fit-for-purpose products that are fully compliant with increasingly stringent water industry regulations.

Emerson�s Fisher� Cavitrol Hex severe service valve trim reduces or eliminates cavitation to improve rotary valve performance and extend operating life.

Emerson�s Fisher Vee-Ball� Rotary Control Valves are now available with Cavitrol� Hex Anti-Cavitation Trim to reduce or eliminate vibration caused by cavitation. The Cavitrol Hex trim option pr...

A critical component in maintaining a facility�s productivity, safety and profitability is to ensure that every valve is operating at peak efficiency while meeting relevant safety requirements.

With the Trevitest� system, TEAM has the ability to test relief valves and identify those in need of adjustment or full service while the unit remains o...

What is it?: This document specifies the requirements for bursting disc safety devices. It includes the requirements for the design, manufacture, inspection, testing, certification, marking, and packaging.

It is applicable to safety valves having a flow diameter of 4 mm and above which are for use at set pressures of 0,1 bar gauge and above. No limitation is placed on temperature.

Demonstrating their proactive approach to environmental performance and to staff health and safety, Orseal are now accredited to both ISO 14001 and ISO 45001. Following the company�s rapid transition to the latest version of ISO 9001:2015, these new accreditations complete Orseal�s commitment to the highest standards of Quality, Health & Safety and...

Flexitallic UK Ltd has been named as UK manufacturing’s safest company after being crowned overall sector winner in the 2020 International Safety Awards.

After being presented a Distinction level grade from the British Safety Council in the annual awards, the West Yorkshire-based sealing solutions specialist was named ‘Sector Winner &n...

The reliability of safety valves is crucial to process control. Their design has changed little in recent years and partial stroke testing (PST) has been the accepted method of monitoring them. Newer methods linked to the introduction of on-line intelligent safety valve controllers are offering new levels of performance monitoring. Analysis results...

The UK’s leading independent provider of valve automation products, Actuated Solutions Ltd (ASL), has announced the availability of a failsafe option for larger sizes of its hugely popular range of HQ electric actuators.

ISO TC 185 have issued the attached new work item proposal relating to a new performance testing standard for safety valves as part of the ISO 4126 family of standards. BSI will vote on behalf of the UK as to whether this work item should be approved. The purpose of this Hot Spot is both to draw attention to the work item and als...

At Broder Metals Group, health and safety is our priority, and our proactive approach means we’ve had no accidents in the last five years. However, despite our exemplary health and safety record, we’ve decided to partner with Citation, a leading UK business that has provided expert advice to a range of industries in health and saf...

Parker Hannifin, the global leader in motion and control technologies, will preview three aviation fuel safety products at inter airport CONNECT from 20–21 April 2021.

What is it?CEN TC 69 has been working on the development of a new EN standard covering functional safety of safety-related automated valves for a number of years as a preliminary work item. This work has now reached the point where it is being proposed as a formal work item which will be decided by a ballot. The current draft standard is attached f...

In this report, our team research the global Low Pressure Relief Valve market by type, application, region and manufacturer 2014-2019 and forcast 2020-2025. For the region, type and application, the sales, revenue and their market share, growth rate are key research objects; we can research the manufacturers" sales, price, revenue, cost and gross profit and their changes. What"s more, we will display the main consumers, raw material manufacturers, distributors, etc.Geographically, this report split global into several key Regions, with sales (K Pcs), revenue (M USD), market share and growth rate of Low Pressure Relief Valve for these regions, from 2012 to 2023 (forecast), covering

Global Low Pressure Relief Valve market competition by top manufacturers/players, with Low Pressure Relief Valve sales volume, Price (USD/Pcs), revenue (M USD) and market share for each manufacturer/player; the top players including

On the basis on the end users/applications, this report focuses on the status and outlook for major applications/end users, sales volume, market share and growth rate of Low Pressure Relief Valve for each application, including

The Global Safety Valves Industry 2016 Market Research Report is a professional and in-depth study on the current state of the Safety Valves industry.

Firstly, the report provides a basic overview of the industry including definitions, classifications, applications and industry chain structure. TheSafety Valves marketanalysis is provided for the international market including development history, competitive landscape analysis, and major regions’ development status.

Then, the report focuses on global major leading industry players with information such as company profiles, product picture and specification, capacity, production, price, cost, revenue and contact information. Upstream raw materials, equipment and downstream consumer’s analysis is also carried out. What’s more, the Safety Valves industry development trends and marketing channels are analyzed.

8 Major Manufacturers Analysis of Safety Valves Includes Bosch Rexroth, GE Energy, Velan, Weir Group, Emerson Electric, Dorot Instrumentation, Metso Corp, Nihon KOSO, Ross Valve, Rotork, Alfa Laval, LESER, Crane, Curtiss Wright Corporation, Tyco International, Niezgodka, HEROSE.

Self-operated Pressure Regulators Universal Pressure Reducing Valve Type 41-23 Application Pressure regulators for set points from 5 mbar to 28 bar Valves in nominal sizes DN 15 to 100 Nominal pressures

. kymanual or Automatic - it s your Choice ky LKB Automatic or Manual Butterfly Valve Application LKB is a sanitary automatically or manually operated butterfly valve for use in stainless steel pipe systems.

API Flanged Safety Relief Valves Series 26 CATALOG The-Safety-Valve.com 1 Valve finder How to find the right product group High operating to set pressure ratio, high backpressure or low total height? Yes

MAKING MODERN LIVING POSSIBLE Data sheet Assisted lift operated 2/2-way solenoid valves Type EV250B EV250B with assisted lift can operate from zero and up to 10 bar differential pressure. This 2/2-way

Compact Performance Safety Relief Valves Serie 437 Serie 459 EXTENDED CATALOG The-Safety-Valve.com Valve Finder How to find the right Product Group High operating to set pressure ratio, high backpressure

Type 3353 Angle Seat Valve Application On/off valve with pneumatic piston actuator Nominal size DN 15 to 50 (NPS ½ to 2) Nominal pressure PN Temperature range 10 to 180 C Globe valve with an angle seat

0E0-GB PRESSURE REDUCING VAVES MAIN FEATURES The pressure reducing valve is able, by varying its pressure drops, to hold the downstream pressure of the fluid at a constant level against changes in the

Data sheet Solenoid valves EVU EVU solenoid valves are designed to fit into compact refrigeration systems. Available in direct and pilot operated versions, they can be applied in liquid, suction, and hot

Pneumatic Shut-off Butterfly Valve Type 3335/31a SRP or DAP Application Tight-closing butterfly valve for process engineering and industrial applications DN 50 to 300 NPS 2 to 12 Nominal pressure PN 10

OPTIONS: USE: AVAILABLE MODELS: Pilot Operated Pressure Reducing Valve PRV 47 (Steel) PRV47I (St.Steel) DESCRIPTION The ADCA PRV47 pilot operated pressure reducing valves are designed for use on steam,

3/2-way Solenoid Valve, direct-acting, NC or NO Electrical connection cable plug, Form A With or without manual override as standard Threaded port and sub-base s Impulse optional Type 6014 can be combined

- for 2-way valves RAV-/8 (PN 10), VMT-/8 (PN 10), VMA (PN 16) Description RAVV can be combined with 2-way valves RAV- /8, VMT-/8 or VMA 15. Controller closes on rising temperature. There is a special

- for 2-way valves RAV-/8 (PN 10), VMT-/8 (PN 10), VMA (PN 16) - for 3-way valves KOVM (PN 10), VMV (PN 16) Description RAVK can be combined with: - 2-way valves RAV-/8, VMT-/8, VMA, or - 3-way valves

- for 2-way valves RAV-/8 (PN 10), VMT-/8 (PN 10), VMA (PN 16) - for 3-way valves KOVM (PN 10), VMV (PN 16) Description RAVK can be combined with: - 2-way valves RAV-/8, VMT-/8, VMA, or - 3-way valves

3 WAY (3/2) POPPET VALVES FOR AIR AND VACUUM SERVICE SOLENOID OR AIR ACTUATED BROCHURE N-223 HERION S HIGH PERFORMANCE POPPET VALVES For those applications requiring high Cv, fast response times, large

NELES SOFT SEATED BUTTERFLY VALVE SERIES MAPAG BA FOR PSA PLANT ON/OFF AND CONTROL SERVICE Series Mapag BA is a wafer type butterfly valve with a one piece body and soft seat.. It is specially designed

CRANE Σελίδα από 2 DM93 Variable Orifice Double Regulating Valve PN6 Cast Iron Balancing Valve (VODRV), Flanged to BSEN 92-2 The DM93 variable orifice double regulating valves will give satisfactory performance

Order Code for VESTA Sterile Valves Type H_A 2/2 Way Seat Valve engineering for a better world GEA Mechanical Equipment VESTA Sterile Valves are designed for universal use in sterile process technology.

Product Bulletin D103345X012 Baumann 87000 Flexsleev Sanitary Control Valve The Baumann 87000 control valve (figures 1 and 2) is excellent for throttling high purity liquid or gaseous media commonly found

Type 3244-1 and Type 3244-7 Pneumatic Control Valves Type 3244 1 (left) and Type 3244-7 (right) Mounting and Operating Instructions E 8026 EN Edition July 2014 Definition of signal words DNGER! Hazardous

RADIATOR VALVES / MANIFOLD ASSEMBLIES AND DIVERTERS MANIFOLD ASSEMBLIES ONE-PIPE Compatible with most radiators on the market, this pre-assembled manifold for one-pipe radiator systems delivers balancing

Diaphragm Valve SISTO-16TWA/HWA/DLU PN16 DN 15-200 Maintenance-free Flanged Ends Type Series Booklet Legal information/copyright Type Series Booklet SISTO-16TWA/HWA/DLU All rights reserved. The contents

Instruction Manual Alfa Laval SB Membrane Sample Valve ESE02963-EN1 2015-10 Original manual Table of contents The information herein is correct at the time of issue but may be subject to change without

Automatic valves Actuators Accessories Pneumatic actuators The Original! Technics of the top class. Leaflet no. S1-01e-13 Table of contents Advantages and your benefits...page 3 Figure: actuator...page

Solenoid valves 2/2-way direct-operated Type EV210A Features EV210A NC and NO Very compact valves for industrial application, such as control and dosage For water, oil, compressed air and similar neutral

Safety valves SAFE SAFE SAFE-P (Series 900) (Series 920) SAFE-TC (Series 940) 1.0 General information on operating instructions...2-2 2.0 Notes on possible dangers...2-2 2.1 Significance of symbols...

3/2way Mini Solenoid Valve Directacting 0... bar DN mm... DN mm,,, subbase, banjobolt connection 21mm coil spacing when mounted on manifold Type can be combined with... Type 20 Type 207 Type able plug

Page 1 of 12 TI-S21-07 CH Issue 1 Cert. No. LRQ 0963008 ISO 9001 2-Port Self-acting Temperature Control Valve Selection How to select a system Valve selection: 1. Is the application for heating or cooling?

Type series booklet 8448.1/2-EN--US ISORIA Centered disc butterfly valves with AMRING elastomer liner 240 PSI: 1½ to8 150 PSI : 10 to 24 Design in accordance with ISO 10631 Manual, electrical, pneumatical

Data sheet Flow controller with integrated control valve (PN 16, 5, 40*) AFQM, AFQM 6 - return and flow mounting Description AFQM 6 DN 40, 50 AFQM DN 65-15 AFQM DN 150-50 AFQM(6) is a self-acting flow

Worldwide Contacts www.tyco-fire.com RAPID RESPONSE Model RSV-1 Residential Shut-Off Valve, 1 Inch and 2 Inch (DN25 and DN50) for Dual-Purpose Residential Water Supply General Description The TYCO RAPID

TA-FUS1ON Fully adjustable Kvs control and balancing valves. That s just two good. Supported by the Reece hvac-r network. Through our 36 stores around Australia, Reece hvac-r is committed to supporting

Pneumatic Control and Shut-off Butterfly Valve Pfeiffer Type BR 14b/31a and Type BR 14c/31a Application Tight-closing, double eccentric butterfly valve for process engineering and plants with industrial

Specification: FLANGED END BALL VALVE - Chem Oil s two-piece ball valve has been designed to handle extreme service applications with unsurpassed reliability. Valve body machined from solid wrought material

1. General company and product information 2. Flanged gate valves for water 3. Other gate valves for water 4. Combi valves 5. Service connection valves for water 6. Valves and fittings for gas 7. Fire

2 WAY (2/2) AND 3 WAY (3/2) BRASS AND STAINLESS STEEL SOLENOID VALVES DIRECT ACTING Brochure N-289 SPECIFICATIONS Port Size: 1/8 and1/4 Solenoid Valve for air, oil, water and other fluids Flow Direction:

VALVES FOR REFRIGERATING SYSTEMS FROM QUALITY OUR NATURAL DEVELOPMENT Achieved the goal of fi fty years working in the industry of Refrigeration and Air Conditioning, Castel Quality Range of Products is

System 8 ü www.nassmagnet.com ( +9 11 7-0 System 8 The name System 8 stands for a modular system of solenoid coils, armature systems, solenoid operators and solenoid valves. The diameter of the armatures

4/2-Way Pneumatic Solenoid Valve Robust servo assisted piston valve Service friendly manual override Single or block assembly Explosion-proof versions Type 5413 cam be combined with Type 2508 Cable plug

- for 2-way valves RAV-/8 (PN 10), VMT-/8 (PN 10), VMA (PN 16) - for 3-way valves KOVM (PN 10), VMV (PN 16) Description RAVI is self-acting thermostatic actuator primarily for use for temperature control

MAIN FEATURES The pneumatic S GATE knife gate valve is intended for the automatic shut off of pipes of the heavy fluids like slurries and powders. The main fields of application are the water treatment,

+SBF CARBON STEEL Type: ball valve SBF ANSI B16.5 Body: round Material: A105/F316 Ball seats: from DN13 up to DN150 O-Rings: NBR, FKM, EPDM, MVQ Operating pressure: 20 Bar - 50 Bar - 100 Bar 150 Bar -

Valve series MN-06 acc. to NAMUR, 3/2-way G1/4 750 Nl/min (0.762 Cv) Order code Series and function 1) Plug socket see page 5.042. MN-06-310-HN-442 Standard coil 1) 441 = 12 V DC, 4.2 W 442 = 24 V DC,

Product Bulletin D1039X012 24003 Valve Baumann 24003 3 Way Bronze or Stainless Steel Control Valve 3 Way Rugged Industrial Control Valve For Mixing and Diverting Applications The Baumann 24003 3 way control

OWNER S MANUAL Model MH1230 Important Safety Instructions Assembly Instructions Parts and Hardware Identification Pallet Jack CAUTION: Read, understand and follow ALL instructions before using this product

Cable Plug acc. to DIN EN 175301-803, Form A Complete program Contact form 18 mm Also available with LED indicator Optional 4-pin version for pressure switch or impulse valves respectively Versions with

A comprehensive range of pneumatic actuators, conforming to EN ISO 5211, providing compact, reliable and economical powered operation for all types of quarter turn valves. Features Mounting to valve either

M & S Sikkerheds - og Overtryksventiler/ M & S Safety - and Relief Valves - Side 1. Issue AB:06-2012 255 HyCom Fjedersikkerhedsventil / HyCom-Safety Valve Spring Loaded - Manuel / Manual - For gasarter,

ARI-EURO-WEDI Stop valve with soft seal Free of maintenance stop valve - soft sealed (to 120 C) ARI-EURO-WEDI - Fig. 070 Page 2 ARI-EURO-WEDI - Fig. 071 Page 2 ARI-EURO-WEDI - Hood valve Fig. 070 Fig.

Data Sheet Thermostatic Sensor RAS-C² with RA-FN Radiator Valve (Fixed Capacity) Application RAS-C² thermostatic sensor RA-FN angle valve The RAS-C² thermostatic sensor is a selfactuating proportional

Telescoping Post Indicator Wall Post KENNEDY VALVE ISO 9000 ISO 14001 Telescoping Post Indicator 2945 A 1" SQUARE STEM 9" MAX. = 10" MIN. = 7" FIELD ADJUSTMENT INSTRUCTIONS 1. Remove the top section from

Operation Installation and Maintenance Instructions Pressure regulating valve with modulating kit, type DRV hp-technik GmbH Industriepumpen-Förderaggregate und Anlagenbau Gablonzer Straße 21 D-76185 Karlsruhe

BALLOMAX PN6 / 40, DN 0-50 helsvejset stålkugleventil Fully-welded steel ball valve 0 2 3 6 4 7 5 A B 2 3 4 5 6 Benævnelse Materiale Article Material Svejseende Stål St 37.0 Welding end Steel St 37.0 A

8613371530291

8613371530291