north america safety valve quotation

Of all the challenges you face keeping your customers’ plants operating at full capacity, safety and relief valves shouldn’t be one of them. NASVI’s job is to give you the confidence that your valve supply chain is rock solid regardless the pressure it’s under.

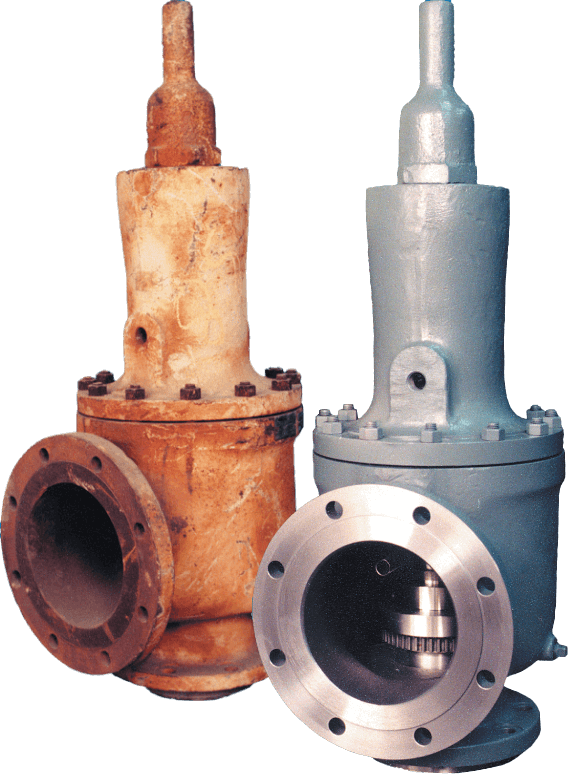

A customer urgently needed information on the availability of five 4-inch liquid flanged valves. Unfortunately, the end user had ordered the wrong valves and desperately needed the correct ones right away. NASVI not only had them in stock, but also shipped the valves same day. It was a happy ending to the customer’s frustrating day of tracking down the valves only to hear there was a six-week lead time. It’s why our customers’ call NASVI, their trusted safety valve distributor, first.

When the pressure is on, you can count on us to come through with 35,000 safety valves in stock shipped same or next-day. When there are unknowns involved, our experienced applications engineers guide you to the right valve make and model so you can be your customers’ hero.

Safety valve is a type of valve that automatically actuates when the pressure of inlet side of the valve increases to a predetermined pressure, to open the valve disc and discharge the fluid and when the pressure decreases to the prescribed value, to close the valve disc again. It is called a safety valve as a final safety device which control the pressure and discharges.

Distributor of hydraulic press safety, quick opening safety, rotary and safety valves. Amerigear®, Boston Gear®, Carlisle®, DeMag®, Desch® and IMI Norgren®, pneumatic, double action, quick release and flow control valves also provided. Repair and preventative maintenance services are offered. Value added services such as custom barcoding, CAD capabilities, OEM assembly, plant surveys and third party logistics are also available. Serves the metal processing, metal service center, paper mill and paper converting, canning, grinding, commercial laundry, marine, oil and gas and material handling industries. Vendor managed inventory (VMI) programs available. Kanban delivery.

Solenoid directional valves and cartridges with inductive sensors to monitor the spool/poppet position, certified to Machine Directive 2006/42/EC. Pressure relief valves certified to PED 2014/68/EU.

Safety valves are an arrangement or mechanism to release a substance from the concerned system in the event of pressure or temperature exceeding a particular preset limit. The systems in the context may be boilers, steam boilers, pressure vessels or other related systems. As per the mechanical arrangement, this one get fitted into the bigger picture (part of the bigger arrangement) called as PSV or PRV that is pressure safety or pressure relief valves.

This type of safety mechanism was largely implemented to counter the problem of accidental explosion of steam boilers. Initiated in the working of a steam digester, there were many methodologies that were then accommodated during the phase of the industrial revolution. And since then this safety mechanism has come a long way and now accommodates various other aspects.

These aspects like applications, performance criteria, ranges, nation based standards (countries like United States, European Union, Japan, South Korea provide different standards) etc. manage to differentiate or categorize this safety valve segment. So, there can be many different ways in which these safety valves get differentiated but a common range of bifurcation is as follows:

The American Society of Mechanical Engineers (ASME) I tap is a type of safety valve which opens with respect to 3% and 4% of pressure (ASME code for pressure vessel applications) while ASME VIII valve opens at 10% over pressure and closes at 7%. Lift safety valves get further classified as low-lift and full lift. The flow control valves regulate the pressure or flow of a fluid whereas a balanced valve is used to minimize the effects induced by pressure on operating characteristics of the valve in context.

A power operated valve is a type of pressure relief valve is which an external power source is also used to relieve the pressure. A proportional-relief valve gets opened in a relatively stable manner as compared to increasing pressure. There are 2 types of direct-loaded safety valves, first being diaphragms and second: bellows. diaphragms are valves which spring for the protection of effects of the liquid membrane while bellows provide an arrangement where the parts of rotating elements and sources get protected from the effects of the liquid via bellows.

In a master valve, the operation and even the initiation is controlled by the fluid which gets discharged via a pilot valve. Now coming to the bigger picture, the pressure safety valves based segment gets classified as follows:

So all in all, pressure safety valves, pressure relief valves, relief valves, pilot-operated relief valves, low pressure safety valves, vacuum pressure safety valves etc. complete the range of safety measures in boilers and related devices.

Safety valves have different discharge capacities. These capacities are based on the geometrical area of the body seat upstream and downstream of the valve. Flow diameter is the minimum geometrical diameter upstream and downstream of the body seat.

The nominal size designation refers to the inlet orifice diameter. A safety Valve"s theoretical flowing capacity is the mass flow through an orifice with the same cross-sectional area as the valve"s flow area. This capacity does not account for the flow losses caused by the valve. The actual capacity is measured, and the certified flow capacity is the actual flow capacity reduced by 10%.

A safety valve"s discharge capacity is dependent on the set pressure and position in a system. Once the set pressure is calculated, the discharge capacity must be determined. Safety valves may be oversized or undersized depending on the flow throughput and/or the valve"s set pressure.

The actual discharge capacity of a safety valve depends on the type of discharge system used. In liquid service, safety valves are generally automatic and direct-pressure actuated.

A safety valve is used to protect against overpressure in a fluid system. Its design allows for a lift in the disc, indicating that the valve is about to open. When the inlet pressure rises above the set pressure, the guide moves to the open position, and media flows to the outlet via the pilot tube. Once the inlet pressure falls below the set pressure, the main valve closes and prevents overpressure. There are five criteria for selecting a safety valve.

The first and most basic requirement of a safety valve is its ability to safely control the flow of gas. Hence, the valve must be able to control the flow of gas and water. The valve should be able to withstand the high pressures of the system. This is because the gas or steam coming from the boiler will be condensed and fill the pipe. The steam will then wet the safety valve seat.

The other major requirement for safety valves is their ability to prevent pressure buildup. They prevent overpressure conditions by allowing liquid or gas to escape. Safety valves are used in many different applications. Gas and steam lines, for example, can prevent catastrophic damage to the plant. They are also known as safety relief valves. During an emergency, a safety valve will open automatically and discharge gas or liquid pressure from a pressurized system, preventing it from reaching dangerous levels.

The discharge capacity of a safety valve is based on its orifice area, set pressure, and position in the system. A safety valve"s discharge capacity should be calculated based on the maximum flow through its inlet and outlet orifice areas. Its nominal size is often determined by manufacturer specifications.

Its discharge capacity is the maximum flow through the valve that it can relieve, based on the maximum flow through each individual flow path or combined flow path. The discharge pressure of the safety valve should be more than the operating pressure of the system. As a thumb rule, the relief pressure should be 10% above the working pressure of the system.

It is important to choose the discharge capacity of a safety valve based on the inlet and output piping sizes. Ideally, the discharge capacity should be equal to or greater than the maximum output of the system. A safety valve should also be installed vertically and into a clean fitting. While installing a valve, it is important to use a proper wrench for installation. The discharge piping should slope downward to drain any condensate.

The discharge capacity of a safety valve is measured in a few different ways. The first is the test pressure. This gauge pressure is the pressure at which the valve opens, while the second is the pressure at which it re-closes. Both are measured in a test stand under controlled conditions. A safety valve with a test pressure of 10,000 psi is rated at 10,000 psi (as per ASME PTC25.3).

The discharge capacity of a safety valve should be large enough to dissipate a large volume of pressure. A small valve may be adequate for a smaller system, but a larger one could cause an explosion. In a large-scale manufacturing plant, safety valves are critical for the safety of personnel and equipment. Choosing the right valve size for a particular system is essential to its efficiency.

Before you use a safety valve, you need to know its discharge capacity. Here are some steps you need to follow to calculate the discharge capacity of a safety valve.

To check the discharge capacity of a safety valve, the safety valve should be installed in the appropriate location. Its inlet and outlet pipework should be thoroughly cleaned before installation. It is important to avoid excessive use of PTFE tape and to ensure that the installation is solid. The safety valve should not be exposed to vibration or undue stress. When mounting a safety valve, it should be installed vertically and with the test lever at the top. The inlet connection of the safety valve should be attached to the vessel or pipeline with the shortest length of pipe. It must not be interrupted by any isolation valve. The pressure loss at the inlet of a safety valve should not exceed 3% of the set pressure.

The sizing of a safety valve depends on the amount of fluid it is required to control. The rated discharge capacity is a function of the safety valve"s orifice area, set pressure, and position in the system. Using the manufacturer"s specifications for orifice area and nominal size of the valve, the capacity of a safety valve can be determined. The discharge flow can be calculated using the maximum flow through the valve or the combined flows of several paths. When sizing a safety valve, it"s necessary to consider both its theoretical and actual discharge capacity. Ideally, the discharge capacity will be equal to the minimum area.

To determine the correct set pressure for a safety valve, consider the following criteria. It must be less than the MAAP of the system. Set pressure of 5% greater than the MAAP will result in an overpressure of 10%. If the set pressure is higher than the MAAP, the safety valve will not close. The MAAP must never exceed the set pressure. A set pressure that is too high will result in a poor shutoff after discharge. Depending on the type of valve, a backpressure variation of 10% to 15% of the set pressure cannot be handled by a conventional valve.

Shipment: All products and/or services covered by the quotation are sold F.O.B. either our plant in Linden, NJ or the manufacturer"s plant for the parts and/or valves required, unless otherwise indicated. The risk of loss or damage in transit will be upon the purchaser. The products will be prepared for shipment in a manner prescribed by us or the manufacturer and shipped by any public carrier which we deem satisfactory, unless the purchaser provides other specific shipping instructions when placing orders. Any date provided by us for completion of work or for shipment is intended as an estimate only and is not to be deemed a term of the quotation. Shipping charges shall be pre-paid and billed at the time of shipment.

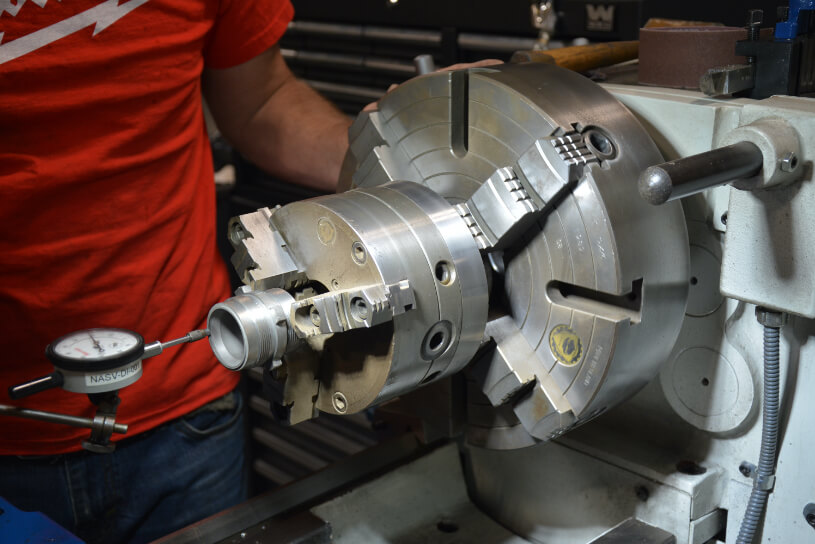

Warranties and Limitations: We warrant only that our products will conform to their description herein and that at the time of sale our products will be free from defects on workmanship and material. The name and reputation of Certified Valve Repair stands prudently behind every valve or piece of equipment we recondition. We are valve repair specialists, if at any time, in any way, a valve or piece of equipment that we have repaired fails to provide complete satisfaction, please bring the matter to our attention. Every repaired valve, pump, instrument, or equipment when used in accordance with the manufacturer and our recommendations is guaranteed to be free from defective workmanship and material. We will repair or replace without charge, F.O.B. our plant any repaired unit which our own examination proves to be defective within a period stated by our firm at the time of delivery. We assume no responsibility for incidental damage or expense. Authorization is required before returned articles will be accepted.

Standard materialsinclude 316 stainless steel bodies and removable seat glands with 17-4PH stainless steel removable stem and stem seats. Standard O-ring material on the stem is Viton Valves may be used up to 400° F.

Inlet connections are for 9/16" O.D. tubing (HF9) with adapters for other sizes available. Outlet connections are 1/2" NPT. These valves are not recommended for use below 1,500 psi, and are not readily adjustable in the field without proper test equipment. Pressure settings are made at the factory and valves are tagged accordingly.

HiP relief valves are now available with CE marking. These products will proudly be marked with the CE symbol, signifying they comply with the stringent requirements of the Pressure Equipment Directive (PED). To order, add -CE to your relief valve part number.

Standard materials include 316 stainless steel bodies and removable seat glands with 17-4PH stem and seal ring. Standard O-ring material on the stem is Viton. The seat material is Peek. Valves may be used up to 400°F with standard Vtion O-ring or 450°F with the Kalrez O-ring option.

Inlet connections are for 9/16" O.D. tubing (HF9) with adapters for other sizes available. Outlet connections are 1/2" NPT. These valves are not recommended for use below 1,500 psi, and are not readily adjustable in the field without proper test equipment. Pressure settings are made at the factory and valves are tagged accordingly.

HiP relief valves are now available with CE marking. These products will proudly be marked with the CE symbol, signifying they comply with the stringent requirements of the Pressure Equipment Directive (PED). To order, add -CE to your relief valve part number.

HiP relief valves are now available with CE marking. These products will proudly be marked with the CE symbol, signifying they comply with the stringent requirements of the Pressure Equipment Directive (PED). To order, add -CE to your relief valve part number.

Fluidyne BoilerFull Lift Full Flow Safety Relief Valve is a high performance valve designed and developed for steam and water service. It can also be used for most other applications like gases and vapors, saturated steam, superheated steam. Fluidyne Safety Relief Valve is designed for steam service. The valves are designed as per API 520, API 526 and meets the requirements of ASME Sec VIII-Division I. Fluidyne Boiler Safety Valves are offered with IBR Certification in Form III-C. The valves have a full nozzle or half nozzle and guided at the guide of the valve body, increasing the eficiency of the valve assembly. Specially designed disc holder ensures full lift within 5% to 10% overpressure or increase of pressure above the set pressure value. Blow down of a maximum of 5% to 10% is achieved in this design. Lapping of valve seat to optical flatness ensures leak tightness at seat. Full lift of valve disc ensures that the certified flow of the safety valve is discharged. Spring made of chrome vanadium steel is precisely selected and assembled so that the valve operates precisely and a good leak tightness is achieved at high temperatures with great repeatability.

Pressure Safety Valve Market research report offers updates on Business Strategies including Mergers, Acquisitions, Partnerships, R and D, Expansion Plansand Collaborations adopted by theseMajor Global Players,Revenue by Type (Spring Operated Valve, Pilot Operated Valve, Dead Weight Valve), Forecasted Market Size by Application (Oil and Gas, Power and Energy, Healthcare and Pharmaceutical, Water Supply System, Others)

Pressure Safety Valve Market Size (sales, revenue) forecast by regions and countries from 2023 to 2027 of Pressure Safety Valve industry.The detailed information is based on current trends and historic milestones. This section also provides an analysis of the volume of production about the global market and about each type from 2017 to 2027. This section mentions the volume of production by region from 2017 to 2027. Pricing analysis is included in the report according to each type from the year 2017 to 2027, manufacturer from 2017 to 2023, region from 2017 to 2023, and global price from 2017 to 2027.Pressure Safety Valve Market Share, distributors, major suppliers, changing price patterns and the supply chain of raw materials is highlighted in the report.

Industrial valves comprise many products that manage the flow of gases and fluids in industrial applications. Among these, pressure safety valves are designed for process control, process safety, original equipment manufacturer (OEM) applications, and others across several end-user industries.These valves prevent the over-pressurization of pressure-based equipment and machineries by sensing and subsequently guiding the additional surge in pressure towards alternate passages or into atmosphere. As a result, they are used in steam boilers, heating boilers, pressure-based vessels and systems, OEM applications, industrial machineries, and other applications. The valve design and construction are varied to have a manual or automatically-operated opening and closing of valves at working settings during the system operation.

Market Analysis and Insights: Global Pressure Safety Valve MarketThe global Pressure Safety Valve market is valued at USD 45 million in 2019. The market size will reach USD 51 million by the end of 2026, growing at a CAGR of 1.6% during 2021-2026.Global Pressure Safety Valve

This report provides an all-inclusive assessment of the analysis for the Global Pressure Safety Valve Market. The market estimates provided in the report are the result of in-depth secondary research, primary interviews and in-house expert reviews. These market estimates have been considered by studying the impact of various social, political and economic factors along with the current market dynamics affecting the Global Pressure Safety Valve Market growth

Along with the market overview, which comprises of the market dynamics the chapter includes a Porter’s Five Forces analysis which explains the five forces: namely buyers bargaining power, suppliers bargaining power, threat of new entrants, threat of substitutes, and degree of competition in the Global Pressure Safety Valve Market. It explains the various participants, such as system integrators, intermediaries and end-users within the ecosystem of the market. The report also focuses on the competitive landscape of the Global Pressure Safety Valve Market.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Pressure Safety Valve in these regions, from 2017 to 2027, covering ● North America (United States, Canada and Mexico)

The market analysis entails a section solely dedicated for major players in the Global Pressure Safety Valve Market wherein our analysts provide an insight to the financial statements of all the major players along with its key developments product benchmarking and SWOT analysis. The company profile section also includes a business overview and financial information. The companies that are provided in this section can be customized according to the client’s requirements.

The global Pressure Safety Valve market Growth is anticipated to rise at a considerable rate during the forecast period, between 2023 and 2027. In 2023, the market was growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.Pressure Safety Valve Market Forecast by regions, type and application, with sales and revenue, from 2023 to 2027.

Pressure Safety Valve Market Report also mentions market share accrued by each product in the Pressure Safety Valve market, along with the production growth.Pressure Safety Valve Market Trend for Development and marketing channels are analysed. Finally, the feasibility of new investment projects is assessed and overall research conclusions offered. Pressure Safety Valve Market Analysis Report focuses on Pressure Safety Valve Market key trends and Pressure Safety Valve Market segmentation (Types,Application),and all the regions.

The Pressure Safety Valve market report offers major growth drivers, restraining factors, opportunities, and potential challenges for the market. Comprehensive insights into regional developments are explained in-depth in the study. It also includes a list of major market players as well as strategies adopted by them to stay ahead of the competition. The latest industry developments such as product launches, partnerships, mergers, and acquisitions are listed in the report. The study also offers a detailed understanding of the recent COVID-19 pandemic on the Pressure Safety Valve market. The ongoing recession and inflation as well as their impact on the market have been assessed in our latest research report.

Study Objectives of this report are: ● To study and analyze the global Pressure Safety Valve market size (value and volume) by company, key regions/countries, products and application, history data from 2017 to 2020, and forecast to 2027.

● Focuses on the key global Pressure Safety Valve manufacturers, to define, describe and analyze the sales volume, value, market share, market competition landscape, SWOT analysis and development plans in next few years.

8613371530291

8613371530291