north american safety valve industries inc price

Of all the challenges you face keeping your customers’ plants operating at full capacity, safety and relief valves shouldn’t be one of them. NASVI’s job is to give you the confidence that your valve supply chain is rock solid regardless the pressure it’s under.

Expect expert service, the most extensive inventory in the nation and emergency service whenever needed. That’s how we’ve got our customers’ backs since 1975.

A customer urgently needed information on the availability of five 4-inch liquid flanged valves. Unfortunately, the end user had ordered the wrong valves and desperately needed the correct ones right away. NASVI not only had them in stock, but also shipped the valves same day. It was a happy ending to the customer’s frustrating day of tracking down the valves only to hear there was a six-week lead time. It’s why our customers’ call NASVI, their trusted safety valve distributor, first.

When the pressure is on, you can count on us to come through with 35,000 safety valves in stock shipped same or next-day. When there are unknowns involved, our experienced applications engineers guide you to the right valve make and model so you can be your customers’ hero.

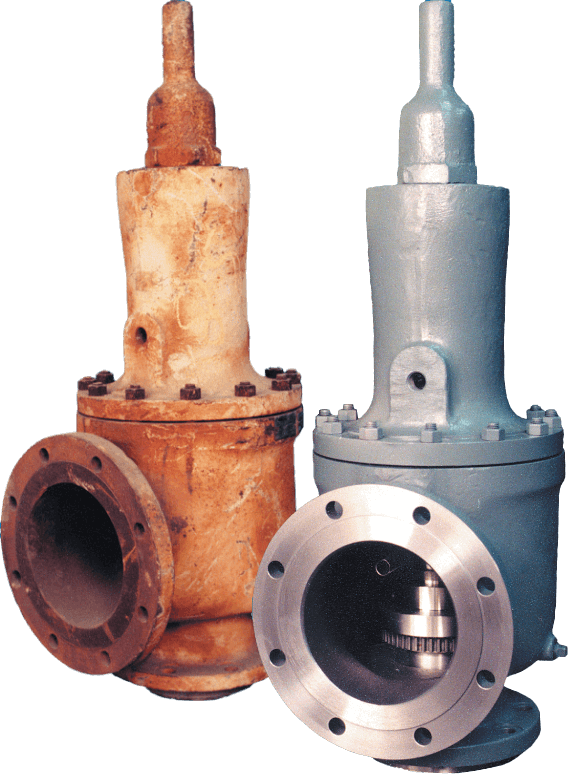

Choosing remanufactured safety and relief valves is a smart alternative for saving money and minimizing down time. It makes good sense for the majority of industrial uses because they are:

How much time and money have you lost because of price, availability and delivery times associated with new safety valves? Get production back up to speed affordably and confidently with remanufactured valves.

If a remanufactured valve doesn’t meet your expectations for any reason, within 5 days of receipt and prior to installation, return it for full credit plus shipping and return freight costs.

Kunkle Relief Valve OverviewWhen it comes to industrial and commercial safety and relief valve products, Kunkle’s valve’s catalog is second to none in steam, air, gas, and liquid applications.

Kunkle relief valves range in size from ¼” NPT to 6” flange and are suitable in cryogenic and high temperatures up to 800°F environments at vacuum to 7,500 psig pressure. Kunkle Valve’s code certifications meet several global and national board standards, including ASME Section I, Section IV, and Section VIII, PED, CRN, TU and Chinese, as well as non-code requirements.

Relief Valves for Steam ServiceSteam supplies heat for industrial and chemical processes and also is used to heat buildings, supply mechanical energy, and drive mechanical equipment. Steam moves from the boiler to the end point, then heats by direct heating or indirect heating through a heat exchanger. Kunkle steam relief valves are critical to protecting equipment such as boilers, steam lines, and pressure valves, from being over-pressurized.

Relief Valves for Air ServiceKunkle designs valves for air service, for example for air compressors in mechanical shops and small factories where either low-pressure or high-pressure air is required. NASVI stocks Kunkle relief valves for air service in iron, steel and bronze for a variety of uses.

Relief Valves for Liquid ServiceKunkle also makes valves for liquid service, which provide bypass relief in a variety of applications and liquid types.

More About KunkleKunkle Valve is a renowned pressure relief valve manufacturer. Erastus B. Kunkle invented the safety valve to prevent overpressure in locomotive engines. Kunkle patented it in 1875. Since that time, Kunkle has earned its reputation for high-quality valves, and other equipment manufacturers ship their products with Kunkle’s valves pre-installed.

NASVI has stocked Kunkle safety relief valves since we opened in 1975, so we are confident when we call ourselves Kunkle safety valve experts. Every day we fulfill orders for our customers looking for Kunkle relief valves for steam, air, gas, and liquid applications.

You don’t have to be an expert in the field of safety and relief valves to sell them because that’s our job. And we’re only a phone call away. We’ll help you select the proper valve and give an immediate price quote on the phone. The sole responsibility of our dedicated application engineers is to take care of your requirements.

We will help you with sales planning, product selection and after-sale service when needed. We will even provide you with catalogs that have no reference to NASVI. Place your company’s sticker on it and you’ll have your own safety valve catalog to pass out to your customers … and it costs you nothing.

Our commitment is to you. Our goal is to help you exceed your customer’s requirements – from quality products to on-time delivery backed by quick and accurate customer service. We carry all makes of safety and relief valves in our extensive inventory – from the common to hard to find. And same-day shipping is the rule, not the exception.

Our repair service center is designed to keep your customer’s safety and relief valves at peak operating efficiency. And put extra profits in your pocket.

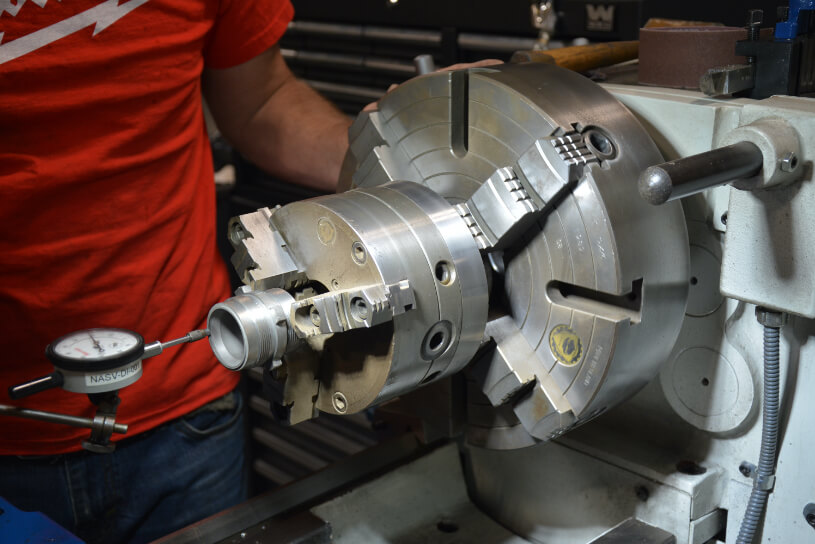

North American’s Service Center is equipped to handle any safety valve repair. NASVI has the specifications for nearly every safety valve ever made—allowing technicians to make repairs to exact specifications. The center has six lathes on site, so technicians can restore tolerances on existing parts in quick order. If a part cannot be restored, it can generally be replaced from our extensive parts inventory.

Once repairs are complete, valves are tested and then set at one of six, fully equipped test stations. The boiler is on every day for testing steam valves. It’s always ready, allowing us to set and ship your valves fast.

Over the years, our Service Center has proven popular with maintenance managers. It allows the plant to have their valves repaired, serviced and set quickly, which minimizes downtime. They also like the service because it saves them money.

Our repair service also includes updating the valve to the latest design standard when necessary. All valves serviced in our repair facility carry a one-year standard warranty. North American holds ASME’s V and UV stamps and National Board’s NB and VR stamps. The next time your customer has questions about repairing or upgrading their safety or relief valves, give one of our application engineers a call.

With North American’s Service Center, you can maximize your customer’s uptime while saving both time and money. Make our Service Center your service center. Just one call will provide quick solutions to all your repair needs. An application engineer will work directly with you to customize a program to meet your customer’s needs.

You don’t have to be an expert in the field of safety and relief valves to sell them. We are here to help. Our goal is to make it easy for you to profit from the sales of safety and relief valves. Our expertise comes from taking care of our customers for over 42 years. And our large inventory allows us to offer same day shipment from stock on every valve Kunkle makes.

The sole responsibility of our dedicated applications engineers is to take care of your requirements. We will help you with sales planning, product selection and after sale service when needed. We will even provide you with catalogs that have no reference to NASVI. Our valuable advice is free and as close as your phone. So the next time your customer calls and needs a safety or relief valve, call a NASVI Applications Engineer.

They’ll have a quick answer on price, availability and shipment. When it comes to selling safety valves, you don’t have to stock anything. Simply call 1-800-800-8882 or visit us on the web at www.nasvi.com. We’ll make it easy for you!

Our two-truck unit responds to customer requests anywhere, offering on-site repair and resetting of safety valves during scheduled maintenance shutdowns.

Step into the mobile repair unit and you’ll find all the equipment necessary to perform highest-caliber repairs: sand blaster, compressor, lathe, mill/drill press, lapping machine–-it’s all inside. There’s also a Consolidated® seat-resurfacing machine with all adapters for every orifice in the Maxi-Flow® boiler line. Completed valve work will carry the VR stamp.

The Field Service Unit also includes a state of-the-art computerized lift-assist testing unit that allows for testing set pressures and resetting high-pressure safety valves in the field. The testing unit makes testing valves that are welded in-line or stationary possible without removing the valves. Your customers won’t be required to pressure down or increase pressure to test for set pressure. The lift assist testing unit also allows for resetting valves after repairs have been made while the valves are on-line.

If you have prospects or customers that bought their replacement valves elsewhere because you haven’t been able to provide on-site service, you will want to get back with them and talk about this service. If you have questions about pricing and scheduling of our Field Service Unit, give us a call at (800) 800-8882.

AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCabo VerdeCambodiaCameroonCanadaCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos IslandsColombiaComorosCongoCongo, Democratic Republic of theCook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzechiaCôte d"IvoireDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly SeeHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People"s Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People"s Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRomaniaRussian FederationRwandaRéunionSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint MartinSaint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwedenSwitzerlandSyria Arab RepublicTaiwanTajikistanTanzania, the United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkmenistanTurks and Caicos IslandsTuvaluTürkiyeUS Minor Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVenezuelaViet NamVirgin Islands, BritishVirgin Islands, U.S.Wallis and FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

Pressure relief valves are designed to protect equipment from overpressure. The valve should be handled with care, not subject to heavy shock loads, and protected to prevent dirt from getting inside. Failure to do so could result in property damage or serious injury to personnel.

Mount the valve in a vertical position so that the valve body is self-draining. If a body drain port is provided, make sure it is open when required by the ASME code. Do not plug any bonnet vent openings. The inlet piping should be as short as possible, with no elbows, and equal to or greater than the size of the pressure relief valve inlet connection. This will help limit the inlet pressure drop to 3% or less when the valve is relieving.

When discharge piping is connected to valve outlet, make sure it is self-draining when a body drain port is not used. The valve should not be connected to any discharge pipe that contains pressure before the valve opens or to any pipe where the pressure build-up is greater than 10% of the set pressure when the valve is open and relieving. Discharge piping other than a short tailpipe must be supported by something other than the valve. For steam service, a drip pan elbow or flexible connection between the valve and the pipe should be used to prevent excessive pipe stress, due to thermal expansion, from being imposed on the valve body.

For threaded valves, apply a small amount of pipe thread sealing compound to external threads only. Do not put any sealing compound on the first thread or any internal threads. To do so may cause the sealing compound to enter the valve and cause seat leakage. Use wrench flats provided to tighten the valve to the connecting pipe. Do not use the valve body or bonnet and do not over-tighten. To do so may cause valve leakage.

Maintain a system operating pressure at least 5 psig or 10% below the set pressure of the valve – whichever is greater. Operating too close to the valve set pressure will cause seat leakage and will shorten the time between valve maintenance.

Do not use the safety valve as a control valve to regulate system operating pressure. Excessive operation will cause the seat to leak and will require more frequent valve maintenance.

ASME Code-stamped valves equipped with lift levers are designed to be operated only when the system pressure is 75% of the set pressure or greater. When hand operating the valve, hold it open long enough to purge any foreign matter from the seat area. If a cable or wire is attached to the lift lever for remote actuation, make sure the direction of pull is the same as it would be if the lever were pulled directly by hand.

Maintenance should be performed on a regular basis. We recommend an initial inspection interval of 12 months. Depending on the service conditions and the condition of the valve, the suggested inspection interval may decrease or increase.

NASVI’s 100,000 sq. ft. warehouse is stocked with 35,000 ready-to-ship valves from the world’s most trusted brands. Plus, decades of helping with sales planning, valve selection and post-sale service makes NASVI your single source for new safety relief valves.

In business since 1975 and a team of factory-trained technicians, they feel confident calling ourselves safety valve experts. Employees are long-timers, and what they know comes in handy when you or your end user has questions about or problems with safety valves.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Allied Valve is the industry leader in valve sales, service, and distribution. Driven by three key principles – safety, reliability, and quality – Allied Valve is a leading supplier of pressure relief valves, control valves, rupture discs, conservation vents, flame arresters, blanket gas regulators, back pressure valves, actuation, and valve services in the upper Midwest. Helping your business meet tight production schedules and reduce downtime with 24/7/365 services delivered on-time, on-site, and in-person, Allied Valve is your trusted partner to keep your business running seamlessly.

Our factory-trained, OEM-certified technicians deliver time-tested solutions that reduce downtime and costs while maintaining the integrity of your safety program. With locations in IA, IL, IN, MN, ND, OH, and WI, our 100+ certified service technicians are at your service. We operate five Consolidated Green Tag Centers, two authorized Kunkle Assemblers plants, and five Masoneilan™ Authorized Repair Center (MARC™), dedicated to providing quality products.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

8613371530291

8613371530291