oil line fire safety valve in stock

Fusible valves are approved for kerosene and No. 2 fuel oil. Pressure rated for 10 P.S.I. Valves with standard hand wheel close at about 165 deg. F. ambient temperature. Double seal to prevent stem leaks. All fusible valve rubber washers and o-rings are made of Viton or equivalent material. 3/8" F.

"content":"\u003cp\u003eFusible valves are approved for kerosene and No. 2 fuel oil. Pressure rated for 10 P.S.I. Valves with standard hand wheel close at about 165 deg. F. ambient temperature. Double seal to prevent stem leaks. All fusible valve rubber washers and o-rings are made of Viton or equivalent material. 3\/8\" F.\u003c\/p\u003e",

"description":"\u003cp\u003eFusible valves are approved for kerosene and No. 2 fuel oil. Pressure rated for 10 P.S.I. Valves with standard hand wheel close at about 165 deg. F. ambient temperature. Double seal to prevent stem leaks. All fusible valve rubber washers and o-rings are made of Viton or equivalent material. 3\/8\" F.\u003c\/p\u003e",

[{"id":42893120700650,"title":"Default Title","option1":"Default Title","option2":null,"option3":null,"sku":"463906","requires_shipping":true,"taxable":true,"featured_image":null,"available":true,"name":"OEM 3\/8 In. Female Oil Tank Fusible In-Line Safety Valve","public_title":null,"options":["Default Title"],"price":1699,"weight":0,"compare_at_price":null,"inventory_management":"shopify","barcode":"00662766542967","requires_selling_plan":false,"selling_plan_allocations":[]}]

By isolating burner fuel pumps from supply line pressure sources a supply pump or overhead tank, the osv relieves ores sure strain on fuel pump inlets and seals and prevents tank siphoning and spilling caused by accidental line breaks

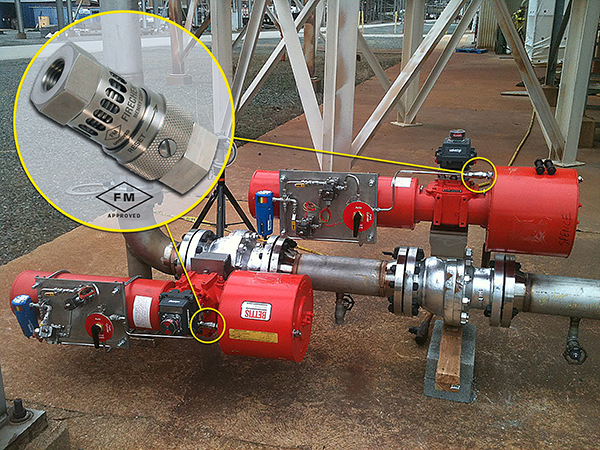

Assured Automation"s FM Fire-Safe Thermal and Electro-Thermal ball valve and butterfly valve assemblies are designed to shut off automatically and control hazardous conditions. The heat actuated, U.L. listed thermal links automatically shut off or open the valve at predetermined temperatures. Ball and Butterfly assemblies are available with manual levers or gear operator which will allow the valve to operate manually at any time without affecting the fusible links or removing the spring loaded canister.

R.W. Beckett’s burner controls were created with customer satisfaction and safety in mind. Our entire suite of burner controls utilizes the most current technology to safely control the combustion process.

We advance safety by finding smarter ways to help safeguard businesses and protect people where they live and work. Using proven and trusted technology, we offer a versatile line of fire valves for diverse applications, including oil and gas, energy and power generation, tunnels and transportation, storage facilities, commercial, industrial, or residential systems.

The Easi Heat Standard Oil Line Fire Valve - 3/8in features a fuseable head and provides protection from fire spreading to the oil tank in the event of a fire breaking out at the boiler. When the valve is subjected to a temperature of about 85 degree Celsius, an inner block is released allowing an integral spring to slam the valve spindle closed and shut off the oil supply. The standard oil line fire valve provides peace of mind in relation to your oil tank in the event of a fire. Replacement hand wheels are easily available.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

One of the more recent developments in industrial tools to prevent fire is the introduction of fire safety valves. These valves are designed to prevent a fire from spreading if the fuel valve gets damaged or causes a leakage.

A valve is a device that adjusts, directs, or controls the flow of a fluid by opening, closing, or partially blocking various passageways. Valves are technically a type of fitting but are usually discussed separately. In an open valve, fluid flows from higher pressure to lower pressure. The simplest kind of valve is simply a freely hinged flap that drops to obstruct flow one way but is pushed open by fluid flowing the opposite way. This ancient valve is called a check valve, as it stops or "checks" the flow in one direction. Modern valves may regulate pressure or flow downstream and operate on sophisticated automation systems.

Valves have industrial applications for controlling processes, residential uses such managing water flow to dish and clothes washers and taps in the home. They are found in almost every industrial process, including mining, water and sewage processing, power generation, food manufacturing, processing of oil, gas and petroleum, chemical and plastic manufacturing, and many other fields.

Fire-safe valves are spring-loaded valves that are thermally actuated. In case of fire, they close automatically and stop the fuel flow. The fuel flow from the crankcase of the engine and the reserve oil supply gets hindered, thus minimizing the chances of leakage.

Spring-loaded valves help with preventing the flow of fuel such as oil, gas, petrol, and other combustibles, and are useful and effective against any damage. The benefits of using fire-safe valves in a system are the protection of human life, lower insurance rates, and the protection of equipment and the building.

It is because of these benefits that the use of these valves is highly recommended and appreciated. These days, many companies offer an extensive range of fire-safety valves to provide protection even in high temperature and high-pressure conditions.

A fire safety valve aims to keep ignitable fluids away from a flame. These valves close when exposed to heat, separating a flammable liquid from the heat source. They close in the midst of overheating of the pipeline, brought on by fire or similar events. The obligation to use fire safety valves is subject to any tenets, regulations, and laws concerning the unique methodology, plant, pipeline, or vessel.

Fire-safe ball valves use a combination of a floating ball, graphoil seals, and metal-to-metal seating to provide tight shut-off while preventing external stem leakage. In normal working conditions, the ball rests against two seats, ensuring bubble-tight closure. When the valve is exposed to a temperature above the limits the seats can withstand (for example, +450°F), the seats become deformed and are subject to extrusion. When the seats have been completely destroyed, the ball in the valve will come to rest firmly against the end cap, producing a metal-to-metal closing. Stem seals, which have high temperature-resistant properties, further restrict leakage in conjunction with a blow-out-proof anti-static stem, so that the flammable fluid stays separate from the heat source that may ignite it.

A fire-safe valve may also be made up of four main mechanisms: a spring pack, a trigger assembly, mounting hardware, and a fusible link. The components work in unison to close the valve should a fire be detected within a facility. The fusible link is the key part of the assembly. It keeps the valve open by maintaining tension on a spring pack through the trigger assembly. When a fire breaks out, the fusible link separates once it is heated to a certain high temperature, which releases the spring pack and allows it to close the valve.

A fire-safety valve with fusible links has a primary drop-tight seat, usually made of TFE, along with a second seat made of metal for isolation in a fire. The secondary seat also has graphite seals for further protection. This means that the shut-off valves can be paired with any quarter-turn ball valve, butterfly valve, or plug valve.

This article presents an understanding of fire safety valves. For more information on related products, consult our other guides or visit the Thomas Supplier Discovery Platform to locate potential sources of supply or view details on specific products.

RM2BHFJN7–Coryton, Stanford-le-Hope, Essex, UK. 25th Apr, 2020. A build up of pressure caused a safety valve to release at a power station (initially thought to be the oil refinery nearby) in Coryton, close to DP World port cranes on the Thames Estuary, creating steam and noise in the area leading people to believe that there had been an explosion. Local fire brigade and emergency services attended

RMT94YD7–Papin holding a diagram of a steam engine, lithograph, 1689. Denis Papin (August 22, 1647 - 1712) was a French physicist, mathematician and inventor. He worked with Robert Boyle from 1676-79, publishing an account of his work in Continuation of New Experiments (1680). During this period, Papin invented the steam digester, a type of pressure cooker with a safety valve.

RMGE4JB3–(September 6, 1963) Vent flowing cryogenic fuel and T/C Rake mounted on a 1/10 scale model Centaur in the l0 x l0 Foot Supersonic Wind Tunnel. The fuel being used is liquid hydrogen. The point of the test is to determine how far to expel venting fuel from the rocket body to prevent explosion at the base of the vehicle. This vent is used as a safety valve for the fumes created when loading the fuel tanks during launch preparation. Liquid hydrogen has to be kept at a very low temperature. As it heats, it turns to gas and increases pressure in the tank. It therefore has to be vented overboard whi

RMMR3WYE–Illustration depicting Papin"s steam engine (1707) for pumping water from mines. It was the first engine to use the safety valve he had invented twenty-seven years earlier for his "digester". (1647-1713) a French physicist, mathematician and inventor, best known for his pioneering invention of the steam digester, the forerunner of the pressure cooker and of the steam engine. Dated 19th century

RM2BHFJR5–Coryton, Stanford-le-Hope, Essex, UK. 25th Apr, 2020. A build up of pressure caused a safety valve to release at a power station (initially thought to be the oil refinery nearby) in Coryton, close to DP World port cranes on the Thames Estuary, creating steam and noise in the area leading people to believe that there had been an explosion. Local fire brigade and emergency services attended

RME14RJF–Apr. 18, 2012 - The main road through the area is always busy: The gaunt, Barren Hills are a constant reminder of the wilderness of the territory afar. The safety valve with its ever-burning flame at the top is behind the wire pending on the night.

RMCYXCAB–A well engineered brass and ferrous metal model gas fired horizontal stationary steam set, The brass boiler with metal cladding and normal fittings, weight and lever safety valve, main stop and lagged steam line to single horizontal cylinder¦ mill engine with overmounted valve chest and brass bound cylinder, barrelled connecting rod, counterbalanced crankshaft, spoked flywheel and multi rope pulley. Other details include feed water heater and hand feed pump ,the whole finished in maroon, black and polished brightwork and mounted on a brick and tiled plinth with, Additional-Rights-Clearences-NA

RMT965J2–Color enhanced lithograph of Papin holding a diagram of a steam engine, 1689. Denis Papin (August 22, 1647 - 1712) was a French physicist, mathematician and inventor. He worked with Robert Boyle from 1676-79, publishing an account of his work in Continuation of New Experiments (1680). During this period, Papin invented the steam digester, a type of pressure cooker with a safety valve.

RMW56XWK–Model of a Hydraulic Press, Model of a simple hydraulic press on a wooden floorboard. On the one hand is a manually operated pump, equipped with a pump arm, regulator, overflow and safety valve. The pump arm can be set in two positions. The regulator is a screw valve. The safety valve is adjusted with a weight. A tube for the liquid runs from the pump to the bottom of the press, where an oval press platform is pushed upwards., Joseph Bramah (possibly), United Kingdom, 1820, iron (metal), copper (metal), wood (plant material), model: h 41 cm × w 56 cm × d 27 cm packaging capsule: h 45.5 cm × w

RMMR3X05–Illustration depicting Papin"s steam engine (1707) for pumping water from mines. It was the first engine to use the safety valve he had invented twenty-seven years earlier for his "digester". (1647-1713) a French physicist, mathematician and inventor, best known for his pioneering invention of the steam digester, the forerunner of the pressure cooker and of the steam engine. Dated 19th century

RM2JM8GB6–Alain Sauthier, Director of Nant de Drance poses in front of a safety valve of the penstock in the newly operational Nant de Drance pumped storage electricity power plant in Finhaut, Switzerland, August 4, 2022. REUTERS/Denis Balibouse

RMCYXC6B–A well engineered brass and ferrous metal model gas fired horizontal stationary steam set, The brass boiler with metal cladding and normal fittings, weight and lever safety valve, main stop and lagged steam line to single horizontal cylinder¦ mill engine with overmounted valve chest and brass bound cylinder, barrelled connecting rod, counterbalanced crankshaft, spoked flywheel and multi rope pulley. Other details include feed water heater and hand feed pump ,the whole finished in maroon, black and polished brightwork and mounted on a brick and tiled plinth with, Additional-Rights-Clearences-NA

RF2JHG6MN–An industrial pressure safety valve, abbreviated as "psv" a well-known concept in the industry. Specially made to prevent dangerous high pressures in

RMP3880C–. Grand Geyser Cone and safety valve, Yellowstone National Park. Coverage: 1881-1889. Source Imprint: Fargo, D.T. : F. Jay Haynes, 1881-1889.. Digital item published 1-25-2006; updated 2-12-2009. 129 Grand Geyser Cone and safety valve, Yellowstone National Park, by Haynes, F. Jay (Frank Jay), 1853-1921

RM2JM8G81–Alain Sauthier, Director of Nant de Drance talks to a journalist in front of a safety valve of the penstock in the newly operational Nant de Drance pumped storage electricity power plant in Finhaut, Switzerland, August 4, 2022. REUTERS/Denis Balibouse

RF2JHG6N4–An industrial pressure safety valve, abbreviated as "psv" a well-known concept in the industry. Specially made to prevent dangerous high pressures in

RMP38806–. Grand Geyser Cone and safety valve, Yellowstone National Park. Coverage: 1881-1889. Source Imprint: Fargo, D.T. : F. Jay Haynes, 1881-1889.. Digital item published 1-25-2006; updated 2-12-2009. 129 Grand Geyser Cone and safety valve, Yellowstone National Park, by Haynes, F. Jay (Frank Jay), 1853-1921 2

RM2D3PPTK–Iraqi looters wave to the passing convoy of U.S. Marines as they ride a stolen small construction vehicle in the suburbs of Iraqi capital Baghdad April 7, 2003. British Air Marshal Brian Burridge said during his briefing at Central Command on Monday looting was almost "an inevitability". "There is a release of pent up annoyance and hatred against the Ba"ath Party and the Ba"ath regime but once that safety valve is blown...the business of protecting property becomes easier," he said. REUTERS/Oleg Popov OP/AA

RMTWH30F–Relief and safety valve of turbine unit no. 1, located in the subway below the Generator Room; looking south. The safety valve was manufactured by the Chapman Valve Company of Springfield, Massachusetts. It is identical to the adjacent safety valve for turbine unit no. 2. Photo by Jet Lowe, HAER, 1989. - Puget Sound Power and Light Company, White River Hydroelectric Project, 600 North River Avenue, Dieringer, Pierce County, WA; Shuffletin, Samuel L; Stine, Charles; Webster, Edwin; Baker, Charles H

RMD6K57N–A technician walks away from the safety valve of the drill on the drilling platform of German-Canadian oil company Firma CEP (Central European Petroleum GmbH) near Pudagla on the island of Usedom, Germany, 02 April 2012. After suspedning the controversial search for oil on Usedom in the fall of 2011, work on the the platform now starts up again. Photo: STEFAN SAUER

RM2CF74YH–Vent flowing cryogenic fuel and T/C Rake mounted on a 1/10 scale model Centaur in the l0 x l0 Foot Supersonic Wind Tunnel. The fuel being used is liquid hydrogen. The point of the test is to determine how far to expel venting fuel from the rocket body to prevent explosion at the base of the vehicle. This vent is used as a safety valve for the fumes created when loading the fuel tanks during launch preparation. Liquid hydrogen has to be kept at a very low temperature. As it heats, it turns to gas and increases pressure in the tank. It therefore has to be vented overboard while the rocket sits o

Our fire safety valves are designed to close off the oil supply to the burner in the event of a fire. The range includes the notable Teddington KBB brand of fire valve, as well as more economy models that are available depending upon your preference. Take a look at our fire valve testing unit, it’s a must have piece of equipment for every

8613371530291

8613371530291