oil safety valve location quotation

Guide to OSVs - Oil Line Safety Valves: this article describes check valves and fusible link oil safety valves used on oil piping at heating appliances as both a fire safety device and to assist in oil burner servicing.

We explain the purpose of OSVs, which way to turn the OSV or oil line safety valve to open or close it, and we describe common oil line valve installation or use mistakes.

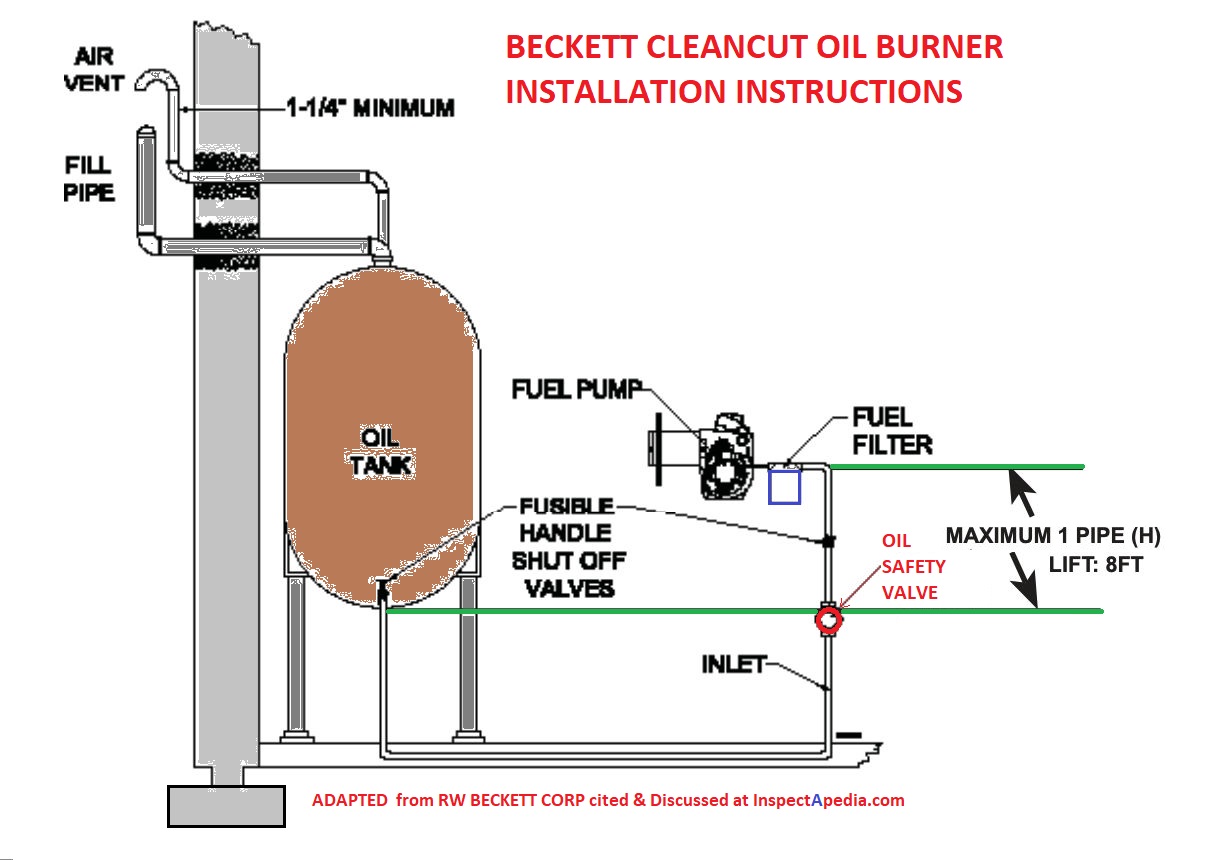

How & Where do We Install a Fusible-Link Firomatic™ Type Oil Safety Valve? This article series explains the installation & use of OSBs, or Fusible Link Oil Safety Valves. We describe and explain the differences in function and use among fusible link fire safety valves (OSVs) like the Firomatic®, vacuum operated OSVs like the Webster OSV and Suntec PRVs, oil line check valves, Tiger Loop and other oil system air removing devices, and oil delay valves or quick-stop valves that are also referred to as oil safety valves.

We explain where each valve is installed and what it does. We include oil safety valve and check valve troubleshooting advice, and we describe defects in heating oil piping & control valves.

The OSV or oil safety valve controls flow of fuel oil to the oil burner of oil-fired heating boilers, furnaces, and water heaters. This inline oil valve is intended to close automatically and thus stop the flow of oil in the oil line in the event of a fire.

Some suppliers use other names for this valve including the "Firomatic" valve (R.W. Beckett) or the "Oil Safety Valve OSVA-38" (Capital City Tool, Inc.).

Fusible Fire Safety Valves are designed to reduce fire damage by shutting off the flow of oil from the oil tank in the event of a fire. These valves conform to UL/ULC 842 and are listed in the US and Canada. They are required by code in residential oil heating installations in conformance with NFPA 31. - R.W. Beckett [4a]

Because the valve includes a fusible link (a lead or other soft metal core), in event of a fire the fusible link melts and the internal spring pushes the valve stem down, closing the valve and stopping oil flow.

Sometimes additional stop valves or OSVs may be installed at other locations (such as at the outlet of an above ground oil storage tank), but the critical location is at the oil burner since that"s a more likely location at which a fire may occur.

Watch out: the Firematic™ fusible-link automatic oil line shutoff valve (photo at left) should only be present on the oil supply line. We explain below

that installing an OSV on the return line of a two pipe oil system can lead to disaster. Instead, where it is necessary to prevent leakage from the return oil line during oil burner servicing we can install a simple one-way check valve on the oil return line (if the oil burner"s fuel unit manufacturer permits.)

Our photo at below left shows an example of a Firematic™ safety valve right at the oil burner. Synonyms people use for this valve include OSV, fire safety valve, oil line valve, Fire-o-Matic valve, Fusible link valve, oil line shutoff valve, oil safety valve, and Fireomatic valve.

In particular, the OSV shown here is installed between the oil filter canister and the fuel unit intake port. That means that it would be impossible to service the oil filter without spilling heating oil unless the service technician finds another oil line shutoff valve somewhere between the oil tank and the inlet side of the oil filter.

With the shutoff valve between the filter canister and the oil burner (above right), changing the oil filter in the canister will require the service tech to go to the more distant oil tank to find and close a valve in that location (if one is even present).

The technician moved the Fire-o-matic OSV to its proper location at the inlet side of the oil filter, and he also installed a Firomatic oil line check valve between the oil filter and the oil burner.

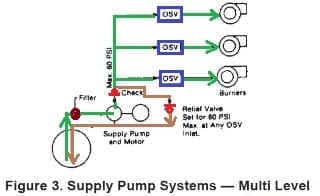

This is an important fire-safety detail as in event of a fire a closed valve on the return line (if it closes before the OSV on the supply line) could cause blowing seals on the oil pump or a blown oil line fitting, spewing fuel oil over the building fire.

In sum, the proper place for the fusible link oil valve (Fire-o-Matic Safety Valve™ for example) is on the oil supply line just before the inlet to the oil filter canister (red arrow, below left), not between the canister and the oil burner as shown at below right (orange arrow).

Below is another two-line oil system showing the OSV on the inlet side of the fuel filter canister just ahead of the oil burner and the oil return line exiting from the bottom of the fuel unit.

Regarding "the best location of an oil filter", NFPA 31 (2011): 7.5.8, for indoor tanks up to 330 gallons, requires that a thermally activated shutoff valve be placed inline as close as practical to the outlet from a tank and that a proper filter or screen be installed downstream and WITHIN SIX INCHES of the required thermally actuated valve. If it"s required in the code, it doesn"t have to "the best" - it just has to comply with the code.

Many oil heat technicians sensibly want to install a fusible-link oil supply line valve at the oil burner, not only because this makes servicing the oil burner easier but because it also recognizes that the most-likely location of a fire is at the oil burner rather than possibly at a more distant oil storage tank.

The photograph above shows the right location for this safety device: at the input end of the oil filter. This permits the service technician to conveniently turn off the oil supply inorder to change the oil filter cartridge.

The writers of NFPA 31 (2011) 7.5.8 as specified above were focused on safety including wanting to avoid oil spills from the tank, but they might also have recognizede that putting an oil filter at the oil tank protects the oil line (between tank and oil burner) from sludge-clogging.

(Jan 23, 2014) oilman said: Your info is wrong. The filter belongs on the tank so it also protects the oil line. If you must install at the burner, it must be piped at least 12" from the pump. Hence why they make 12" flexible oil lines.

Reply: We agree that there is an advantage to protecting the oil line. However some HVAC instructors (including mine) teach that if the filter is not installed by the burner it is too often forgotten at service time.

When the oil tank is a bit more remote - across the garage and buried by the homeowner"s stored surfboards and hiking boots and boxes of tax receipts, the service tech enjoys being able to find the oil burner. Having inspected several thousand heating systems, my [DF] experience is that most of the time the OSV and filter are installed where they are convenient for service - which is usually close to the burner, notwithstanding the very good reasons for locating a filter at the inlet end of the oil line.

Our OPINION [DF] is that if the technician installs an OSV at the oil burner (and ahead of a filter if one is installed there), s/he should install a second OSV on the same oil supply line at the outlet from the oil tank, particularly if the oil tank outlet piping exits at the tank bottom, and ahead of the oil filter (if that"s where it"s installed).

In our OSV photos below, the first photo (below left) shows the oil line safety valve in the OPEN position - oil will flow when the threaded portion of the valve shaft extends fully up through the rotatable knob pointed to by my pencil.[Click any image to see an enlarged version. Thanks to reader Bernie Daraz for pointing out the need for these two photos]

In our heating oil line valve photo at above right the valve has been manually CLOSED - no oil will flow. The threaded valve stem has disappeared down into the valve body and has shut off the valve and oil flow.

Watch out: if (for example in case of a fire) the fusible link inside of an OSV has melted permitting the spring to close the valve, then from outside the valve may look as if it is in the open position - the threaded stem will still be poking out - but the valve has snapped and closed internally. Most likely you"ll know this also because there will have been a fire or other horrible event that melted the OSV fusible link.

Watch out: A simple oil line shutoff valve may not be a fusible-link safety valve. The simple shutoff valve might be any plumbing valve that can manually stop oil flow in the line, but it is not a safety device.

Make sure you"ve installed a fusible-link safety valve at each location where it"s most needed - at each oil burner. Even when one of these valves is installed at the oil tank the proper place for this protection is on the fuel oil supply line

In the event of a fire, if the return oil line valve closes before the supply line oil valve your oil burner pump may burst the oil line or it may cause a fuel pump gasket or seal to fail, leading to uncontrolled oil flow and perhaps worse, spray heating oil everywhere, possibly feeding the building fire.

Thanks to Dave Ferris for this fire safety tip and thanks to reader Rick Johnston for adding clarification. (Note that not oil burners use both an oil supply and oil return line between the oil tank and oil burner.)

Suntec points out in their installation literature for fuel units (oil pumps for oil burners) that pressures over 10 psi on an oil inlet line (normally running at a vacuum) may damage the shaft seal on the pump - i.e., leak heating oil.

Watch Out: If the oil line fire safety valves are missing or are not at the right location, we recommend immediate installation of a Fire-o-matic™ type oil line safety

Recommended (red arrow, photo above left): an automatic oil line shutoff valve on the oil supply line right at each and every individualoil burner: (a type that will shut off oil supply to the heating equipment in the event of a fire, such as a Fire-o-Matic™ valve) is shown in our photo at left.

By every oil burner, we mean for example that if your heating system and also your hot water heater each has its own oil burner then each burner should have an oil safety valve. (As in our photo above left).

A common but poor practice is to install an oil valve just at the oil tank or perhaps installing a single oil safety valve at the oil burner for the heating boiler but omitting the oil safety valve for the oil fired water heater in the same building.

A second oil line shutoff valve on the oil supply line at the oil tank (photo above right) is ok as long as you have also provided the first oil safety valve at the oil burner(s).

Some service technicians install a second oil safety valve at the oil tank or at another remote location away from the oil burner, such as at the building wall where an outdoor oil tank line enters the building, or right at the oil tank (photo at above right - this oil tank valve is leaking).

This second valve is helpful if it becomes necessary to replace the oil line between oil tank and oil burner. Although our photo above shows a fusible link oil valve at the oil tank, the oil line shutoff valve at the oil tank or at a location remote from the oil burner or other more likely fire sources can be a normal plumbing stop valve.

However a common exception we see in the field is an OSV at the oil burner and a second OSV (or perhaps a simple shutoff valve, not thermally linked) at the oil tank end of the oil line.

Teflon tape at OSV threaded oil line or fuel unit connections: Webster"s instructions and some other manufacturers also specifically warn: Do Not Use Teflon Tape. Use of teflon tape voids all warranties. (Webster 2011)

The concern is that should a fire occur in the building, and should an OSV on the oil return line close before the OSV on the supply line, the fuel unit may over-pressurize the oil lines, causing a burst oil line that then sprays high-pressure oil into the fire, increasing its size and spread-rate.

Use an oil line check valve instead. Or if the heating equipment manufacturer recommends against using a check valve in the oil piping system (Suntec prohibits, Webster recommends) then leave it out.

Our photo (left, red arrow) illustrates this hazard: you will see fusible link safety valves on both the oil feeder line (blue arrow, left side of photo before the oil filter canister) and the oil return line (red arrow, right side of the photograph).

Unlike a fusible link OSV that shuts in response to high temperature to provide fire protection at the oil burner, a vacuum operated OSV opens only in response to a "sustained vacuum" created at its outlet end when the oil burner"s fuel unit pump is drawing oil from the supply.

Vacuum-operated safety valves offer protection against oil line leaks and against overpressure conditions on the supply side of the fuel unit. They are not a fire-safety valve.

Protection against over-pressure from the supply piping prevents leaks at the fuel pump inlet or seals that might occur when the fuel pump is not operating but the supply piping is under pressure from the oil source.

If two oil lines are used to supply an oil burner, (a supply and a return) install an oil safety valve or OSV or fusible link oil line shutoff valve only on the oil supply line at the oil pump on the oil burner.Do NOT install an automatic oil line shutoff on the return oil line between the oil burner and the oil tank.

If a protection against oil back-flow at the return line is a concern, and if the manufacturer recommends it, use a check valve instead. Check valves like this one permit oil to flow just in one direction. They do not close down in event of a fire. Installed on the oil return line a check valve permits oil to flow from the oil pump in one direction only: back to the oil tank.

Typically the oil line de aerator device such as the Tigerloop is installed at the same location as the oil filter - just before oil enters the fuel unit (oil pump), as shown in our photograph at left, provided courtesy of reader E.I..

The Firomatic® oil line valve can be installed in ANY position - (vertical, horizontal, upside down) at least that"s what we were taught and what we have seen - the valve is spring loaded.

In a fire the fusible link, a lead core, melts at 165°F and a spring in the valve assembly snaps the valve shut to assure that the heating system does not feed oil to a building fire. It has to work in any orientation.

This list provides some of the companies produce fusible-link inline oil safety valves (OSVs). The footnote links point to the companies" contact information in our REFERENCES section, but generally you would purchase an OSV from your local heating equipment supplier or plumbing supplier.

AFL Industries, AFL OIL STOP VALVE PRODUCT BULLETIN [PDF] AFL Industries, 1101 West 13th St., Riviera Beach FL 33404 USA, Tel: 561-844-5200 includes OSV installation instructions for the contractor.

Bursey, Charles, "The Oil Safety Valve (Service)", Charles Bursey, Sr., Fuel Oil News, February 2006 (Still trying to get the full article - October 2008 - DF) Charles W. Bursey Sr. can be reached at F.W. Webb Co. www.fwwebb.com/

Cleanburn Energy CLEANBURN MULTI-OIL FURNACE OPERATORS MANUAL [PDF] (2009) Clean Burn Energy Systems, CLEAN BURN, INC. 34 Zimmerman Road Leola, PA 17540 U.S.A. includes Oil Safety Valve Installation Instructions

R.W. Beckett (U.S. & Canada) Firomatic Fire Safety Valves Beckett Corporation produces /distributes a wide range of oil burners & oil burner accessories * equipment including the oil safety valve (OSV) referred to as Firomatic® fusible fire safety valves, oil line check valves, and fusible link thermal switches

Beckett"s Firomatic® OSVs are provided in both 3/8" and 1/2" sizes and in flare and threaded designs. OSVs are provided designed for installation at the oil burner and in a different model at the oil storage tank.

Fusible fire safety valves are designed to reduce fire damage by shutting off the flow of oil from the oil tank in the event of a fire. These valves conform to UL/ULC 842 and are listed in the U.S. and Canada. They are required by code in residential oil heating installations in conformance with NFPA 31.

All[Firomatic® fire safety] valves are embossed with the direction of oil flow and include unique part number identification ring on each valve. The seal stem uses a double seal washer/o-ring system with high grade Viton® equivalent materials suitable for No. 2 fuel oil, kerosene, and jp to 205 biodiesel blend.

Oil under pressure or vacuum is supplied to the inlet of the PRV valve. Vacuum is required at the outlet of the PRV valve to open it and to allow oil to flow. When a burner starts, the pump will supply the vacuum necessary to open the valve. Any leak in the system which prevents vacuum from being exerted on the outlet port of teh valvewill prevent oil from flowing.

ISP Automation, Firomatic Globe Type Oil Line Valves & Lever Type Fusible Link Control Valves: ISP Automation, Inc., 1035 Old Georges Road, North Brunswick, NJ 08902, Phone: 866-383-3481, FAX 866-383-3482, Email: support@ispautomation.com http://www.ispautomation.com/

Webster "Service Technician"s Handbook, Webster Fuel Pumps & Valves" [handbook]. Webster Fuel Pumps & Valves, Capitol City Tool, Inc., http://www.websterfuelpumps.com/ , Division of Capital City Tool, Inc., Op. Cit.

Webster, OSV SERIES OIL SAFETY VALVES DIMENSIONS & SPECIFICATIONS [PDF] Fuel oil safety valves, Webster Fuel Pumps & Valves, web search 10/12/2011 original source http://www.websterfuelpumps.com/pdffiles/osv1.pdf

Webster, "Dimensions & Specifications, OSV Series Oil Safety Valves, OSVA 38, OSVA 50", Webster Fuel Pumps & Valves, (1980), Op. Cit. retrieved 2/24/2014, original source: http://www.websterfuelpumps.com/pdffiles/osv1.pdf

The current fusible link valve product properly named Firomatic is so widely also called "Firematic" and "Fireomatic" that we include those terms to assist readers in finding this information. Who manufactures the Firomatic fusible link valve? R.W. Beckett. Who manufactures vacuum-operated OSVs? Webster & Suntec (the PRV). We explain the differences among these products in this article series.

RW BECKETT RECALL for FIROMATIC 1/2" FEMALE PIPE THREAD FUSIBVLE SAFETY VALVE [PDF] P/N 12130 - the stem may not travel far enough to shut off the flow of fuel if exposed to trip point temperature. Posted until 4/1/2017, retrieved 2019/10/09 original source: https://static.globalindustrial.com/site/pdf/RW_Beckett_Firomatic_Female_Pipe_Thread_Recall.pdf

Excerpt: Recently, we became aware of a design deficiency in our ½” ‘Firomatic’ Fusible Safety Valve part number 12130. This bulletin covers ONLY the ½” FPT version p/n 12130, previous p/n B200F.

Under certain conditions, if the valve is exposed to temperatures exceeding the handle’s temperature rating and the valve ‘fires’ or actuates, the stem may not travel far enough to properly seat the valve and shut off the flow of fuel. This could result in a dangerous situation if there is a ruptured fuel line downstream of the valve. There have been no reports of this situation arising, but the potential for this issue to occur does exist. This does not affect the valve’s operation when used as a manual shut off valve.

The current design of the 12130 – ½” FPT valve and handle assembly was in production prior to R W Beckett’s acquisition of the Firomatic® product line. We have been unable to determine exact dates for any changes made to the design by previous manufacturers. Therefore this bulletin covers all Firomatic® ½” FPT valves, whether using our part number 12130 or the obsolete part number B200F, used by Highfield Manufacturing. Suspect valves can be identified by the name ‘Firomatic’ cast into the body of the valve. See illustration below.

A re-design of the 12130 valve will be available pending agency approvals and manufacturing process lead times. We are anticipating the re-designed valve to be available by January 1, 2017.

RW BECKETT RECALL for FIROMATIC 1/2" FEMALE PIPE THREAD FUSIBVLE SAFETY VALVE [PDF] P/N 12130 - OLDER COPY - the stem may not travel far enough to shut off the flow of fuel if exposed to trip point temperature. Posted until 4/1/2017, retrieved 2019/10/09 original source: https://static.globalindustrial.com/site/pdf/RW_Beckett_Firomatic_Female_Pipe_Thread_Recall.pdf

It might matter tremendously which way your OSV or oil safety valve is installed and in any event we ought to follow the manufacturer"s instructions including the flow arrow.

Here"s just one example. Some OSVs such as sold by Webster include a pressure-isolating feature that protects the fuel unit (the oil pump) from additional pressures that might come from the oil feed such as from an overhead oil feed line or even an elevated oil tank. Typically codes specify that the input pressure from the oil delivery piping ahead of the burner"s fuel unit not exceed 3 psi.

Those Webster OSVs include an internal valve that is designed to OPEN in RESPONSE to the FUEL UNIT OPERATION. So if the valve is installed backwards that feature will not work and the fuel unit may not pump oil properly to the burner nozzle.

Fusible Fire Safety Valves are designed to reduce fire damage by shutting off the flow of oil from the oil tank in the event of a fire. These valves conform to UL/ULC 842 and are listed in the US and Canada. They are required by code in residential oil heating installations in conformance with NFPA 31.

All valves are embossed with the direction of oil flow and include unique part number identification ring or each valve. The seal stem uses a double seal washer/ o-ring system with high grade Viton® equivalent materials suitable for No. 2 fuel oil, Kerosene and up to 20% Biodiesel blend.

Watch out: That"s because in the event of a fire a lead core in the valve is intended to melt to allow the valve to close - to stop feeding oil to a possible building fire. So if the valve is jammed it"s unsafe.

My concern is the stem does not go back into the valve or come out of it any further than it currently is no matter which direction I turn the valve or how many turns I make. Since the valve does not STOP turning in either direction, I"m concerned the valve is faulty.

If the stem pokes up out of the valve handle you"ve screwed the valve "down" and it is "open" to pass oil. Remember that these valves are threaded opposite of most others.

The knob on my OSV does not tighten up no matter how many times I turn it in either direction. The threaded stem in the center is protruding out about 2mm so I"m not sure if the valve is fully opened or closed. Is there a fix for this or do I need to replace the OSV?

If you have a fusible link valve that doesn"t seem to turn off you might try tapping the exposed end of the valve stem. I have found a stuck, or slow to close OSV on a few rare occasions. A gentle tap, not hard enough to damage threads, loosens it after which I open and close the valve a few times to convince myself it now moves freely. A burr on the brass interior or more likely internal sludge or debris could be the culprit.

Because at the oil burner the OSV is likely to be used at least once a year during service, that"s a good opportunity to discover if the valve is not closing fully.

In my opinion painting a fusible link is potentially unsafe - paint may interfere with mechanical operation of the valve. Most likely the manufacturer will agree, though they may not have imagined that event.

there must be an exception to the rule. my firematic valves open counter-clockwise and close clockwise and are definitely firematic valves because of their construction. they are just like the photos above but turn in the opposite direction you describe

I have a Themopride oil furnace that loses prime over night when the thermostat is lowed. It has a tigerloop installed. Why is there oil in the tigerloop if it loses prime?

Also, how do you recommend trouble shooting this? There are several valve one at each end of the supply line and one before the tigerloop that I could close for a few hours and see if it solves the problem (that would atleast narrow it down to a few fittings)

On a manual 1" fireomatic valve where the bonnett section joins the valve body, is that a brass on brass fit or is there suppose to be an o-ring or gasket? Does the OEM (Fireomatic) permitt valve disassembly for installation purposes? Thanks.

Mike I"ve installed these valves but have not tried disassembling one. If your unit is from Beckett, who currently provides the Fireomatic oil safety valve as well as the "New England Safety Switch" that uses a similar mechanism, then you might give them a call to ask.

Is there a inspection protocol for these valves like Morrison has on there fusible link valves (some quarterly inspections some yearly) and are they fine to use on gasoline lines I see only oil mentioned.

Watch out: do not use an oil line safety valve in ANY application other than those listed by UL and by the manufacturer - in this case, on heating oil supply lines.

Continue reading at OIL LINE SAFETY VALVE TURN DIRECTION to OPEN or SHUT or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

OIL LINE SAFETY VALVES, OSVs at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

[1]AUDELS OIL BURNER GUIDE, INSTALLING, SERVICING, REPAIRING, [PDF online copy of this book] Frank D. Graham, Theo. Audel & Co., New York 1946, 1947, 1955 (out of print, copies occasionally available from antique book dealers and on EBay). Use THIS LINK to read a free online copy of this helpful classic textbook.

[2] Beckett Model SR Oil Burner Instruction Manual, R.W. Beckett Corporation, PO Box 1289, Elyria OH 44036 and R.W. Beckett Canada, Ltd., 430 Laird St., Guelph, Ontario, Canada N1G 3x7

[17] Newmac Furnaces & Boilers, "Installation, Operating, and Service Manual, Oil Fired Boiler Model NBR-2001 NBR 2002", (2007) Newmac Manufacturing, Inc., Debert Air Industrial Park, Lancaster Crescent, PO Box 9, Debert, Nova Scotia, BOM 1GO Canada, Tel: 902-662-3840, retrieved 2/23/2014

Thanks to Rick Johnston for pointing out that the more likely cause of a fire safety valve in the return oil line is a burst seal on the fuel unit 4/6/2009

Thanks to reader Bernie Daraz for suggesting the need for clear photographs illustrating the OSV or oil line safety valve in the open and closed positions. Personal correspondence 2/15/2013.

Thanks to reader T.R. for suggesting clarity on where oil safety valves should or should not be installed and for discussing the proper hook-up location for the Tigerloop and similar oil line prime protection & air removal devices. April 2011.

Thanks to reader Anonymous by request 2/23/2014, for requesting clarification of the safety hazards involved in placing an OSV on the return line of a two-pipe oil system.

TECHNICAL REFERENCE GUIDE to manufacturer"s model and serial number information for heating and cooling equipment, useful for determining the age of heating boilers, furnaces, water heaters is provided by Carson Dunlop Weldon & Associates

In our oil safety valve photo at page top the OSV is in the OPEN position - the telltale indicator is that the screw is visible protruding up through the top of the silver-gray valve handle.

Fusible-link oil line valves such as the Fire-o-Matic valve work opposite from usual plumbing valves - that is, internally, because of the "reverse-threaded" valve stem, these oil line control and safety valves seem to operate backwards from what you"d expect.

To Open the OSV - let oil flow: turn the oil line valve counter-clockwise (left to right - in the direction of my finger to OPEN heating oil fuel flow. The threadsOn this part are cut opposite from usual plumbing shutoff valves. As you turn the valve handwheel in this direction the threaded valve stem will protrude upwards through the rotating knob. Oil will flow when the valve is open. In my photo the valve was about half-way open.

When the valve stem protrudes fully up through the turn-knob as far as possible you have compressed an internal spring inside the valve, and the valve is open to let oil flow. The handwheel actually feels "tighter" (as you are compressing the spring) and the handwheel moves down against the valve body as the valve opens.

To Close the OSV - stop oil flow: rn the Firematic type OSV clockwise (right to left) to close the valve and stop oil flow. As you turn the valve handwheel or knob in this direction (opposite to the direction my finger is pointing) the valve stem will disappear down into the valve body, pushed by its internal spring. You are closing the valve - oil will not flow.

When the turn knob is rotated so that the valve stem moves down through the knob until the stem end is flush with the knob top and the knob is loose, the valve is fully closed and oil will not flow.

Watch out: if the control valve on a heating oil line is not a fusible-link safety valve such as the Fire-o-Matic™, it will probably be an ordinary plumbing stop valve that works as all plumbing valves:clockwise closes those valves by moving the valve stem down and counter-clockwise to move the valvestem up opens them. Sometimes we find a common stop valve on the oil line at the oil tank and a fusible-link safety valve just at each oil burner.

An internal spring pressure, combined with a fusible link in the valve stem are what shut the oil line valve in event of a fire. In this design, when the valve is open to permit heating oil to flow it is also under spring tension. Because the valve includes a fusible link, in event of a fire the fusible link melts and the internal spring pushes the valve stem down, closing the valve and stopping oil flow.

As you turn the handle on the oil piping safety valve counter-clockwise you will feel increasing spring tension as you are opening the valve (lifting the stem out of the valve body) against the spring pressure.

Because of the use of "reverse" threads on the valve stem, when you turn the OSV knob counter-clockwise the underside of the control knob, remaining in contact with the surface of the valve body, causes the valve stem to move up (against pressure of the valve"s internal spring) until the threaded stem protrudes fully through the knob and you cannot turn the knob any more. In my photo the valve is about half-way open.

When the valve is fully open to permit fuel flow, the valve stem is "all the way out" of the valve body and the valve is being pushed-on by the internal spring. In this position the valve"s knob has been turned clockwise, all the way down against the body of the valve.

When this oil line fusible-link valve is completely open to heating oil fuel flow, the valve stem is screwed all the way up "out" of the valve body. As you turn the valve knob clockwise you"ll feel it moving against the internal valve spring pressure and you will see the valve stem moving up and out through the center of the oil valve knob.

When the oil safety valve handle is screwed clockwise (right to left) so that the threaded rod has disappeared fully down into the valve body the valve handle will become loose and the valve internal components will be in the closed position - heating oil fuel will not flow.

Because of the use of "reverse threads" on the valve stem, when you turn the OSV knob clockwise , as the knob itself remains in contact with the valve body, the spring-loaded valve stem will move down into the valve body, closing off the oil flow.

As you turn the oil valve knob clockwise you will see the valve stem move back into the valve body and you will feel the spring tension on the device lessen.

For the last few counter-clockwise turns on the valve stem/screw you should feel a complete release of tension of the spring mentioned just above and if you keep turning the valve knob counter-clockwise it will unscrew and come off. Don"t panic if this happens. The threaded portion of the valve stem protrudes up through the valve body and you can simply screw the knob back on.

In our OSV photos below, the first photo (below left) shows the oil line safety valve in the OPEN positin - oil will flow when the threaded portion of the valve shaft extends fully up through the rotatable knob pointed to by my pencil.

In our heating oil line valve photo at above right the valve has been manually CLOSED - no oil will flow. The threaded valve stem has disappeared down into the valve body and has shut off the valve and oil flow.

Watch out: if (for example in case of a fire) the fusible link inside of an OSV has melted permitting the spring to close the valve, then from outside the valve may look as if it is in the open position - the threaded stem will still be poking out - but the valve has snapped and closed internally.

Put another way: if you turn the oil line valve until the handle begins to come off, the valve is in the CLOSED position. You will see that at this point you have removed all tension against the valve"s internal spring and the spring has pushed the valve shut or closed. The valve stem has moved into the valve body.

If you turn the valve against its spring tension the valve is in its OPEN position. You will see that in this position you have turned the valve against its spring tension - the spring tension is increased - and the valve is open. The valve stem has moved out of the valve body.

at OIL FILTERS on HEATING EQUIPMENT where during heating equipment oil filter servicing the valve is used to close and later open the oil line feeding the oil burner

Thanks so much; what a great way to remember which way to turn the fire-o-matic valve stem: NO STEM = NO OIL - if you don"t see the valve stem poking up through the knob then the valve has been closed.

This is such a helpful article ! Thank you . After reading it I"ve concluded - " no stem , no oil " so I just remember that as I gently turn the valve handle ;

Watch out: if you are not trained and familiar with how to perform all of those steps correctly you risk not only poor oil burner operation but a possible puffback explosion that can be caused by leaving air in the oil system or by an improperly-adjusted oil burner. In the old days we could "tune" an oil burner by eye and a bit of spit but modern high speed burners need to be adjusted using training and equipment such as CO2 or O2 measurement, smoke measurement, draft measurement, and temperature measurement.

What"s the best way to bleed out the air from the filter? I"ve bled the burner which is after the filter, should I also bleed the filter/filter housing as well by getting the furnace to call for oil, or does bleeding the burner essentially take out any air in the loop?

Thanks! I kind of freaked out a bit after changing the filter wondering why when i opened the valve no oil was coming through. I thought I just turned my dollar saving filter changing exercise into an expensive service call....

In a two-line oil pipe system one line supplies oil to the fuel unit and the other is a return back to the oil tank. On that installation you to actually C300 oil pipes the supply of oil coming in through the filter, the return line to the tank, and a smaller-diameter high pressure line that feeds oil at high pressure out of the fuel unit and into the oil burner.

My point about tank elevation was that It"s Perfectly Natural that if the take oil height is not above the height of the fuel unit you won"t feed oil by gravity to the fuel unit but when the unit runs is perfectly capable of lifting oil, typically up about 6 feet at Max, or lifting even higher in a two line system.

Sorry forgot to add yes I have turned the valve completely counterclockwise all the way to the point it does move anymore and the stem is fully exposed. I"ve also turned the furnace on and bled the burner so it appears that there is absolutely oil going thru the lines when the furnace is calling.

I believe it is tank->supply line-> OSV -> in to filter -> out to the burner, then another line that appears to go out (which seems to me to be a 2 line?), no other valves in that setup that I saw.

My valve looks the same as this but when it is in the Open position it doesn"t seem that oil flows through on it"s own, but when I turn the boiler on and there is a call for oil it is definitely going through. I discovered this as I went to change the filter and wanted to open the valve to release any air that may have been in the line, but with the valve open no oil was flowing, only when the boiler is on and calls. Is there something special about how this has been setup that it would do this?

So....left to right is CLOCKWISE,,,,,right to left is COUNTERCLOCKWISE.....to CLOSE the valve you rotate counterclockwise and allow the inner spring to close the valve. To OPEN the valve you would rotate clockwise and provide a counterbalance to the spring.

Sometimes a valve is loosened so as to allow the valve spring to close the valve but the valve sticks. A technician might tap gently on the valve stem to be sure it"s fully CLOSED.

These oil valve turned in the opposite direction from that to which you are accustomed. It sounds as though you were turning off the oil flow to your burner. That"s why the burner goes off.

Counter-clockwise turning of the handwheel on an OSV feels as if you are "tightening" the valve and the valve stem moves "up" through the handwheel - fully CCW opens the valve and oil can flow. The valve stem is "reverse threaded" compared with normal plumbing valves.

I think you"ve got your open and closed backwards, you seem to say the same thing for both normal valves and firematic valves ( See under watch out Clock wise is open ccw is closed ?) Confusing. While under summary, you have it correct.

Watch out: if you break it off you"ll have a financially ruinous oil tank flood in your home so take great care. If some fool does snap off an oil valve and can"t otherwise shut off oil flowing from an above ground oil tank, for an emergency repair just bent and crimp the copper tubing to stop the oil flow.

You describe an irritating problem indeed. If the oil safety valve simply won"t close you"re at least lucky to continue to have heat. The solution is to use up oil in the tank, have its remains pumped out, then replace the valve.

- the line is cut near the oil tank (or near the oil burner where an OSV valve should be anyway) and a second new working valve is installed on the lines.

I suppose a very confident plumber with help from an assistant might try putting down a pan, trying to fix the valve while spilling oil, but given the trouble of cleaning up an oil spill that live approach makes me nervous.

I haven"t seen it used on an oil line and there might be problems, but plumbers also use a heat soluble plug that can be jammed into a pipe to permit repairs, then dissolving the plug with heat.

Question: I have a fire-O-matic valve attached directly to the oil tank: it"s now open and the furnace is running fine. I would like to close the valve and replace the downstream filter element. But when I turn the handle in either direction the stem turns with the handle..

.in other words, I cannot close the valve. I"ve tried the tapping on the end of the stem approach mentioned in the stuck valve section, but to no avail.

"When the valve is fully open to permit fuel flow, the valve stem is "all the way out" of the valve body and the valve is being pushed-on by the internal spring. In this position the valve"s knob has been turned clockwise, all the way down against the body of the valve.

When this oil line fusible-link valve is completely open to heating oil fuel flow, the valve stem is screwed all the way up "out" of the valve body. As you turn the valve knob clockwise you"ll feel it moving against the internal valve spring pressure and you will see the valve stem moving up and out through the center of the oil valve knob."

In both of these paragraphs the use of the word clockwise should be replaced with the word Counter-clockwise. I know this is just a typo but it will be very confusing to someone who is not familiar with these valves. It"s hard enough for people to understand without adding typos to the mix. Other than this thank you for publishing an excellent article.

If you have a fusible link valve that doesn"t seem to turn off you might try tapping the exposed end of the valve stem. I have found a stuck, or slow to close OSV on a few rare occasions. A gentle tap, not hard enough to damage threads, loosens it after which I open and close the valve a few times to convince myself it now moves freely. A burr on the brass interior or more likely internal sludge or debris could be the culprit.

Because at the oil burner the OSV is likely to be used at least once a year during service, that"s a good opportunity to discover if the valve is not closing fully.

What is the difference among all these different kinds of valves used on oil piping and at the oil burner or oil tank: check valve, fusible link valve, fire-o-matic type valve, vacuum operated valves, quickstop valves, solenoid valves, and oil delay valves. It"s really confusing.

We agree that there are enough valves and enough similarity in their names that the controls used at oil tanks, on oil piping, and at the oil burner to manage the flow of oil can be confusing. Worse, valves that do different things and have different purposes may all be called "oil safety valves" in marketing and technical literature.

Don"t confuse the built-in check valve in the fuel unit with external check valves, fusible link oil safety valves, solenoid operated quick-stop oil valves, and their sisters, solenoid operated oil delay valves.

OIL LINE SAFETY VALVE TURN DIRECTION to OPEN or SHUT at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

[1]AUDELS OIL BURNER GUIDE, INSTALLING, SERVICING, REPAIRING, [PDF online copy of this book] Frank D. Graham, Theo. Audel & Co., New York 1946, 1947, 1955 (out of print, copies occasionally available from antique book dealers and on EBay). Use THIS LINK to read a free online copy of this helpful classic textbook.

[2] Beckett Model SR Oil Burner Instruction Manual, R.W. Beckett Corporation, PO Box 1289, Elyria OH 44036 and R.W. Beckett Canada, Ltd., 430 Laird St., Guelph, Ontario, Canada N1G 3x7

[3] Thanks to Bottini Fuel service tecnician Bob for discussing the buzzing aquastat relay problem, 4/18/2012. Bottini Fuel is a residential and commercial heating oil distributor and oil heat service company in Wappingers Falls, NY and with offices in other New York locations. Bottini Fuel, 2785 W Main St, Wappingers Falls NY, 12590-1576 (845) 297-5580 more contact information for Bottini Fuel

e-Mail : information@suntec.fr, [copy on file as /heating/Oil pumps fuel units/Form 2155 - PRV-38 Installation.pdf]. You can download this file from Suntec"s website. ,

[10] Firomatic Globe Type Oil Line Valves & Lever Type Fusible Link Control Valves:ISP Automation, Inc., 1035 Old Georges Road, North Brunswick, NJ 08902, Phone: 866-383-3481, FAX 866-383-3482, Email: support@ispautomation.com

[14] "The Oil Safety Valve (Service)", Charles Bursey, Sr., Fuel Oil News, February 2006 (Still trying to get the full article - October 2008 - DF) Charles W. Bursey Sr. can be reached at F.W. Webb Co. www.fwwebb.com/

[19] Thanks to reader Bernie Daraz for suggesting the need for clear photographs illustrating the OSV or oil line safety valve in the open and closed positions. Personal correspondence 2/15/2013.

Thanks to Rick Johnston for pointing out that the more likely cause of a fire safety valve in the return oil line is a burst seal on the fuel unit 4/6/2009

Thanks to reader T.R. for suggesting clarity on where oil safety valves should or should not be installed and for discussing the proper hook-up location for the Tigerloop and similar oil line prime protection & air removal devices. April 2011.

Abandon a Buried Oil Tank, How To - Abandoning Commercial Underground Tanks, Russ Brauksieck, ASHI Tech. Journal, Vol.3 No.1 Spring 1993, P. 40-41 [Reprint]

Petroleum Bulk Storage J. Sibblies, NY State DEC, Advice to Home Owners and Home Inspectors about Oil Storage Tanks - summary from ASHI Chapter Seminar.

TECHNICAL REFERENCE GUIDE to manufacturer"s model and serial number information for heating and cooling equipment, useful for determining the age of heating boilers, furnaces, water heaters is provided by Carson Dunlop Weldon & Associates

The oil and gas industry is cyclical, dependent on the stock market’s energy, natural resources and oil barrel trading and pricing. However, the COVID-19 pandemic caught the industry by surprise, creating new challenges. The emphasis on the importance of total cost of ownership has come into scrutiny with more glaring awareness when selecting valves for oil and gas projects, as well as for maintenance replacement in plant facilities.

With the current declining oil prices, product pricing is only one aspect when reviewing all of the contributing factors that affect cost of ownership. Remaining afloat during these stressful economic times requires critical thinking applied to strategic long-term planning.

End users frequently make the mistake of focusing solely on the current product’s price without planning for the potential loss of maintenance programs or lack of funding for frequent replacement of leaking valves due to misapplication in the field.

The following are some of the questions that should be answered first in the critical-thinking stages for long-term project management planning when deciding between a two-piece or three-piece ball valve at a chemical processing facility:

Next, weigh the pros and cons of each design using the current budget versus the long-term estimated costs of maintenance when deciding on whether a two-piece or three-piece design is the right choice for the application. To equate the TCO, determine what the true costs would be for a potential emergency versus scheduled shutdowns to replace leaking valves. Taking into account the pros and cons of each design by comparison (Image 1) will provide further insight into the TCO in valve selection and what will be the right choice to reduce operation, maintenance and sustainability costs.

As the valve quotation process plays one of the biggest roles in valve selection, thus affecting TCO, the best course of action the end user can take is to provide the distributor and/or manufacturer with accurate, detailed technical data. The technical data is crucial for accurate valve quoting and should include the type of valve, pressure class, size, type of ends, material for the body, trim, ball, seat, seals of the valve, the bore-port and the valve design.

An example of an outdated technical data sheet influencing the valve quoting process is an inquiry for a “fire safe ball valve that is fire tested to API 607 (no graphite allowed).” Without graphite, the ball valve cannot pass a fire test, nor can the valve be considered fire safe. Upon review of the submitted technical data sheets, last revised in 1964, the discrepancy was highlighted for the end user.

Another quoting tip is to ensure valve inquiries being quoted through various distribution channels are equivalent to one another in construction of materials and body design. As a 15-year veteran valve specialist in project management advised: “Make sure you are quoting apples to apples.”

When reviewing valve inquiry bids, each valve quotation should include the manufacturer’s part, with a detailed description of the valve, valve pricing and delivery, along with the valve cut sheets for ease of comparison.

When submitting a valve replacement inquiry, especially in an emergency situation, technical information can be gathered from the inline valve, through observance and knowing where to locate the technical data tags and inscriptions on the valve.

The identification tag found on the back of the valve body will provide the needed, in-depth valve specifications for accurate quoting, while confirming the type of valve, temperature and pressure range from observation—as well as the information provided on the front of the valve. For smaller-sized valves, the identification tag can be found on the neck of the valve or flange, dependent on the type of valve end.

Although many valves appear to look alike on the outside, the insides are not. Pay particular attention to the small components of the valve to ensure it will perform well in the application.

There is no such thing as providing too much data. The more data received will culminate in accurate valve quoting. Open communication between the end user, distribution channel and manufacturer will reduce the risk for misquoting, thus decreasing cost of ownership for future production.

Siemens VOG15 is an electro-hydraulic actuator three-way oil valve design. It provides safety shut-off control for industrial and commercial burner applications. The normally closed port on the valve is rated for safety shut-off function. The normally open port location is on the bottom of the valve is typically used for recirculation of heavier oils. A 3/4-inch NPT pipe plug (comes with VOG) is in the bottom port for two-way applications. The compact VOG15 actuator opens slowly when power is on and if power interrupts, it closes in less than a second. A visible position indicator on the front of the actuator displays position, and a light indicates when the actuator is on.

The electro-hydraulic actuator consists of a cylinder filled with oil, a piston containing an electric oscillating pump, and a relief system. Supply power to the actuator, then the relief system closes, and the pump moves the piston downward in the cylinder, opening the oil valve. If power interrupts to the actuator, the relief system opens and the oil valve closes in less than one second. A position indicator, visible through the transparent portion of the terminal cover, shows the entire stroke range of the actuator. The oil valve only uses about 1/4-inch of the actuator’s stroke. A light, which is visible through the lower left transparent portion of the terminal cover, indicates when the actuator receives power.

A non-adjustable SPDT POC over travel switch signals the valve closed position after the oil valve has closed. If optional equipment supplies an SPDT auxiliary switch, it changes state when the oil valve is more than 80% open.

We provide onsite safety relief valve diagnostic testing and repair services while helping you manage your overpressure protection assets for regulatory compliance.

Legislation requires that the owner of a facility has access to repair and recertification documents for pressure management equipment. Our pressure management experts provide relief valve asset audits to generate, maintain, and utilize applicable data for use in your facility’s maintenance planning activities and recertification.

MCM Oil Tools Surface Safety Valve Unit is a “failsafe-closed” or “failsafe-open” hydraulically actuated gate valve used in well testing in offshore and land operations.

Pressure relief valve is related to Microchek.com. We offer competitive pricing and reliability because we are the manufacture. Parts are molded and assembled in the U.S. The Microchek system incorporates this cartridge and a wide selection of end pieces to accommodate most connection requirements. The Microchek valve is a cartridge check valve incorporating an innovative guided poppet design. Relief valves are used to hold a fluid circuit or reservoir at a positive or negative pressure. We can select valves that fall into a specific cracking pressure range if needed. The Microchek valve has a low pressure drop and can be specified with a wide variety of cracking pressures.

The Microchek valve is a cartridge check valve incorporating an innovative guided poppet design. Relief valves are used to hold a fluid circuit or reservoir at a positive or negative pressure. We want the opportunity to help you solve your flow control applications and we can build special configurations.

To the running engine, the lubrication system is much like the heart and blood of the entire operation. The pump, valves, bearings and oil play a large role in bringing modern engines to the couple hundred thousand miles plus they see these days. The high pressure safety valve, or oil pressure relief valve, is just one of the devices implemented to keep things running smoothly.

While the engine is running, oil is picked up from the reservoir or oil pan for most vehicles. The oil is drawn into the pump, compressed and distributed throughout the engine. At lower speeds the pump generates enough volume to support the rotating assembly. As the engine speed increases, so does pump output. At a certain point the pump is moving more oil than the engine is demanding and the pressure inside the system can reach a level where it can blow seals. The pressure relief valve opens to send oil back to the reservoir and keep the volume and pressure steady.

Oil cools the engine as well so a consistent flow allows the oil to do it’s job, drain and cool off in the pan before returning to the engine. Heavy-duty vehicles generally require an added oil cooler because of the added load.

Problems arise when the demand for oil is greater than the available supply. In this case, the pressure relief valve may be stuck open and allowing too much oil to bypass the system and dump back into the reservoir. If the oil pressure relief valve sticks closed, pressures inside the system can spike high enough to burst oil filter housings or damage oil cooler cores and seals. A stuck-closed valve and low oil level together can run the reservoir dry as well and cause damage to all of the components of the lubrication system including the pump itself.

Modern vehicles include the pressure relief valve in the oil pump housing which can be found inside the engine behind the timing cover or the oil pan. Because of this, a vehicle service manual is mandatory to find the location of the valve as the design varies.

Step 1: Do some homework. Familiarize yourself with the instructions in the manual and the locations of the parts on the vehicle before tearing anything apart. Doing this beforehand may enlighten you about any possible special tools required for the job.

Step 2: Prepare your safety materials. Always wear eye protection when working on a vehicle and it is necessary to use protective gloves to keep the chemicals off of your skin.

Step 4: Drain the engine oil. Drain the engine oil and replace the drain plug now so it doesn’t get lost. Remove the engine oil filter. Once the work is done, you will add new oil and a new filter.

Step 5: Gain access to the pressure relief valve. Locate and remove the relief valve if your vehicle is equipped with an external unit near the oil filter housing. It may be necessary to remove the oil filter housing or oil pan to access the relief valve on some models.

Note: Never reuse an old oil seal as many are made of rubber and petroleum products will weaken rubber materials over time. The seal may not have been leaking before you removed the part, but it surely will leak if the old gasket is used again.

Step 9: Top off fluids. Fill the engine with oil and if you haven’t done so, put on the new oil filter. There are few things worse than starting a vehicle with no oil filter and wasting a gallon of fresh oil.

Note: If the oil filter mounts vertically with the open side up, fill the oil filter with fresh oil. This method avoids a dry start and get the oil moving quickly.

Step 10: Start the car. With the fluids full and all fasteners tight, you are ready to start the vehicle. Start the vehicle and allow it to run for about 10 seconds. After 10 seconds turn the vehicle off and check the oil level. Top off if necessary.

The engine"s lubrication system is back in working order with the proper safety measures intact. Always use the type of oil recommended by the manufacturer to avoid fluctuations in oil pressure that may cause major damage to the engine assembly. The oil pressure relief valve is designed to the grade of oil to be used in the engines service life and you must adhere to the proper recommendations for the best results and longevity of the engine.

Among the most important parts of an engine is the oil that it contains. Without the right amount of oil pressure in an engine, it will be hard for all of the moving parts to get the lubrication that they need. It is the job of the high pressure safety valve to ensure that the right amount of oil pressure stays consistent. Once the right oil pressure is achieved, this safety valve will turn down the oil pump to reduce the amount of pressure that it is putting out. Usually, the oil pump will have to run its hardest when the car first starts up.

Typically, this valve will last as long as your car does, but there are instances when it will have to be replaced. Much like any other switch or valve in a vehicle, the heat of the engine can affect the way that the high pressure safety valve operates. Since this part is not checked on a regular basis, the only time that most car owners will have any interaction with it is when it becomes broken. Dealing with the broken valve as soon as problems start to surface can help to prevent a lot of damage.

Getting the damaged high pressure safety valve replaced is a job that is best suited for a professional. The oil pressure is a vital part of your engine and attempting to fix components of this system without the right amount of experience can lead to less than stellar consequences. A professional will be able to troubleshoot the issues with your oil pressure and get the right repairs made in no time. When the high pressure safety valve in your engine is damaged, here are a few of the things you may start to notice.

Finding and fixing the issues with your car’s oil pressure should be a priority. Running an engine with low oil pressure levels can lead to a lot of problems and will cause a lot of damage.

Tired of messing with an old, unreliable, dirty fuel oil burner? One easy solution is the installation of the Carlin Gas Conversion Burner that can be installed in almost any oil fired furnace, boiler or water heater.

If it’s time to stop messing with your oil burner and switch to clean burning, environmentally friendly propane gas, give CES a call at 800-874-1975 to schedule a review and FREE no obligation quote.

8613371530291

8613371530291