osha air compressor safety valve in stock

An OSHA COMPRESSED AIR SAFETY SHUT-OFF VALVES should be placed immediately after the air control shut off valve and before the hose on a compressor, and after each discharge port that a hose is connected to.

Before starting the compressor the air control valve should be closed completely. When the compressor unloads, open the air shut off control valve very slowly. Full port ball valves tend to work better than gate or butterfly type valves.

The air shut off control valve must be fully open for the OSHA COMPRESSED AIR SAFETY SHUT-OFF VALVES to work. Some portable air compressor manufacturers recommend start-up with the air control valve slightly open. In this case you may have to close the valve and reopen it slowly to the full open position, or wait for the safety shut-off valve to reset itself.

If the OSHA COMPRESSED AIR SAFETY SHUT-OFF VALVES fails to operate despite meeting all condi-tions, check the hose line for obstructions or a hose mender restricting normal air flow.

• Turn on air supply slowly (to avoid tripping OSHA safety valve). Prior to fully reaching operation conditions, the OSHA COMPRESSED AIR SAFETY SHUT-OFF VALVES should suddenly activate and stop air flow.

• If the OSHA COMPRESSED AIR SAFETY SHUT-OFF VALVE is not activated the unit should be disconnected and the lower flow range OSHA COMPRESSED AIR SAFETY SHUT-OFF VALVES should be used. This means you need to use a different valve with a lower scfm range.

• At temperatures below 40°F ensure that OSHA COMPRESSED AIR SAFETY SHUT-OFF VALVES are not subject to icy conditions which may prevent proper functioning.

*OSHA 29 CFR 1926.302(b)(1): Pneumatic power tools shall be secured to the hose or whip by some positive means to prevent the tool from becoming accidentally disconnected. Additionally 1926.302(b)(7) states: All hoses exceeding ½-inch inside diameter shall have a safety device at the source of supply or branch line to reduce pressure in case of hose failure.

The check valve should be the same diameter as the hose that will be used, do not increase or decrease the hose size from the compressor or manifold after the check valve is installed. Do not use a check valve of a different size to reach a desired SCFM cut off range.

Per Section 1417 of the Safe Drinking Water Act (SDWA) use Lead free parts in all consumable water applications. Lead free refers to the wetted surface of pipes, fittings and fixtures in potable water systems that have a weighted average lead content = 0.25%. Source: California Health & Safety Code (116875). Vermont Act 193*171NLF

Brand new, certified 1/8" Male NPT Threaded 70 PSI air compressor / tank pressure safety relief valve. Also known as a "Pop Off" or "Blow Off" valve. This relief valve is manufactured in the United States and is stamped with "UV" & "NB" symbols. The relief pressure of this valve is set at 70 PSI and is accurate within + or - 3% of the set pressure.

The OSHA Safety Standard Regulation 29CFR CHXVII Paragraph 1926.302(b)(7) states: All hoses exceeding 1/2-inch inside diameter shall have a safety device at the source of supply or branch line to reduce pressure in case of hose failure.

Prevent dangerous air hose whips and accidents. Protect your most important assets: Your employees and their equipment. OSHA COMPRESSED AIR SAFETY SHUT-OFF VALVESoffers simple but efficient protection to pneumatic systems in the event of a broken compressed air hose or pipe.

OSHA says reduce your slips, trips and falls. Slips, trips and falls constitute the majority of general industry accidents, which cause 15% of all accidental deaths, and are second only to motor vehicles as a cause of fatalities. The OSHA standard for walking and working surfaces apply to all permanent places of employment, except where only domestic, mining, or agricultural work is performed.www.osha.gov

Consider adding reels to increase safety & efficiency with your electrical cords, welding cables, air hose, oil, grease, liquid/water or fuel hoses. This could be one of your most effective equipment additions you’ll ever make…as well as one of the safest!

Provide a Safer Work EnvironmentHose reels decrease you chances of injuries from tripping hazards. Reduce accidents and insurance expense: Slips, trips and falls are the leading cause of work stoppage in industry. Reels can help you meet OSHA Safety Requirements.

Reels are used to transfer air, water, motor oil, transmission fluid, grease, gear oil, anti-freeze, diesel fuels, welding gases, fuel oil, liquid pesticides, fertilizers, detergents, hydraulic oils, cutting oils, printing inks, solvents, chemicals, and blacktop sealers.

Probably one of the largest uses of hose reels is for Compressed Air. Compressed air is clean, readily available, and simple to use. As a result, compressed air is often chosen for applications for which other energy sources are more economical. Inappropriate uses of compressed air include any application that can be done more effectively or more efficiently by a method other than compressed air.

Don’t WASTE your Compressed Air. Check your facility for wasteful and perhaps even unsafe uses of compressed air. Bottom Line: Invest in durable, quality reels that make hoses, cords and cables more productive, keep them easily accessible and make them last longer.

When using a portable air compressor on a worksite, what component should (almost) always be part of the job? The answer is a safety check valve (SCV), properly installed between the compressor and the hose. In fact, if your air hose has an inside diameter of more than a ½ inch, OSHA requires a SCV to be installed at the source of the air supply to shut off the air automatically in case of hose failure. (If a check valve is not being used, OSHA requires a safety cable, such as Dixon’s King™ safety cable, to be attached to the hose.) But selecting the right safety check valve is an important but often times confusing task. There are many factors that play into that decision: air pressure, tool flow rate, compressor flow rate, the size of your hose, and the length of your hose, among them. Here’s a quick guide to helping make that decision an easier one.

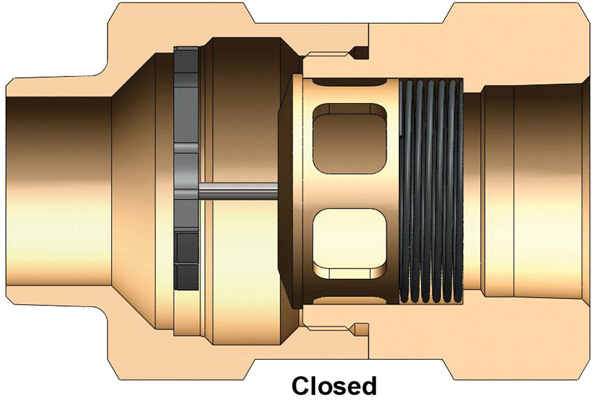

Safety check valves are used to shut off flow in the event of a full-flow condition, which could be caused by a line break or damaged tool. During a full-flow condition, the compressor blasts air like a geyser and can whip the hose around the worksite, potentially causing serious injury to personnel or damage to equipment.

As air passes through the safety check valve, the valve flutters back and forth, allowing the air to bypass the valve and go downstream to the tool. In the event of a hose failure, the sudden rush of air through the valve causes it to slam shut, eliminating potential danger. A pin-sized hole in the valve allows a small amount of air to escape, but not enough to whip the hose around. That’s why you’ll still hear some air hissing at the end of the hose, even when the safety valve is engaged. Once the hose is repaired and the full flow condition goes away, the safety check valve will reset itself, allowing airflow to resume. Without this feature, you would have to manually reset the valve, a time-consuming task.

What is the maximum airflow possible, in SCFM, through your air hose, at the end of the length of the hose? (Note: If the hose you’re using is more than 100 feet long, contact Dixon for recommendations.)

It’s very important to select both the correct hose ID as well as the correct size spring within the valve. If the spring is too large or too small, it will cause the valve to shut prematurely or not to check at all.

The safety shut-off valve taper (NPT) size must be the same as the nominal ID size of the airline on which it is used. (Note: Never increase or decrease the hose size from the compressor to the tool or from the compressor to the manifold.)

To avoid nuisance cut-offs, the SCV selected should have a cut-off range of 110% of the maximum anticipated airflow to the tool, or tools, to be used. (As a general rule, you want your tool consuming less flow than the cut-off range of the SCV and you want your compressor capable of supplying more flow than the cut off range of the SCV.)

The maximum SCFM of the supply side airline must be above the cut-off range of the valve. The cut-off range of Dixon"s shut-off valves is given at 90 PSI. To determine the cut-off range at other PSIs, please refer to Dixon’s Cut-off Rate Chart on our product spec sheet.

In certain applications, like pile driving or sand blasting, where a surge of air is needed right away, you’ll have to use a safety cable since a check valve won’t work properly.

In closing, whenever you’re using an air compressor for jobs other than the ones mentioned directly above, it’s important to include a safety check valve in the system. Knowing how to select the proper SCV for the job creates a safer, more efficient worksite. As always, if you have any questions about safety check valves, please call a Dixon representative at 877.963.4966.

Thank you for your letter dated January 31 concerning your constituent, Mr. James Lyle McCloy II, President of Compressed Air Parts Company. Mr. McCloy is concerned about the lack of enforcement by the Occupational Safety and Health Administration (OSHA) of its rules requiring safety check valves on compressed air equipment. I apologize for the delay of this response.

As Mr. Roy Gurnham of my staff discussed with Mr. Mark Staudohar of your office in mid-February when he called to explain we could not meet with Mr. McCloy at the time, OSHA continues to recognize the need for safety check valves and is concerned that accidents have occurred because such valves were not provided as required. We will remind our compliance officers of the importance of this provision and that their inspections should include a review of such equipment as appropriate.

As you may be aware, the State of Arizona is responsible for occupational safety and health enforcement within the State under a plan approved and monitored by Federal OSHA. Under its plan, Arizona adopts standards identical to those promulgated by Federal OSHA and utilizes equivalent enforcement procedures. If your constituent wishes to discuss safety and health enforcement in Arizona, we suggest that he contact the Arizona industrial Commission at the following address:

The enclosed information is sent for your consideration. Please investigate this matter and forward to me the information for response to my constituent, Mr. James Lyle McCloy II, President of Compressed Air Parts Company.

Introducing our product in mid 1972, with several other manufacturers, sales were quite brisk and the Department of Labor was very active insuring compliance. Since early 1976 enforcement has been very `spotty". As of this time only ourselves and one other manufacturer are still providing valves to meet Federal Regulations. Fortunately we have been the primary source.

Recently we were dismissed from a One Million Dollar ($1,000,000) product liability suit in which it was determined that the air compressor in use was not equipped with a safety check valve as required. This incident took place on a Federally funded Interstate bridge repair contract. Also, there is currently a multi-million suit concerning the lack of a safety check valve (actually there was a valve on the compressor but was removed for unknown reasons). In that case a worker has a severe head injury and has been in a nursing home for two years and cannot recognize his family.

This checklist covers regulations issued by the U.S. Department of Labor, OSHA under General Industry standard 29 CFR 1910.169. It applies to air compressor tanks (compressed air receivers used to store compressed air generated by an air compressor), and other equipment used in providing and using compressed air for operations such as cleaning, drilling, hoisting, and chipping. The regulations cited apply only to private employers and their employees, unless adopted by a state agency and applied to other groups such as public employees.

Is a drain pipe and valve installed at the lowest point of every air compressor tank so accumulated oil and water can be removed? [29 CFR 1910.169(b)(2)]

Is the air compressor tank drained frequently (either manually or by an automatic drain valve) to prevent the accumulation of excessive amounts of liquid in the tank? [29 CFR 1910.169(b)(2)]

Is every air compressor tank equipped with a readily visible pressure gauge and with one or more spring-loaded safety valves? [29 CFR 1910.169(b)(3)]Note: The total relieving capacity of this safety valve shall be enough to prevent pressure in the receiver from exceeding the maximum allowable working pressure of the receiver by more than 10 percent.

Are safety valves located and installed so that they cannot easily be made inoperative by any means, including the elements? [29 CFR 1910.169(b)(3)(iii)]

Compressed air is a gas under more pressure than the air in the general environment. Compressed air is dangerous because – without proper personal protective equipment – it can damage any part of the human body.

If compressed air gets into the bloodstream, the result can be fatal. A pressure strong enough to dust or clean is strong enough to break the skin and penetrate the body. Even pressures as low as five to 10 pounds per square inch can cause an injury.

Almost any part of a compressed-air system can be hazardous including the compressor, the storage tank, valves, regulators, and the line that moves the air to the point of use.

Even at a relatively low pressure, flammable gases, such as acetylene, butane, ethylene, hydrogen, methylamine, and vinyl chloride, can burn or explode when they are accidentally released from a broken or leaking valve or from a safety device.

However, installation of a block valve on the inlet of a relief valve can be considered acceptable for facilities located in states that enforce ASME boiler / pressure vessel code as the law (as indicated in the OSHA standards interpretation below).

This section applies to compressed air receivers, and other equipment used in providing and utilizing compressed air for performing operations such as cleaning, drilling, hoisting, and chipping. On the other hand, however, this section does not deal with the special problems created by using compressed air to convey materials nor the problems created when men work in compressed air as in tunnels and caissons. This section is not intended to apply to compressed air machinery and equipment used on transportation vehicles such as steam railroad cars, electric railway cars, and automotive equipment.

(a) All safety and relief valves for use on pressure vessels or piping systems shall be designed to meet the protection and service requirements for which they are intended and shall be set to relieve at a pressure which does not exceed the “maximum allowable working pressure” of the pressure vessel or piping system. Relief valves are not required to have huddling chambers for other than steam service. In addition, safety valves used on vessels in which steam is generated shall meet § 52.01-120 of this subchapter except § 52.01-120(a)(9). For steam service below 206 kPa (30 psig), bodies of safety valves may be made of cast iron. Safety relief valves used in liquefied compressed gas service shall meet subpart 162.017 or 162.018 in subchapter Q (Specifications) of this chapter as appropriate.

(b) Pilot-valve control or other indirect operation of safety valves is not permitted unless the design is such that the main unloading valve will open automatically at not over the set pressure and will discharge its full rated capacity if some essential part of the pilot or auxiliary device should fail. All other safety and relief valves shall be of the direct spring loaded type.

(c) Safety and relief valves for steam or air service shall be provided with a substantial lifting device so that the disk can be lifted from its seat when the pressure in the vessel is 75 percent of that at which the valve is set to blow.

(d) Safety and relief valves for service other than steam and air need not be provided with a lifting device although a lifting device is desirable if the vapors are such that their release will not create a hazard.

(e) If the design of a safety or relief valve is such that liquid can collect on the discharge side of the disk, the valve shall be equipped with a drain at the lowest point where liquid can collect (for installation, see UG-134 of section VIII of section VIII of the ASME Boiler and Pressure Vessel Code (incorporated by reference; see 46 CFR 54.01-1).

(f) Cast iron may be employed in the construction of relief valves for pressures not exceeding 125 pounds per square inch and temperatures not exceeding 450 °F. Seats or disks of cast iron are prohibited.

(g) The spring in a relief valve in service for pressures up to and including 250 pounds per square inch shall not be reset for any pressure more than 10 percent above or 10 percent below that for which the relief valve is marked. For higher pressures, the spring shall not be reset for any pressure more than 5 percent above or 5 percent below that for which the relief valve is marked.

(h) The rated relieving capacity of safety and relief valves for use on pressure vessels shall be based on actual flow test data and the capacity shall be certified by the manufacturer in accordance with one of the following:

(2) 110 percent of the valve set pressure for valves rated in accordance with UG-131 of section VIII of section VIII of the ASME Boiler and Pressure Vessel Code.

Before youbuy compressed air receiver tank, take some time to learn about the device itself. Our guide to compressed air receiver tanks explains how they work, what they do, and how you can use them to maximize the efficiency of your compressed air system.

An air receiver tank (sometimes called an air compressor tank or compressed air storage tank) is what it sounds like: a tank that receives and stores compressed air after it exits theair compressor. This gives you a reserve of compressed air that you can draw on without running your air compressor.

An air receiver is a type ofpressure vessel; it holds compressed air under pressure for future use. The tanks come in a range of sizes and in both vertical and horizontal configurations.

An air receiver tank provides temporary storage for compressed air. It also helps your air compression system run more efficiently. The air receiver tank has three main functions in your compressed air system:

The primary role of an air receiver tank is to provide temporary storage for compressed air. Storing compressed air allows the system to average the peaks in compressed air demand over the course of a shift. You can think of your air receiver tank as a battery for your compressed air system, except it stores air instead of chemical energy. This air can be used to power short, high-demand events (up to 30 seconds) such as a quick burst of a sandblaster, dust collector pulse, or someone using a blowgun to dust themselves off. The air in the tank is available even when the compressor is not running. Storing compressed air reduces sudden demands on your air compressor, prolonging the life of your system. Using an air receiver tank may also allow you to use a smaller horsepower compressor for larger jobs.

The air receiver tank provides a steady stream of air to compressor controls, eliminating short-cycling and over-pressurization. Uneven compressed air utilization causes uneven demand on the air compressor, resulting in rapid cycling of the compressor controls as the compressor turns on and off to meet moment-by-moment demand. Each time the system turns on and off (or loads/unloads) is called a “cycle”; it is better for the compressor motor to keep these cycles as long as possible. Over time, frequent short cycling will lead to premature failure of switches and other compressor components. Rapid cycling can result in excessive wear of the motor contactor or even a direct motor short because of winding insulation. The air receiver tank eliminates short cycling and provides more consistent system pressure to controls.

As air is compressed under pressure, its temperature increases; this is a simple law of physics known as thePressure-Temperature Law. Depending on the type of air compressor you are using, the air discharged from the compressor may be as hot as 250 – 350°F. This is too hot for most air-operated equipment to use directly. Hotter air also contains more moisture, which will result in excess water vapor that will condense in control lines and tools if it is not removed. The condensed air must be cooled and dried before it is utilized. Aheat exchangeris used to remove excess heat caused by compression. The air receiver tank acts as a secondary heat exchanger; as air sits in the tank or slowly flows through it, it naturally cools over time. The air receiver tank supports the work of a primary heat exchanger; lowering the temperature of the air an additional 5 – 10°F is not uncommon.

As the air compressor cycles on and off, compressed air can be wasted. Every time arotary screw air compressorunloads, the sump tank (oil tank) is vented. Compressed air is released during the venting. Over time, this adds up to the loss of thousands of cubic feet of compressed air that could otherwise have been used to power processes in your facility. A properly sized air storage tank reduces frequent cycling and venting.

Compressed air storage also allows you to reduce the pressure at which your air compressor operates. Without a store of compressed air to draw on, the system will have to operate at higher pressures, so it is always ready to meet peak demands. In essence, you are asking your system to operate as if your facility is always running at maximum demand. This leads to increased energy use and wear and tear on the system. On average, for every 2 PSI that you increase the pressure of your system increases the energy demand by 1%. This can lead to hundreds or thousands of dollars added to your energy bills annually. As explained above, adding an air receiver tank to your compressed air system will even out these peaks in demand, allowing you to meet intermittent periods of high demand without increasing the overall pressure of your system.

The heat exchanger function of the air receiver tank helps to improve the efficiency of your air dryer. As air passes slowly through the receiver tank, it cools. Cooler air can’t hold as much moisture as warm air, so excess moisture condenses and falls out of the air as a liquid. The water drains out of a valve at the bottom of the tank. By removing some moisture in advance, the air receiver tank reduces the amount of work the air dryer needs to do. This improved efficiency translates to additional energy savings for your system.

When shopping for an air receiver tank, you may be asked whether you want “wet” or “dry” compressed air storage. The difference is in the location of the air storage tank in your compressed air system; there is no difference in tank construction or design.

“Wet” storage tanks are locatedbeforethe air drying system. Air flows through the tank in this configuration, entering through the bottom port from the compressor and exiting out the top to the dryer.

“Dry” storage tanks are locatedafterthe air dryers to store compressed air that has already been dried and filtered. It is not necessary to flow the compressed air through the tank for dry storage.

With wet air storage, the receiver tank is positioned in between the air compressor and the air dryer. Wet air enters the receiver tank from the air compressor through the lower port in the tank and exits through the upper port to enter the air drying system. A wet air receiver tank has several benefits.

As explained above, wet storage increases the efficiency of your air dryer by allowing excess water and lubricant to condense out of the air before it hits the dryer.

A wet air storage tank also prolongs the life of the pre-filter element, which is located in between the wet storage tank and the dryer. Since the air going through the filter is cleaner and dryer than it would be directly out of the air compressor, slugging of the filter with liquids is minimized, along with resulting pressure drop on the air dryer side of the system.

The compressor does not experience backpressure because the air does not go through filtration before entering the tank. This results in a steadier pressure signal to the compressor controller.

Without a dry air tank, air from the wet tank will have to go through the air dryer before it is used. During periods of high demand, the dryer is at risk of becoming over-capacitated as the system tries to pull air through at higher volumes than the dryer is rated for. If the dryer cannot keep up with the demand, drying efficiency is reduced, potentially leading to unwanted water in the air lines.

The ideal ratio of compressed air storage is1/3 wet to 2/3 dry capacity. For example, if you have a total of 1,200 gallons of compressed air storage, 800 gallons should be dry storage, and 400 gallons should be wet. Dry air is ready to use on-demand. The wet air tank increases the efficiency of the dryer and acts as a secondary reserve when dry air is exhausted. Dry air storage needs to be greater than wet storage to minimize the risk of over-capacitating the air dryer during periods of high demand.

An exception to this rule is for applications that have steady airflow without sharp peaks in demand. In this case, there is no need for a dry storage tank because air will simply flow through it without being stored up. This is often the case in robotic manufacturing facilities where airflow is consistent and predictable.

A good rule of thumb for most applications is to havethree to five gallons of air storage capacity per air compressor CFM output. So if your air compressor is rated for 100 CFM, you would want 300 to 500 gallons of compressed air storage. As explained above, 1/3 of the total storage capacity should be wet storage, and 2/3 should be dry storage.

While the standard rule works well for many applications, you will also want to consider other variables in determining your compressed air storage needs. Flow consistency has a large impact on storage requirements.

Facilities with very steady airflow, such as robotic facilities, typically don’t need as much stored air. That’s because they don’t have frequent high bursts of demand that rely on stored air. In this case, air storage can be reduced to 2 gallons per CFM of air compressor capacity. All storage should be wet storage in this case, as explained above.

Facilities with high variability in airflow and large peaks in demand may require larger volumes of stored air. This extra capacity will ensure that the system will be able to keep up with periods of high demand. Testing to determine CFM at peak demand will be needed to calculate air storage requirements.

The final consideration in determining compressed air storage requirements is the size of the pipework in the system. The pipes also store air for your compressed air system, and the larger the pipes, the more storage they provide. For systems with pipework of 2” or greater diameter, it may be worthwhile to consider that volume into the calculation.

Compressed air receiver tanks can be bulky, so many compressed air system owners would prefer to store them outside. Outdoor storage saves precious floor space in the facility.

It also helps to reduce strain on your HVAC system in warm weather. The compressed air storage tank radiates heat as hot air from the compressor cools within the tank, raising temperatures in the compressor room. Storing your tank outside avoids excess heat buildup in the compressor room and also helps the storage tank perform its secondary job as a heat exchanger more efficiently.

However, outdoor storage only works in milder, non-freezing climates. Make sure your climate is suitable for outdoor placement of your compressed air tank.

Outdoor storage of the air receiver tank is only appropriate for environments that stay above freezing year-round. In freezing temperatures, outdoor tanks can ice up and even rupture—a costly and potentially dangerous outcome. If your area experiences freezing temperatures during part of the year, it is safest to keep your tank indoors.

If you are storing your air receiver tank outdoors, be sure to conduct frequent inspections to monitor for corrosion. Any signs of corrosion should be addressed immediately to maintain the integrity of the tank.

The majority of air receiver tanks are bare steel on the inside with a primer coating on the outside to reduce corrosion. The exterior paint is commonly matched to the compressor equipment. A basic steel tank works well for most applications and is the least expensive option. However, they may be prone to corrosion if too much liquid is allowed to build up inside the tank.

Epoxy coatings are sprayed onto the interior as a liquid and then cured into a tough, anti-corrosive coating. Epoxies work by creating a moisture-proof barrier between the air and the base metal of the tank.

Both methods provide long-lasting protection for the interior of the tank, but they do add to the cost and lead time. Coated or galvanized tanks are better at maintaining air purity because they reduce the risk of particulates caused by corrosion entering the airstream. Applications needing higher purity air, or users concerned about the longevity of their air tanks, may want to consider one of these options.

Stainless steel air receiver tanks are primarily used for specialty applications where very high-purity air is required. They are the most expensive option, but they are highly durable and corrosion-resistant and maintain exceptional air purity. Hospitals, labs, electronics manufacturers, and other applications requiring high-purity air should consider a stainless steel tank.

Air receiver tank accessories are essential for tank safety and operation. While the tank itself is just a large sealed metal tube, all tanks must have at a minimum:

Automatic drain valves eliminate the need for daily manual draining of liquid inside the air receiver tank. Anelectric automatic drain valveis programmed to open at set intervals to let accumulated liquid drain out.

Zero air-loss condensate drainsalso provide automatic drainage of the tank. Instead of draining at set intervals, they use a float mechanism to control drainage. The drain will only open when needed, saving energy and reducing air loss from the tank.

The pressure gauge provides a visual indicator for the interior pressure of the air in the tank. You need the gauge to monitor pressures and ensure that the tank is not under stress from over-pressurization.

A pressure relief valve is required for all air receiver tanks per OSHA and ASME guidelines. The pressure relief valve opens automatically to release some air if pressures in the tank are too high. This safety mechanism is essential to minimize the risk of a dangerous rupture due to over-pressurization. The relief valve is typically set to 10% higher than the working pressure of the compressed air system but never more than the rated pressure of the tank’s ASME certification.

Vibration pads are not required for all applications, but they are recommended if the air compressor is mounted on top of the tank. Vibration pads absorb vibrations from the compressor motor and reduce fatigue on the tank.

Many buyers wonder if ASME certification is important for air receiver tanks—and the answer is yes. All air receiver tanks used in industrial applications must be certified by ASME for safety and performance.

The American Society of Mechanical Engineers, or ASME, is an organization that sets engineering codes and manufacturing standards for a variety of machines, parts, and system components. ASME acts as an independent quality assurance organization to ensure the safety and quality of manufactured items. An ASME certification stamp means that the manufacturer has met all safety and engineering standards for their product.

ASME has developed a set of codes and standards for pressure vessels, including air receiver tanks. The ASMEBoiler and Pressure Vessel Certification Programsets rules governing the design, fabrication, assembly, and inspection of pressure vessel components during construction. These rules include engineering standards for the thickness of the tank body, welds and joints, connections, and other components of the tank. Tank manufacturers must conform to all of the rules to obtain ASME certification.

Some big box stores carry non-code air receiver tanks. While these may be cheaper, they have not undergone the rigorous manufacturing processes and quality testing needed to ensure that they are safe and reliable. Using a non-code air receiver tank could put your life and the lives of your coworkers at risk.

If you are not sure whether or not your air receiver tank meets code requirements, you should have it inspected. Your local Fire Marshall may provide this service. They will stop in and test your tank with ultrasonic metalthickness testing technology. If your air receiver tank does not pass the inspection, it should be decommissioned and replaced immediately.

All air receiver tanks must also be inspected periodically once they are installed. OSHA does not mandate a specific testing interval, but it is recommended that all air receiver tanks be inspected at least annually. Your insurance company or local governing board may have different requirements. OSHA requires that formal inspections be performed by an inspector holding a validNational Board Commissionand in accordance with the applicable chapters of the National Board Inspection Code. Manufacturers are required to keep records of formal inspections and make them available to OSHA representatives upon request.

In between formal board inspections, manufacturers should conduct frequent visual inspections of the air receiver tank to look for signs of corrosion, damage or weld failure. Check drains daily and pressure relief valves quarterly to make sure they are operating correctly. Contact your manufacturer or compressed air system installer immediately if you see any signs of problems with your air receiver tank.

Pressure vessels must be built to withstand high internal pressures over a long period of time. Over time, corrosion, stress, and fatigue can make tank failure more likely. The most common causes of air receiver failure are:

The high internal pressures within an air receiver tank make failure extremely hazardous. Cracking or weld failure can cause the tank to burst with explosive force, projecting large pieces of metal or fragments of shrapnel at high speed. Air receiver tank failure may result in extensive damage to the facility and nearby equipment and severe injury or death for nearby workers.

An appropriately-sized air receiver tank will improve the efficiency of your system—and can even reduce your operating costs for your compressed air system. Your air receiver tank reduces energy consumption and saves wear and tear on your system.

Your compressed air receiver tank is like a battery for your facility, providing an extra reservoir of compressed air you can draw on during periods of high demand. This lets you reduce the overall operating pressures for your system, resulting in lower energy costs. You may also be able to purchase a smaller air compressor with lower CFM capacity by relying on your air receiver tank for high-demand events.

As explained above, the air receiver tank reduces cycles counts for your air compressor by evening out peaks in compressed air demands. Lower cycle counts add up to lower energy use and less wear and tear on other system components, extending the life of your air compressor.

The air receiver tank functions as a pulsation dampening device, absorbing vibrations from the air compressor motor and pulsations in the air stream. This reduces fatigue on piping and other system components.

As the air cools in the air receiver tank, the excess liquid condenses and falls out of the air. This results in less work for the air dryer and less energy consumption.

Particulates can enter the airstream due to corrosion within the system, motor exhaust from the air compressor, or particulates in facility air. Many of these particulates will fall out of the air along with condensate within the air receiver tank. The excess dirt is then simply drained away with the liquids. As a result, the air entering the air dryer is both cleaner and drier than air directly from the air compressor.

Your air receiver tank is an essential component of your compressed air system. Having a properly sized air receiver tank ensures the safe and efficient operation of your system and provides a reservoir of extra power for use during periods of peak demand.

If you’re not sure how much air storage capacity you need, or if you have questions about maintaining your tank for safe operation, the experts at Fluid-Aire Dynamics can help. We will perform an assessment of your compressed air usage patterns and recommend an air receiver tank that will fit your needs. We can also help you inspect, repair, or upgrade your current storage system.

8613371530291

8613371530291