ordinary lay wire rope pricelist

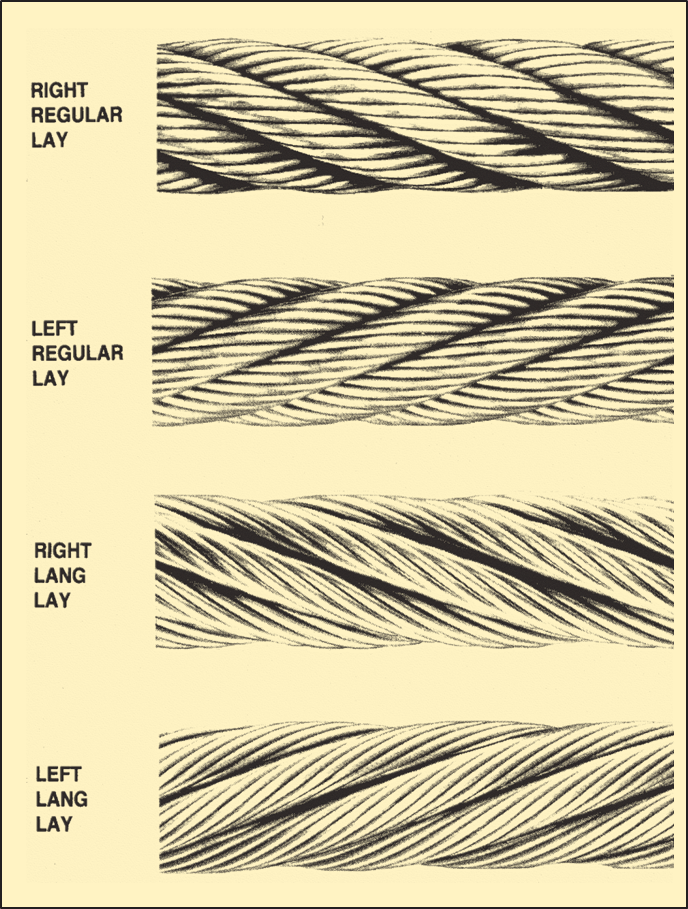

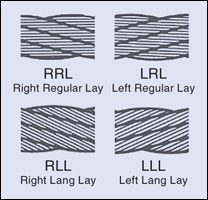

Left hand lay or right hand lay describe the manner in which the strands are laid to form the rope. To determine the lay of strands in the rope, a viewer looks at the rope as it points away from them. If the strands appear to turn in a clockwise direction, or like a right-hand thread, as the strands progress away from the viewer, the rope has a right hand lay. The picture of steel wire rope on this page shows a rope with right hand lay. If the strands appear to turn in an anti-clockwise direction, or like a left-hand thread, as the strands progress away from the viewer, the rope has a left hand lay. (The rope in the left hand lay photo shows one left hand lay rope from left to right and top to bottom, with 5 right hand lay strands, and part of a sixth in the upper left. It is not 5 right hand lay ropes adjacent to each other.)

Ordinary and Ducay"s lay describe the manner in which the wires are laid to form a strand of the wire rope. To determine which has been used, first identify if left or right hand lay has been used to make the rope. Then identify if a right or left hand lay has been used to twist the wires in each strand. (On ordinary lay, the outer wires approximately follow the alignment of the rope: with Lang"s lay they are cross at an angle of about 45�.) Lang"s laid rope is able to flex over sheaves more easily (with less damage) but it has the disadvantage of having a high torque tendency (it tends to untwist when tension load is applied) compared with ordinary laid rope. Untwisting can be dangerous with a steel-cored rope: load is shed from the strands and may cause the core to fail as it becomes higher loaded. For this reason, swivel termination units can be dangerous.

The specification of a wire rope type � including the number of wires per strand, the number of strands, and the lay of the rope � is documented using a commonly accepted coding system, consisting of a number of abbreviations.

MAX Groups Marine is one of the most trusted suppliers of stainless steel and galvanised wire ropes/cables. Wire ropes consist of several strands of metal wire twisted into a helix form, forming extremely durable wire ropes for various marine purposes. Wire ropes are exposed to high fluctuation of contradicting forces, wear and tear or even corrosion in some cases. Thus, the quality of wire rope has to be taken very seriously.

Constant eye inspection and tests should be carried out to make sure the wire ropes are performing as they should. In MAX, all manufacturing of wire ropes are supervised and tested by professional technicians at all times.

Commonly used types of wire ropes may be of a fiber core (FC), Wire Strand core (WSC) or an Independent Wire Rope Core (IWRC). Usually IWRC core ropes are more durable whereas fibre core wire ropes are more elastic. The choice of wire rope core mostly depends on the usage and situation.

Most wire ropes are made from high-carbon steel, iron, stainless steel, bronze and more. Carbon steel wire ropes are graded from IPS (Improved Plow Steel), EIPS (Extra Improved Plow Steel to EEIPS (Extra Extra Improved Plow Steel), with each grade signifying its nominal strength. The most popular MAX steel wire ropes are of EIPS grade.

It doesn’t matter whether the lay direction is right (Z) or left (S), ordinary lay or langlay, MAX wire ropes are designed to have high durability and tensile strength for heavy industry usage.

For wire rope slings, you may opt for thimble eye (where a thimble if fixed inside the loop to preserve the natural loop shape and prevent direct contact that will damage the cable) or soft eye. Besides, rope ends with machine swaged with ferrules or sockets is a better option than hand spliced slings as it offers more protection.

Do you experience a short lifespan for your steel wire ropes? Deal with a supplier who is slow in responding & customer service? Or did you pay high prices for average quality products that fails you all the time? 83% of our clients claim that these made them search for a better option and subsequently worked with us since.

Rope Services Direct supplies a variety of anti-spin non rotating wire rope (also called rotation resistant wire-rope). All standard rope wirehas a tendency to develop torque and therefore prone to rotation, whereas non-rotating wire ropes are designed so that the wire-rope outer rotational force naturally counteracts the inner strands rotational force. This is in the event that a rope is subjected to a load.

Rope elongation and rotation occurs on standard ropes when loaded, which can therefore spin the load, quite possibly out of control, which can be dangerous. When the rope rotates in this way the strands will begin to unravel. This causes the rope to lose strength and will undoubtedly fail, which could be catastrophic. It is for these reasons that non rotating wire rope is commonly used for many types of lifting applications including main hoist rope, whip rope,crane rope, off-shore and deck rope and more.

Non rotating wire rope or rotation resistant wire rope has a different construction to standard. as wires and strands are not laid in the same direction like they would be on standard rope. Inner and outer strands of wires are laid in opposite directions. For example the inner may be constructed in left hand lay whilst the outer layer is in right hand lay. The nature of this construction means that torsional forces on the inner and outer wires/strands will counteract each other and therefore minimising the risk of unraveling.

It is worth noting that the number of strand layers will have an effect of the resistance of rotation. A 2 layer rope has less resistance than a 3 layer rope. Therefore the more layers the rope has the greater rotation resistance it will have.

These types of ropes can be classified as spin resistant, rotation resistant or non rotation resistant. Classed on the basis of the number of rotations a certain length of rope does when a force of 20% of the MBF is applied; with 1 turn or less the rope will be classified as non rotating; with rotations between 1 & 4 the rope is classed as low rotation and for rotations between 4 & 10 the rope will be classified as spin resistant, any higher and the rope is NOT rotation resistant at all.

Correct usage and care with handling will prolong the working life. This is due to the friction on the inner wires caused by the strand crossover’s which will eventually cause the inner wires to break up. This is more apparent on non rotating wire rope with two layers. Ropes with 3 or more strand layers will distribute the radial pressures more evenly. Which will reduce friction and stress on the inner wires.

Regular,thorough inspectionsof non rotating rope are essential due to the fact that it is the inner strands that often break first and broken internal wires often go unnoticed as they are difficult to see.Rope Services Direct offer inspectionson all rope with certification issued on completion.

Holding both ends of the rope will prevent unraveling. Correctly fitted terminations will help to prevent damage. Kinking and unraveling may occur and they can also have an effect on the rotational balance if not fitted correctly.

A six strand wire rope in which three strands are ordinary lay and three strands are lang lay is known as an alternate lay wire rope and combines some of the desirable properties of both the regular lay and langs lay type of rope.

Wire rope is identified not only by its components parts, but also its construction, i.e., by the way the wires have been laid to form strands, and by the way the strands have been laid around the core.

( "a" and "c" ) shows strands as normally laid into the rope to the right - in a fashion similar to the threading in a right-hand bolt. Conversely the "left lay"rope strands (illustration "b" and "d" ) are laid in the opposite direction.

Again the first two ( "a" and "b" ) show regular lay ropes. Following ( "c" and "d" ) these are the types known as lang lay ropes. Note that the wires in regular lay ropes appear to line up with the axis of the rope; in lang lay rope the wires form an angle with the axis of the rope. This difference in appearance is a result of variations in manufacturing techniques: regular lay ropes are made so that the direction of the wire lay in the strand is opposite to the direction of the strand lay in the rope; lang lay rope are made with both strand lay and rope lay in the same direction. Finally ( "e" and "f" ) called alternate lay consists of alternating regular and lang lay strands.

Choosing the right wire rope for a job will be based on many factors: application, required strength, and environment, to name a few. Understanding the basic terminology and the abbreviations associated with wire rope can help you decide which will work best for you.Size

Displayed as inch or fractional inch measurements, the size indicates the diameter of the rope. Industry standards measure the rope at its widest point. A wide range of sizes are available.

The numbers used in describing wire rope indicate its construction. For example: a 6 x 19 construction wire rope, the first number is the number of strands (6); the second number is how many wires make up one strand (19).

Regular lay:Also known as a right lay or ordinary lay, this indicates that the strands pass from left to right across the rope and the wires in the rope are laid in opposite direction to the lay of the strands. This type of construction is the most common and offers the widest range of applications for the rope.

Lang lay:This indicates that the wires are twisted in the same direction as the strands. These ropes are generally more flexible and have increased wearing surface per wire than right lay ropes. Because the outside wires lie at an angle to the rope’s axis, internal stress is reduced making it more resistant to fatigue from bending. This type of rope is often used in construction, excavating, and mining applications.

Fiber cores are made of vegetable (sisal, etc.) or synthetic (polypropylene, etc.) fiber and offer more elasticity. Independent wire rope cores offer more support to the outer strands, and has a higher resistance to crushing and heat. Independent wire rope core also has less stretch and more strength.

Non-rotation resistant ropes usually achieve more bending cycles than rotation-resistant ropes or semi-rotation resistant ropes. However, they exert a torque on the end fitting when under load.

Non-rotation resistant ropes are always the right choice, when the characteristic “rotation-resistance”, which only rotation-resistant ropes offer, is not required. This is the case for many rope applications, e.g. for luffing ropes, trolley ropes, pendant ropes or installation.

Note: With coupling of non-rotation resistant ropes, e.g. pendant ropes or grab ropes, only identical ropes of the same construction, meaning: the same diameter, the same lay type and lay direction have to be used (figure 78). Combining ropes with different lay directions would turn up the ropes and thus destroy them.

Wire rope is a preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands laid in a helical pattern around a core. Wire rope comes in a variety of strand patterns including single layer, filler wire, seale, warrington, and combination. Wire rope strands can be laid around the core in different configurations including regular lay wire rope, lang lay wire rope, and alternate lay wire rope. There also many types of grades of wire rope, including: improved plow steel (IPS), extra improved plow steel (EIPS), and extra extra improved plow steel (EEIPS). Some types of wire rope is preferred over others due to the unique properties, including: rotation resistant wire rope, compacted strand wire rope, swaged wire rope, plastic coated wire rope, plastic impregnated (PI) wire rope.

EXPERTISE FROM 225 YEARS OF EXPERIENCE What started back in 1790 with simple hemp ropes has since evolved into a globally successful group of enterprises specializing in the development and production of fiber and steel wire ropes, strapping, and composites. Vast diversity Its products are designed for a wide variety of applications ranging from cranes and marine applications to packaging and through to the automotive sector. It is the continuity and stability of a family business that makes us the reliable partner who supports you, competently and effectively, in coping with your daily...

TEUFELBERGER SEIL GES.M.B.H. WE OFFER MORE . In manufacturing, research & development, and marketing & sales, TEUFEL ERGER focus exclusively on high quality B special purpose steel wire ropes. Breakthrough technologies and top quality products are the base of our success. Our technology. Your benefit. Flexibility, quality, perfect spooling, rotation resistance, breaking force, life time, safe and reliable in use. TEUFELBERGER Service PLASTFILL INSERT Expert advice The lubricated steel core is covered in a tight synthetic coat. This provides TEUFELBERGER‘s network of experts rovides...

HIGH PERFORMANCE STEEL WIRE ROPES HIGH PERFORMANCE STEEL WIRE ROPES ROPES FOR OFFSHORE CRANES & WINCHES ROPES FOR MARINE RISER TENSIONERS Continuous use in extreme environmental conditions places high demands on offshore cranes and winches. Meeting high standards in terms of reliability and safety is of crucial importance for the use of steel wire ropes, also in offshore environments. TEUFELBERGER ropes live up to these standards day after day on countless cranes operating on offshore platforms throughout the world. Riser tensioners are important installations on floating oil platforms...

HIGH PERFORMANCE STEEL WIRE ROPES ROPES FOR DRILLING OPERATIONS Extreme environmental conditions and bending over sheaves at high loads present challenging application scenarios for drilling lines on platforms around the world. The use of TEUFELBERGER high performance steel wire ropes with PLASTFILL® insert significantly contributes to the high reliability of the platform. The colors of the headlines coordinate with 6-strand ordinary lay rope with SUPERFILL® 6-strand ordinary lay rope with PLASTFILL® the those of the ropes in the illustrations. compaction technology and PLASTFILL® insert,...

ROTATION RESISTANT EVOLUTION / ROTATION RESISTANT EVOLUTION EVOLUTION TK18 is our high performance rope for large cranes and winches, mainly for the offshore industry in brutally harsh conditions. This rope offers excellent dimensional stability, high resistance to corrosion, and ideal lubrication, especially due to its Pro Active Core Lubrication in combination with a PLASTFILL® insert. EVOLUTION TK18 is the best choice for cranes in combination with active heave compensation. EVOLUTION TK16 The result of a revolutionary design, high quality materials, and perfectly harmonized production...

/ ROTATION RESISTANT EVOLUTION EVOLUTION TKie1*8 Higher breaking forces for special customer needs. The consistent and systematic further development and improvement of the production processes involved facilitate particularly narrow manufacturing tolerances. - Ordinary lay or lang’s lay, right or left lay ✓ MULTILAYER SPOOLING Other rope diameters are available on request. There is a minimum quantity requirement for customized products.

NON-ROTATION RESISTANT EVOLUTION / QS 816 V(G) Extreme resistance to negative external influences distinguishes this rope from others. SUPERFILL® compaction technology developed by TEUFELBERGER provides high breaking forces and highest safety in use. Compaction in the core and a PLASTFILL® insert ensure stability against lateral pressure. Specifications_ - QS 816 V in ordinary lay configuration, QS 816VG in lang"s lay configuration, right or left lay - 10-42 mm: 8 x K26WS - EPIWRC (K), RCN 09 - 44-50 mm: 8 x K31WS - EPIWRC (K), RCN 11 - 52-70 mm: 8 x K42WS - EPIWRC (K), RCN >13 - Use...

NON-ROTATION RESISTANT EXECUTION / NON-ROTATION RESISTANT PERFECTION PERFECTION M8 Galvanized lang’s lay rope used for marine riser tensioners. The strong point of this rope is its excellent performance under extreme bending fatigue loads. SUPERFILL® compaction technology ensures highest breaking forces and thus maximum safety levels during operation. The application of this technology - even in the core - gives this rope optimum dimensional stability to lateral pressure and high bending fatigue life. EXECUTION D6s Flexibility, resistance to mechanical wear and high breaking force: these...

DISCARD CRITERIA DISCARD CRITERIA The discard criteria for TEUFELBERGER special steel wire ropes are defined according to: — ISO 4309 — API 2D FIFTH EDITION This includes: reduction of rope diameter, corrosion and wire breaks. For assesing the discard condition based on wire breaks, the rope category number (RCN) is used. For TEUFELBERGER special steel wire ropes, this number is listed in the following tables. For further details regarding the discard criteria and general handling for wire ropes to ISO 4309 or API 2D FIFTH EDITION, see the “Application Handbook – High Performance Offshore...

TEUFELBERGER Seil Ges.m.b.H. Böhmerwaldstraße 20 4600 Wels, Austria Telephone: +43 (0) 7242 615-0 Fax: +43 (0) 7242 605-01 wirerope@teufelberger.com www.teufelberger.com © 05/2015 | Oil and Gas: Special steel wire ropes |

With over 25 years of manufacturing, technical and lifting experience, Absolute Wire Rope Solutions is an established strategic safety partner with reputable global manufacturers.

With efficiency and client centric focus, Absolute Wire Rope Solutions ensures a wide range of readily available stock at competitive prices. To this end, the following types of wire rope are available through us:

The South Africa market size for steel wire rope reached a value of more than USD 10.75 million in 2021. The South Africa steel wire rope market is expected to grow at a CAGR of 2.60% between 2023 and 2028, reaching a value of USD 12.68 million by 2027.

Steel wire rope is a strong and durable rope used for fastening, securing, and positioning equipment because of its characteristics such as rigidity, toughness, and strength. Steel wire rope’s bending fatigue resistance is increased by adding a layer of plastic between outer strand, through an independent wire rope core (IWRC), and by increasing the area of contact between the sheave and steel wire rope.

Focus on bringing on new advancements and various other experimentation to South Africa by the key players is contributing to the growth of the South Africa steel wire rope market.

Increasing use of steel wire rope in mining, and oil and gas offshore transportation has largely contributed to the market growth. Ropes required at offshore need to be able to withstand extreme environmental conditions and which is why steel wire rope is used.

Corrosion resistance is one of the key trends that is increasing the demand for steel wire ropes. It increases the cost-effectiveness of the steel wire ropes as the non-corrosive nature keeps the wire intact, particularly in vital installations, and further enhances durability.

Based on type of lay, the South Africa steel wire rope market can be segmented into regular lay, lang lay and alternate lay. On the basis of strand pattern, the market can be divided into single layer, filler wire, Warrington, and combination. By coating type, the market is categorised into vinyl, zinc, nylon, and PVC, among others. Based on application, the market is divided into oil and gas, heavy machinery, mining, marine, general engineering, and construction, among others.

The comprehensive EMR report provides an in-depth assessment of the market based on the Porter"s five forces model along with giving a SWOT analysis. The report gives a detailed analysis of the following key players in the South Africa steel wire rope market, covering their competitive landscape and latest developments like mergers, acquisitions, investments, and expansion plans.

The strands in regular lay flows in the opposite direction due to which they have higher stability and greater resistance to crushing. These characteristics have resulted in regular lay type occupying a significant segment of the South Africa steel wire rope market.

The flow of the strands in lang lay are in same direction which makes pulling, lifting, pushing, and hoisting of objects easier. Lang lay steel wire ropes are also abrasion resistant and have superior tolerance to fatigue.

Alternate lay is a combination of lang lay and regular lay. It contains three strands of lang lay and other three of ordinary lay along, resulting in a combination of properties of both the lay types. Alternate lay steel wire ropes are typically used for special applications.

Different applications of steel wire ropes can benefit from different coating materials. Nylon is usually applied as a coating in order to prevent damage and corrosion of the steel wire rope. Meanwhile, vinyl and PVC are used as a coating for galvanised steel wire rope and stainless steel.

PVC is used for resistance from water and harsh weather conditions. PVC is widely adopted by individuals because it is cost-effective too. Nylon is tough when compared to other coatings which is why is used for various load running application. Nylon is considered for the largest market share holder in the South Africa steel wire rope market due to its toughness and damage protection capabilities.

Rope Constructions Company was established in 1919 with its headquarter in Johannesburg, South Africa. They provide quality steel wire ropes, rigging gear, lifting equipment, and anchoring equipment to their consumer markets.

Regular laydenotes rope in which the wires are twisted in one direction, and the strands in the opposite direction to form the rope. The wires appear to run roughly parallel to the center line of the rope. Due to the difference in direction between the wires and strand, regular lay ropes are less likely to untwist or kink. Regular lay ropes are also less subject to failure from crushing and distortion because of the shorter length of exposed outer wires.

Lang layis the opposite; the wires and strands spiral in the same direction and appear to run at a diagonal to the center line of the rope. Due to the longer length of exposed outer wires, lang lay ropes have greater flexibility and abrasion resistance than do regular lay ropes. Greater care, however, must be exercised in handling and spooling lang lay ropes. These ropes are more likely to twist, kink and crush than regular lay ropes.

Right or left layrefers to the direction in which the strands rotate around the wire rope. If the strands rotate around the rope in a clockwise direction (as the threads do in a right hand bolt), the rope is said to be right lay. When the strands rotate in a counterclockwise direction (as the threads do in a left hand bolt), the rope is left lay.

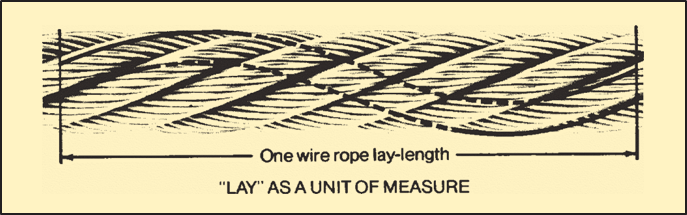

When a lay-length is used as a unit of measure, it refers to the linear distance a single strand extends in making one complete turn around the rope. Lay-length is measured in a straight line parallel to the center line of the rope, not by following the path of the strand. The appropriate time to replace a wire rope in service is frequently determined by counting the number of broken wires in the length of one rope lay.

The choice of the lay type must consider the specific use of the rope, the rope construction, crane components and the expected wear factors in use, which determine the lifetime of the rope substantially.

The aim of the rope choice is a high rope lifetime ensuring a high safety factor at the same time, which means the operator can recognize the secure operating condition of the rope reliably at any time, considering the discard criteria of the specific application. Therefore a general statement about the use of regular or lang’s lay ropes is not possible or not useful without knowledge of the specific case/application.

Ordinary lay ropes are widespread which are therefore presumably considered as universally applicable. Ordinary lay ropes have a very good structural stability due to the opposing stranding of the wires and strands which make them more resistant against external twist. The rope torque is lower than the one of lang’s lay ropes. Ordinary lay ropes also offer a good wear-resistance. Construction wise the externally visible wire breaks appear earlier of ordinary ropes than of lang’s lay ropes due to the higher pressure between wire and rope groove and a stronger wire bend within the strand, which makes it easier to recognize wire breaks and thus the rope state, making it easier to evaluate the discard criteria. Ordinary lay ropes are still no universal ropes for all applications under the abovementioned aims of the rope choice.

Lang’s lay ropes are more demanding not only in the production process, but also with the application, beginning with the installation. The reason for this lies in the stranding of wires and strands in the same direction, which raises the rope torque and makes lang’s lay ropes substantially more sensitively against every kind of external twist.

Lang’s lay ropes reach very high bending cycles until break because of the geometrically more favorable contact conditions between wire and rope groove which leads to the reduction of the pressure in the contact areas. This reduction of pressure is advantageous to the lifetime of the crane components and the rope itself.

However, it must also to be mentioned that in comparison to ordinary lay ropes the development of the externally visible wire breaks occurs more slowly. Therefore the recognition of the discard criteria due to externally visible wire breaks can be complvicated. For this reason the numbers of wire breaks until discard are clearly lower for lang’s lay ropes than for ordinary ropes with identical rope construction. Therefore also lang’s lay ropes are no universal ropes for all application under the abovementioned criteria of rope choice.

Important: As described in the “Lang’s Lay ropes” paragraph, these ropes can have an increased amount of internal wire breaks, which are not visible on the outside. This is expecially the case with rotation-resistant ropes in Lang Lay under bending cycle usage. This should always be clarified with a rope expert.

Besides the rope itself crane components and crane geometry are important criteria for the right rope choice. The applied drum system and the crane geometry constructively selected fleet angles are to mentioned particularly.

While on single-layer drums the rope gets stressed due to tensile load and substantially due to bend and lateral deflection and thus twists, dominates on multi-layer drums mechanical wear and lateral pressure stress between the touching ropes.

The crane geometry constructively selected fleet angle is a very important characteristic for a reliable rope spooling and the degree of rope wear. For multi-layer spooling a maximum fleet angle of 1,5° is recommended, while single-layer drums can work with higher fleet angels like for example up to 4°.

The following basic rules for the correct choice of rope lay types for ropes that spool on drums have proved themselves and therefore are also recommended by us:single-layer drums = ordinary lay ropes

On single-layer drums the ordinary lay ropes have clear advantages, because it can usually compensate the bigger fleet angle. Also the easier recognition of externally visible wire breaks is an important argument for the use of ordinary lay ropes on single-layer drums where strong mechanical rope wear, which also leads to wire breaks, does not or not substantially exist.

On multi-layer drums the bending fatigue resistance of the rope is not decisive for the rope lifetime but its resistance to mechanical impact is. Ordinary lay ropes are less suitable for multi-layer drum spooling because the wires of the neighboring ropes can rub with each other. This leads to high mechanical wear. The touch of the neighboring ropes during the spooling process is also well “audible”. The results are premature wire breaks. Lang’s lay ropes have proved themselves in the multi-layer spooling because neighboring ropes can not rub into each other, which raises the lifetime of the rope significantly.

The abovementioned statements have proved themselves in practice. Customer desired, occasionally divergences should therefore be analyzed thoroughly with regard to:specific operating conditions of the rope

This construction is used where ropes are dragged on the ground or over rollers, and resistance to wear and abrasion are important factors. The wires are quite large and will stand a great deal of wear. In fact, this construction is sometimes called “coarse laid” because of the large wires. The 6x7 is a stiff rope and needs sheaves and drums of large size. It will not withstand bending stresses as well as ropes with smaller wires. Because of the small number of wires, with the resulting higher percentage of load carried by each wire, a larger factor of safety should be considered with 6x7 ropes than with ropes having a larger number of wires.

The 6x19 Classification of wire rope is the most widely used. With its good combination of flexibility and wear resistance, rope in this class can be suited to the specific needs of diverse kinds of machinery and equipment. The 6x19 Seale construction, with its large outer wires, provides great ruggedness and resistance to abrasion and crushing. However, its resistance to fatigue is somewhat less than that offered by a 6x25 construction. The 6x25 possesses the best combination of flexibility and wear resistance in the 6x19 Class due to the filler wires providing support and imparting stability to the strand. The 6x26 Warrington Seale construction has a high resistance to crushing. This construction is a good choice where the end user needs the wear resistance of a 6x19 Class Rope and the flexibility midway between a 6x19 Class and 6x37 Class rope.

The 6x36 Class of wire rope is characterized by the relatively large number of wires used in each strand. Ropes of this class are among the most flexible available due to the greater number of wires per strand, however their resistance to abrasion is less than ropes in the 6x19 Class. The designation 6x36 is only nominal, as in the case with the 6x19 Class. Improvements in wire rope design, as well as changing machine designs, have resulted in the use of strands with widely varying numbers of wires and a smaller number of available constructions. Typical 6x37 Class constructions include 6x33 for diameters under 1/2", 6x36 Warrington Seale (the most common 6x37 Class construction) offered in diameters 1/2" through 1-5/8", and 6x49 Filler Wire Seale over 1-3/4" diameter.

Alternate Lay, sometimes referred to as reverse lay, is a stranded rope where the type of lay of the outer strands is alternately regular lay followed by lang lay such that three of the outer strands are regular lay and three are lang lay. Alternate lay wire rope has the extra flexibility of lang lay in combination with the structural stability of regular lay. It unites the best features of both types of wire rope. Alternate lay is made with relatively large outer wires to provide increase of abrasion resistance to scrubbing against sheaves and drums. Finer inside wires and flexibility enable alternate lay ropes to absorb severe bending stresses. It is well suited to winding applications where abrasion and crushing can occur. Alternate lay wire rope applications include boom hoists and numerous types of excavating equipment like clamshells, shovels, cranes, winches and scrapers.

The 8x19 Classification rotation resistant ropes are recommended for hoisting unguided loads with a single-part or multipart line. The eight outer strands are manufactured in right lay, with the inner strands being left lay. These ropes are slightly stronger and significantly more rugged than the 19x7 construction. However, the rotation-resistant properties of the 8x19 rotation-resistant ropes are much less than those of the 19x7 construction. These ropes are manufactured in right regular lay in the 8x19 Seale and 8x25 Filler Wire constructions.

19x7 is recommended for hoisting unguided loads with a single-part line. The rotation-resistant properties of this rope are secured by two layers of strands. The inner strands are left lay, while the 12 outer strands are right lay, which enables one layer to counteract the other layer"s rotation. The rotation-resistant characteristics of the 19x7 wire ropes are superior to those of the 8x19 Class wire ropes.

Fatigue Resistance. Improved fatigue properties are derived through the combination of the flexible 19x19 construction and die drawn strands. The drawn strand surfaces minimize the interstrand and interlayer nicking that take place in round rotation resistant ropes.

Abrasion Resistance. Die drawn ropes provide improved abrasion resistance as compared with round wire ropes because of the greater wire and strand bearing surfaces contacting sheaves and drums.

Resistance to Drum Crushing. SFP 19 wire ropes are resistant to the effects of drum crushing due to the compacted strands and smoothness of the rope surface.

Superior Rotation Resistance. The SFP 35 rope is the most rotation resistant rope manufactured by WW. Due to its rotation resistant properties, SFP 35 may be used with a swivel in both single part and multipart reeving.

6-PAC is recommended for use where the rope is subjected to heavy use or where conditions are extremely abusive, such as offshore pedestal, crawler and lattice boom equipped truck crane boom hoist applications. 6-PAC is also recommended for winch lines, overhead cranes, multipart hoist lines where rotation-resistant ropes are not required, and other applications where flexibility, high strength and resistance to crushing are important, and a cost-effective 6-strand rope is desired.

Fatigue Resistance. Improved fatigue properties are derived from the combination of 6-PAC"s flexible constructions and the compacted strands. The compacted strand surface minimizes the interstrand and interlayer nicking that take place in standard 6-strand ropes.

Abrasion Resistance. 6-PAC"s compacted strand design provides improved abrasion resistance as compared to standard 6-strand ropes because of the increased wire and strand surfaces contacting sheaves and drums.

Drum Crushing. 6-PAC dramatically increases the amount of wire contact with the drums and sheaves, reducing the wire rope, sheave and drum wear normally associated with standard wire rope.

Recommended for applications where abrasion and fatigue resistance is required, such as for winch lines, chokers, skylines, and haul backs, as well as any application where a swaged rope is used

8-PAC is recommended for hoist ropes for steel mill ladle cranes and hoist and trolley ropes for container cranes, or other hoisting applications with heavy duty cycles or where severe bending occurs.

Superior Performance. 8-PAC has higher breaking strength and gives superior performance in difficult hoisting applications compared to standard 6-strand and 6-strand compacted ropes.

Abrasion Resistance. 8-PAC compacted strand design provides improved abrasion resistance as compared to standard 6 and 8 strand ropes because of the increased wire and strand surfaces contacting the sheaves and drums.

SUPER-PAC is a double compacted product ideal for applications where abrasion and drum crushing are an issue. When compared with standard ropes, SUPER-PAC provides: Better resistance to multi-layer drum crushing. SUPERPAC dramatically reduces the damage at cross over points on smooth face drums, such as those found on many boom hoist systems on mobile cranes. This is achieved by compaction of the strands and the rope, making a tough but flexible product.

Superior Fatigue Resistance. SUPER-PAC is engineered for overall performance, its wire tensile strength being the key to its superior fatigue resistant properties. In addition to contribution to SUPERPAC’s EEEIP breaking strength, the wire used in the manufacture of SUPER-PAC remains ductile, minimizing the occurrences of external and internal wire breaks caused by operating stresses.

TRIPLE-PAC was developed for the most demanding hoist applications. TRIPLE-PAC offers the extra high strength and crushing resistance needed for applications such as boom hoist ropes, boom pendants and multipart load lines.

TRIPLE-PAC provides superior abrasion and fatigue resistance as compared with most compacted ropes due to WW’s unique design of compacting the IWRC, individual strands and the rope itself. Other benefits include:

Superior Resistance to Multilayer Drum Crushing. TRIPLE-PAC provides superior resistance to crushing through its design. Its triple compaction provides a denser cross section, enabling the rope to withstand the rigors of multilayer spooling. Damage at the cross over points is also significantly reduced.

BXL is infused with a specially- engineered polymer, creating a well-balanced matrix. BXL is recommended for numerous hoist, marine and logging rope applications. BXL provides: Fatigue Resistance. Improved fatigue resistance is derived from the cushioning and dampening effect of the polymer on the wires and strands. BXL also evenly distributes stresses which may lead to fatigue breaks.

Abrasion Resistance. The polymer acts as a barrier between the individual strands, preventing penetration of any adverse material. BXL distributes and reduces contact stresses between the rope and sheave, reducing wire rope wear.

Service Life. BXL minimizes corrugation and wear normally associated with standard rope usage by restricting water and dirt penetration and eliminating pickup of abrasive materials.

This rope is particularly suitable where severe conditions of crushing and abrasion are encountered on the drum or where a higher strength design factor is required than can be obtained with a similar round rope.

The triangular strand shape not only provides better resistance to crushing, but also offers a greater exposed surface area for contact with sheaves, drums or underlying layers of spooled rope. This feature, in connection with the use of Lang lay construction, distributes the abrasive wear over a greater number and length of wires. The smooth surface of the rope also helps minimize wear on drums and sheaves.

ROEPAC is a three strand compacted rope with high breaking strength and stable construction making it perfect as a pulling rope for overhead transmission lines and underground conduits. It’s flexibility and flat surface provides snag-free guidance of the attached lines.

Abrasion Resistance. Compacted design provides improved abrasion resistance compared to standard 6 strand ropes because of the increased wire and strand surfaces contacting the sheaves and drum.

8613371530291

8613371530291