ordinary lay wire rope for sale

While some use these two terms interchangeably, technically wire rope refers to a diameter greater than 3/8”. Cable rope - also called aircraft cable - applies to all smaller variations.

Consequently, aircraft cable is only used for lighter-duty purposes, such as winch lines, fences, and railings, while wire rope can be using for lifting, towing, hoisting, etc. Both are ideal for outdoor environments because the strength and length remain constant regardless of whether they are wet or dry.

If you are looking for an option specifically designed for lifting, check out our wire rope slings. They come in a number of configurations - choices include leg count, end hardware, and more.

Generally composed of wires, strands, and a core shaped in a spiral pattern, wire rope is incredibly durable. Steel wires are aligned in a precise helix geometric pattern to form a strand in a process known as "stranding." A "closing" comes next, where the strands are laid around the core to form a wire rope.

The greater the diameter, the greater the break strength. Our selection of 1/8" stainless steel cable has a break strength of less than 2,000 lbs., while our 2-1/2" wire rope has a break strength of more than 600,000 lbs.!

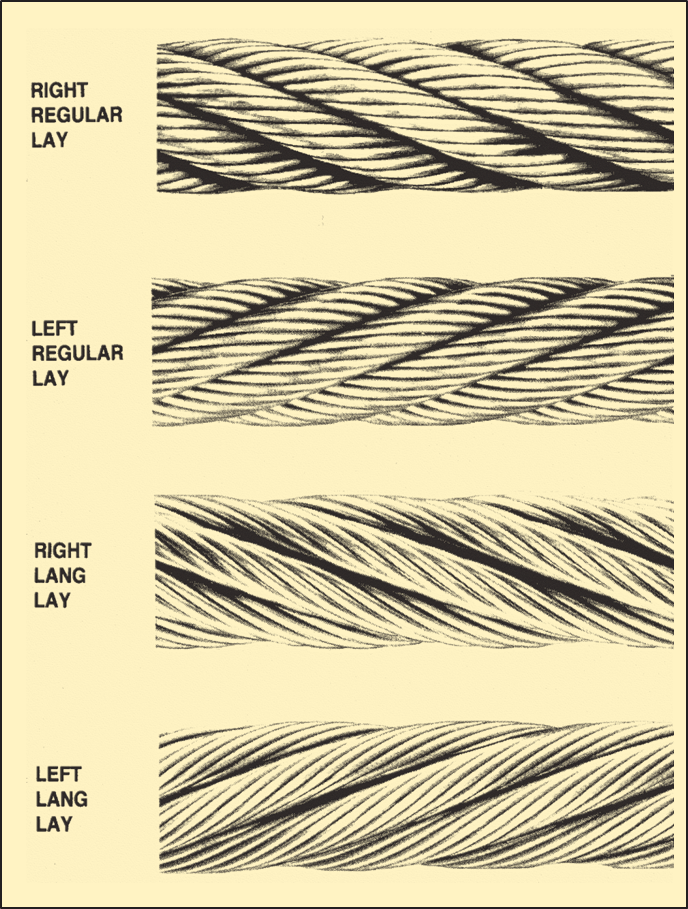

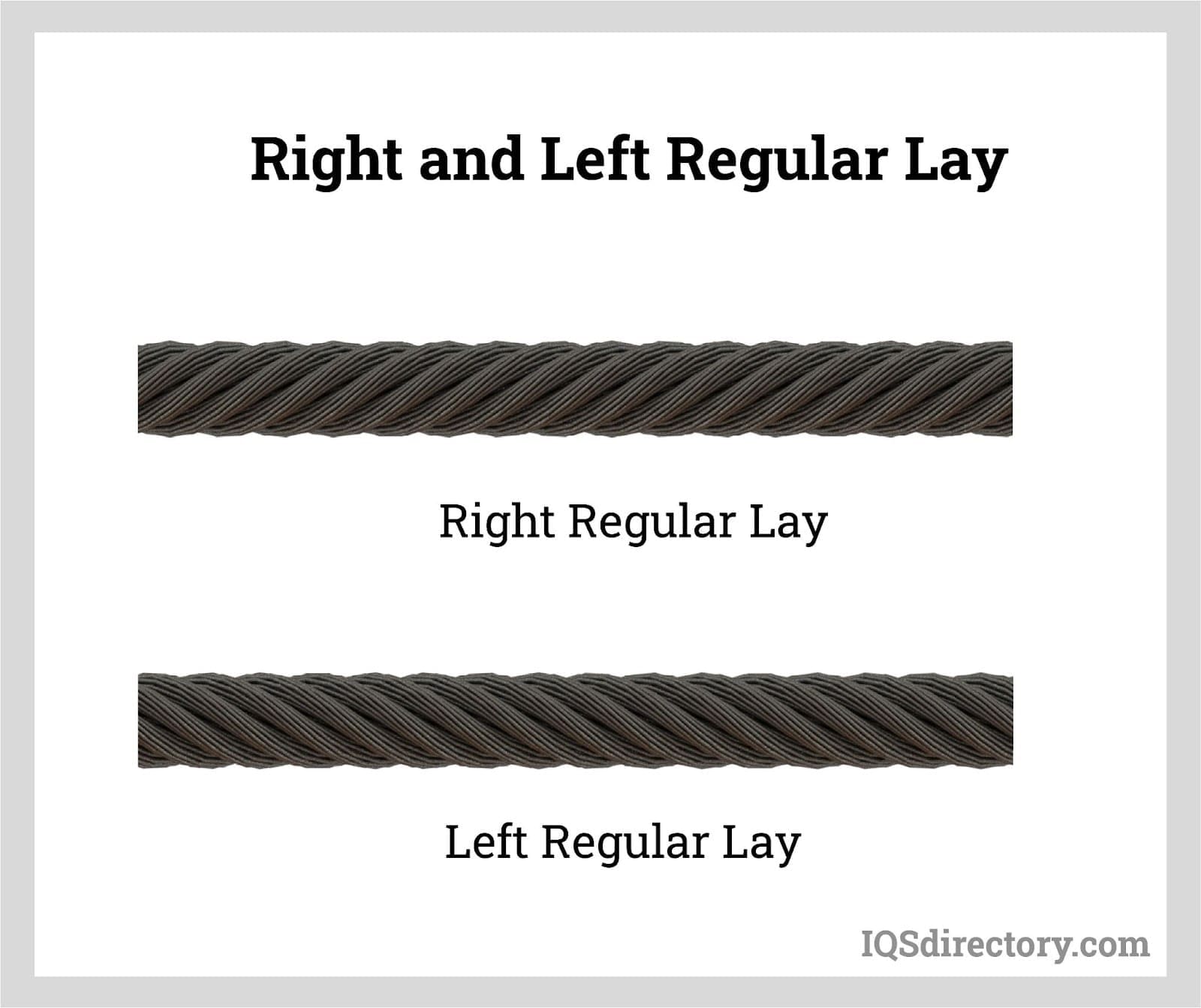

Right hand and left hand designations indicate which way the strands wrap around the core of the steel rope, while regular lay and Lang lay designations specify which way the wires that make up the strand are formed in the helix pattern.

Regular lay means the wires are rotated opposite the direction of the strands around the core. Lang lay means the wires are twisted in the same direction as the strands wrapped around the wire rope core.

Our wire rope lay is right hand regular lay, with strands wrapped around the core to the right, and the wires making up the strand turned and rotated to the left.

Independent wire rope cores (IWRC) are made from steel, offer more support to the outer strands, and have a higher resistance to crushing. IWRC also offer more resistance to heat and increase the strength of the rope.

This refers to how many strands make up the rope and how many wires make up one strand. For instance, a 6x26 wire rope has 6 strands around a core with 26 wires making up each strand.

All wires consist of layer(s) arranged in a specific pattern around a center. Pattern designation is affected by the size of the wires, the number of layers, and the wires per layer. Wires can utilize either a single pattern style or a combination of them, known as a combined pattern:

Warrington - Two layers of wires. The outer layer has two diameters of wire (alternating between large and small), while the inner layer has one diameter.

Although wire rope is extremely strong, it can become damaged with improper use, making it unsafe to use. It"s important to have regular inspections for breaks, corrosion, overuse wear, and kinks.

Our rigging supplies category includes hardware and accessories for cranes, dredging, excavating, hoists & winches, logging, and marine uses. If you"re unsure what you need or have questions, call for help from our product specialists with expertise in wire rope/cable rigging supplies.

A six strand wire rope in which three strands are ordinary lay and three strands are lang lay is known as an alternate lay wire rope and combines some of the desirable properties of both the regular lay and langs lay type of rope.

Wire rope is identified not only by its components parts, but also its construction, i.e., by the way the wires have been laid to form strands, and by the way the strands have been laid around the core.

( "a" and "c" ) shows strands as normally laid into the rope to the right - in a fashion similar to the threading in a right-hand bolt. Conversely the "left lay"rope strands (illustration "b" and "d" ) are laid in the opposite direction.

Again the first two ( "a" and "b" ) show regular lay ropes. Following ( "c" and "d" ) these are the types known as lang lay ropes. Note that the wires in regular lay ropes appear to line up with the axis of the rope; in lang lay rope the wires form an angle with the axis of the rope. This difference in appearance is a result of variations in manufacturing techniques: regular lay ropes are made so that the direction of the wire lay in the strand is opposite to the direction of the strand lay in the rope; lang lay rope are made with both strand lay and rope lay in the same direction. Finally ( "e" and "f" ) called alternate lay consists of alternating regular and lang lay strands.

Left hand lay or right hand lay describe the manner in which the strands are laid to form the rope. To determine the lay of strands in the rope, a viewer looks at the rope as it points away from them. If the strands appear to turn in a clockwise direction, or like a right-hand thread, as the strands progress away from the viewer, the rope has a right hand lay. The picture of steel wire rope on this page shows a rope with right hand lay. If the strands appear to turn in an anti-clockwise direction, or like a left-hand thread, as the strands progress away from the viewer, the rope has a left hand lay. (The rope in the left hand lay photo shows one left hand lay rope from left to right and top to bottom, with 5 right hand lay strands, and part of a sixth in the upper left. It is not 5 right hand lay ropes adjacent to each other.)

Ordinary and Ducay"s lay describe the manner in which the wires are laid to form a strand of the wire rope. To determine which has been used, first identify if left or right hand lay has been used to make the rope. Then identify if a right or left hand lay has been used to twist the wires in each strand. (On ordinary lay, the outer wires approximately follow the alignment of the rope: with Lang"s lay they are cross at an angle of about 45�.) Lang"s laid rope is able to flex over sheaves more easily (with less damage) but it has the disadvantage of having a high torque tendency (it tends to untwist when tension load is applied) compared with ordinary laid rope. Untwisting can be dangerous with a steel-cored rope: load is shed from the strands and may cause the core to fail as it becomes higher loaded. For this reason, swivel termination units can be dangerous.

The specification of a wire rope type � including the number of wires per strand, the number of strands, and the lay of the rope � is documented using a commonly accepted coding system, consisting of a number of abbreviations.

It is important to attach steel wire ropes at the correct locations on a smooth drum as improper winding methods will cause the spreading of terns in the first layer of steel wire ropes on the drum. Then the second layer of wire ropes may be wedged between the open coils of first layer, crushing and flattening the rope as successive layers are spooled.

Generally, steel wire ropes are wound from the top of the one reel to the top of another or from the bottom to bottom. But how to start wire ropes on a drum may puzzle lots of our customers. The following illustration will give you the best solution.

The use of wire rope, sometimes called steel cable, steel sling rope, or steel rigging wire, is extremely popular in the material handling industry. Wire ropes come in a huge variety of designs and constructions, all suited for different lifting applications. Each type of wire rope has benefits and drawbacks. What all wire ropes have in common however, is that they are made up of steel wires which form individual stands. These strands are laid in a helical pattern around a fiber or steel core to form the rope. Different wire configurations and strand structures offer specific benefits to fit virtually any rigging application. These benefits include:

Selecting the correct wire rope for your rigging application often requires the rigger to make a compromise between different steel cable properties. For example, a wire rope with a small number of large outer wires will be more resistant to crushing, but less resistant to bending fatigue. Conversely, a wire rope with a larger number of small outer wires will be more bending fatigue resistant but less crushing resistant. These differences not only change the way the wire rope is used but they also change the way the wire rope is to be properly cared for.

Here at Tri-State Rigging Equipment we pride ourselves on providing our customers with only the highest quality steel wire ropes, from only the most reputable manufacturers. We can provide you with any rigging product on the market so if you cannot find what you are looking for, or if you don’t know exactly what you need, call or email our sales team to speak with a rigging product specialist.

The wires of a cable rope are the smallest component and are twisted together to form individual strands. Wires can be constructed in a variety of materials and grades, all affecting the properties offered by the cable rope. These materials include:

These different materials and grades affect the cable rope’s strength, bending fatigue resistance, corrosion resistance, wear resistance, and curve of the wire rope.

The strands of the steel cable consist of two or more wires and are laid in a helical pattern around the core. The way strands of steel cable are laid affect the properties offered by the steel cable.

The job of the core inside a steel cable rope is to support the strands and keep them in place relative to each other when bending and when under load. Wire rope cores can be made of a variety of materials including natural fiber, synthetic fiber and steel.

The lubrication of a steel cable rope is extremely important and often overlooked. Wire rope lubricant is added during the manufacturing process and penetrates the wire rope throughout, core included. The purpose of wire rope lubrication is twofold. First, it reduces friction between wires and strands. Second, it provides corrosion resistance to wires, strands and the core. A lack of proper lubrication is very serious and is cause to remove any and all affected wire rope from service.

In a preformed steel wire rope, the wires and strands are manufactured into the helical shape they will take when the wire rope is constructed. Preformed wire rope offers more flexibility and fatigue resistance than non-preformed wire rope. This allows the rigging wire to be uniformly spooled on a drum.

When riggers talk about the lay of a rope, they are talking about two things. One, the way the wires are laid to form a strand (right or left), and two, the way the strands are laid around the wire rope core (regular, lang, or alternate).

Regular Lay: The wires are parallel with the core of the rope. The direction of the wires is opposite to the direction of the strands. Compared to lang laid wire rope, regular lay offers more crushing and rotation resistance, allowing it to spool better on a drum.

Lang Lay: The wires are laid at an angle to the wire rope core. The direction of the wires is the same as the direction of the strands. Compared to other wire rope lays, lang lay offers more bending fatigue and abrasion resistance.

Wire ropes can be constructed using one of the five main strand patterns or a combination of two or more of the basic strand patterns. The wire rope strand pattern refers to the number of wires per layer, the number of layers, and the size of the wires. The strand pattern of a wire rope is a very important determining factor when it comes to choosing the correct wire rope for your specific rigging application. The five basic strand patterns are:

Filler Wire: This strand pattern is constructed by laying two layers of same sized wires around a center. The outer layer will have 2x the amount of wires than the inner layer. In the valleys of the inner wires are small filler wires to fill in the gaps between the inner and outer layers.

Seale: A layer of same sized wires smaller than the center wire is laid around the center. The outer layer consists of the same amount of wires as the inner layer but bigger in size. The outer wires lay in the valleys of the inner wires.

Warrington: This strand pattern consists of two wire layers. A layer of wires is laid around a same sized center wire to form the inner layer. The outer layer is formed by laying wires of alternating sizes, big and small, around the inner layer. The larger outer wires lay in the valleys of the inner wires and the smaller outer wires lay on the crowns of the inner wires.

Combination: A combination wire rope strand pattern is constructed by combining two or more of the strand patterns above to form a single unique strand pattern.

Fiber cores offer riggers more flexibility due to their natural or synthetic polypropylene fibers. This also means, however, that fiber core wire ropes are more susceptible to crushing and are not suitable for high heat environments.

In environments that exceed 180° F, a steel wire rope core should be used. Steel wire rope cores can be either an independent wire rope or an individual wire rope strand. Steel wire rope cores offer greater support for the strands and wires of the steel cable when compared to fiber cores.

The classification of a wire rope is based on the number of strands, as well as the number of wires in each strand. Below is a table of the most common wire rope configurations arranged in specific classifications.

In addition to the general classifications of steel wire rope, here at Tri-State Rigging Equipment, we also offer a wide range of specialty wire rope constructions. These include:

Rotation Resistant Wire Rope: This special construction of steel cable rope is designed to resist twisting and turning while under load. Rotation resistant wire rope must be specially cared for to prevent introducing twist into the rope.

Compacted Strand Wire Rope: This special type of wire rope is constructed using compacted outer strands. The outer strands are run through rollers or a die before the rope is closed. This increases the density of the outer stands and gives the steel cable rope a smoother outer surface. Compacted strand wire ropes offer greater strength and durability than standard round wire rope.

Swaged Wire Rope: Unlike a compacted wire rope, a swaged wire rope is compacted using a swaging machine after the wire rope had been closed. The outer wires of a swaged wire rope can be either compacted or round. Like compacted strand wire rope, swaged wire rope offers more strength and durability when compared to similar sized round wire ropes, however, it offers less bending fatigue resistance.

Plastic Coated Wire Rope: This type of wire rope is coated in a layer of plastic to protect the rope from abrasion, wear, and environmental factors. A drawback to plastic coated wire rope is that the plastic coating covers the strands and wires making it harder to inspect the wire rope.

Plastic Impregnated (PI) Wire Rope: A plastic impregnated wire rope is filled internally with a matrix of plastic that fills the gaps between wires and strands. This plastic filling reduces internal friction and improves bending fatigue resistance.

Plastic Coated or Plastic Filled IWRC Wire Rope: This type of wire rope features an independent wire rope core that is either filled or coated in plastic. This reduces internal friction in the wire rope and gives the wire rope greater bending fatigue resistance.

Tri-State Rigging Equipment is a service provider and distributor for all steel wire rope and steel cable for rigging and lifting, serving clients from coast to coast, Canada, Mexico and especially focused in the states of Missouri, Illinois, Indiana, Iowa, Kansas, Nebraska, Arkansas, Mississippi, Tennessee, Kentucky, South Carolina, Florida, and Oklahoma.

There are many different sizes, configurations, and materials that form wire rope, and these are different types including stainless steel wire rope, galvanized wire rope, and bright wire rope.

Looking for accessories to use with wire ropes? Our rigging supplies include hardware and accessories for use with cranes, hoists & winches, and oilfield applications.

Diameter:To properly measure the diameter of steel wire ropes, measure the rope at its widest point. This is an industry standard with wire cable manufacturers and steel cable suppliers.

Grade of Steel – EIPS, EEIPS: EIPS is Extra Improved Plowed Steel and has roughly 10% more strength than IPS. EEIPS is Extra Extra Improved Plowed Steel and is approximately 10% stronger than the EIPS. We offer every variety of EIPS Wire Rope and have a one day lead time on any EEIPS ropes.

Direction of Lay: Right hand and left hand designates which way the strands wrap around the core of the steel rope. Regular lay and Lang lay specify which way the wires are formed in the helix pattern. Regular lay means the wires are rotated opposite the direction of the strands around the core. Lang lay means the wires are twisted in the same direction as the strands are wrapped around the wire rope core.

Finish – Bright Wire, Galvanized Wire, and Stainless Steel: Most wire ropes have a bright, self-colored finish hence the name. Wire ropes generally have a coating of lubricant to reduce friction and protect from corrosion. However, there are wire ropes that are galvanized, stainless steel, or coated in vinyl and other plastics.

Material of the Core: Fiber Core (FC) or Independent Wire Rope Core (IWRC) – Fiber cores are made of natural (sisal, etc.) or synthetic (polypropylene, etc.) fibers and allow for increased flexibility. IWRC offers more support to the outer strands, and have a higher resistance to crushing. IWRC also offers more resistance to heat, reduces the amount of stretch, and increases the strength of the rope.

Strands: Another variable in wire rope is how many strands make up the rope and how many wires make up one strand. For instance, a 6×26 wire rope has 6 strands around a core with 26 wires making up each strand. The 6×19 class is the most common and offers higher resistance to abrasion whereas the 6×37 class offers higher flexibility.

Although there are exceptions for special applications, the constructions in 6×36 classification are primarily designed to be the most efficient for each rope diameter. As the rope size increases, for instance, a large number of wires can be used to achieve required fatigue resistance, and still those wires will be large enough to offer adequate resistance to abrasion.

The 6×19 classification of wire ropes includes standard 6 strand, round strand ropes with 16 through 26 wires per strand. This is a good rope to withstand abrasion or crushing on the drum. Ropes with independent wire rope strands and a core (IWRC) in general, are more crush resistant than fiber core ropes.

When you purchase our 6×19 Class of wire ropes, you get more than just another rope. Manufactured in an ISO 9001 certified factory and backed by the industry’s largest staff of professional engineers, we do more than meet published specifications.

The 6×26 WS has better resistance to abrasion than a 6x25FW. It features a compact construction with solid support for the wires; therefore it has a high resistance to crushing. Its number and relative size of the inner wires add to the stability of the strand and gives it a fatigue resistance comparable to a 6×25 FW. A standard 6×26 WS construction provides the best rope for a wide range of applications. In general, we recommend the use of the 6x26WS in any application where a 6x25FW is used.

Mast Raising Lines, also called Bull Lines or Bridle Lines, are usually two pieces: each having sockets on both ends. These lines can be fabricated from either right regular lay rope or right lang lay rope. They must be fabricated from IWRC ropes.

Premium ropes may be used for specific applications. PFV cushions the strands, distributes internal stresses, keeps in wire rope lubricant and keeps out dirt and debris, extending the service life.

Flex-X® 9 features compacted strands and swaging for extra drum crushing resistance and increased stability. Its high-density strands deliver extra strength and resistance to abrasion. Flex-X® 9 is manufactured with a dual compaction process to produce a compact cross-section with minimum voids and greater surface area on outer wires that contact drums, sheaves and the rope, itself during operation. The high-density compacted strands minimize nicking at strand-to-strand contact points. Flex-X® 9 was specifically designed for boom hoist applications and tubing line applications where drum crushing is a challenge.

Flex-X® 6 users receive superior performance and increased service life in many applications compared to the ropes they had previously employed. When compared to conventional six-strand ropes, Flex-X® 6 ropes provide greater surface area and more steel per given diameter. This increases rope stability and strength. This results in a longer service life and less sheave and drum wear.

Flex-X® 19, a Category 2 rotation resistant rope, is made from 19 strands. Six strands are laid around a core strand in one direction, and then 12 strands are laid around this first operation in the opposite direction. Because of its tightly compacted smooth design, Flex-X® 19 offers more crushing resistance than standard 19×7 rope, higher strength-to-diameter, resistance to bending fatigue, exceptional stability, reduced wear to sheaves and drums, and improved handling, operating and spooling characteristics.

6x36 is a flexible general engineering wire rope readily available in galvanised, ungalvanised and marine grade stainless steel. The wire rope has an equal lay construction (warrington seale) and achieves a superior breaking load to the 6x19 construction range. The construction has been designed to give a flexible rope with a good fatigue life. A 6x36 wire rope is available with either FC (fibre core) or IWRC (independent wire rope core) and is used for a wide range of applications, examples of which are shown below:

Equivalent Wire Rope for Stahl, Rope Length: 45 m, Diameter: 9 mm, Lay Type and Direction: Right Hand Ordinary, Minimum Breaking Load: 77.900 kN (replaces 443405240)

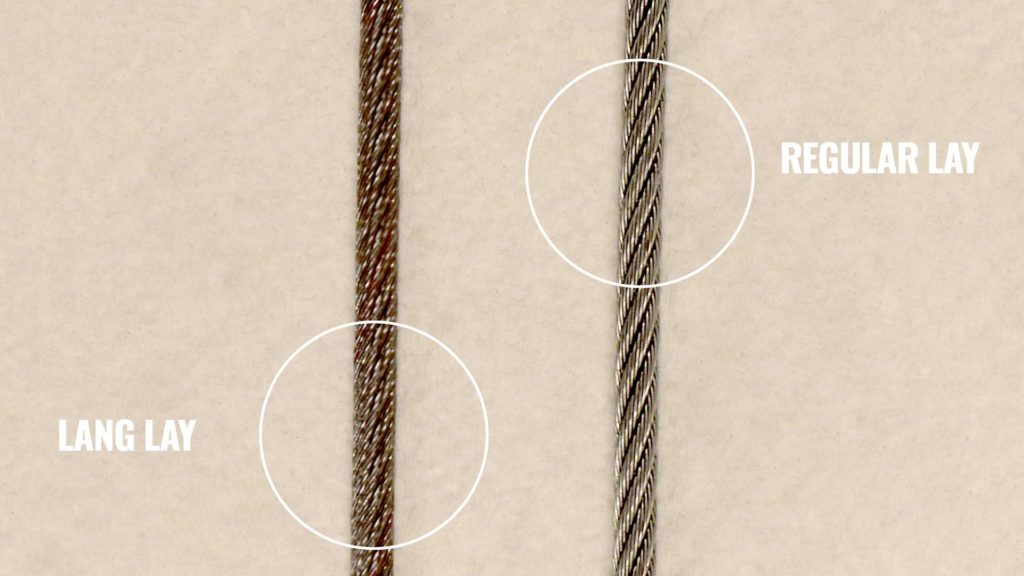

Similar to regular lay, the right hand vs left hand is merely the way the wire rope closes with the strands in left hand lay rotating counterclockwise and right hand lay rotating clockwise. With lang lay rope, the wires in each strand lie in the same direction as the strands. When looking along a length of lang lay cable, the wires will appear to angle across the rope, following the general flow of the strands. Lang lay cables are more susceptible to pinching and kinking than regular lay, which best suits hoisting applications where the cable only moves along one axis. Lang lay is typically more flexible than regular lay. The third image down on the left is an example of right hand lang lay and the image below is left hand lang lay.

Now that you know about the differences and capabilities of each wire rope lay type, you can feel confident in purchasing the right lay for your wire rope applications! If you would like to check out our wire rope options, visit our website here. Alternatively, our team is happy to help if you have any questions! Reach out to us by email at sales@loosco.com or by phone at (860) 928-7981.

PREFORMING: A manufacturing process wherein the strands and their wires are permanently formed, during fabrication, the helical shape that they will ultimately assume in the finished wire rope. Proper preforming prevents the strand and wire from unlaying during normal use. The vast majority of wire ripe sold today is preformed.

FINISH: Wire rope is either sold as “bright” (or “black”), meaning uncoated, or galvanized for better corrosion resistance. “Drawn Galvanized” wire has the same strength as bright wire, but wire, “galvanized at finished size” is usually 10% lower in strength. Plastic coated wire rope is also available, usually galvanized or stainless steel cable. The most common plastic coverings are vinyl or nylon in either clear or white, although other materials and colors are available. These coating do not add strength to the wire rope itself.

LUBRICATION: During fabrication, wire ropes receive lubrication. The kind and amount depends on the rope’s size, type a use, if known. This in-process treatment will provide the finished wire rope with ample protection for a reasonable time if it is stored under proper conditions. But, when the wire rope is put into service, the initial lubrication will normally be less than needed for the full useful life of the wire rope. Because of this, periodic applications of a suitable wire rope lubricant are necessary.

ORDERING WIRE ROPE: Construction, lay, core, finish and other factors mentioned above impart greatly differing characteristics to different wire ropes. They must be understood and considered when selecting wire rope. There is no perfect wire rope for all applications; usually some less desirable properties are traded off for other, more desirable one. Refer to the Wire Rope Users Manual by the Wire Rope Technical Board for a better understanding of wire rope properties and consult professional help when in doubt.

If a supplier receives an order for 6 x 19 wire rope he may assume this to be a class reference and is, therefore, legally identified in furnishing any construction within this category.

When discussing the physical properties of wire rope, people often focus on the material, strength, and size specifications above all else. While these details are essential to understand how a product will survive in the field, they are not the only factors that drive cable performance. In fact, the lay direction of a cablehas as much impact on its functionality as any of the other aforementioned characteristics, because it determines how much a cable will rotate, twist, and kink.

Lay direction describes the relationship between the way wires are wrapped into strands, and the way those strands are wrapped into wire ropes and cables. In general, there are two different configurations of lay directions: regular lay, and lang lay, which can rotate either to the left or to the right.

In a regular lay cable, the wires and strands are laid opposite to each other. In other words, all of the wires are laid in one direction as they are made into strands, and those strands are then laid in the opposite direction of the wires as they are combined into cable. When looking along a length of regular lay cable, the wires will appear to run parallel and straight the entire way. You can tell a cableis right regular lay because the strands will all flow to the right, or clockwise direction, compared to a regular left lay cable which flows the strands in a leftward, counterclockwise direction.

In a lang lay configuration, the wires and strands are laid in the same direction. If all the wires are laid to the right as they are made into strands, then those strands will also be laid to the right as they are combined into cable. The same applies to a left lang lay configuration, where both the wires and strands would lay to the left. When looking along a length of lang lay cable, the wires will appear to angle across the rope, following the general flow of the strands. You can tell a cable is a right lang lay cable because both the wires and strands will flow rightward, in a clockwise direction. A left lang lay cable flows both wires and strands in a leftward, counterclockwise direction.

Cable is generally manufactured with a standard right regular lay because it is useful for a variety of different applications and complies with most equipment. In general, regular lay cable is more resistant to crushing forces than lang lay cable of an identical material and size, though lang lay cable is typically more flexible. Lang lay cables are usually more susceptible to pinching and kinking than regular lay, which means they are better suited to hoisting applications where the cable only moves along one axis.

In summary, the wires and strands in regular lay cable flow in opposite directions while the wires and strands in lang lay cable flow in the same direction. Lang lay cable is great for lifting, hoisting, and push-pull applications, while regular lay cable outperforms in situations where bends are required. To learn about our range of flexible, non-rotating, and non-flexible wire rope and aircraft cable, visit https://strandcore.com/products/aircraft-cable/ or contact us at https://strandcore.com/contact/.

Wire rope tends to kink during uncoiling or unreeling, especially if it has been in service for a long time. In order to unreeling the wire rope is to run a steel pipe or strong rod through the center and mount the reel on drum jacks or other supports so the reel is off the ground. In this way, the reel will turn as the rope is unwound, and the rotation of the reel will help keep the rope straight.

During unreeling, pull the rope straight forward and avoid hurrying the operation. As a safeguard against kinking, never unreel wire rope from a stationary reel.

To uncoil a small coil of wire rope, simply stand the coil on edge and roll it along the ground. Never uncoil it by pulling on the end because such practice can kink or twist the rope.

The closer the position of the wire rope to the vertical, the safer it will be operated in safer conditions and with a longer lifespan, tension inside being distributed much more evenly between the strands and wires.

Non-rotating wire ropes have strands twisted around the core and the lay direction for outer strands is opposite to immediately inner strands. The outer rotational force of the rope will counteract the rotational force of the inner strands, leaving a wire rope that is resistant to rotating.

They have a long flexibility and lifespan, thanks to the winding of wires and strands in such a way that they generate low values for torsion time and tension when subjected to a load.

An important consideration in wire rope construction is the way the wires have been laid to form strands and the way the strands have been laid around the core.

Lay is classified by both direction and type. The lay direction of the wires within a strand and of the strands within a rope is either left or right. Rope lay is further classified as either regular or lang. In a regular lay rope, the wires in the strands are laid in the opposite direction as the strands in the rope. In a lang lay rope, the wires in the strands are laid in the same direction as the strands in the rope.

Regular and lang lay ropes are easily identified by the appareance of the outer wires with respect to the rope axis as shown by the examples to the right.

Right regular and right lang are the most common types of lay in use. Each possesses unique characteristics important to proper selection. Wire rope can be manufactured with five types of lay.

Regular lay ropes are generally more stable and more resistant to crushing. Lang lay ropes are significantly superior in fatigue and abrasion resistance. However, lang lay ropes are more susceptible to crushing and require good winding conditions. They are also extremely prone to rotate under load; they must never be used unless both ends are restrained.

Alternate lay rope combines the best features of regular and lang lay ropes. It offers the advantages of both constructions while minimizing the disadvantages. This construction is ideal where high bending stresses (fatigue) are combined with high rope-to-sheave pressure (crushing); for example, as applied to boom hoist rope.

Combinations of lays are sometimes employed to achieve rotation resistant properties. In this 19 x 7 rope, (as well as in 8 x 19 IWRC Rotation Resistant rope), the extreme rotational property of lang lay rope is used in the core to counteract the tendency of the outer regular lay strands to rotate in the opposite direction.

Wire rope is a machine! It is the workhorse that lifts the heavy loads on wire rope hoists. As a crane technician, there is an endless amount of information you should know about wire rope. The more you understand, the better resource you can be to your customers. Luckily, you don’t need to be the expert! There are others to help you out including, crane and hoist manufacturers, wire rope manufacturers, and other crane technicians. In this article, we will talk about how Demag designs wire rope hoists, selects the wire rope for models that you can buy today, and those you will still find in the field for inspections and repair.

In the world of wire rope, lay has many meanings and definitions. First, we will go through the directional meanings. Lay can refer to the direction in which the strands are twisted around the core of the wire rope. When left hand and right hand lay is referred to like this, it is describing whether the strands are twisted clockwise (left hand) or counter-clockwise (right hand) around the core. For a frame of reference, grab the wire rope in either hand with your thumb pointing up. When the strand appears as if going up to the left, this is a Left Hand lay rope. When it appears as though it is going up to the right, this is a Right Hand lay.

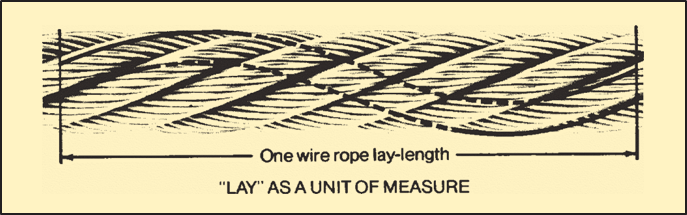

Lay can also refer to the cut of the groove corkscrew in the drum and the corkscrew can go to the left or right. The wire rope will start gathering on the left-hand side of the drum in the case of a left lay and the opposite for right lay. One way to determine this is to look at the drum from the end where the rope is clamped. The term lay can be used to describe the distance of a complete wrap of a strand once around the core. When conducting a wire rope inspection, knowing how to measure the lay is critical. It is measured by determining the distance starting on the outside wrapping the strand one complete time back to the same outside position. This measurement is used to determine the maximum number of broken wires allowed within a single lay and for the number of broken wires in the same strand in a lay. Always consult your inspection criteria bodies, like CMAA and HMI, for the most up-to-date standards.

Lay can also denote whether a rope is Regular Lay or Lang Lay. Regular lay and Lang lay rope are different types of wire rope and differ based on the wire orientation in the strand. Regular lay rope wire appears as though the outermost wire surface is aligned parallel with the centerline of the wire rope axis. Lang lay rope wires appears to be at a 45 degree angle with the wire rope centerline axis. Lang lay type of rope allows for more surface contact with the groove surface on the drum or sheave, increasing the support zone and decreasing the load by spreading it out over a larger area. It is more costly to manufacture, but it can be used in special cases where better wear life for the drum and sheaves is needed. Today, Regular Lay rope is commonly used unless there is a specific design need to use Lang Lay wire rope.

Countries and industries may have different standards or best practices for wire rope. In the USA, the wire rope industry recommends using a Right Hand (RH) lay rope on a Left Hand (LH) drum corkscrew and a Left Hand (LH) lay rope on a Right Hand (RH) drum corkscrew. This is recommended for good spooling of the rope, especially on a grooveless drum. In most cases, Demag designs their wire rope hoists in violation of this best practice, but for a major engineering reason that benefits the user and for additional safety.

Demag wire rope hoists are designed for RH rope on a RH drum and LH rope on a LH drum. This design creates straighter drops of wire rope down to the bottom block as using the same strand lay and corkscrew twists the strands tighter around the core. The straighter drop eliminates interference in a 4/1 reeving configuration as the rope crisscrosses during lifting. This becomes very apparent when the lift height is around the 70 foot range. To make sure that the hoist has positive spooling, the drum is designed with a partial groove and is equipped with a rope guide with pressure rollers or a ring that keeps the rope in the groove.

When it comes to hoists configured for 4/2 reeving with 2 attachment points for the same rope, only one side of the drum follows the best practice. Since there are 2 attachment points in 4/2 reeving, one drum corkscrew is RH and the other LH. Inherent from the reeving design, close to vertical lifting is achieved and crisscrossing interference is not a concern.

Due to wear on the drum and sheaves, we will never recommend changing the lay of the rope used on a hoist when the wire rope needs changed. The existing wire rope lay has already established wear patterns on the drum and sheave that could make changing the rope with a different lay dangerous. Being able to identify or find out what type of rope is used on a wire rope hoist is key to success when wire rope needs changed.

Wire rope is a complex machine, lifting the heaviest loads like space shuttles and precast concrete components. It does the heavy lifting when a load is being lifted by a crane and wire rope hoist. Having a good understanding of wire rope is essential for all crane technicians. Being able to understand what lay means and how to determine what kind of rope is on an existing hoist is just the beginning. Not only will this knowledge allow you to be a more effective technician for your customers, but you can promote safety in the industry.

Any assembly of wires spun into a helical formation (either as a strand or a wire rope), when subjected to a tensile load, can extend in three seperate phases, depending on the magnitude of the applied load:

Phase 1 and 2 are highly important because they represent a part of the qualities of the rope. Phase 3, on the other hand, can be caused by wrong choose of rope or lack of rope inspection. The phases are connected to eachother and cause a course of event in all ropes that are exposed to gradual increased load. Due to this a new rope, which are exposed to overloading, will go through phase 1 and 2 before the third phase (permanent extension) begin.

When loading a new product, extension is created by the bedding down of the assembled wires with a corresponding reduction in overall diameter. This reduction in diameter creates an excess length of wire which is accommodated by a lengthening of the helical lay.

When sufficientely large bearing areas have been generated on adjacent wires, to withstand the circumferential compressive loads, this mechanically created extension ceases and the extension in phase 2 commences.

The initial extention can not be accurately determined and depend on, apart from the strand or the rope construction, the various load and the current load frequency.

The proportionality factor normally is a material constant called Modulus of Elasticity (E-module). To steel wire ropes the E-module is more of a construction constant than a material constant.

The modulus of elasticity varies with different rope constructions. According to manufacturing factors, wire dimensions and a lot of other factors the E-module various between different wire ropes of the same construction and dimension. If exact E-module olf a certain rope is necassary a modulus test have to be done at that rope.

The elastic extension is valid until the proportionality or elasticity limit is reached. By load exceeding this limit extension according to phase 3 take place. Elasticity limit are defined as the largest strain where the rope return to its original length when unloaded.

These values are current for ropes operating with safetyfactor 5:1. By lower safety factors the module of elasticity indicated are raised and by higher safety factors they sink.

Load that cause tension in the steel wire rope, which exceeding the yield point of the material, the linear relation, due to phase 2, between stress and strain. This mean a small increase of load cause a lager extension than it would be in the elastic elongation area. If the load continues to increase the extension will increase faster than the load. This relation accelerate until a condition of permanent extension is reached and finally of the rope without further loading.

The elongation can be caused by a free rope end being allowed to rotate when loaded, e. g. "free" load or montage of swivel. The lay will be extended and cause an elongation.

The total elongation of a 200 m length of steel wire rope type 28 mm 265-wires (6x36-IWRC) at a tension of 10 tons (safety factor 5:1) and with an increase in temperature of 20°C.

In selecting the right steel wire rope, it is important to determine how important the various properties are in relation to the application and then to assign priorities to these. It is also important to be aware of the relevant standards and regulations. If you are in any doubt, please contact our sales consultants or our Technical Department.

The tensile strength of the steel wire rope depends on the rope’s dimensions, the tensile strength of the wires and the construction. The minimum guaranteed tensile strength for the different kinds of rope is shown in the Randers Reb product catalogue.

The design of the steel wire rope does not significantly affect the tensile strength (up to approx. 5%). A change of core from fibre to steel makes slightly more difference (approx. 10%). The greatest change is achieved by changing the dimensions, usage of Compacted steel wire ropes or tensile strength of the wires (see also fig. 28).

It is often required that the steel wire rope must have a specific SWL value (Safe Working Load), also known as a WLL value (Working Load Limit). This means the steel wire rope’s tensile strength divided by the safety factor required for the relevant application.

Steel wire ropes with thick outer wires (e.g. 6x7 Standard or 6x19 Seale) provide good abrasion resistance. Lang lay ropes provide better abrasion resistance than regular lay steel wire ropes (see also fig. 28). Abrasion resistance can also be increased by using wires with greater tensile strength.

The greater the number of wires in the strand, the greater the bending fatique resistance and flexibility. Lang lay ropes provide better bending fatique resistance than regular lay steel wire ropes. Bending fatique resistance can also be increased by using pre-formed steel wire ropes (see also fig. 28).

Galvanised and rustproof wires provide excellent protection against corrosion. Lubrication with special types of grease or oil will also increase resistance to corrosion. If the steel wire rope is subjected to significant corrosive influences, it is recommended that strands with thick outer wires are used.

Steel wire ropes with fewer wires (e.g. 1x7 Standard and 1x19 Standard) are subject to the least elongation (have the greatest elasticity modulus). This type of steel wire rope is ideally suited for guy ropes, but is not suitable to be run over sheaves/blocks. If only a small degree of elongation when running over sheaves is required, 6x7 or 6x19 steel wire rope should be used, in each case with a steel core or with certain special constructions. For larger dimensions, 6x36 steel wire rope with a steel core can also be used (see also Elongation and Pre-stretching, page 8-28).

Standard 6-lay and 8-lay steel wire ropes will rotate when they hang free and carry a load. Regular lay steel wire rope provides greater resistance to rotation than lang lay steel wire rope. A steel wire rope with a steel core rotates less than a steel wire rope with a fibre core. The type of rope that provides greatest resistance to rotation is, as the name suggests, low-rotation and rotation-resistant steel wire rope (special constructions, see also ”Low-Rotation and Rotation-Resistant Steel Wire Rope”, page 8-10).

A steel core provides better support for the strands than a fibre core, which is why the risk of flattening is less in a steel wire rope with a steel core. Strands with fewer, thicker wires have greater resistance to flattening/crushing. Also, a 6-lay steel wire rope has greater crushing resistance than an 8-lay rope (see also fig. 28).

Vibrations, from wherever they might come, send shock waves through the steel wire rope, which will be absorbed by the steel wire rope at some point, and in some cases they may cause localised destruction of the steel wire rope (not necessarily on the outside). This may, for example, be at places where the steel wire rope comes into contact with a sheaf/block, or enters the drum, and by the end terminals. In general, those steel wire ropes with the greatest flexibility also have the greatest vibration resistance.

Changes in the tension of a steel wire rope, depending on the size and frequency, will reduce the rope’s life expectancy. In general, steel wire ropes with the greatest flexibility can cope better with intermittent loading. Great care should be taken in the use of end terminals or fittings, as their pulsation resistance is equally as important as the selection of the right steel wire rope.

Lang lay steel wire ropes are the ones most suited to running over sheaves and are the most durable, but if they are to be used, three things must be observed:

The reason for Lang lay steel wire ropes’ excellent qualities of abrasion resistance and pliability is that the wires are affected/loaded in a different way and have a larger load-bearing surface than a regular lay steel wire rope (see fig. 29). Note that the largest wearing surface is on the Lang lay steel wire rope.

As specialist for manufacturing quality steel wire ropes over 20 years, our company can supply strong, durable and reliable ropes that capable to minimize your downtime and maximize cost effectiveness. Decades of experience we owned make us know clearly the work you do and capable to provide professional guidance.

We select the best steel or stainless steel as raw material for wire rope manufacturing. Our products are manufactured under strict quality managements and test before they leave the factory.

Our engineers can provide professional advice about picking up optimal steel wire ropes for their application, installation guidance to ensure maximum return in their wire rope system.

If you are going to pick up steel wire ropes that suit your project perfectly, you must have an ideal about the construction about them. Our company can supply bright wire rope, galvanized wire rope, stainless steel wire rope, compacted wire rope, rotation resistant wire ropes, mining wire rope, elevator wire rope, crane wire rope and gas & oilfield wire ropes. Here are some details to solve the problem that may puzzle you whether you are browsing the web or picking up steel wire ropes.

Bright steel wire ropes mean no surface treatment is applied to the rope. Therefore, they have the lower price among these three wire ropes. Generally, they are fully lubricated to protect the rope from rust and corrosion.

Galvanized steel wire ropes feature compressed zinc coating for providing excellent corrosion resistance. With higher break strength yet lower price than stainless steel, galvanized steel wire ropes are widely used in general engineering applications such as winches and security ropes.

Stainless steel wire ropes, made of quality 304, 305, 316 steels, are the most corrosive type for marine environments and other places subjected to salt water spray. Meanwhile, bright and shiny appearance can be maintained for years rather than dull as galvanized steel wire ropes.

Steel wire ropes are composed of multiple strands of individual wires that surrounding a wire or fiber center to form a combination with excellent fatigue and abrasion resistance. These wires and strands are wound in different directions to from different lay types as follows:

Beside above lay types, alternative lay ropes which combine regular lay and lang lay together and ideal for boom hoist and winch lines, can also be supplied as your request.

Two main methods about seizing steel wire ropes in conjunction with soft or annealing wire or strands to protect cut ends of the ropes form loosening.

8613371530291

8613371530291