rocol wire rope dressing free sample

High performance semi-fluid wire rope dressing grease providing excellent corrosion protection in multiple environments including saltwater and under water.

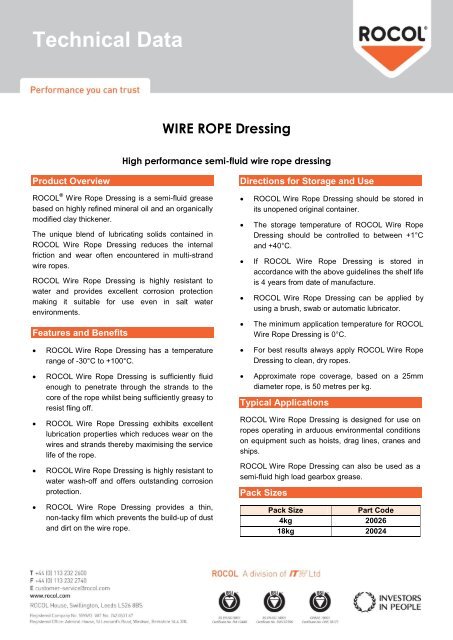

Product Overview Directions for Storage and Use ®ROCOL Wire Rope Dressing is a semi-fluid grease ROCOL Wire Rope Dressing should be stored inbased on highly refined mineral oil and an organically its unopened original container.modified clay thickener. The storage temperature of ROCOL Wire RopeThe unique blend of lubricating solids contained in Dressing should be controlled to between +1°CROCOL Wire Rope Dressing reduces the internal and +40°C.friction and wear often encountered in multi-strand If ROCOL Wire Rope Dressing is stored inwire ropes. accordance with the above guidelines the shelf lifeROCOL Wire Rope Dressing is highly resistant to is 4 years from date of manufacture.water and provides excellent corrosion protection ROCOL Wire Rope Dressing can be applied bymaking it suitable for use even in salt water using a brush, swab or automatic lubricator.environments. The minimum application temperature for ROCOLFeatures and Benefits Wire Rope Dressing is 0°C.

ROCOL Wire Rope Dressing has a temperature For best results always apply ROCOL Wire Rope range of -30°C to +100°C. Dressing to clean, dry ropes.

ROCOL Wire Rope Dressing is sufficiently fluid Approximate rope coverage, based on a 25mm enough to penetrate through the strands to the diameter rope, is 50 metres per kg. core of the rope whilst being sufficiently greasy to Typical Applications resist fling off. ROCOL Wire Rope Dressing is designed for use on ROCOL Wire Rope Dressing exhibits excellent ropes operating in arduous environmental conditions lubrication properties which reduces wear on the on equipment such as hoists, drag lines, cranes and wires and strands thereby maximising the service ships. life of the rope. ROCOL Wire Rope Dressing can also be used as a ROCOL Wire Rope Dressing is highly resistant to semi-fluid high load gearbox grease. water wash-off and offers outstanding corrosion protection. Pack Sizes ROCOL Wire Rope Dressing provides a thin, Pack Size Part Code non-tacky film which prevents the build-up of dust 4kg 20026 and dirt on the wire rope. 18kg 20024Technical Data

Property Test Method Result Appearance Visual Soft grey/black grease Base Fluid Type N/A Highly refined mineral oil Thickener N/A Organically modified clay Base Fluid Viscosity at 40°C IP71 465cSt Blend of molybdenum Solids N/A disulphide & HLWS Worked Penetration IP50 420 NLGI Classification IP50 00 4-Ball Weld Load IP239 315kg

The information in this publication is based on our experience and reports from customers. There are many factors outside our control orknowledge which affect the use and performance of our products, for which reason it is given without responsibility.Issue: 1 Date: 01-11 SAFETY DATA SHEET WIRE ROPE DRESSING Page: 1 Compilation date: 26/10/2011 Revision No: 4

Company name: ROCOL ROCOL House Swillington Leeds West Yorkshire LS26 8BS ENGLAND Tel: +44 (0) 113 232 2700 Fax: +44 (0) 113 232 2740 Email: customer-service@rocol.com

[cont...] SAFETY DATA SHEET WIRE ROPE DRESSING Page: 2

[cont...] SAFETY DATA SHEET WIRE ROPE DRESSING Page: 3

[cont...] SAFETY DATA SHEET WIRE ROPE DRESSING Page: 4 Odour: Perceptible odour Evaporation rate: Negligible Oxidising: Non-oxidising (by EC criteria) Solubility in water: Insoluble Viscosity: Highly viscous Melting point/range°C: > 150 Flash point°C: > 150 Autoflammability°C: > 200 Relative density: 0.95

[cont...] SAFETY DATA SHEET WIRE ROPE DRESSING Page: 5

![]()

A tenacious, semi-fluid, non-melting grease designed for complete lubrication and corrosion protection on most types of wire ropes, particularly in hostile conditions.

ROCOL® Wire Rope Dressing is highly resistant to water and provides excellent corrosion protection making it suitable for use in salt water environments even under water.

Nov022015ROCOL CHAIN GUARD 550, PACK SIZE:20 LITRES (WE INTEND TO CLAIM REWARDS UNDER MERCHANDISE EXPORT FROM INDIA SCHEME.Sri LankaChennai Air CargoNOS165,97265,972

Sep162015BISCUIT MACHINE ACCESSORIES ROCOL MAKE FOODLUBE SUGAR DISSOLVING FLUID 500 ML. BATCH NO. 2127F4366. LNG 32 (P.NO. 33890)NigeriaBombay Air CargoNOS412,8973,224

Aug252015ROCOL CHAIN GUARD PART NO: 22075 PACK SIZE: 20 LITRES (WE INTEND TO CLAIM REWARDS UNDER MERCHANDISE EXPORT FROM INDIASri LankaChennai Air CargoNOS166,38266,382

A new wire rope and umbilical lubricant from ROCOL developed to meet much tougher global marine ecology regulations has proven its uncompromising performance capabilities in trials with a leading offshore and subsea services provider.

The company ran a trial usingBiogen Wireshieldon ROVs operating from its Grampian Surveyor vessel for a three-month period off the coast of West Africa. The trial was designed to put the lubricant through its paces on umbilicals in the deepest operating waters (between 1,000m and 3,000m) – much deeper than the 100m to 200m depths typically found in the North Sea.

As an Environmentally Acceptable Lubricant (EAL), Biogen Wireshield was developed by ROCOL specifically to meet the biodegradable definition according to the OECD 306 test method. Prior to customer trials, product testing had already demonstrated 0 galvanic reaction after 1,000 hours in salt spray tests, plus shear stability in the presence of salt water with little degradation.

8613371530291

8613371530291