roller swage press wire rope quotation

What is Roller Swaging? Put simply, a component is forced through a set of rotating dies to transform the diameter of the component. This type of "work hardening" adds a lighter touch to the brute force of the pressing process. The result is a more aesthetically pleasing finish which is ideal for architectural, balustrade and yacht applications.

If you need a wholesale wire rope swaging machine, Alibaba.com is the platform to visit. This online shop has collaborated with many Alibaba.com dealers to offer customers a wide range of products that lie within their budget. Moreover, the platform offers customization services. So, if you need a custom-made machine, you can place a customization order. This shop also operates on a 24/7 hour clock enabling you to place your order at any time with a few clicks.

Moreover, the cost of the machinery also matters. The cost will largely depend on the model of the equipment. Additionally, the purchasing, installation, and maintenance costs of the machine you select should lie within your budget as it will help you avoid financial strains. Look at the prices offered by different suppliers to land a favorable deal. Lastly, it is important to consider the size of the wire rope swaging machine. The cable manufacturing equipment you buy needs to fit into your working space and leave some space for the operator.

Several industries utilize cable manufacturing equipment. These industries include the medical, telecommunication, military, and automotive industry. Hospitals have specific requirements for their cabling and wiring needs. They require wire rope swaging machine that fulfills those requirements. Secondly, with a wholesale wire rope swingaging machine, the telecommunications industry produces custom-made cables that they use in the manufacture of smartphones, computers, laptops, and tablets. In the military, the equipment is used to produce cables used to power foreign military bases and secure private communications on battlefields. Lastly, the automotive industry uses this machinery to make wires used to suit communication technologies in ambulances and police cruisers. Whether you"re looking for a wider or of connection, look to the wiring parts as available as Alibaba.com"s wholesale store is the place to find them.

Manufacturer & distributor of rigging supplies & material handling equipment. Products include tie downs, electric, manual, wire rope & air hoists, winches, decking, hydraulic cranes, load binders, bridles, dock fenders & personal floatation devices. Other products such as fall protection devices, wire rope assemblies, round, chain & nylon slings, augers, spreader beams, lifting devices, cargo control straps & devices, oil absorbents, romp rollers & anti fouling paints are also available. Services include equipment rentals, crane load testing, OSHA compliance inspection, electric hoist repair & testing, rigging workshops, training & design, installation, inspection & repair of cranes. Chain hoists, air hoists, lever pullers, rollers, air winches & dynamometers are available for rent. Markets served include marine, industrial, construction & commercial.

Both swaged and swageless cable railing fittings provide a reliable connection between the cable and fitting. Indeed, both options can provide a link that equals or exceeds the breaking strength of the railing cable. So the question is swage vs. swageless.

However, there are minor differences between the two fitting styles that can impact the installation process and quality of the finish. Here’s what you need to know about swage vs swageless cable railing fittings.

Swaging is a method of securing cable railing wire with a permanently fitted cable or sleeve. The connection typically exceeds the rated breaking strength of the wire rope or cable. This is accomplished using fittings known as swages.

A railing system secured with swage fittings is called a swaged system. Swaged systems have been around since cable railing systems were invented. Initially, railing cable installers hand-swaged the fittings using a variety of hand crimping tools and smaller swaging tools.

Hand crimpers (which look like bolt cutters) smash the swage fitting onto the cable with manual force, creating a seal. And it generally takes multiple crimps to achieve a proper connection.

Later, however, machine-swaged fittings were invented. These fittings are created in a shop by a fabricator using either a press swagger or a rolling swagger. The process cold-forms the fitting around the cable using much more force than hand crimpers can manage, resulting in a much stronger connection. This resulted in a more secure cable railing system.

As technology advanced even further, a new evolution of fittings known as swageless systems arrived. Swageless fittings don’t require any form of swaging or crimping. Instead, the fittings features a small one-way locking mechanism. This locking mechanism secures the railing system by allowing cables to enter in only one direction. It then grabs the cable if it is pulled in the opposite direction.

Assuming that you’re using 1/8 inch or 5/32 inch diameter cables, both swage and swageless fittings can provide a solid and very reliable connection between the cable and fitting. However, they have varying pros and cons.

You can install Swageless cable railing fittings while installing the cable railing frames. Unlike with swage fittings, you do not have to wait for the exact measurements.

The high cost is a major downside of swageless cable railing fittings. Swageless fittings are much more expensive than swaged options. Costs can quickly add up on a large project.

If neither swage nor swageless fittings are suitable, a third option is available. You can have your fittings pre-swaged on both ends by a fabricator.

However, pre-swaging, too, has a few shortcomings. For one, you need to supply exact measurements to the fabricator to swage the fittings onto the cable. Additionally, the fittings come attached to the cable. Therefore, you must drill oversize holes during installation for them to pass through.

Swaged systems, such asAtlantis Rail’s RailEasy stainless steel cable railing system stand out among the options. These fittings are not only easy to work with but also extremely cost-effective.

The above shown 500tonnes 4 tie rods compact wire rope splicing press which can splice up to 30mm wire rope in single bite. This is our new indigenous design for wire rope splicing. The machine is working with satisfactory result in Indian market. This machine is available in two options

This press is fabricated in mid steel of IS 226, 2026 or 449 grade. Duly tested chemically as well as physically before manufacturing. The hydraulic cylinder is manufactured of solid bars and duly packed with high pressure chevron packing seals and dust cover seal. The press is provided with the 10H.P. power pack with & without dual pump system as per client’s requirement.

#630-663 Langelier Co. Model #4 Swaging Press; swaging couplings to wire rope; die holder base: 8″x6″; die holder: 5″x4″; present die size: 2-1/2″ x 2-1/2″; foot pedal-air pneumatic tool clamp; Ajax electric motor: 7.5HP – 1140 RPM; 220/440 – 3 – 60cycle; 5 belt V-drive

Swaging is actually a cold forging process in which the dimensions of a fitting are altered using dies. The dies can be designed for either a a Hydraulic Swage Press (typically a single or double acting vertical hydraulic ram that presses the fitting into a size dictated by the die dimensions). Talurit is an excellent brand in this category or

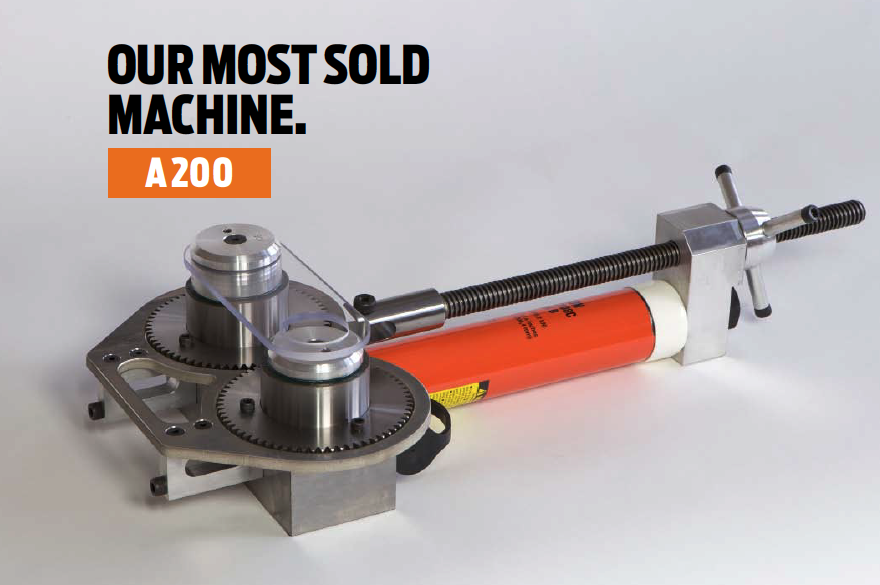

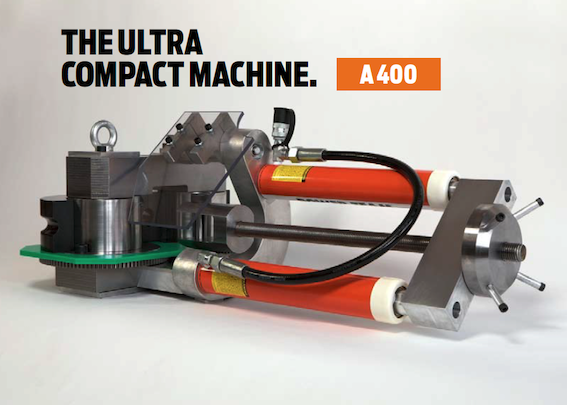

a Roller Swage Press through which the item is forced (typically single or double acting hydraulic rams actuating cammed dies that work by forcing the fitting through a decreasing radius) Wireteknik (Full Swedish Company name is WIRETEKNIK LEIF ANDERSSON AKTIEBOLAG)is an excellent brand in this category.

It is important that swage terminals are swaged down to the correct diameter. Because of standards (sizing of fittings globally), a reliable and repeatable MBS can be achieved in a connection if Stainless Steel terminals are swaged to the wire rope with an adequate swaging machine (mechanical or hydraulic) that will achieve the required reduction in outside diameter.

The table below is for reference only. It is the sole responsibility of the person or company doing the swaging to ensure the correct dies are used and that the swage has been correctly applied. In any critical application, destruction testing of a construction where all components and dimensions are known and documented must be completed to ensure a properly tested rig.

Low Cost Wire has a full rigging shop and prototype fabrication facility, and can arrange destruction testing and proof certificates. In our shop we sell and use a wide range of machines (presses) including Talurit Presses and Wireteknik Roller Presses. Our decades of rigging and swaging experience can often simplify a problem in minutes or prevent a costly disaster with a small conversation. If in doubt, contact us to discuss your swaging requirements. Valid Swaging Dimensions

We not only connect all of our fittings on to the wire rope for you but we will also special order any other fitting we may not have in stock to custom make exactly what you want!

Machinery International’s success in the swaging machine industry has been derived from the ability to supply swagers for many applications, the capability to help customers determine the best swaging machine for an application and the access to a large inventory of swagers and pointers located in our warehouses in the United States and in England. In addition, our loyal customers trust us to sell their swaging machines and pointers exclusively for them which increases the availability of these machines to our new clients.

The selection of the most appropriate swaging mill for an application is essential to the success of any project and Machinery International’s experience in this industry has aided customers in determining the proper swaging requirements for an application and the subsequent matching of the best used swager allowing for that success. We have successfully assisted clients with such diverse swaging applications as pointing wire and tube for redraw, continuous reduction of wire rope, tube, wire and rod reducing, the attachment of fitting onto cables for the marine aerospace industry, etc.

Machinery International’s inventory includes used swaging machines and pointers available in any and all configurations needed for today’s requirements such as 2 DIE, 4 DIE, ROTARY SWAGING MACHINES, STATIONARY DIE SWAGERS, as well as HYDROFORMERS, (DIE CLOSING MACHINE), HAND POINTERS AND CONTINUOUS ROLL POINTERS. Our extensive inventory includes swaging and pointing equipment produced by the top manufacturers in the industry like:

The selection of the proper support equipment is an extremely important in component of any swager project. Although a majority of swaging machine applications are hand fed, some could not be accomplished without the proper feed mechanisms or material handling devices. Machinery International carries in its inventory many types of equipment that may be needed for today’s applications. Hydraulic, rack and pinions, coil openers, as well as air operated swaging machine feeds can be supplied.

Machinery International is the company that can satisfy all of your swager and pointer requirements whether they are large or small. Please contact us with your application and allow our swaging machine specialists assist you with the selection of the right swager.

8613371530291

8613371530291