rouster wire rope factory

We’ve changed our name from Rouster Lifting & Rigging to Mazzella Rouster Rigging. Aside from the new name and logo, our member experience is virtually unchanged. Here are some common questions and answers related to this change.

In 2015, Rouster Wire Rope & Rigging was acquired by Mazzella Companies to expand lifting and rigging products and services to the south of the United States.

In 1954, James Mazzella founded Mazzella Wire Rope & Sling Co. in Cleveland, OH. For over 65 years, the company has grown organically by nurturing historic relationships, expanding its product offerings, and entering new markets through acquisition.

Mazzella Companies has acquired Rouster Wire Rope & Rigging. This acquisition will expand Mazzella Companies’ footprint and enhance their expertise in high-performance synthetics.

“Chuck Farmer and Rouster Wire Rope & Rigging are well-known as experts in the lifting business. Chuck’s vision and knowledge in the application of high-strength synthetic ropes will be invaluable to Mazzella. Their focus on safety has been the foundation of their outstanding reputation and fits right in with our culture,” says Tony Mazzella, CEO of Mazzella Companies.

Rouster is based in Beckley, WV and has been in business since 1993. Rouster has established a reputation as one of the industry’s most innovative, reliable, and knowledgeable companies in the rigging and lifting industry. The Rouster team possesses an undying commitment to extraordinary innovation, quality, safety, and service.

Chuck Farmer, who will continue to lead the growth and expansion of the business said, “The opportunity to sell additional lifting products and services is exciting. Expanding on the latest and emerging technologies in the lifting business has just been magnified. Our customers will reap the benefits of Rouster becoming part of the family of Mazzella Companies.”

Supplier of chain slings, synthetic and wire rope. The company manufactures and supplies chain slings, synthetic and wire rope and nylon and polyester web slings in USA.

Rouster is a supplier of synthetic rope, wire rope, chain slings, nylon and polyester web slings. The company is based in Mabscott, West Virginia, USA.

Tony Mazzella, Mazzella Companies CEO, said, “Chuck Farmer and Rouster Wire Rope & Rigging are well known as experts in the lifting business. Chuck"s vision and knowledge in the application of high strength synthetic ropes will be invaluable to Mazzella. Their focus on safety has been the foundation of their outstanding reputation and fits right in with our culture.”

Chuck Farmer, who will continue to lead the growth and expansion of the business said, “The opportunity to sell additional lifting products and services is exciting. Expanding on the latest and emerging technologies in the lifting business has just been magnified. Our customers will reap the benefits of Rouster becoming part of the family of Mazzella Companies.”

Introducing our brand new Performance Wire Ropes Catalog. Included in this catalog is our crane usage table, our high performance compacted strand ropes, category 1 and 2 ropes, and end fittings and connections. Call 215-721-9333 to get a physical copy, or click below to download a PDF version.

5048 Timber Creek Dr. • Houston, Texas 77017 • Ph: 713.979.5300 • Fax 713.979.5304 • sbrewer@premierwirerope.com • www.premierwirerope.comSLINGS TO THE MAX

Wire Rope News & Sling Technology June 2014A long view up the thousands of cables that make their way across the Royal Gorge. photograph © Thomas Woodruff via Dreamstime.com.

and jibs and guide ropes for elevators and winding apparatuses as well as anchor moorings for dredgers with and without anchor windlasses. Track ropes are ropes on which rollers of conveying means move, for example, such as conveying

23 illustrates the characteristic construction parameters of lines 20a, 20b, the envelopes extending along the longitudia stranded rope 10. The diameter D of the stranded rope nal direction L. The envelopes 22a, 22b can be determined

Figure 25 shows an image data capturing device 24 adapted to capture a rope 10 in an image data set. In the preferred embodiment 4, the image data capturing device 24

simple, and personnel training and certification are readily available. Their wire rope test instruments detect Localized Flaws (LFs) frequently caused by external and

corrosion and wear. The company has a built-in chart recorder so that the rope testers may be used for daily safety inspections and their NDT_CARE™ (Computer-Aided

said that most of the regulations that it wasn’t properly tagged. And ofmake it into OSHA get there written ten, when they are not used for lifting people, they are used for lifting

Stainless Steel Wire Rope all packed by clean plywood reel, reel on plywood pallet for easy loading and unloading. clear plastic film also covered to avoid dirt and water.

Looking for ideal Coated Galvanized Cable Manufacturer & supplier ? We have a wide selection at good prices to help you get creative. All the Rouster Wire Rope are quality guaranteed. We are China Origin Factory of Steel Rope Bunnings. If you have any question, please feel free to contact us.

Sheffield Metals is part of the Mazzella Group, which has a dozen different companies in three main divisions. Its Crane Division includes: Progressive Crane, Mazzella Crane Services, KCI Crane Service, and FHS – Overhead Cranes, Hoists, Conveyor Systems & Storage Racks. The Rigging Division includes: Mazzella Lifting Technologies, J. Henry Holland, Tennessee Sling Center, Indusco Wire Rope & Supplies, Alabama Sling Center, and Rouster Lifting & Rigging. The Metals Division includes Sheffield Metals International, and New Tech Machinery.

“My grandfather, Antonio Mazzella, started our parent company in 1954,” says Adam Mazzella, Sheffield Metal’s Vice President for Sales, Marketing & New Business. “It was a lifting and rigging company that manufactured wire rope slings for industrial applications. My father, Tony, came into the business in 1977, and steadily grew it over time.” According to Adam, Tony bought Sheffield Metals from its former owner in 2004, and hired Mike Blake, the company’s current President, to run it for him. At that time, the company had two locations – Atlanta, Georgia and Sheffield Village, Ohio, a suburb west of Cleveland.

EPIC JOuRNEy OF WORLDS FASTEST GONDOLA CAbLEINTERNATIONAL SALES MAGAZINERISING. ONE WORLD TRADE CENTERROuSTER TRANSFORMS THE MINING INDuSTRy8-1/8 (8.125) Trim8-3/8 (8.375) Bleed11-1/8(11.125)Bleed10-7/8(10.875)TrimATTN: Rick ColvinPH: 707.748.1700 FAX: 707.748.1701rickc@landmannwire.comPlease fax back approvalK ApprovedClient SignatureK Please make noted changesand fax back for my approval4736LDMad03r13WRXPub: Wire Rope Exchange2804 Foster AveNashville, TN 372101-800-643-5189Erik Von Colln (Printer)erik@midtownprinting.comwww.wireropeexchange.comClient: Rick ColvinLandmann Wire Rope Products6500 Goodyear Rd.Benicia, CA 94510800-331-0794/ph707-748-1701/faxDesign: Garson Design Services239 Concord AvenueFairfield, CA 94533707 428-1743/phone707 428-3652/faxmail@garsondesign.comIssue1: Nov-Dec of Each YearDeadl: 11/12/11-FriIssue2: Jan-Feb of Each YearDeadl: 01/16/12-MonIssue3: Mar-Apr of Each YearDeadl: 03/15/12-ThuIssue4: May-June of Each YearDeadl: 05/16/12-WedIssue5: July-Aug of Each YearDeadl: 07/16/12-MonIssue5: Sept-Oct of Each YearDeadl: 09/14/12-FriIssue5: Nov-Dec of Each YearDeadl: 11/12/12-MonTime: 04/25/15-8:00amFile: 4736LDMad03r13WRX.qx6Run File: 4736LDMad03r13_042512.pdfK OPTION 1.1Full page - Wire Rope Exchange WRX Trim: 8-1/8 (8.125) x 10-7/8 (10.875) Bleed: 8-3/8 (8.375) x 11-1/4 (11.25) Colors: CyanMagentaYellowBlackSEND:Program: Hi-res PDFFonts: IncludedLittle Rock, AR3000 West 65th Street800 . 749 . 3690Muscle Shoals, AL1904 Webster Street256 . 383 . 3212Pascagoula, MS5615 Telephone Road228 . 712 . 2933Memphis, TN - Head Ofce950 Stage Road 800 . 395 . 5438Cable Service Four Yarbrough locations to serve your rigging needsYour Full Service Rigging Supplier www.yarcable.comYou know us for our large, load tested below-the-hook wire rope rigging. Now get to know Yarbrough as your full-service rigging supplier.Yarbrough can fabricate synthetic rigging to meet the requirements of any project. Need high-capacity synthetic rigging? Yarbrough is an authorized Slingmax dealer and can fabricate Twin-Path slings up to 500,000 lb. capacity.Yarbrough is your source for quality wire rope blocks, sheaves, rollers, or fairleads from McKissick, Lebus, Young, Gunnebo Johnson, and Skookum.Need chain? We mechanically assemble and load test chain assemblies of all types, including lifting chains, tie-down chains, and more.From the smallest aircraft cable assemblies to the largest multi-part wire rope slings, our wire rope technicians have the knowledge and experience to fabricate wire rope rigging for any application, large or small.2 JANUARY-FEBRUARY 2013 WIRE ROPE EXCHANGE[EDITORS NOTE]Climbing over 1500 feet on a skeletal steel frame would make anyones heart beat faster. Now imagine doing this everyday. Tis is exactly what the Ironworkers of New York City do. You could call them sky cowboys for their valor; but I believe their peace of mind comes from a combination of pride in their work and faith in the products, equipment and training used to bring them back down to the ground safely day in and day out.Safety, its always at the frontline of discussion and analysis in our business. Its a continuous goal to ensure our products not only exceed standards on site but also ensure the lives in the places, around the projects and on the jobs.In this issue, we look at a few businesses that go above and beyond in the work they do, literally. ASC Industries/Python and the Bilco Group are just two of the companies who have come together to help build One World Trade Center, planned for completion later this year. Te products they supply are helping the building rise to become the tallest tower on the Western Hemisphere. We also meet Chuck Farmer he and his business, Rouster Wire Rope & Rigging, recently were honored for bringing a new standard of safety below the earth in the coal mines of West Virginia. In a mining industry that judges itself based on accidents, its no wonder that safety and prevention is paramount. With safety always at the forefront of thought in our industry, work can be seemingly routine or uneventful. After all, assuming everything goes according to plan, there should be no surprises. While we arent personally climbing to the top of skyscrapers, nor are we churning away below the Earths surface, we give attention to the results of our work as if we were. Te pride and efort that goes into creating a safe environment allows people to exercise the routine of going home each day. So, lets take a break to congratulate, and to thank, the individuals and companies who quietly approach each day with this enduring focus on progress and safety.Tank you for being a part of the Exchange and let us know what how your business is growing! Melissa Hood, Editor | Wire Rope ExchangeP.O. Box 159323, Nashville, TN, 37215Email: mhood@wireropeexchange.com Upcoming Events 2013NATE 2013 February 18-21, 2013 | Ft. Worth, TX www.natehome.comSC&RA Specialized Transportation Symposium February 27-March 1, 2013 | Orlando, FL www.scranet.org2013 SPE/IADC Drilling ConferenceMarch 5-7, 2013 | Amsterdam, The Netherlands www.iadc.orgMid-America Trucking Show (MATS) 2013March 21-23, 2013 | Louisville, KY www.truckingshow.comSC&RA Annual ConferenceApril 2-6, 2013 | Austin, TX www.scranet.orgNASCC: The Steel Conference April 17 19, 2013 | St. Louis, MO www.aisc.orgAWRF Spring General Meeting & P.I.E April 28-May 1, 2013 | Ft. Worth, TX www.awrf.orgWindPower Expo 2013May 5-8 | Chicago, IL www.windpowerexpo.orgOTC 2013 May 6-9, 2013 | Houston, TX www.otcnet.orgWSTDA 2013 Annual Meeting May 6-9, 2013 | Napa, CA www.wstda.comAISTech 2013: Iron and Steel Technology ConferenceMay 6-9, 2013 | Pittsburgh, PA www.aist.orgACRP General AssemblyMay 7 - 10, 2013 | San Antonio, TX www.acrp.netIADC 2013 Drilling Onshore Conference & ExhibitionMay 16, 2013 | Houston, TX www.iadc.orgCordage Institute Annual ConferenceJune 2-4, 2013 | Dublin, Ireland www.ropecord.comCHECK IT OUT: www.wireropeexchange.comUPDATE: IN OUR NOVEMBER-DECEMBER 2012 ISSUE, we featured Bridges to Prosperity and the businesses that are helping this organization build footbridges in rural communities. Since the article was published, Hoisting Wire Rope & Sling has also made a generous donation of a full container load of 1 3/8 and 1 1/4 inch wire rope that will be used to build bridges in Nicaragua. Thank you to Jay Anderson and his team at Hoisting Wire Rope & Sling!PLEASE NOTE: IN OUR NOVEMBER-DECEMBER 2012 Riggers Corner, we would like to thank LinkedIns Lifting and Rigging Group for the origin of our Riggers Corner Question: How often do you replace polyester round slings? The LinkedIn Groups continue to be a strong resource for opinions and advice from businesses within our industry. All participants in our Riggers Corner who answered the question were individually contacted outside of the group discussion.E-mail: sales.us@vanbeest.com www.vanbeest.com Member of Van Beest InternationalRegistered trade marks Green Pin and ExcelVan Beest B.V. is manufacturer and supplier of wire rope- and chain accessories with branches inThe Netherlands, Germany, France and USA, and stock holding distributors in over 80 countries worldwide.Manufacturer of EXCEL

hooks and chain accessories: genuine made in France product.Special rates available at the beautiful El Tropicano Hotel110 Lexington AvenueSan Antonio, TX 782051.877.214.9768www.eltropicanohotel.com$109.00/Single | $109.00/DoubleRegistration Information:800.690.3921acrp.netDedicated to Improving Crane and Rigging ActivitiesSpeakers include:Agenda:Golf Tournament & Softball GameKeynote Address: Harry Costner, PE, Mammoet Wednesday, May 8thBreakfastCrane & Rigging Jeopardy: CrosbyCase Studies of Super Critical Lifts: Harry Costner, PE, Mammoet Wind Turbine Lifting Considerations: Donald Strong, PE, Vestas Offshore Rigging: George Watson, Holloway Houston LunchBreakout Workshop: Wire Rope SplicingBreakout Workshop: Chain Sling Mechanical Assembly & InspectionBreakout Workshop: Wire Rope InspectionBreakout Workshop: Crane Simulator Rodeo Mobile, Tower, Overhead Cranes Thursday, May 9thBreakfastCritical Lift Planning Interactive Workshop: Mike Parnell, Industrial Training InternationalWhat is a Rigging Engineers Function: FLUORLunchBreakout Workshop: Mobile Crane InspectionBreakout Workshop: Crane Pads- DICA FIT System TrainingBreakout Workshop: SMPT TransportersCrane Operator Rodeo ResultsFriday, May 10thBreakfastHeavy Intermodal Lift & Transport-Engineering Considerations: Jim Yates, Barnhart Crane & RiggingOil & Gas Lifting Challenges: Don Jordan, BPCome Learn at theAssociation of Crane & Rigging ProfessionalsGeneral AssemblyMay 7-10, 2013Press Partners include:Rigging Attachments Below Hook LiftersCaldwell quality. Guaranteed.Learn more about our full line of products and services at caldwellinc.com.Or call our team of experienced engineers and technicians at 800.628.4263to discuss the optimal lifting solution for your application. Quality assurance Safety Increased productivity Decreased maintenance Peace of mind Cost savingsTHE INDUSTRY"S FIRST ANDONLY 2-YEAR WARRANTY.A promise of performance.5055 26th Ave. Rockford, IL 61109 800.628.4263 caldwellinc.comCW_CW_AD_COMP_091412_Layout 1 9/14/12 3:32 PM Page 122 | ROUSTER MAKES A WINNING CASE FOR CORDAGEChuck Farmer, President of Rouster Wire Rope & Rigging, receives the Equipment Innovation Award from the West Virginia Coal Association and Marshall University for his tireless efort to improve the safety record in coalmines throughout the U.S. In doing so, Farmer also proves the strength of synthetic fber rope over traditional applications in one of the most demanding environments. [CONTENTS]WIRE ROPE EXCHANGE JANUARY-FEBRUARY 2013 5WIREROPEEXCHANGE.COM | 800.643.5189JANUARY/FEBRUARY 2013VOLUME 28 | ISSUE 127 | Whats NewB/A Products introduce their new Twist Lock Shackle, RiggSafe Develops New Riggers App, Gunnebo Johnson enhances their oshore hook, and more.29 | InnovationsRoland Verreet of Wire Rope Technology Aachen, a wire rope failure analysis company, has created a new wire rope testing machine with better and more realistic results. Learn how his work is improving our industry. 33 | WRE CatalogView the latest product oerings and updated listings. WRE CATALOG GUIDEFEATURES 2 | EDITORS NOTE 7 | INDUSTRY NEWS72 | WRE UPDATE | PROJECT76 | WRE ADVISOR | BUSINESS79 | ADVERTISERS INDEX80 | RIGGERS CORNERON THE COVER: IRONWORKERS ATTACH CABLES to a steel beam ahead of lifting to the summit of One World Trade Center. When completed, 1WTC will be the tallest building in the Western Hemisphere, the third tallest building in the world by pinnacle height, with its spire reaching a symbolic 1,776 feet (541.3 m).Photo courtesy of PANYNJIN THIS ISSUE1672The 1WTC superstructure steel framing rises into the New York City skyline. Photo courtesy: Joe Woolhead22Rouster introduces cordage to a new feld.Knight Equipment Splicing hard at work in Vail, CO. 16 | HONOR JOB, RAISING 1WTC Scheduled for completion this year, One World Trade Center represents a long efort to not only rebuild after the devastating events on 9/11, but also construct what may be the most advanced and safest tower of its size ever built. Integral to this project was the combined efort of many partners, including rigging companies such as ASC Industries/Python America, the Bilco Group, and Brugg Wire Rope.Rigging Attachments Below Hook LiftersCaldwell quality. Guaranteed.Learn more about our full line of products and services at caldwellinc.com.Or call our team of experienced engineers and technicians at 800.628.4263to discuss the optimal lifting solution for your application. Quality assurance Safety Increased productivity Decreased maintenance Peace of mind Cost savingsTHE INDUSTRY"S FIRST ANDONLY 2-YEAR WARRANTY.A promise of performance.5055 26th Ave. Rockford, IL 61109 800.628.4263 caldwellinc.comCW_CW_AD_COMP_091412_Layout 1 9/14/12 3:32 PM Page 1Time Tested and Work ProvenCrosbys industry leading brands are time tested and work proven. The result is reliable products of uncompromising quality that performs to the highest standards throughout the world. Crosby is a market leader because of our unrelenting drive for excellence. For more than 120 years, a strong commitment to quality has been evident in every aspect of our business.Customer Service - More than available productIts meeting customer needs, product knowledgeComplete Product Line - Most complete in the industry, off-the-shelf or custom designResearch & Development - Innovative products and services, with many industry firstsRisk Management - Industry first comprehensive product application instructions, world class training Manufacturing - Quality process purchases through production and testingEngineering - State-of-the-art product design systems, and fully equipped metallurgy labWith a complete line of off-the-shelf blocks, sheaves and fittings designed to be used with wire rope, chain or synthetic slings, and the ability to custom design products for any lifting application, no lift is too big. We are The Heavy Lift Specialist! www.thecrosbygroup.comWIRE ROPE EXCHANGE JANUARY-FEBRUARY 2013 7[INDUSTRY NEWS]Limpet L5 Lifts New LEEA Award for Innovation> An ingenious height access and fall prevention system has won the Lifting Equipment Engineers Associations inaugural Product Innovation Award. Developed by Limpet Technology Limited and distributed in the UK by Lift Turn Move Limited (LTM), the Limpet L5 is a portable, multifunction unit that combines powered climb assistance for personnel working at height with integrated fall prevention, rescue and evacuation capabilities.Announcing the award at the LiftEx 2012 exhibition in Coventry on November 29th, Geoff Holden, chief executive of the LEEA, said: The judges were unanimous in their admiration for the Limpet L5, which demonstrates that greater efficiency and improved safety can go hand in hand. Working at height is a major challenge for the lifting industry and there is no doubt that the Limpet L5 will prove an invaluable asset for many people working in the field. John Jones, managing director for LTM, said: We have only been marketing the Limpet L5 for a matter of months and the response has been extremely positive. It is particularly useful in applications that put a real strain on workers in terms of climbing, such as stage rigging and wind turbine maintenance. This award underlines what a major step forward the Limpet represents in terms of both speed and safety.Measuring just 658 x 506 x 403mm, the L5 is ideal for supporting workers that need to access high structures. Users simply clip their harness to the Limpets integral safety line. An electric hoist controlled by sophisticated sensing technology then provides an intelligent vertical pull of up to 90% of the users weight (including tools and equipment). As a result, Limpet users can make twice the number of ladder climbs with half the effort, resulting in less fatigue, fewer mistakes and reduced health risks. Where no ladder exists, the L5 can be used as a powerful personnel hoist, providing a simple and cost-effective method of positioning workers for difficult- to-access areas.In addition to greater efficiency, the Limpet L5 guarantees outstanding levels of personal safety. Providing a constant tight rope from above, fall prevention is built-in and slips are arrested within 10mm. Furthermore, in the event of a medical emergency at height, the Limpets controls can be used to simultaneously lower two people to the ground.The Limpet L5 weighs just 65kg in standard configuration and operates from a 220-240AC/16A/50-60Hz single phase power supply. Suitable for users weighing 40kg to 140kg, it is fully compliant with the HSE 08 Type Test.For more details on the Limpet, visit www.liftturnmove.co.ukMore information on the work of the LEEA can be found at www.leeaint.com yTway Company Produces 2" Slings at Indianapolis Plant> The Tway Company, Inc. has produced its first 2-inch diameter wire rope sling in Indianapolis with an ultimate strength of 370,000 pounds. Providing the highest quality product of this size required The Tway Company to make significant investments in personnel, capital equipment and training at their Indiana location. The 24,000 square foot plant manufactures certified lifting equipment from USA-made raw materials by The Crosby Group, WireCo, Loos & Co., Bridon, and Bethlehem Wire Rope.Building a wire rope products plant in Indiana strengthened our position with the industrial sector across the Midwest and brings another manufactured product to the state, says Peter Hansen, President and CEO. There are few plants in the country capable of producing lifting gear this heavy, same day, and we are excited to be among the best. Founded by Joseph R. Tway in 1945, The Tway Company is a full service rigging manufacturer and distributor of lifting and handling equipment, wire rope, construction and mill supplies. The Company also operates a Heavy Rigging Rental division from the Oliver Avenue Plant. The Board is chaired by Peter Hansen, the third generation Chief Executive Officer.For more information, please see The Tway Companys website at twaycompany.com. yLGH Helps Habitat for Humanity> Lifting Gear Hire Corporation (LGH) recently donated a Modular 24 Spreader Beam with top rigging to help the New Orleans Area Habitat for Humanity (NOAHH). The Habitat for Humanity homes to be built come partially pre-constructed. LGH provided a Modular 24 Spreader Beam, at 20 length, to help assist in the placement of the walls and roof.NOAHH builds homes for families that are unable to qualify for traditional home loans but have stable jobs, good or no credit and are willing to contribute 350 hours to the building of Habitat homes. Giving back to the community is very rewarding. LGH appreciates the opportunity to work with the New Orleans Area Habitat for Humanity on this wonderful project, said Eric Kottemann, LGH Rental Representative in New Orleans, LA.Founded in 1990, Lifting Gear Hire Corporation (LGH) is the United States largest single organization devoted exclusively to the provision of lifting and moving equipment for rent and sale. LGH provides hoisting, pulling, jacking, rigging, material handling and safety equipment available for immediate and safe use. LGH Puts Safety First. www.lgh-usa.com yChant Engineering Breaks Ground on 25,000 Sq. Ft. Building Addition and New Executive Team > Chant Engineering Co. hits the ground running in 2013. Breaking ground lastTime Tested and Work ProvenCrosbys industry leading brands are time tested and work proven. The result is reliable products of uncompromising quality that performs to the highest standards throughout the world. Crosby is a market leader because of our unrelenting drive for excellence. For more than 120 years, a strong commitment to quality has been evident in every aspect of our business.Customer Service - More than available productIts meeting customer needs, product knowledgeComplete Product Line - Most complete in the industry, off-the-shelf or custom designResearch & Development - Innovative products and services, with many industry firstsRisk Management - Industry first comprehensive product application instructions, world class training Manufacturing - Quality process purchases through production and testingEngineering - State-of-the-art product design systems, and fully equipped metallurgy labWith a complete line of off-the-shelf blocks, sheaves and fittings designed to be used with wire rope, chain or synthetic slings, and the ability to custom design products for any lifting application, no lift is too big. We are The Heavy Lift Specialist! www.thecrosbygroup.com8 JANUARY-FEBRUARY 2013 WIRE ROPE EXCHANGE[INDUSTRY NEWS]month on a 25,000 sq. ft. manufacturing building addition, the company is doubling its manufacturing space to over 50,000 sq. ft. Chant, which partnered with TALURIT AB in 2012 as its authorized North American distributor, will use this space to house the full line of Talurit Swagers, Dies and other products and inventory, while continuing to grow its testing equipment production. In addition, Chant just finalized a partnership with Friedrich Hoppe GMBH in Germany, and is now the authorized stocking distributor for Hoppe heavy duty wire rope thimbles in North America.Not only is Chant expanding its facility, Chants executive team is increasing to manage this growth. The ownership transition was completed in 2012 with Philip Chant now the President and owner. Jules DiRienzo, has stepped into the position of Vice President of Operations and Patrick Shire has been promoted to Vice President of Sales and Marketing. David A. Crane, is now the Senior Mechanical Engineer to round out the Engineering department.The company, with 45+ employees, currently resides in a 38,000 sq. ft. green design energy efficient manufacturing facility and is a global diversified engineering company that designs, manufactures, services and calibrates testing machines, swagers, systems and related accessories for worldwide industrial and military customers. For more information on Chant Engineering, visit http://www.chantengineering.com yNew Times Ahead for Gunnebo Lifting> In October of this past year, Fredrik Wiking was introduced as the new CEO of Gunnebo Lifting and Blocks. Fredrik takes over from Jerker Hglund, and this was a natural step in the process of dividing the business areas of Gunnebo Industries Lifting, Traction, Fastening, Blocks and Telesteps into independent units. Gunnebo Lifting and Blocks will be ran as one company.Fredrik Wiking has extensive experience from the lifting industry, most recently as Business Area Manager at Alimak Hek. Alimak Hek manufactures and sells rack and pinion elevators and work platforms, and they have strong similarities with Gunnebo Lifting in terms of customer segments, distribution model and geographical distribution.I have full confidence in the future of Gunnebo Lifting. We have a strong brand and great products, which is an optimal foundation to build on, says Fredrik Wiking. yBLP Lafayette Branch Moves Into New Facility> Bishop Lifting Products Lafayette is proud to announce its recent move from New Iberia to Broussard in late November. The new 12,500 square foot building that sits on 4.5 acres south of Lafayette, LA, is located on Petroleum Parkway and Highway 90 and is a much larger and more modern facility. Along with a 500,000 lb test bed that is being installed in January, there is a 500 ton ESCO swaggeralong with a 500 ton National and a 20,000 lb. walk through spooling machine. This facility expansion will allow the Lafayette branch to grow in Louisiana as well as along the Gulf Coast.Vern McGehee, Branch Manager in New Iberia, says we have needed this move for a while. This new space allows for greater inventory, new testing facilities and more employees. This is an ISO 9001:2008 certified location. yBarnhart Expands Operations With Four New Branches> Barnhart is expanding and has recently opened three new offices in Charleston, SC, Owensboro, KY, and Richland, WA.These branches, along with a fourth recently-acquired Syracuse, NY location, expand the companys geographical footprint in some key areas. In addition, the company is relocating operations of their Portland, OR branch to Seattle, WA to meet the growing demands of its markets in the Pacific Northwest bringing its branch network to more than 24 locations.The Charleston and Owensboro branches will focus on providing heavy transportation, rigging and lifting services to nuclear and power customers in that region. Barnharts Richland branch will serve the Department of Energys Hanford Site in Washington State as well as industrial facilities in the region.The Charleston branch, with convenient access to rail and interstate transport, is located at the Marine Terminals and includes a roll on roll off (RO-RO) facility at Pier J to accommodate project cargo ships. The facility features more than 200,000 sq. ft. of high bay covered storage and is serviced by overhead cranes. Rail services are provided by CSX, Norfolk Southern & SC Public Railways.The Owensboro branch, located at Owensboro Riverport with RO-RO potential on the Ohio River, is easily accessible to rail and interstate transport and is served by CSX Rail Transport. With the companys new Syracuse Branch, Barnhart will be able to better serve customers in upstate New York particularly those customers in renewable and nuclear energy.Headquartered in Memphis, TN, Barnhart Crane and Rigging is one of the nations largest heavy lift and heavy transportation companies. Services also include logistics, machinery moving, and plant relocations. Barnharts Quality Management System is certified to the ISO 9001:2008 international standard and has been registered since 2000. ySouthwest Wire Rope Continues to Grow> Southwest Wire Rope, a division of Houston Wire & Cable Company, is very pleased to announce the appointment of Jason Fetter to Vice President and General Manager of Southwest Wire Rope.Fetter was born and raised in Williamsport, PA. He earned his B.A. at American University in Washington, DC. Jason received both his law degree and Master of Business Administration simultaneously at Penn State Dickinson Law School and Penn State. Upon graduation, Jason returned to Williamsport where he practiced law for several years.Jason grew up in the wire rope industry working in his familys 4th generation business, Muncy Industries, which includes Muncy Machine and The Upson-Walton Company. Initially, he worked both in the office answering phones and in the shop as a machine operator. Jason worked his way up to Vice President of Sales and Purchasing and quickly became legendary for his cross country driving to visit customers in all corners of the US.Jason has a passion for working in the rigging industry and views Southwest Wire Rope as a great fit. In his words, Our industry enables mankinds legacies from bridges to pyramids. This is a great opportunity to be part of that progression. Southwest Wire Rope is a leader in the industry, and I look forward to the opportunity.In addition to the appointment of Jason Fetter, Southwest Wire Rope is pleased Fetter10 JANUARY-FEBRUARY 2013 WIRE ROPE EXCHANGE[INDUSTRY NEWS]to welcome Brandon Thompson to their Houston sales office. Thompson holds a Bachelors Degree in Business Administration from Belhaven University and is currently pursuing his Masters Degree in Business Admin.Thompson served in the United States army for 4 years. After returning from Iraq in 2006, he began his career in sales. Prior to joining SWWR, Brandon worked at Certex USA.Outside of work, Brandon enjoys working out, leading church activities, mission trips, and spending time with family and friends. He is very excited for the opportunity to apply his expertise in his new position. yTom Hudgins Joins Delta Rigging & Tools As Vice President of Sales and Marketing> Delta Rigging & Tools, Inc., one of the largest providers of lifting and rigging products and related services in the United States, today announced that Tom Hudgins will be joining the company effective January 1, 2013 as Vice President of Sales and Marketing. Hudgins will rely on his more than 25 years of experience in the wire rope, lifting, and rigging industry to direct the sales efforts for Delta Rigging & Tools.Delta Rigging & Tools has consistently progressed to become the leader in both the sales and rental of lifting and rigging products and services since our founding almost a decade ago, said Mitch Hausman, President of Delta Rigging & Tools. Toms extensive background in sales and management is a perfect fit to maintain that growth pattern, and take us to the next level. We are constantly working on new and innovative sales and marketing practices to keep our range of products and solutions at the top of our customers minds, and Toms strong background in our industry will help guide Delta Rigging & Tools to even higher levels of performance.A native of Danbury, Texas, but raised in Oklahoma, Hudgins graduated from Oklahoma State University with a Bachelor of Science degree in Management. After college, Hudgins spent many years in the oil business including stints domestically and internationally with both Conoco and Cooper Manufacturing.When the oil bust occurred in the mid 1980s, Hudgins chose to enter the rigging and lifting industry. His first nine years in the industry were spent in sales management with an industry leading manufacturer of blocks and chain fittings. In 1993 he accepted a Sr. Product Specialist position with the Crosby Group focusing on the implementation of key new products. In 1999 he assumed the position of Southwest Regional Manager and in 2008 was promoted to the VP of Sales for the Crosby Group where he remained until joining Delta.Tom will be based in the Companys headquarters location in Pearland, Texas. yAlps Welcomes Mike Briand and Natosha Anderson> Alps Wire Rope Corporation welcomes Mike Briand as District Sales Manager for the Mid Atlantic and North East. Mike has had more ThompsonHudgins[INDUSTRY NEWS]than thirty-two years in the wire rope industry. Twenty-five years Mike was employed at Wire Rope Industries and the remainder at Yoke, as the VP of sales in North America.In addition, Alps is also excited to announce the hiring of Natosha Anderson as Customer Service Representative at Alps Wire Rope Corporation. Natosha Anderson joins Alps after working as Customer Service for 10 years at a manufacturer for hearing aids. Natosha is looking forward to finishing her Bachelors degree in Business Management at Bendictine University. yElgin Fastener Group Announces Corporate & Sales Additions> Elgin Fastener Group (EFG) announces three new additions to their organization. Brian A. McDonald has been named as Corporate Controller. He is a graduate of Milligan College in Tennessee and holds an MBA from Xavier University. McDonald brings to EFG over 17 years of experience in operations finance with both private and publicly-held organizations, and will be located at the Batesville corporate office.Larry Dray has joined EFG as Director of Supply Chain Management. He received a BA in Political Science/History from the University of Oklahoma and is a Certified Six Sigma Green Belt. Dray has more than 30 years of expertise as a sourcing leader for a variety of domestic and global manufacturing organizations, and is currently located at the Quality Bolt & Screw division of EFG in Brecksville, OH.Alicia Sanford was recently appointed as a Technical Sales Representative with WIRE ROPE EXCHANGE JANUARY-FEBRUARY 2013 11responsibility for the states of Illinois, Wisconsin, and Minnesota. She is a veteran of more than 20 years in the fastener industry, having served in various industrial sales engineering and account management positions with Camcar-Textron, Textron Fastening Systems, Acument Global Technologies, and Ifastgroupe Distribution. She is located in Winnebago, IL.Elgin Fastener Group is comprised of seven leading domestic specialty fastener manufacturers (Ohio Rod Products, Leland Powell Fasteners, Quality Bolt & Screw, Northern Wire LLC, Chandler Products, Silo Fasteners, Landreth Fastener), a metal finishing company (Best Metal Finishing), and an engineering and international procurement division (Elgin Fasteners International). Elgin Fastener Group is a portfolio company of Audax Group. yThe Ulven Companies Announce Christopher Reddy as GM at Skookum> The Ulven Companies are pleased to announce the hiring of Christopher Reddy as General Manager of their Skookum business unit. In this position at TUC, Christopher will be responsible for overall leadership in all functional areas of the business, establishing business objectives, maintaining quality standards, developing new product lines, and continuous improvements utilizing LEAN manufacturing methodologies. Tammy Sievers, Director of Human Resources at Ulven said, We conducted a nationwide search to fill this position and feel that we have found a unique and experienced leader. In a privately held business setting it is vitally important to not only have the skills required for the position but to also be a great cultural fit. We feel Chris is that person. Skookum is seeking expansion of their product lines and markets in the near future and Chris will be leading the way on this front.Chris received his Bachelor of Science in Mechanical Engineering from The University of Portland. His experience includes leadership roles at Precision Cast Parts Corporation, General Electric, and Danaher/Meggitt. Chris has been a leader in plant health and safety, as well as spearheading business initiatives as a Certified Six Sigma Black Belt with both Honeywell and GE.The Ulven Companies have been in the forging industry for over 40 years starting with the creation of Ulven Forging, Inc. in 1971. The Ulven Companies now comprise a group of four different American companies and are privately held. Each company has its unique set of process capabilities in different areas of the industry and is known for bringing high quality, cost-effective products to its customers with reliability and integrity. yAndersonMcDonaldDraySanford12 JANUARY-FEBRUARY 2013 WIRE ROPE EXCHANGE[INDUSTRY NEWS]Lift-It Manufacturing Expands Sales Force, Promotes From Within> Lift-It, a leading manufacturer of quality rigging equipment and a provider of world class training, has expanded its inside sales force to facilitate continued growth and top notch customer service.Amanda Brinegar has joined the company as the purchasing agent and brings a wealth of experience in domestic and international dealings and logistics to Lift-It.Mayra Torres, who recently completed her undergraduate degree is directing marketing support and the coordinating training activities with the assistance of Jenny Batchellor, who is pursuing her undergraduate degree.Vice President and will do an outstanding job, stated Mike Gelskey, Sr. Michelle will be assisted by Jessica Wilson and Viviana Collazo.For more information on Lift-It Manufacturing, please contact info@lift-it.com or visit www.lift-it.com yLoos & Company Grows its Sales & Marketing Team> Loos & Company is proud to announce the hiring of Robert Bobby Davis as their new Sales & Marketing Manager. Bobby adds depth to the sales and marketing team as Loos & Company continues to expand its presence in the aircraft cable, wire rope, and specialty stainless steel wire markets.Michael J. Gelskey, Sr., Chief Executive Officer stated, It is difficult to find quality people, even with spiraling unemployment in Southern California. Our newest team members bring a quest for excellence and sense of enthusiasm that is rare to find and is appreciated by our customers.Michelle Brown, a long time team member of the Lift-It Family has been promoted to Assistant General Manager. Michelle had demonstrated her ability to lead our company in many vital programs over the years and has been instrumental to our growth. She will be taking over more responsibility from Mike Gelskey, Jr., who was recently promoted to BrinegarTorresBatchellorBrownWilsonCollazoDavisWIRE ROPE EXCHANGE JANUARY-FEBRUARY 2013 13Bobby received his undergraduate degree in Marketing from the University of Maryland, and his M.B.A. from the University of Connecticut. Wire rope and wire are nothing new to him - from 2005 through late 2011, Robert was a member of the Loos & Company family. He began his Loos career as a Product Manager and quickly ascended to the position of Sales & Marketing Coordinator.Its great to be back. Bobby stated. I plan on making an immediate impact for the company through new programs focusing on opening new markets and enhancing the customer experience. Our knowledgeable and friendly staff is our greatest asset, and I plan on giving them additional tools to make the Loos experience even better, he continued. yReliance Crane and Rigging Acquisition> Taylor Crane & Rigging (TCR) announces the acquisition of all remaining equipment of Phoenix, AZ based company Reliance Crane & Rigging (RC). The acquired consist of approximately 3000 tons of equipment and rigging gear used for heavy industrial lifting and transport.TCR was established in Coffeyville, KS in 1975 to provide transportation services in the Southeast area of the state. The company has steadily expanded to become a full-service industrial mover and crane services company with about 300 clients ranging from Fortune 500 companies to small independent operations across North America. TCR has operated a satellite office in Tulsa, OK since 1998, and acquired Phoenix, AZ-based Reliance Crane & Rigging in 2012.TCR has become particularly well-known for its resourcefulness when undertaking plant relocations and machine installations in a safe, efficient, and timely manner. For example, when faced with the unexpected challenge of moving a 300-ton generator and a 250-ton turbine across an alternative route that included a 15-ton capacity, 80-foot county bridge, TCR employed an innovation that involved modifying a trailer deck in its fleet. When extended, the trailer deck served as a fortified bridge jumper to cross the river. TCR further modified the deck for use as a lifting beam to solve severe foundation access problems. The Kansas Department of Transportation later determined that this job, accomplished without accident or injury in 2006, was the heaviest permitted load ever moved in the state.Devising innovation solutions involving equipment was nothing new for TCR. A dozen years earlier, TCR founder Jim Taylor convinced Custom Mobile Equipment, Inc. to create the Versa-Lift 40/60 forklift, the new companys first machine, because he was dissatisfied with the bulkiness of the forklifts he owned. Custom Mobile Equipments website also credits him for sharing many other useful ideas about characteristics of the ideal machinery moving forklift.TCRs drive to meet the challenges of the craft helped the company earn two SC&RA Rigging Job of the Year trophies. yTerex Port Solutions Wins Crane of the Year Award > Terex Port Solutions has been presented the Crane of the Year award by leading magazine International Bulk Journal (IBJ) in Hamburg, Germany. The IBJ Award was presented for the Terex Gottwald Model 2 Harbour Crane, which was launched in June 2012. The IBJ Awards have been presented since 2009 and are globally recognised as one of the most sought-after prizes in the bulk materials handling industry. The Model 2 Harbour Crane is the first model within Terex Port Solutions Small Crane Family and has been specially developed for use in small river and sea ports or on narrow quays. This new crane type is based on proven Mobile Harbour Crane technology. It blends the mobility of the classic [INDUSTRY NEWS]14 JANUARY-FEBRUARY 2013 WIRE ROPE EXCHANGE[INDUSTRY NEWS]rubber-tyred Mobile Harbour Crane with the benefits of a drive-under portal solution, which is why it is called the G HRK Rubber-Tyred Portal Harbour Crane. Thanks to its tight turning circle and even on-the-spot-turning, the crane is highly manoeuvrable and can be quickly positioned.Giuseppe Di Lisa, responsible for Sales at Terex Port Solutions, sees the IBJ Award as confirmation of the Companys customer focus and technology leadership: With the Model 2, we are offering the customer a compact, flexible, high-performance crane, which is in great demand throughout the world. This is supported by the fact that Terex Port Solutions received an initial order for three G HRK Rubber-Tyred Portal Harbour Cranes from an Indonesian port operator just as the test phase was completed. It is very gratifying for Terex Port Solutions to receive such a renowned award within a short time after the launch of the Model 2 crane, Di Lisa continues.The Terex Gottwald Model 2 Harbour Crane is offered as a two-rope crane and as a four-rope grab variant with two hoists for professional bulk handling alongside vessels up to the Handysize class. With its maximum lifting capacity of 80 t, a radius of up to 40 m (38 m for the four-rope crane) and hoisting speeds of up to 120 m/min, the Model 2 Harbour Crane can also be used in container handling alongside vessels ranging up to Feeder class. As with the Terex Gottwald Model 3 Harbour Crane that was launched onto the market two years ago, the drive system on the Model 2 crane makes use of alternating current. Crane owners can opt for the energy-efficient and environmentally compatible hybrid drive or a hook-up to a quayside power supply. yOshore Industry Gathers at Launch of Factory for Worlds Largest Ropes> Industry leaders from companies including Heerema, NOV, and Certex assembled in Northern England this week to watch UK Business Minister Michael Fallon open a facility that will manufacture the worlds largest ropes.possible levels of demand. The factorys portside location, along with its state of the art Takeup Stand for lifting reels directly from dock to vessel, will help Bridon to significantly improve logistics. yHanes Supply Acquires Pauls Wire Rope & Sling> Hanes Supply, a manufacturer of chain slings, nylon slings, SlingMax slings and wire rope slings has recently announced the acquisition of Pauls Wire Rope & Sling effective January 2, 2013. Paul Cianciola, founder of Pauls Wire Rope & Sling, is a leader in the wire rope and rigging industry for over 50 years. Hanes Supply stated, We look forward to working with Paul and his team as we support all of our current and future valued customers with world class products and services. Hanes Supply has over 80 years experience splicing wire rope and manufacturing slings, as well as being a Rigging Supplier and an Industrial Supplier to industry and the construction trades. Hanes represents world class manufacturers which include The Crosby Group, Columbus McKinnon, Engineered Lifting Technologies, Harrington Hoist, Bethlehem Wire rope, WireCo Worldwide, Dewalt, Cooper, Milwaukee, Ridge Tool, Klein Tools and many more quality brands.Hanes Supply has 4 sling manufacturing locations, with the capacity and expertise needed in todays fast paced world. For more information on Hanes Supply, their other locations as well as their full range of expertise, visit: www.hanessupply.com. yThe event marked the commencement of manufacturing at Bridon Neptune Quay (BNQ), a state-of-the-art factory constructed by Bridon International which will produce the largest and most complex offshore ropes in the world. The facility will have the capacity to produce highly engineered ropes in package weights of 650 tonnes, boasting enhanced breaking loads, optimised bend fatigue performance, effective lubrication, and minimal rotation under load.The occasion was marked by the switching-on of the factorys rope-closing machine, which is the largest of its kind in existence. The machine, which was constructed to a unique specification by German engineering company SKET, will allow the company to produce far more complex ropes than had ever previously been possible with such weights. Pulling the lever to activate the machine was UK Business Minister Michael Fallon, who praised Bridon for establishing a global technology leadership position through its consistent investment in innovation. Accompanying Bridon Chief Executive Jon Templeman at the event were a host of senior industry figures including Certex CEO Peter Keith and NOV Cranes Division Head Oddvar Hoydal, who noted how Bridons highly engineered ropes could improve their companies heavy lifting and deepwater deployment capabilities.In addition to the switching-on of the facilitys rope-closing machine, the opening event offered a range of technical seminars for attending industry leaders, designed to demonstrate Bridons unique services offering. Focused on ensuring customers get the most out of Bridons highly complex ropes, this package provides tailored support throughout a ropes development, installation and application.Now operational, Bridon Neptune Quay is already taking on orders from major multinational operators, and its production schedule is designed to cater to the highest Eyebolts Nut Eyebolts Turnbuckles & Fittings Rod Ends Eye Nuts Pad Eyes Strap Clamps T-Slot Nuts Set-Up Wedges C-Clamps & Screws D-Rings & Clips Swivel Hoist Rings Custom Forgings - Up to 200 lbs. In StockCarbon Alloy StainlessMore Than 40 Years of Superior Quality and ServiceForged Industrial HardwareToll-Free: 888-KEN-FORGING (536-3674) Phone: 440-993-8091 Fax: 440-992-0360www.KenForging.com E-mail: sales@kenforging.comAll Products Proudly Made in The USA16 JANUARY-FEBRUARY 2013 WIRE ROPE EXCHANGEAmericans decided after 9/11 to return to the site of the tragedy to build a tower bigger and more beautiful than what had been there before as if to tell the World that we will not be moved, we will not be backed into a corner. Its a thrill now to come down the West Side Highway and see the 1 World Trade Center as a beacon, said Elizabeth H. Berger, president of the Downtown-Lower Manhattan Association. Te Lower Manhattan skyline is coming back. Tis is about the concentration of new, green, high-tech commercial space in the middle of what is now an exciting live-work community. Despite the emotionally-charged work atmosphere, the large sums of money it has taken to build, and lengthy negotiations, the new 1WTC is a successful, momentous feat. Te 1WTC tower was designed by Skidmore, Owings, and Merrill (SOM) Architects and co-developed by Te Port Authority of New York and New Jersey with Te Durst Organization to be the tallest building in the Western Hemisphere reaching the prideful height of 1,776 feet at the tip of its antenna. by Stephanie aurora LewiShonor JOBraiSinG the 1 worLD traDe CenterWindow panel installation on the east side of One World Trade Center Image courtesy PANYNJMario Tama/Getty ImagesWIRE ROPE EXCHANGE JANUARY-FEBRUARY 2013 17by Stephanie aurora LewiSI had a sense of pride every time I walked onto the jobsite. Tony Fastuca, ASC/Python AmericaDecember 12, 2012: Ironworkers watch as the frst section of the 408 foot cable-stayed antenna mast is lifted with SLINGMAX Twin-Path High Performance Slings to the top of One World Trade Center. When completed, the spire will bring 1WTC to a staggering 1,776 feet tall, making it the tallest building in the Western Hemisphere.18 JANUARY-FEBRUARY 2013 WIRE ROPE EXCHANGETe 1WTC tower has over 3 million square feet of ofce space with several signed leases including one with the prominent New York-based publisher Cond Nast. In addition to ofce space, the tower will also serve as a tool for radio and television transmission providing broadcasting services similar to that of the Empire State Building. By the time the tower is fnished, it will have cost well over $3 billion to construct. Te 9/11 memorial is located near the tower that has a list of each victim immortalized there. An observation deck is provided for tourists to gain an elevated view of Manhattan from its southern location. Te 1WTC was also designed with cutting-edge green architectural features. Te air quality for the tenants is high quality fltered air. 90% of the occupied spaces use natural lighting to lift morale and to reduce energy costs. Te high performance glass curtain wall is highly insulated glass. Each foor has the ability to control the heating and cooling temperature for the particular tenants occupying the space. Te tower also boasts of architectural features such as a 54-foot high entrance lobby, spaces with a minimum of 9 feet foor to ceiling sizes, and foor designs that do not have columns to interrupt fexible ofce and furniture designs.Addressing safety concerns, the 1WTC tower has a special steel and concrete base designed in accordance with the New York Police and Fire Departments. Te elevator shafts are constructed with high strength block and grout. Likewise, the new transportation hub was strategically designed to protect the area from attack. Most of all, the soon-to-be Freedom Tower symbolizes Americas resilient strength, beautiful creativity, and engineering innovation. The STeel ConSTruCTion ProCeSSTe Bilco Group and ASC Industries/PYTHON America supplied PYTHON High-Performance wire rope for the cranes that sat on the tower as it grew upwards foor by foor. Two cranes were devoted to steel construction and the other to concrete. Te towers were constructed in such a way that once the steel arrived to the site, the ironworkers attached the load to a cranes hook with steel choker cables. Ten, another group of ironworkers would handle and guide the steel bundles into place, securing the steel temporarily with tapered drift pins shoved through the matching bolt holes of the pieces to be connected. Te choker cables were then released and the process started all over as the ironworkers replaced the pins with high-strength bolts.As steel was brought up to each new level on the tower, large steel guide cables were secured from the columns to the foor below. Te steel guide cables were then released as beam connections were made between columns. Corrugated metal deck was then spread over the steel foor members and welded down. Once all of the steel connections were fnished and all of the steel decking installed, the foors were given over to the concrete contractors to fnish each composite fooring system.The TowerS legendary anTennaSOMs vision for the top of the Freedom Tower was a crowning sculpture designed by the famed sculptor Kenneth Snelson. Te sculpture was designed to sheath and work in conjunction with the communications platform ring and a 408-foot, cable-stayed antenna mast. When the project was recently near completion, Te Durst Organization who sought to reduce project costs deleted the antennas sculpture from the building. Still compelling for mention, the design for the antenna had been a mast protected by a one-of-a kind fberglass panel system that was designed to resist wind loading, and to create a protected maintenance area. At the base of the mast, a tetrahedral lattice ring supported the media transmission equipment. Te lattice ring braced eight radio-frequency transparent Kevlar guy cables that supported the mast. When lit at night, a beacon at the top was to send out a horizontal light beam that could have been seen from miles away.Te sculptor artist Kenneth Snelsons art is concerned with nature in its primary aspect, the patterns of physical forces in three dimensional spaces. Snelsons work is ethereal and embodies complex Joe Woolhead | Courtesy of Silverstein Properties (3 below) Images courtesy of ASC Industries/PYTHON AmericaWIRE ROPE EXCHANGE JANUARY-FEBRUARY 2013 19geometries that can only be realized through the use of elegantly strung wires. Used for artistic expressions, wire rope makes his sculptural installations throughout the world remarkable. SOM Architects fought to keep the sculpture, stating it was a critical part of their design.The FaSTeST elevaTorS in The weSTIt is not hard to imagine why the new Freedom Tower would house the worlds third fastest elevators after knowing what happened during the tragic fall of the previous towers and how vertical transportation was cut of. 54 high-speed destination dispatch passenger elevators are included for building occupants and tourists to have access to sufcient and fast vertical transportation from many points throughout the tower.TyssenKrupp Elevator, one of the worlds leading manufacturers of vertical and horizonta l transportation technology, supplied all 73 elevators and eleven escalators for the 1 World Trade Center tower. Tis is the largest order that TyssenKrupp Elevator has provided for any single building in history. Te fastest elevators in the Northern Hemisphere are designed to move at an alarming 29.5 feet per second. TyssenKrupp also stated that the elevators are designed to protect the passengers from ear-popping efects while ascending tourists to the observation decks in less than one minute. Of the $150 million contract, 64 of the elevators will be gearless, six are machine-room-less, and one is a geared elevator. Brugg Wire Rope supplied a large portion of the hoist cable wire ropes for the Freedom Towers elevator collection along with suppliers from Switzerland and the Czech Republic. In an interview with Bruggs Martin Rhiner and In our business, one wrong move, one mistake, could be costly. So we take proper training very seriously. Jason Lemberg, The Bilco GroupOne World Trade Center under construction.Joe Woolhead | Courtesy of Silverstein Properties 20 JANUARY-FEBRUARY 2013 WIRE ROPE EXCHANGEDoug Ingenthron, Doug Walker, Associate Editor with the Rome News-Tribune, discovered that the largest cable Brugg supplied is one-and-three-eighths of an inch in diameter. Each hoist cable is approximately 1,340 feet long and weighs over one ton due to its incredible length. In sum, Brugg supplied more than 826,000 linear feet of steel cables used for all of the Towers elevators. Te wire rope cables used for the elevators have steel cores as opposed to the traditional sisal rope-based core. Rhiner stated to the Rome News-Tribune that they were awarded the contract because of their Rope Life Prediction program.wire roPe inSPeCTion Training Bilco Wire Rope, a PYTHON America master distributor provided the non-rotating high performance ropes for the tower cranes on the 1WTC. As such, Bilco Wire Rope provided thousands of feet of PYTHON rope for the tower cranes and the cranes themselves were provided by Favco, says Jason Lemberg, Sales Manager for Te Bilco Group. Lemberg was the main operator for the project that represented both Te Bilco Group and ASC/PYTHON America as the main providers of wire rope for the buildings construction crews in the feld. Tony Fastuca, Vice President of Sales and Marketing for ASC/PYTHON America, and Lemberg provided many training sessions including: inspection criteria methods, inspections of wires within the ropes, and inspections of the rope conditions for the construction workers in the feld. Teir training seminars also included procedures for the proper installation of the ropes for the cranes. Additional training sessions were developed for the beneft of representatives from the Port Authority as well as from the Department of Building Inspectors.Any time our product is used, we like to give our customers as much training as possible. Tis is a unique aspect of Te Bilco Group and our joint eforts with ASC/PYTHON America, says Lemberg. In our business, one wrong move, one mistake, could be costly. So we take proper training very seriously. Te Bilco Group is supplying the ropes and hardware for the erectors for the 4 Tower as well as for the WTC site transportation hub. Te Bilco Group has been distributing wire rope and related rigging products for over 30 years.Te SLINGMAX Twin-Path High Performance Slings used on the construction site at the 1WTC were manufactured by ASC Industries, a SLINGMAX fabricator in the United States. Tese high performance slings are made with a blend of high-performance aramid fbers that are highly abrasion resistant, lift high capacities, are inspected with fber optics and early warning indicators (EWI), can be repaired if damaged, and have less than 1% stretch. For the 1WTC project, the highest capacity slings we provided had a 250,000 lbs. capacity, says Lemberg. Fastuca says, when asked what it was like to be a part of the 1 World Trade Center tower, I had a sense of pride every time I walked onto the jobsite. Te union of American technologies, manufacturing, and creativity represented there at ground zero is an amazing illustration of how we all banded together to produce an outstanding architectural wonder. yArtistic Rendering of the completed One World Trade Center at night Image courtesy PANYNJPROVEN FOR OVER 20 YEARS ON JOBSITESLIKE YOURSTwin-Path

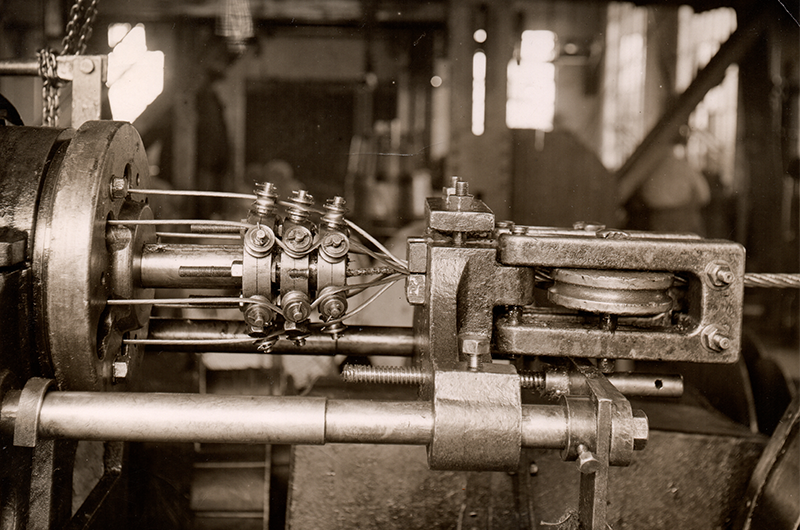

slingsCHECKED with Check-Fast inspectionREPAIRED by Slingmax dealers worldwidePROTECTED by engineered softenersIN SERVICE when you need itP.O. BOX 2423 ASTON, PA 19014-2423 USA800-874-3539 610-485-8500 FAX: 610-494-5835 www.slingmax.com22 JANUARY-FEBRUARY 2013 WIRE ROPE EXCHANGErouSter MaKeS a winninG CaSe For CorDaGe:how one riGGinG CoMpany heLpeD tranSForM the MininG inDuStry( )by: e.h. evanSRouster Wire Rope & Rigging Assembling a Large

8613371530291

8613371530291